Combined track-railbed joining apparatus

a technology of joining apparatus and railbed, which is applied in the direction of toys, constructions, and ways, etc., can solve the problems of not being able to prevent longitudinal, connectors, or fishplates, and being rather delicate objects, and achieves simple configuration, easy replacement, and easy and inexpensive construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

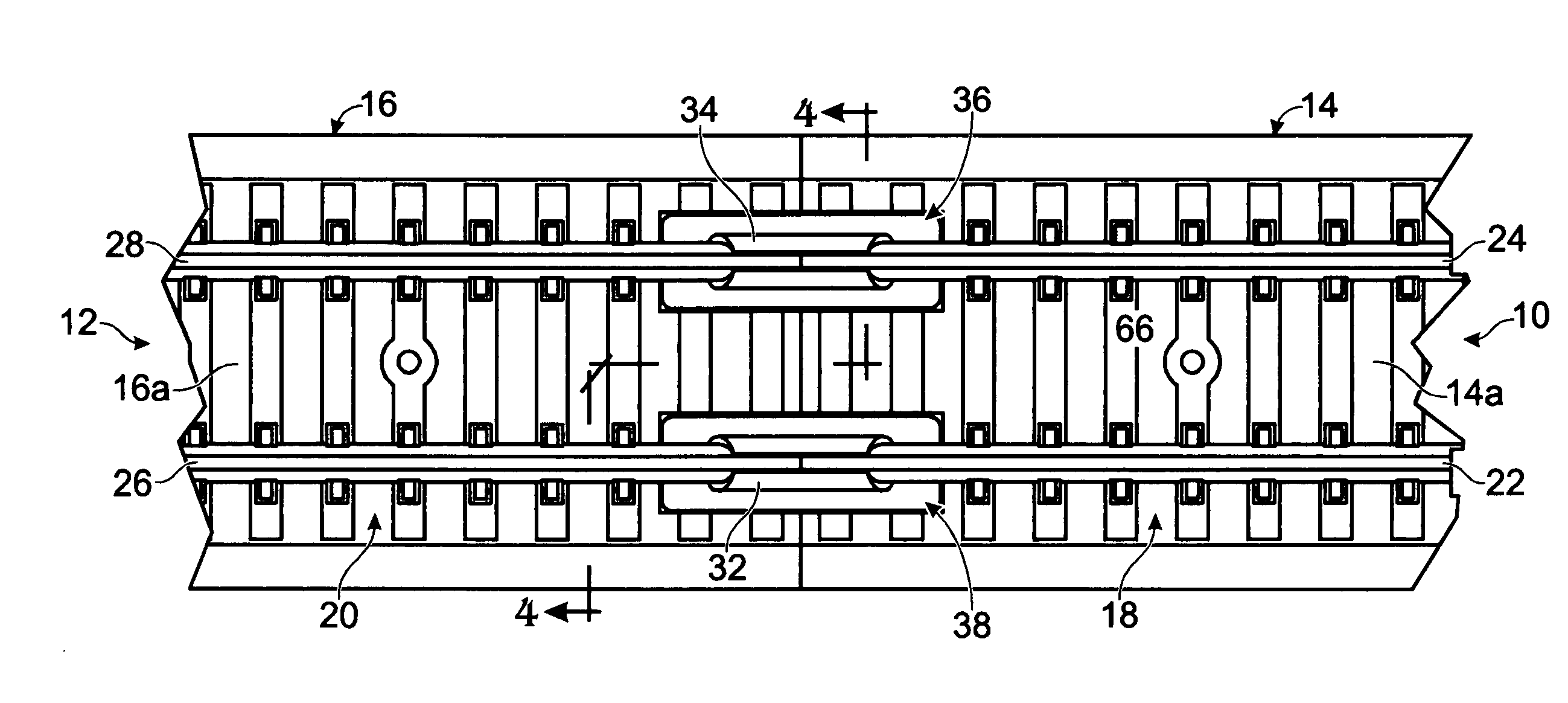

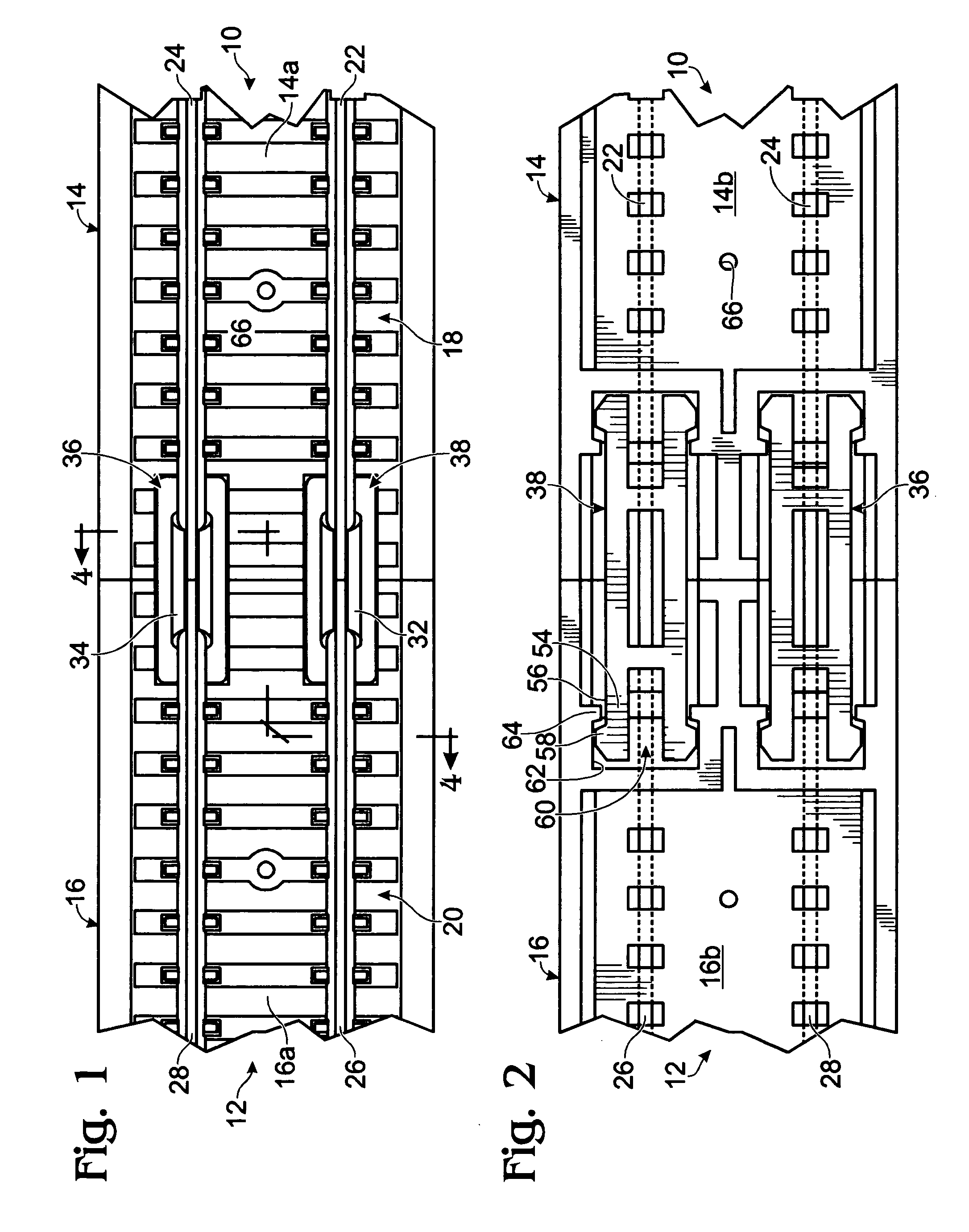

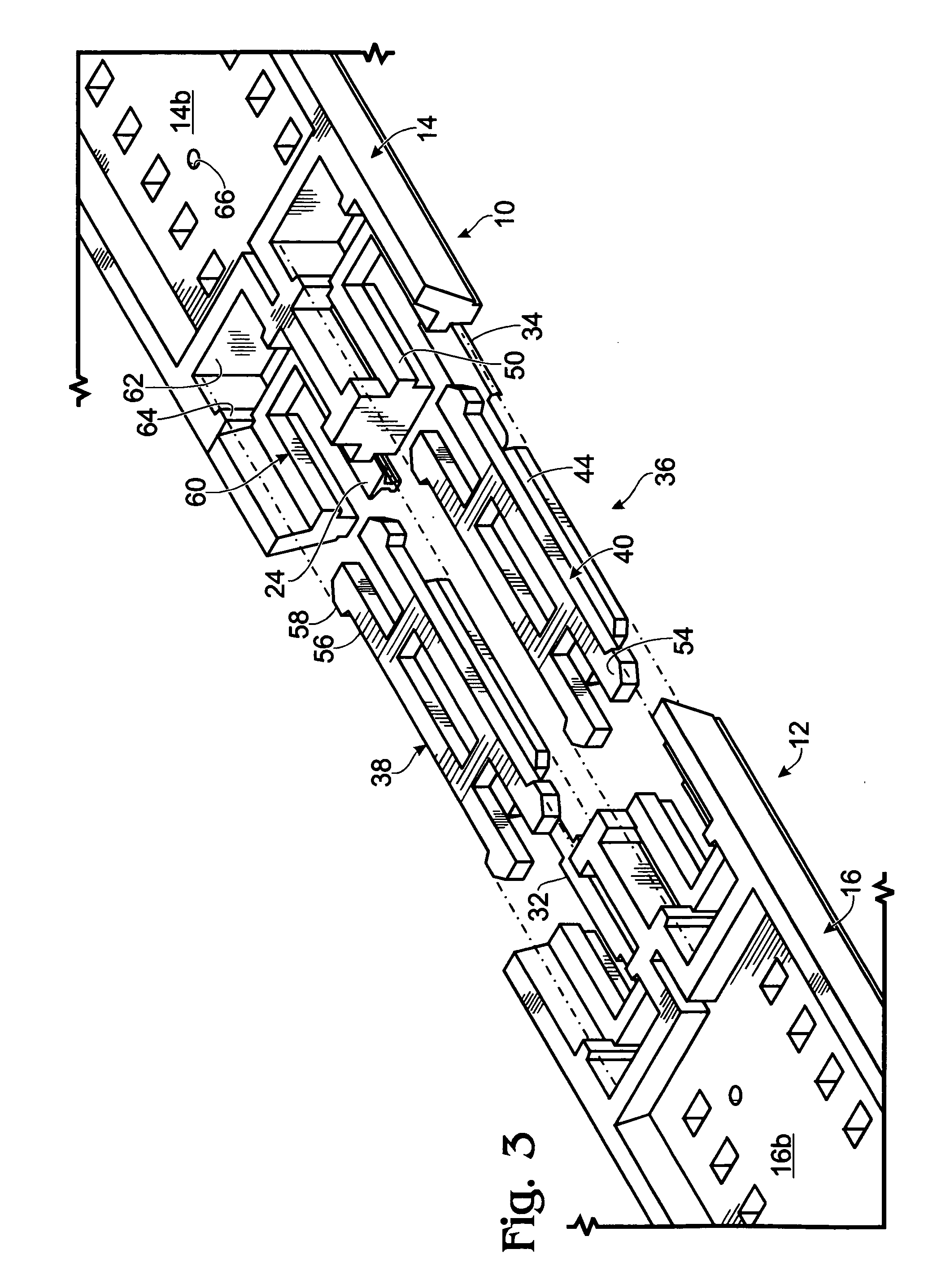

[0026] Referring now to FIGS. 1 - 4, portions of two pieces of sectional combined model railroad track and railbed are shown generally at 10 and 12. Each section of track includes an elongate railbed 14, 16 having upper surfaces 14a, 16a and lower surfaces 14b, 16b, respectively.

[0027] An array 18, 20, of model railroad ties is located on the upper surface 14a, 16a of each railbed. Rails 22, 24 and 26, 28 are positioned in a spaced apart relationship on tie arrays 18, 20, respectively. The rails are electrically conductive and are generally formed from brass or nickel-silver alloy.

[0028] Referring momentarily to FIG. 4, rails 24, 26 are shown in end view. Each rail includes a base, such as 26a, having flanges 26b extending from either side thereof. A central web 26c extends upward from the base and connects with a rail head 26d. The rails are secured to the ties by means of rail “spikes”30 which extend over the rail flanges to hold the rails on the ties. In this embodiment, the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com