A Transformer Core V-Rush Operation Method

A technology of transformer core and operation method, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of noise, large no-load loss due to temperature rise, complex patterning, and increase of transformer cores, etc. The effect of reducing errors, improving production efficiency, and reducing noise

Active Publication Date: 2016-12-28

NANTONG LONGXIANG ELECTRICAL APPLIANCE EQUIP

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The operation method of the "V" notch on the upper and lower yokes of the original iron core is that the upper side of the upper iron yoke and the lower side of the lower iron yoke are punched as reference planes, resulting in the cumulative errors of the size and shape of the yoke pieces being concentrated in the "V" notch On the other hand, it will increase the electromagnetic eddy current, noise, temperature rise, and no-load loss during the operation of the transformer. Due to the complex profiling, the operator has a sense of insecurity

[0003] To sum up, the traditional V-shaped punching operation method of transformer iron core silicon steel sheet does not have a fixed operating platform, and it depends on three points fixed by the bracket. There are many hidden dangers in the operation process: 1. The operator has a sense of fear; 2. The safety is not guaranteed, and the error is larger than that of the "V" notch; 3. The noise, temperature rise, and no-load loss caused by the error are large; 4. The transformer core increases the eddy current

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] Example 1: In the past, the provincial standard S11 transformer with the same capacity had excessive no-load loss, which could only be achieved through external cooperation. After improvement, the same material and the same capacity provincial standard transformer were used to reduce the no-load loss, prompting the S11 provincial standard to also can do.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

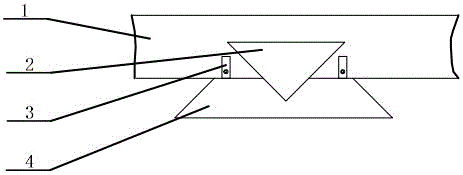

The invention discloses a V-type punching operation method of a transformer core, and relates to the technical field of V punching of the transformer core. A punching platform, a V-type punching die, backers and an iron yoke piece are included, the two backers are arranged on the punching platform, the V-type punching die is fixed to a V-type punching machine, and the iron yoke piece is matched with the backers. The V-type punching operation method of the transformer core comprises the steps that A, the two backers are arranged on the punching platform; B, the V-type punching die is fixed to the V-type punching machine; C, the lower edge of an upper iron yoke or the upper edge of a lower iron yoke of the iron yoke piece is taken as a base level to lean against the backers; D, finally, the iron yoke piece is attached to the punching platform to be moved towards the V-type punching die, and the iron yoke piece is punched to be formed through the V-type punching die. The noise, the temperature rising and no-load losses of a transformer are reduced, an operator feels safe, and the production efficiency is improved.

Description

technical field [0001] The invention relates to the technical field of transformer iron core V punching, in particular to a transformer iron core V-shaped punching operation method. Background technique [0002] The operation method of the "V" notch on the upper and lower yokes of the original iron core is that the upper edge of the upper iron yoke and the lower edge of the lower iron yoke are punched as the reference plane, resulting in the cumulative errors of the size and shape of the yoke pieces being concentrated in the "V" notch On the other hand, the electromagnetic eddy current, noise, temperature rise, and no-load loss will be increased during the operation of the transformer. Due to the complex profiling, the operator has a sense of insecurity. [0003] To sum up, the traditional V-shaped punching operation method of transformer iron core silicon steel sheet does not have a fixed operating platform, and it depends on three points fixed by the bracket. There are man...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01F41/02

Inventor 陈锐张邦国洪友法

Owner NANTONG LONGXIANG ELECTRICAL APPLIANCE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com