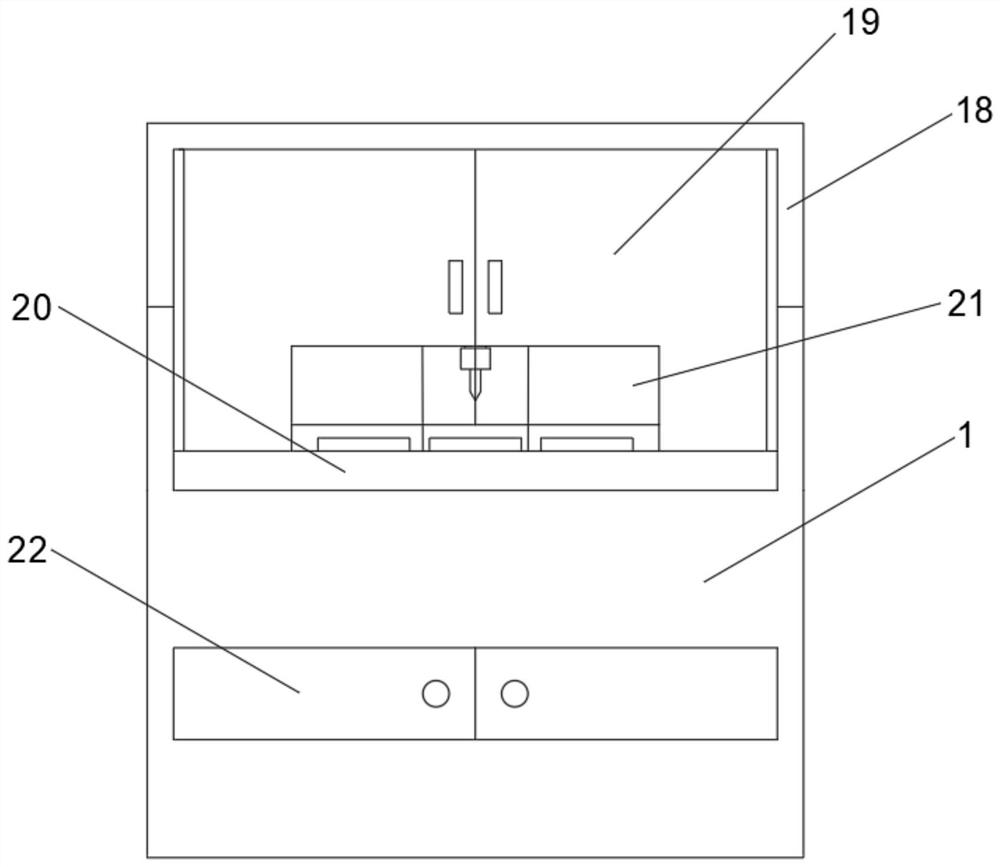

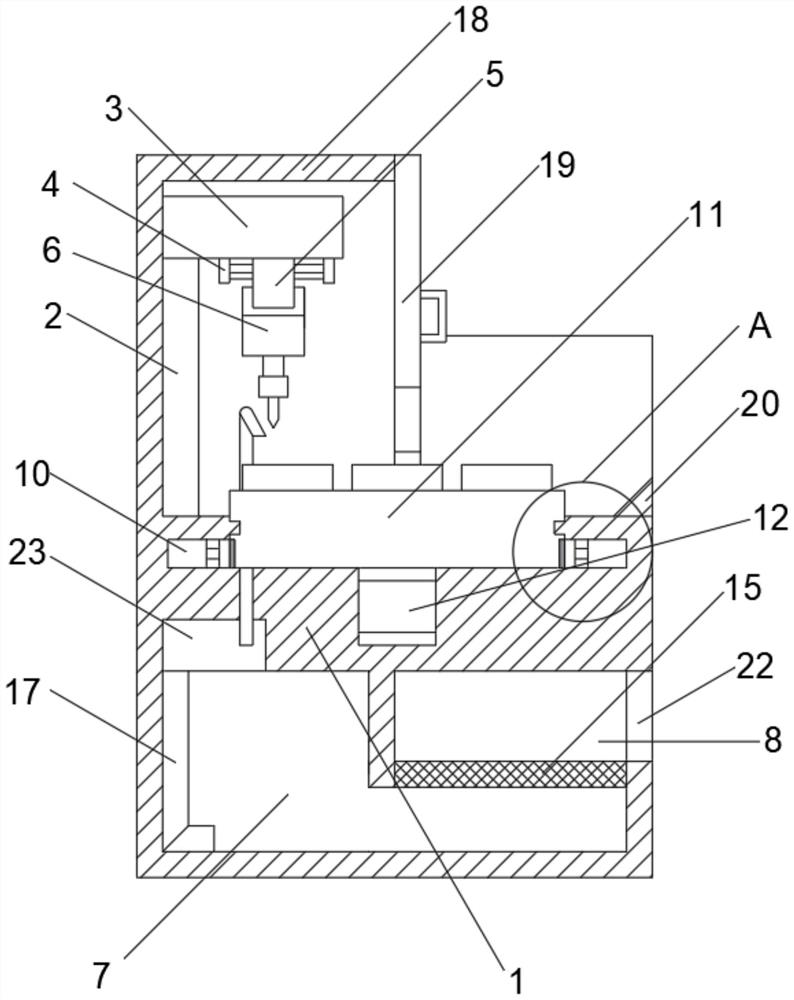

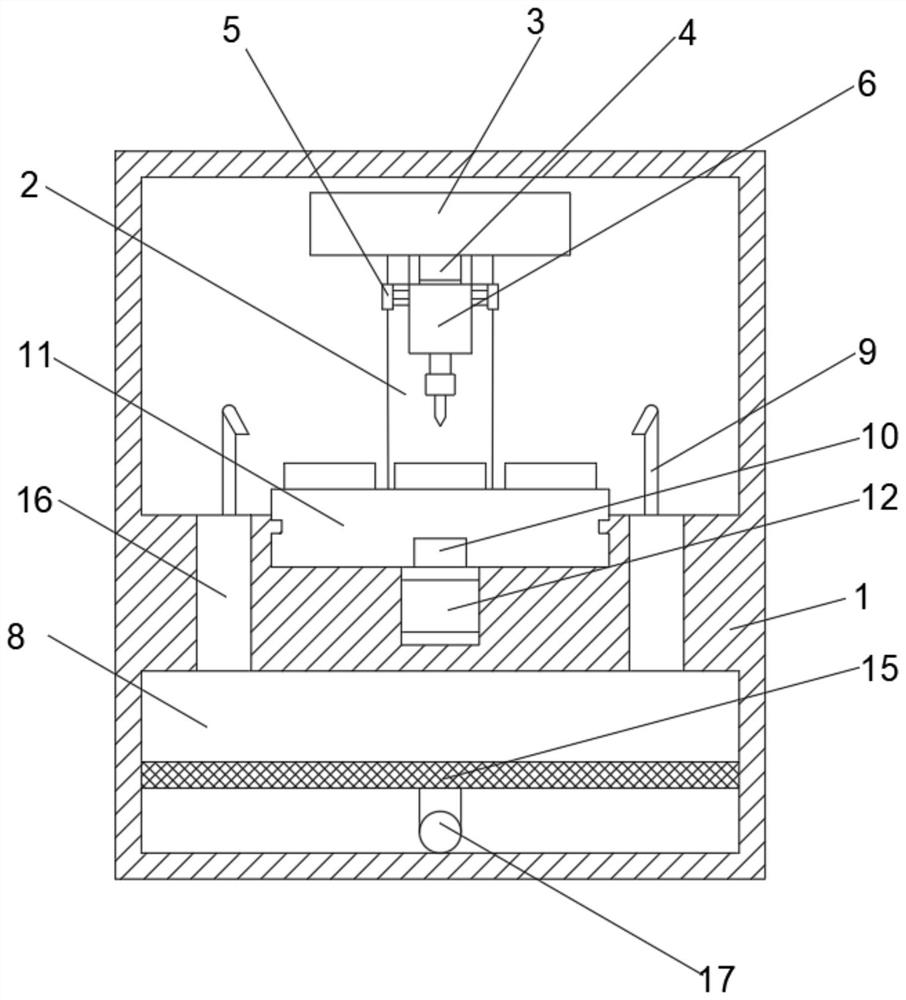

Bench drilling machine for machining wind power generation metal parts

A desktop drilling machine and metal parts technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unfavorable operators, no workers, and long time consumption, so as to save processing time and facilitate operation , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] All of the features disclosed in this specification, or all methods or processes disclosed in this specification, in addition to the features and / or steps of inter-repertril, can be combined in any manner.

[0020] Any feature disclosed in this specification (including any additional claims, abstracts, and Figure), unless otherwise specified, it can be replaced by other alternative characteristics of similar purposes. That is, unless specifically described, each feature is only an example of a series of equivalents or similar features.

[0021] In the description of the invention, it is to be understood that the term "one end", "other end", "outside", "upper", "inside", "horizontal", "coaxial", "central", "end "," Length "," outer end "or the like is based on the orientation or positional relationship shown in the drawings, is merely description of the present invention and simplified description, rather than indicating or implying means of means or The components must ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com