Low pressure rear cylinder water spray hole of turbine and design method of low pressure rear cylinder water spray hole

A design method and spray hole technology, applied to cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of increased desuperheating water volume, weak atomization degree of water droplets, and high impact velocity, so as to reduce the incident velocity, expand the diffusion range, Improves the effect of turbulent mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 5 , the water spray orifice 8 of the low-pressure rear cylinder of the steam turbine is installed and fixed in the upper exhaust guide ring 7 at the outlet of the final stationary blade 5 and the final movable blade 6, arranged along the entire circumference, and the cooling water is sent through the water distribution pipe into the spout.

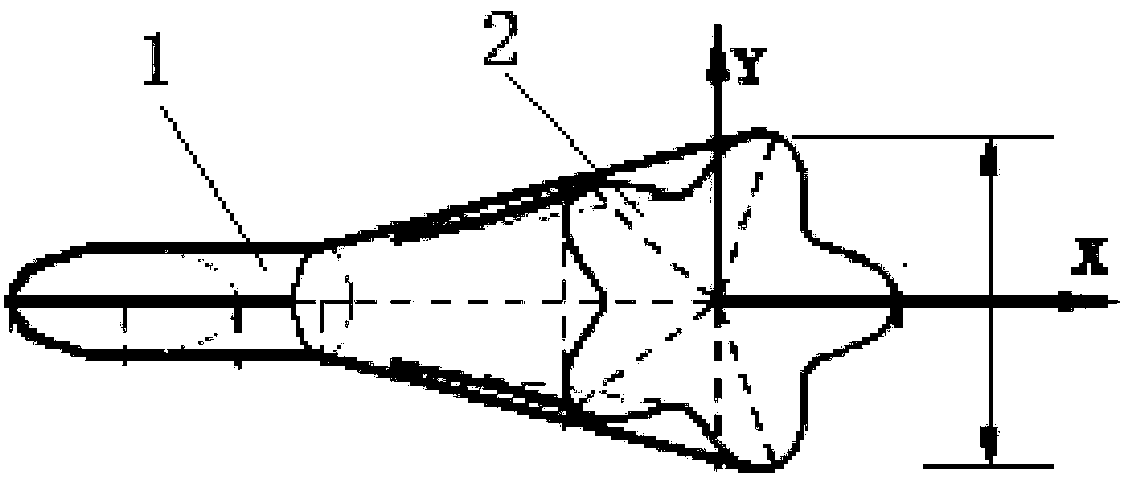

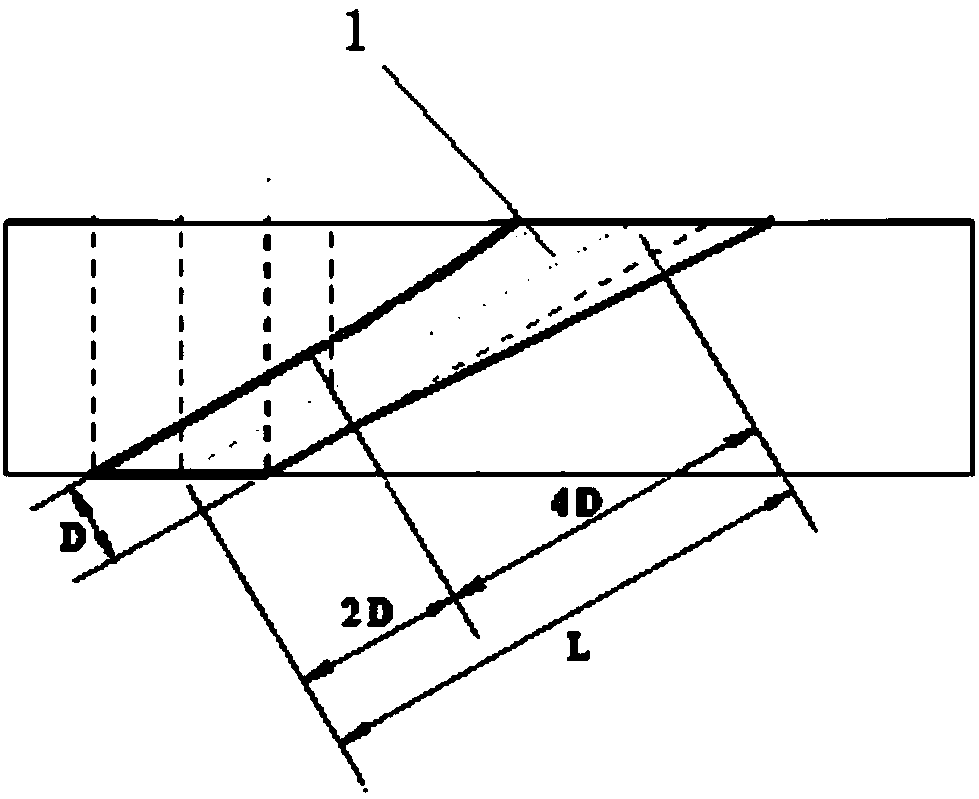

[0021] see figure 1 and figure 2 , a water spray orifice of a low-pressure rear cylinder of a steam turbine, comprising a gradually expanding channel 1 connected to the water spray orifice of the rear cylinder, a water spray port 2 connected to the large end of the gradually expanding channel 1, and the cross section of the water spray port 2 It is star-shaped, the front section of the gradual expansion channel 1 is involute, and the rear section is an inclined channel. The section of the inclined channel gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com