Method for producing high-purity selenium through ultrasonic enhanced reduction

An ultrasonic strengthening, high-purity selenium technology, applied in the field of materials, can solve the problems of long processing cycle, high risk of flue gas pollution to the atmospheric environment, and low selenium purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

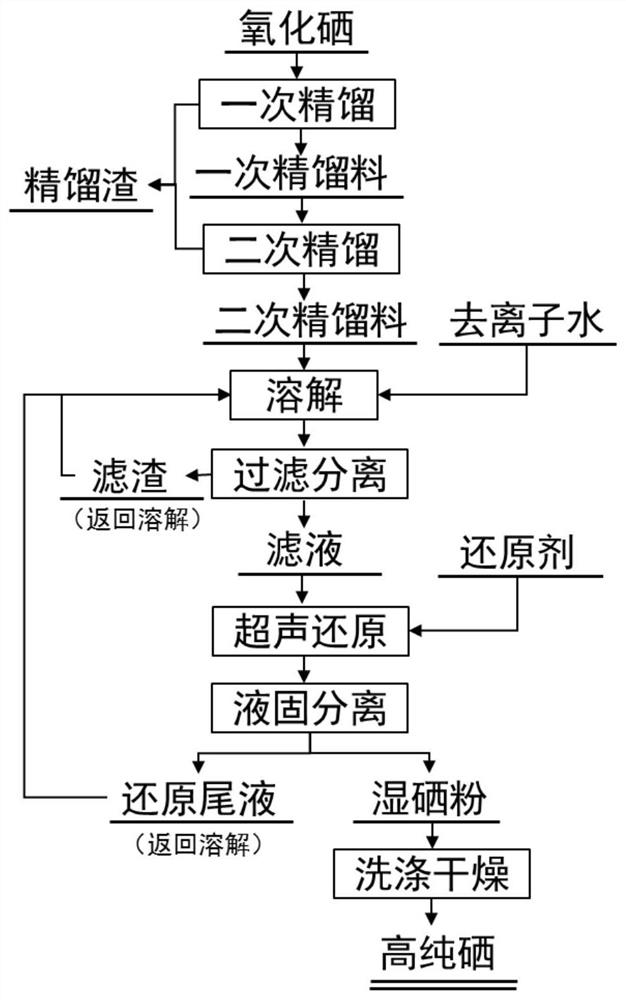

[0024] Embodiment 1: a kind of method that ultrasonic enhancement reduction produces high-purity selenium (see figure 1 ),Specific steps are as follows:

[0025] (1) Selenium oxide is obtained through cascade inert microwave distillation to obtain high-purity selenium oxide; wherein, in terms of mass percentage, the main impurity element content of high-purity zinc oxide is 20.8ppm, and the distillation atmosphere is argon, and the first time of cascade inert distillation The distillation temperature is 300°C and the time is 5 minutes, which can realize a large amount of separation of easy-to-handle selenium oxide and impurities; the second distillation temperature is 500°C and the time is 1 minute, so as to realize the deep separation of residual selenium oxide and impurities;

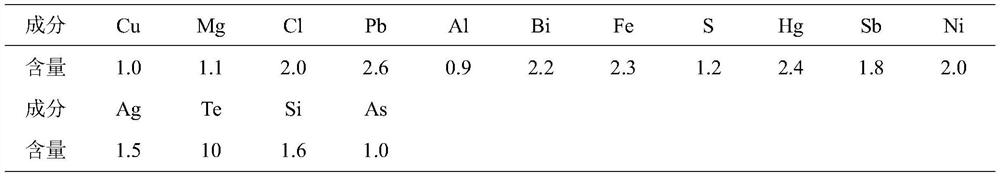

[0026] In terms of mass percentage, the components of selenium oxide raw materials are shown in Table 1, and the components of high-purity selenium oxide are shown in Table 2,

[0027] Table 1 seleni...

Embodiment 2

[0037] Embodiment 2: a kind of method that supersonic enhanced reduction produces high purity selenium (see figure 1 ),Specific steps are as follows:

[0038] (1) Selenium oxide is subjected to cascade inert microwave distillation to obtain high-purity selenium oxide; wherein, in terms of mass percentage, the main impurity element content of high-purity zinc oxide is 14.9 ppm, and the distillation atmosphere is argon, and the first time of cascade inert distillation The distillation temperature is 300°C and the time is 5 minutes, which can realize a large amount of separation of easy-to-handle selenium oxide and impurities; the second distillation temperature is 500°C and the time is 1 minute, so as to realize the deep separation of residual selenium oxide and impurities;

[0039] In terms of mass percentage, the components of selenium oxide raw materials are shown in Table 4, and the components of high-purity selenium oxide are shown in Table 5,

[0040] Table 4 selenium oxi...

Embodiment 3

[0050] Embodiment 3: a kind of method (see figure 1 ),Specific steps are as follows:

[0051] (1) Selenium oxide is subjected to cascade inert microwave distillation to obtain high-purity selenium oxide; wherein, in terms of mass percentage, the main impurity element content of high-purity zinc oxide is 9.6ppm, and the distillation atmosphere is nitrogen, and the first distillation of the cascade inert distillation The temperature is 500°C, and the time is 30 minutes, which can realize a large amount of separation of easy-to-handle selenium oxide and impurities; the second distillation temperature is 700°C, and the time is 15 minutes, so as to realize the deep separation of residual selenium oxide and impurities;

[0052] In terms of mass percentage, the components of selenium oxide raw materials are shown in Table 7, and the components of high-purity selenium oxide are shown in Table 8,

[0053] Table 7 selenium oxide raw material impurity components (ppm)

[0054]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com