High-viscosity material fine emulsifying belt pre-mixing system

A technology of pre-mixing and emulsifying belt, applied in mixers, mixing methods, chemical instruments and methods, etc., can solve the problems of high viscosity, difficult cleaning, incomplete cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

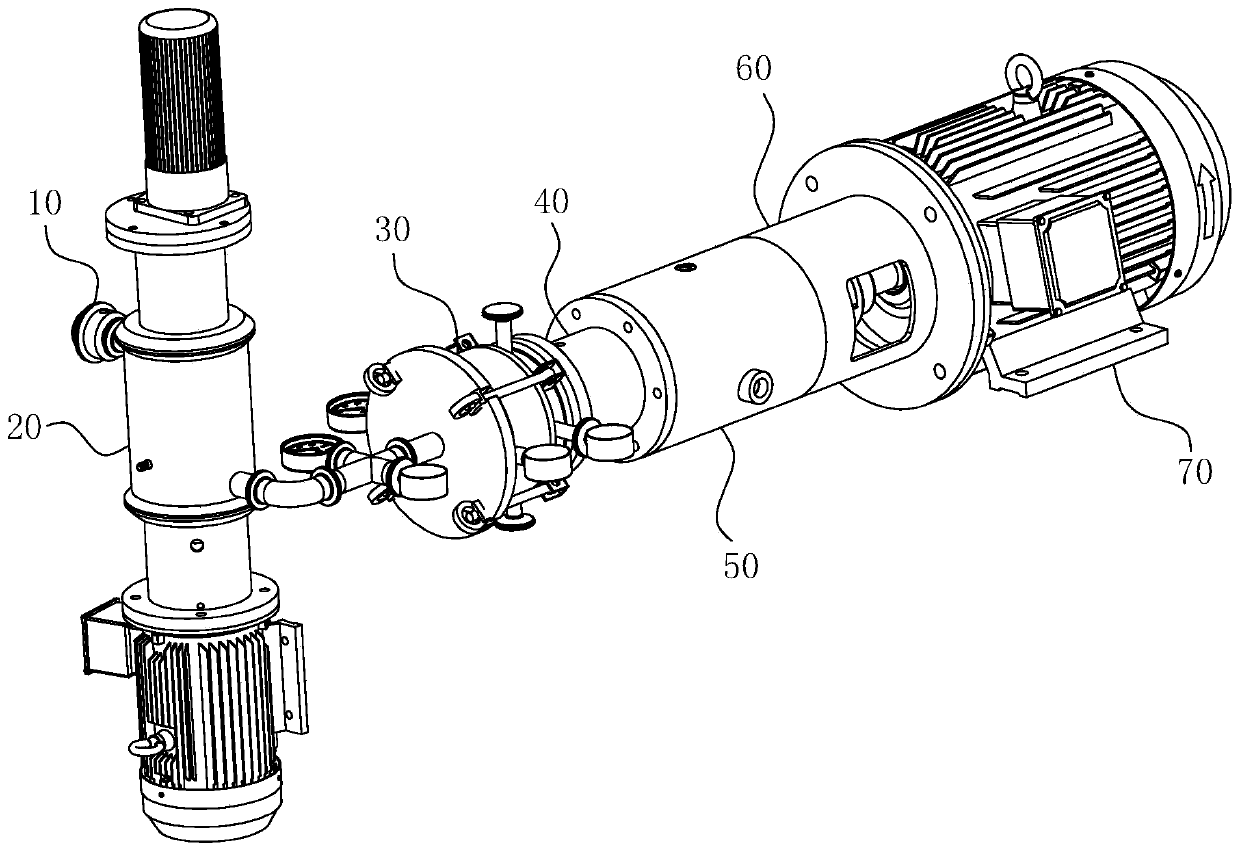

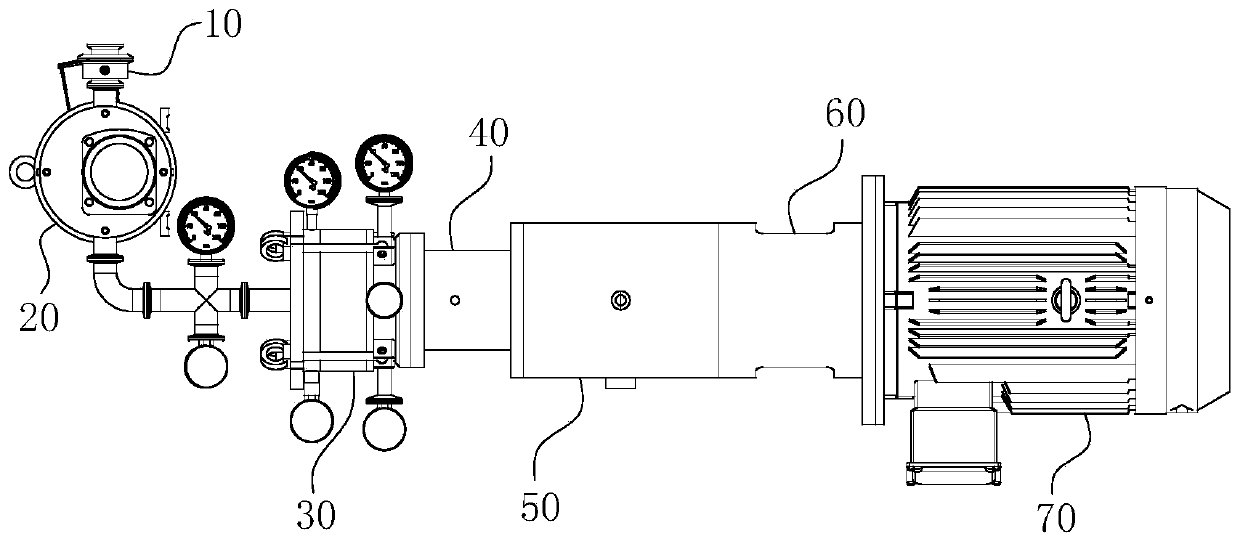

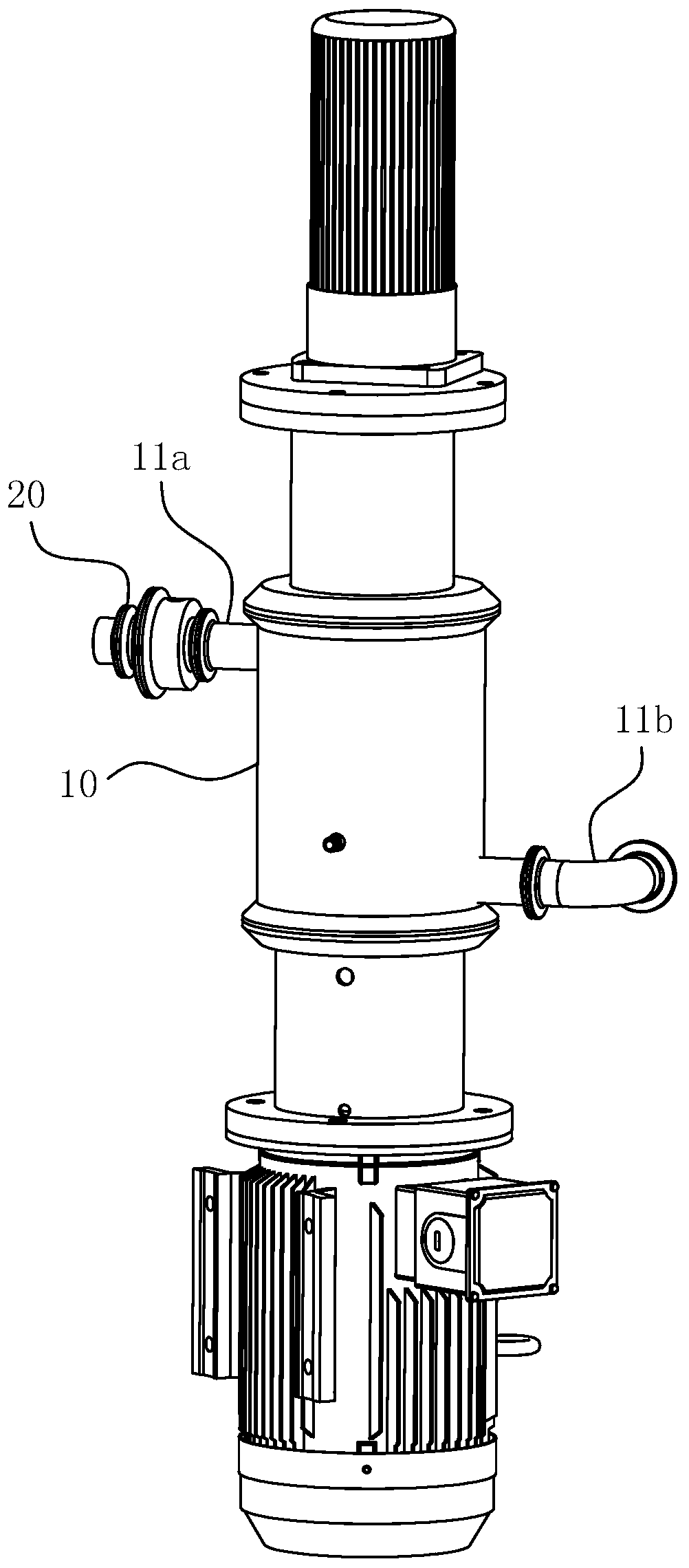

[0058] For ease of understanding, combined here Figure 3-17 , the concrete structure and working mode of the present invention are further described as follows:

[0059] The specific structure of the present invention is as Figure 3-17 As shown, its main part includes pre-mixing equipment for performing preliminary pre-mixing operations of additives and high-viscosity materials and emulsification equipment for performing online fine emulsification operations of pre-mixed materials. The feed port 33a of the emulsification device is connected to the discharge pipe 11b of the pre-mixing device through an intermediate pipeline to ensure the continuity of material progress. in:

[0060] The specific structure of the pre-mixing equipment is as follows: Figure 3-4 and Figure 5-10 As shown, its main body includes two major parts, that is, the synchronous feeding assembly 20 and the pre-mixing assembly 10 . The high-viscosity materials and additives are combined at the synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com