Patents

Literature

127 results about "Seleninic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A seleninic acid is an organoselenium compound and an oxoacid with the general formula RSeO₂H, where R ≠ H. It is a member of the family of organoselenium oxoacids, which also includes selenenic acids and selenonic acids, which are RSeOH and RSeO₃H, respectively. The parent member of this family of compounds is methaneseleninic acid (CH₃SeO₂H), also known as methylseleninic acid or "MSA".

Method capable of improving selenium content for preparing polysaccharide selenite

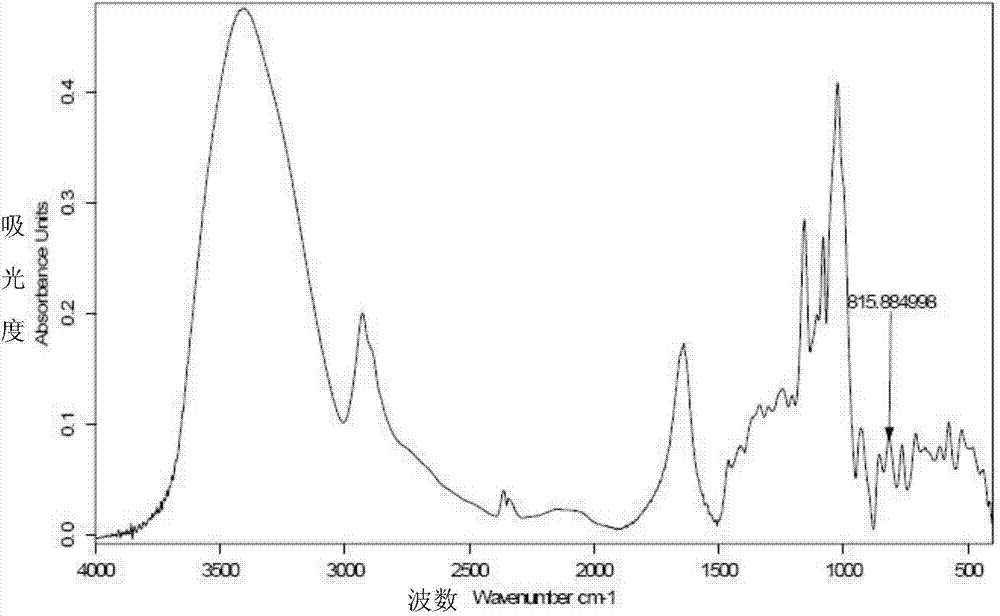

The invention discloses a method capable of improving selenium content for preparing polysaccharide selenite. The method comprises the steps of adding a selenium compound solution having the mass fraction of 60-80% by spraying to a polysaccharide or a polysaccharide complex under a stirring condition and reacting at a temperature in the range of 120-160 DEG C; after the reaction is completed, purifying and drying the reaction product to obtain polysaccharide selenite, wherein the selenium compound is seleninic acid or a selenite. The method is simple in process, easy in after-treatment, controllable in reaction conditions and good in repeatability; in the production process, the generation of toxic gases such as hydrogen selenide is avoided and the use of a strong acid and heavy metals such as a barium salt to catalyze the reaction and the use of toxic organic solvents such as pyridine and benzene are avoided, and therefore, the production process is green and environment-friendly; the polysaccharide selenite prepared by the method is low in toxicity and high in bioavailability, and the selenium content of the polysaccharide selenite is higher than 18% which is far higher than the selenium content of less than 2% of the present commercial organic selenium products.

Owner:浙江皇冠科技有限公司

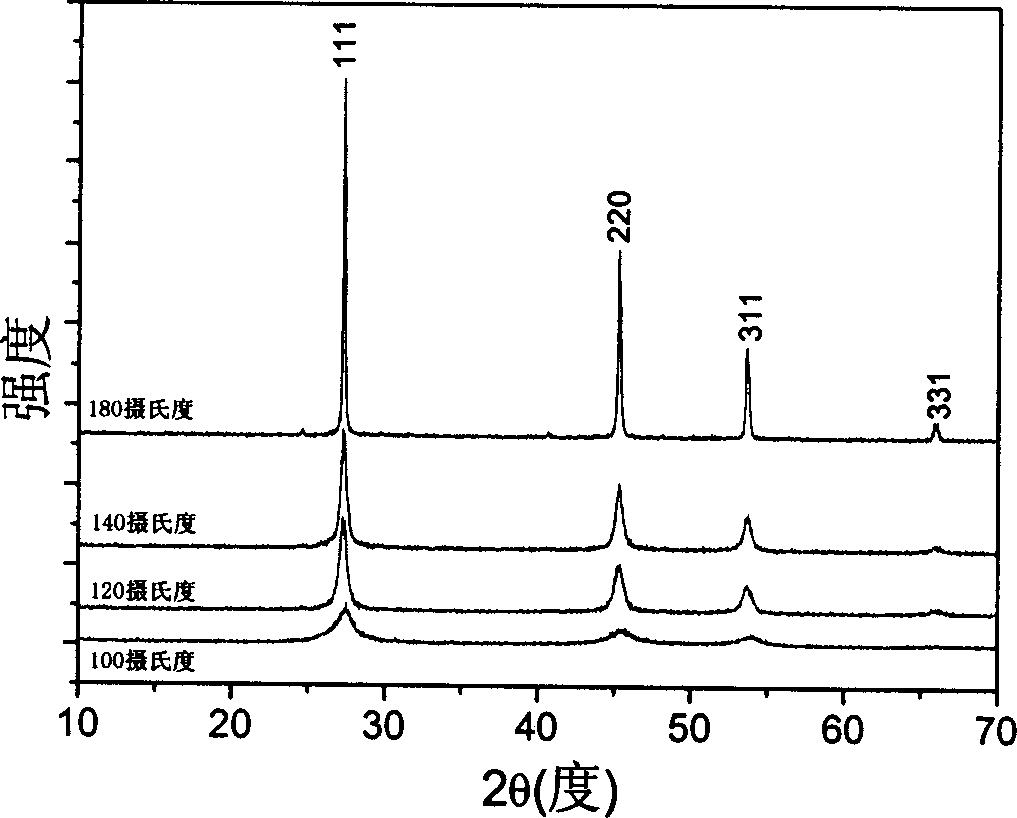

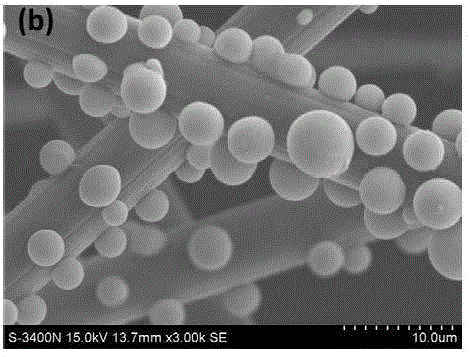

Synthesis of nano hollow balls of zinc selenide

InactiveCN1424248AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureZinc compoundsBinary selenium/tellurium compoundsPhotonic crystalSeleninic acid

A process for synthesizing a micro-class hollow zinc selenide sphere features that hydrothermal reduction reaction between zincic acid radical ions and seleninic acid or soluble selerate under action of hydrazine hydrate as reducer in strong alkaline condition at 100-200 deg.C in a sealed reaction. It is possible to dope it or coat it. Its advantages are low cost and high quality.

Owner:TSINGHUA UNIV

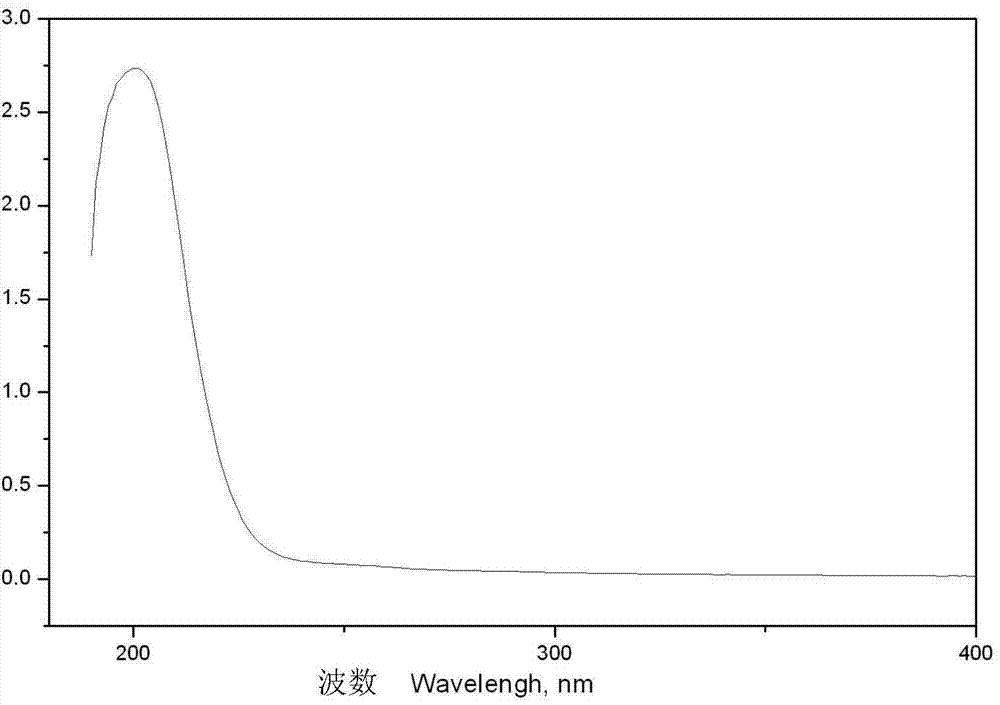

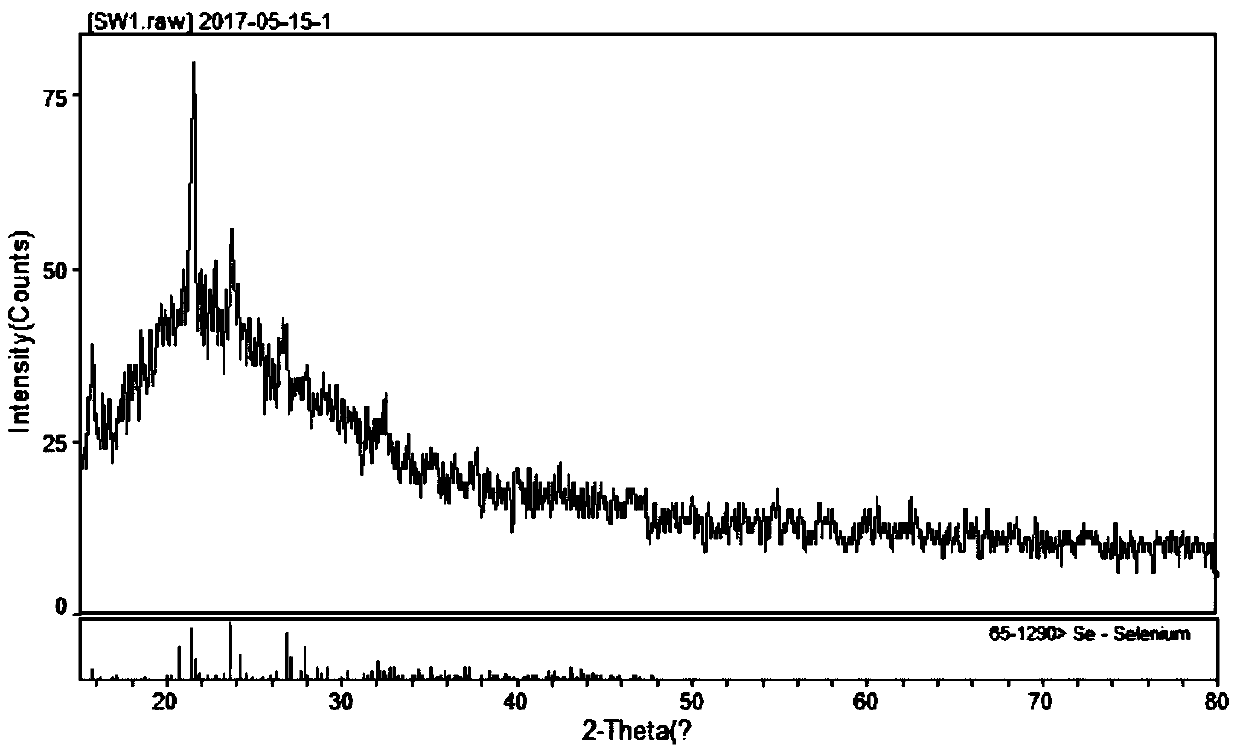

Method for preparing colloidal nano granules of selenium

InactiveCN1480391AHigh sensitivityShorten the timeMaterial analysisElemental selenium/telluriumSeleninic acidNanoparticle

A colloidal Se nanoparticle is prepared from seleninic acid and ascorbic acid at ordinary temp. It can be used as the marker in immunochromatography with high sensitivity and speed. Its advantages are short preparing period and high output.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

Method for recovery of selenium from copper anode mud

InactiveCN106379870AHigh recovery rateReduce recycling costsElemental selenium/telluriumSeleninic acidPhysical chemistry

The invention discloses a method for recovery of selenium from copper anode mud. The method consists of: pre-sulfating copper anode mud containing impurities, then performing roasting to generate gaseous selenium dioxide and sulfur dioxide, sending the mixed gas of selenium dioxide and sulfur dioxide into a lead absorption tower through a pipeline so as to obtain a part of elemental selenium and a part of seleninic acid, recovering absorption liquid with residual seleninic acid into a vacuum circulation jet pump barrel filled with excessive sulfur dioxide, and performing reduction to obtain elemental selenium. The method increases the recovery rate of selenium in copper anode mud from 90%-95% of the conventional process to 99.5% or more, lowers the selenium recovery cost, alleviates the environmental protection pressure, and reduces emission of sulfur dioxide.

Owner:ZHEJIANG YADONG IND CO LTD

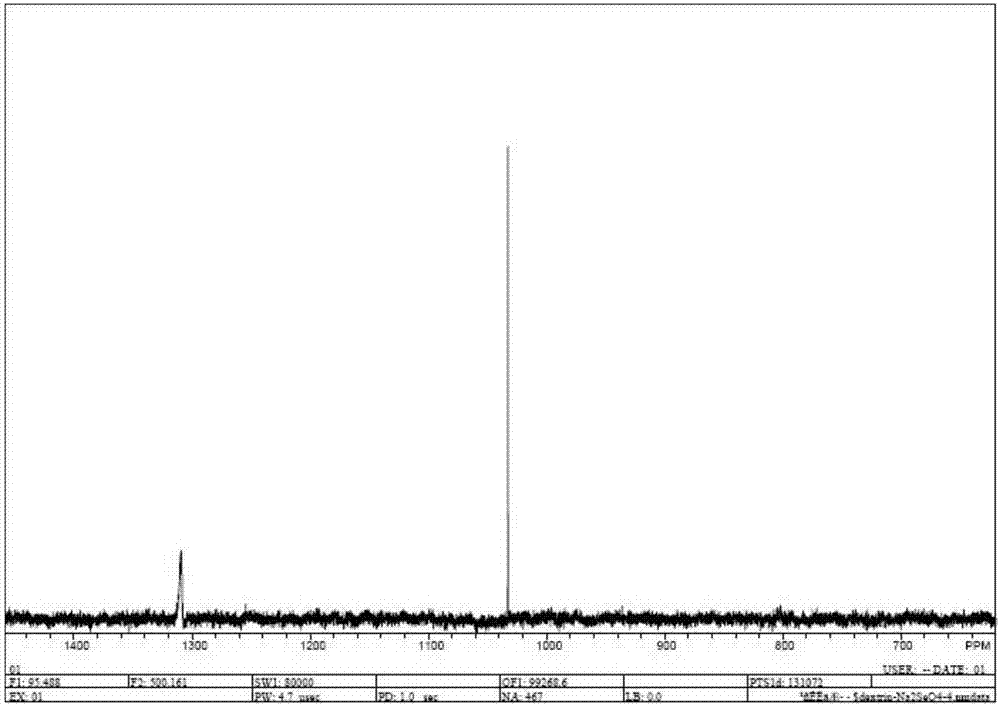

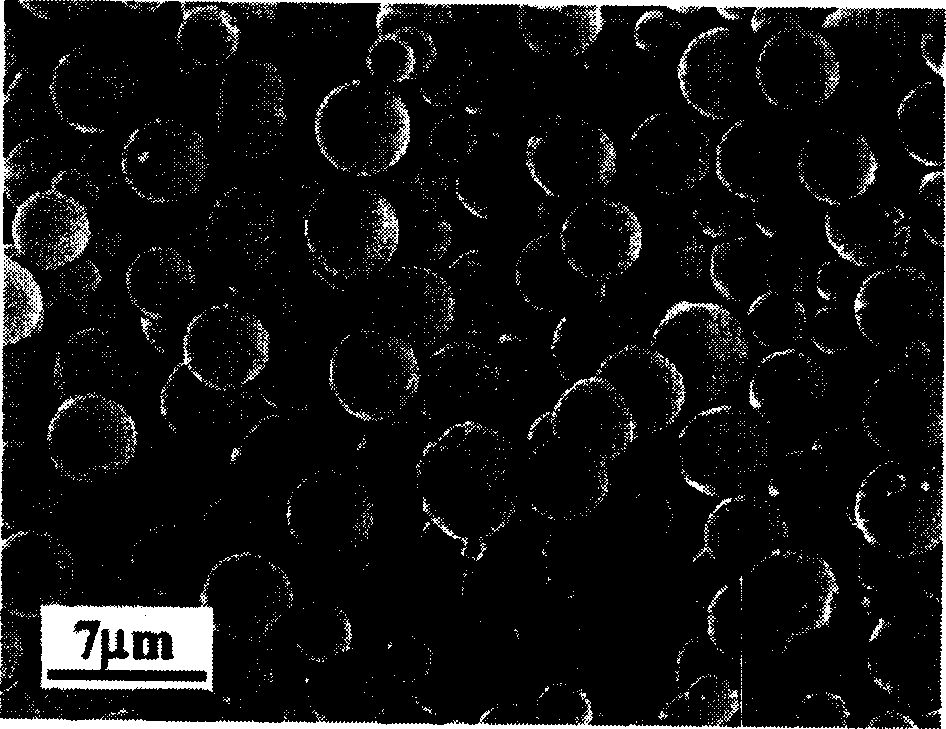

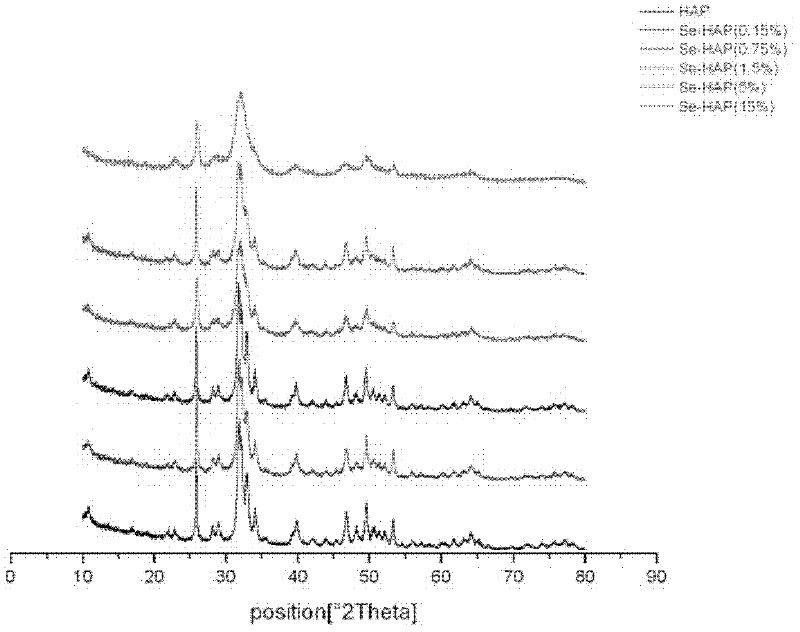

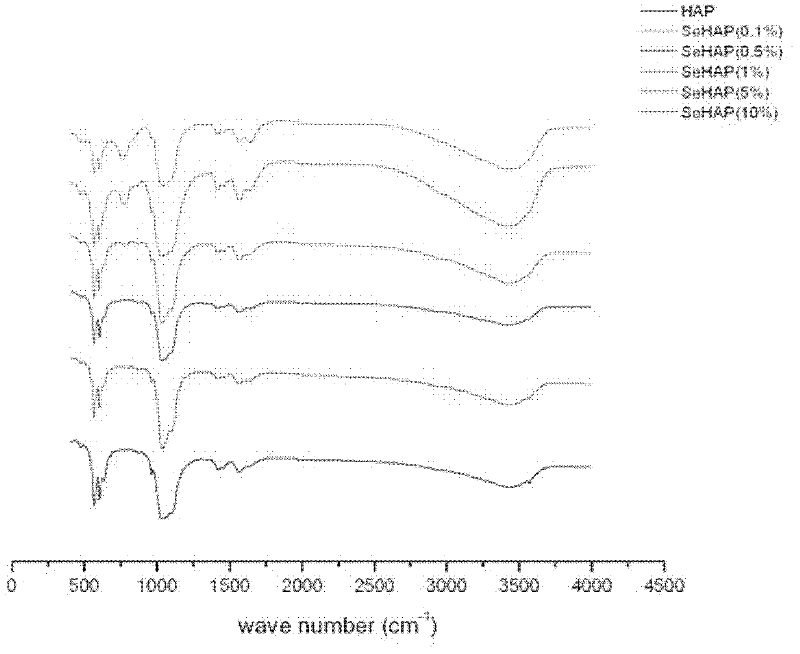

Selenium-doped hydroxyapatite and preparation method thereof

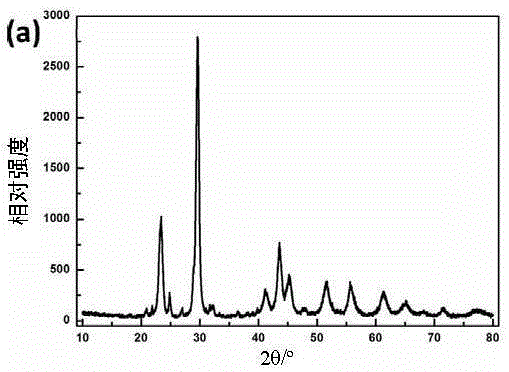

ActiveCN102249206AIncrease productionGood dispersionMaterial nanotechnologyPhosphorus compoundsSeleninic acidHydroxyapatite crystal

The invention discloses selenium-doped hydroxyapatite and a preparation method thereof. The selenium-doped hydroxyapatite which is obtained by the preparation method has an apatite structure; and a selenium element partially replaces the positions of phosphate radical and / or hydroxyl in the hydroxyapatite crystal in the form of seleninic acid radical. The yield of selenium-doped hydroxyapatite ishigh and the selenium-doped hydroxyapatite has high dispersibility.

Owner:ASIA BIOMATERIALS WUHAN CO LTD

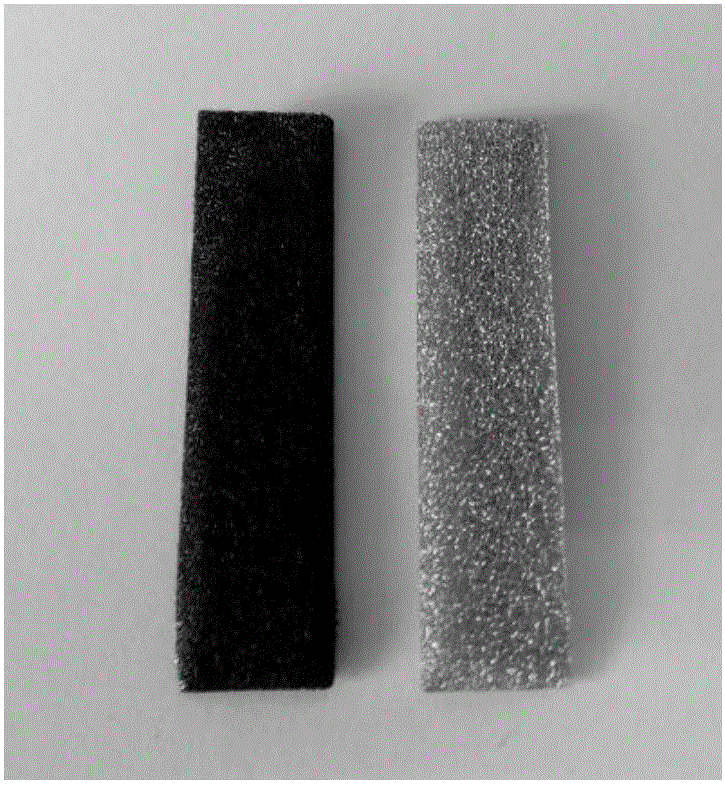

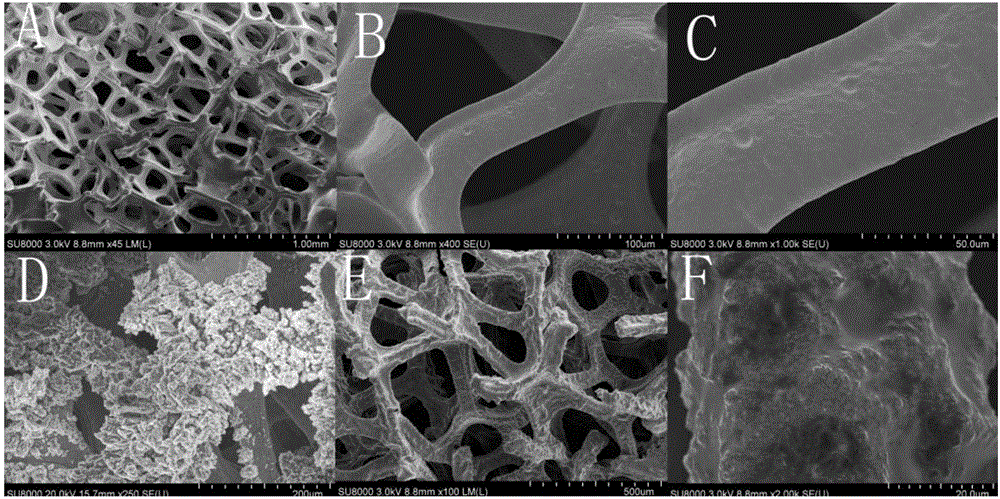

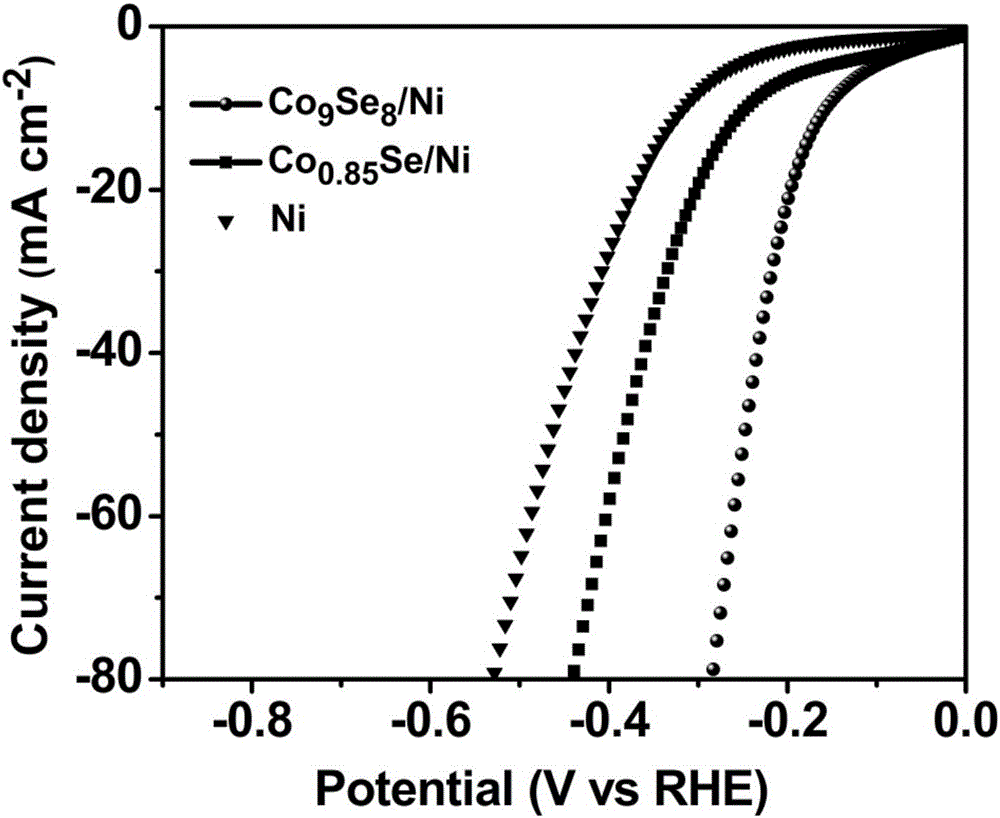

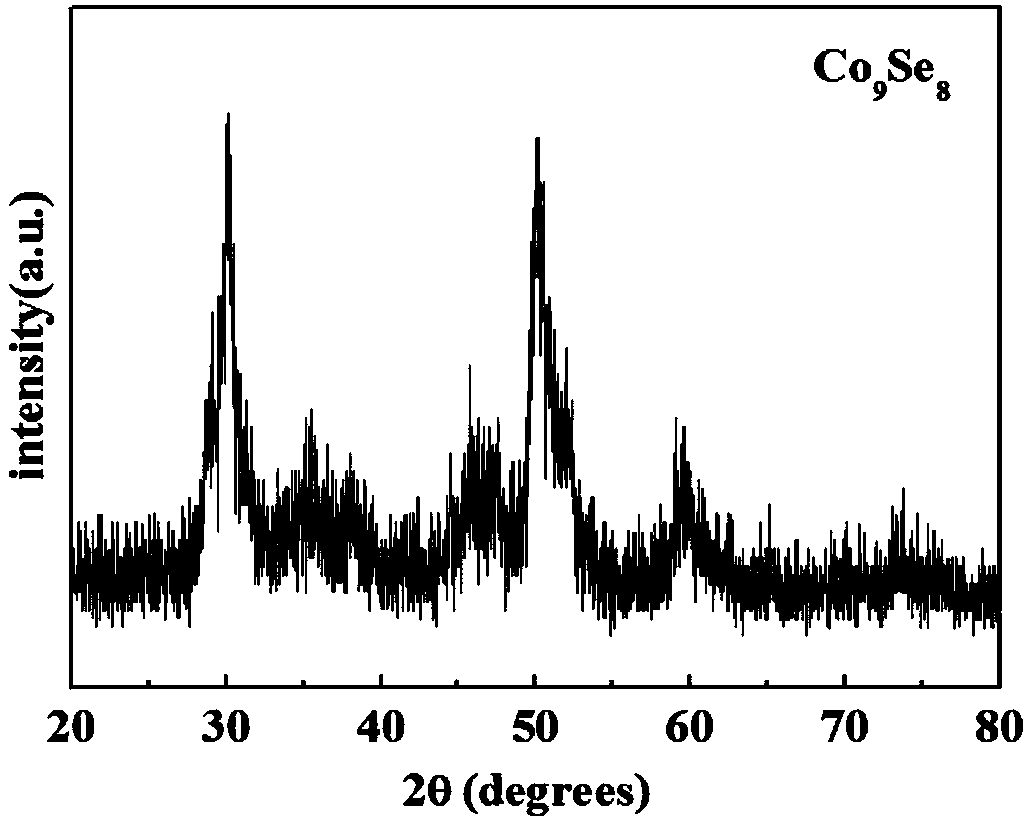

Low overpotential electrocatalyst for producing hydrogen by efficient water splitting and preparation method of electrocatalyst

ActiveCN106492846AImprove hydrogen production efficiencyReduce consumptionPhysical/chemical process catalystsHydrogen productionSodium Selenite PentahydratePotassium

The invention provides a low overpotential electrocatalyst for producing hydrogen by efficient water splitting and a preparation method of the electrocatalyst, and belongs to the technical field of catalyst preparation. The low overpotential electrocatalyst is prepared by in-situ growth of Co9Se8 on foamed nickel. The low overpotential electrocatalyst is prepared by one of cobalt nitrate hexahydrate, cobalt chloride, cobalt acetate or cobalt sulfate and one of sodium selenite pentahydrate, potassium selenite or seleninic acid in an organic amine environment in which the foamed nickel serves as a catalyst. The foamed nickel can serve as both a carrier and the catalyst of a synthetic reaction. The overpotential of the electrocatalyst is only -284mV when the electric current density is 80 mA / cm<-2> and is increased by more than 46.5% relative to that of pure foamed nickel with the overpotential of -530 mV when the electric current density is 80 mA / cm<-2>, and the electrocatalyst is a relatively low overpotential electrocatalyst in non noble metal electrocatalysts. The electrocatalyst is one of advanced technical means for the sustainable production of hydrogen energy, has good industrial application prospects and can be used to relieve an increasingly intense global energy supply pattern at present.

Owner:JILIN UNIV

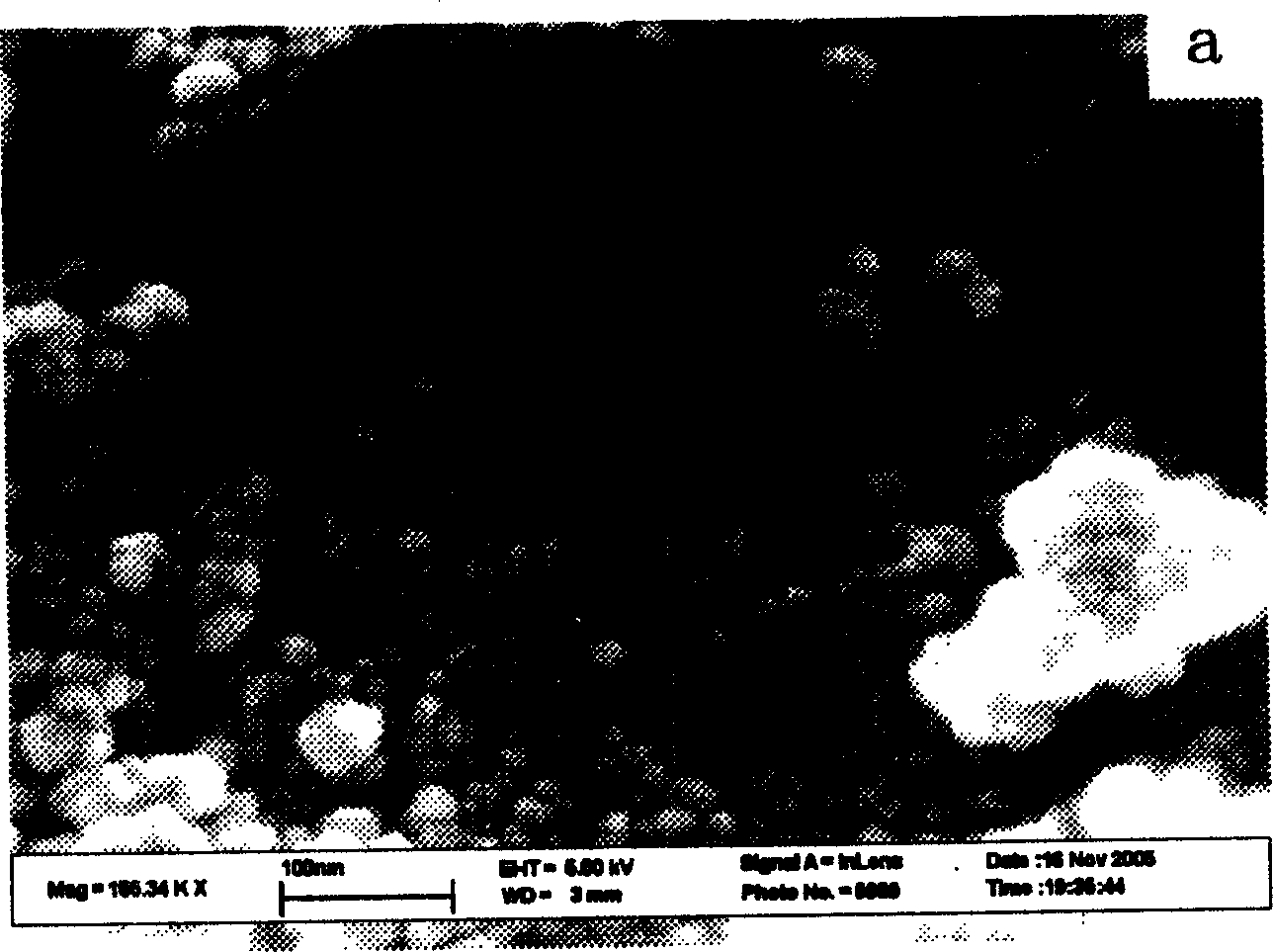

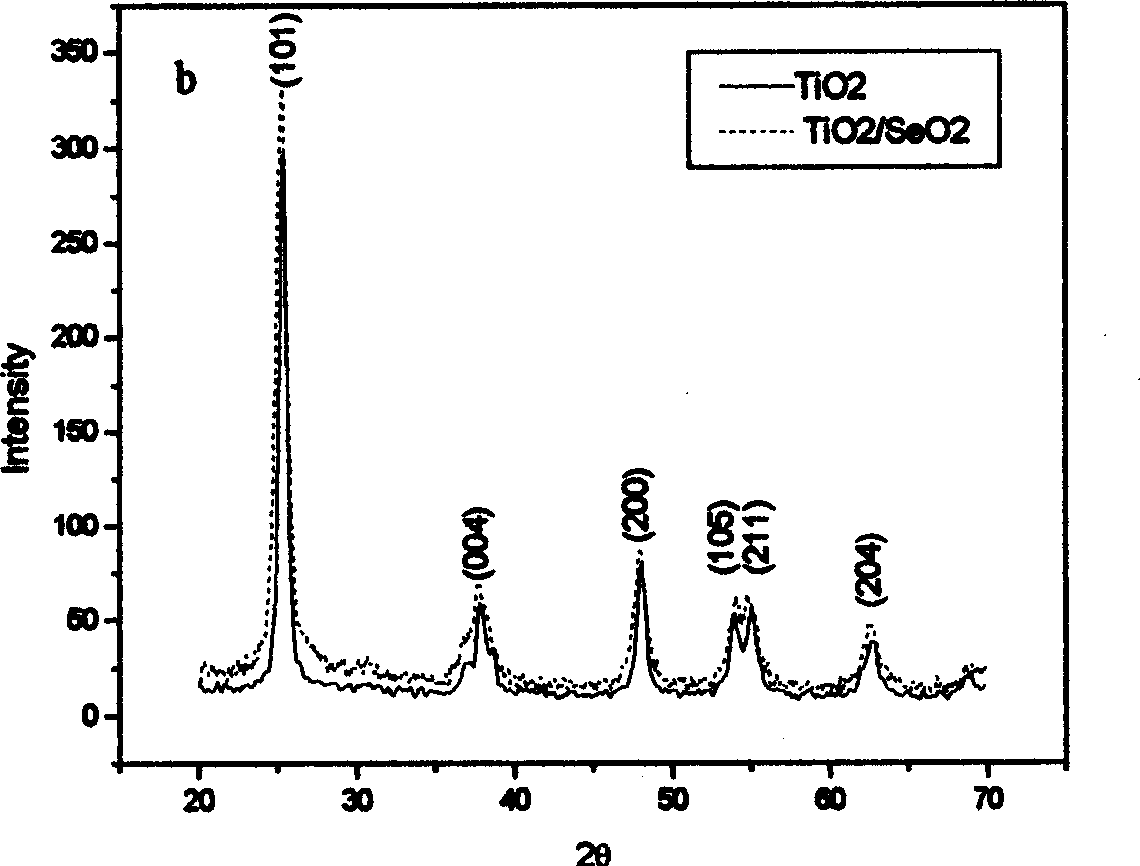

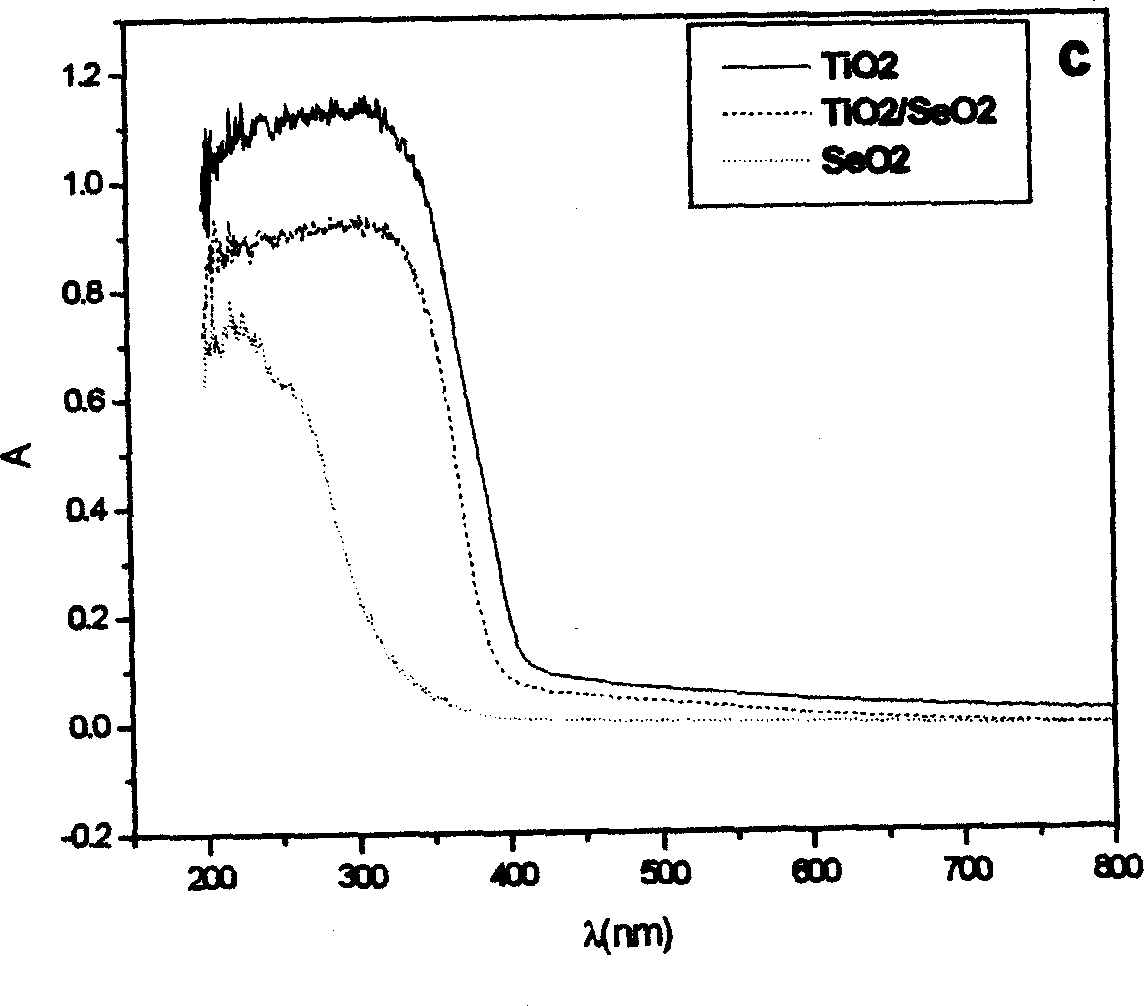

Nanometer titanium dioxide/selenium dioxide composition and its prepn. method

InactiveCN1868582AContent does not decreaseIncrease contentPhysical/chemical process catalystsWater bathsSolar cell

A nano-class TiO2 / SeO2 composition used for solar cell is a spherical nano-particle and has the anatase-phase crystal structure. Its preparing process includes such steps as reaction between titanate or TiCl4 or titanium sulfate or titanium oxide sulfate and SeO2 or seleninic acid, and water-bath ageing or hydrothermal synthesis or high-temp burning.

Owner:ANHUI UNIVERSITY

Method for synthesizing 1,2-cyclohexanediol by cyclohexene under selenium catalysis

InactiveCN102503774AImproved Catalytic Oxidative Hydrolysis ReactionReduce dosagePreparation by oxidation reactionsChemical recyclingPtru catalystDistillation

The invention provides a method for synthesizing 1,2-cyclohexanediol by cyclohexene under selenium catalysis. The method comprises the following steps of: taking cyclohexene as a raw material, taking a selenium compound as a catalyst, and taking hydrogen peroxide as an oxidant; carrying out reaction at a temperature of 15-80 DEG C in the presence of a solvent, wherein a mole ratio of the hydrogen peroxide to the cyclohexene is (0.5-1.5): 1, the mole fraction of the selenium compound and the cyclohexene is 0.1-1 percent, and the concentration of the reaction solution based on a solvent calculation is 1-20 mol / L. Furthermore, the production can be continuously carried out by adding the raw materials for the next turn into reaction residues. After the reaction, the solvent and non-reacted raw materials are respectively recycled by distillation and a product is refined. The selenium compound is selected from diselenide, selenious acid, and phenyl, fluoro-phenyl, tolyl substitutes and the like of the diselenide amd the selenious acid. The solvent is selected from acetonitrile, water, ethanol and acetic acid. The method disclosed by the invention has the advantages of simple process flow, temper reaction conditions, and high yield (the highest yield can be up to 92 percent). The method is efficient, clean and environment-friendly and further has the characteristics of simple components in a reaction system, easiness of product purification, and easiness of recycling the solvent and the catalyst.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Blackening agent used for steel and iron surface at room temperature and preparation method for blackening agent at room temperature

The invention discloses a blackening agent at room temperature and a preparation method for the blackening liquid at the room temperature, which are widely applied to the blackening processing for finished products or parts of various alloy steels, cast irons and the like. The blackening agent at the room temperature is prepared from the following components: 2-4g / L of copper sulfate, 5-8g / L of seleninic acid, 2-4g / L of monopotassium phosphate, 1.5-3g / L of hydroquinone, 3-5g / L of phosphoric acid and 0.08-0.3g / L of OP-10. The preparation method comprises the following steps: respectively dissolving the components except the phosphoric acid and the OP-10 with deionized water through heating and then mixing the components evenly, and finally adding the phosphoric acid and the OP-10 for evenly mixing. The blackening agent has the advantages of quick blackening, good film quality and low production cost.

Owner:JIANGSU DEMEI TECH

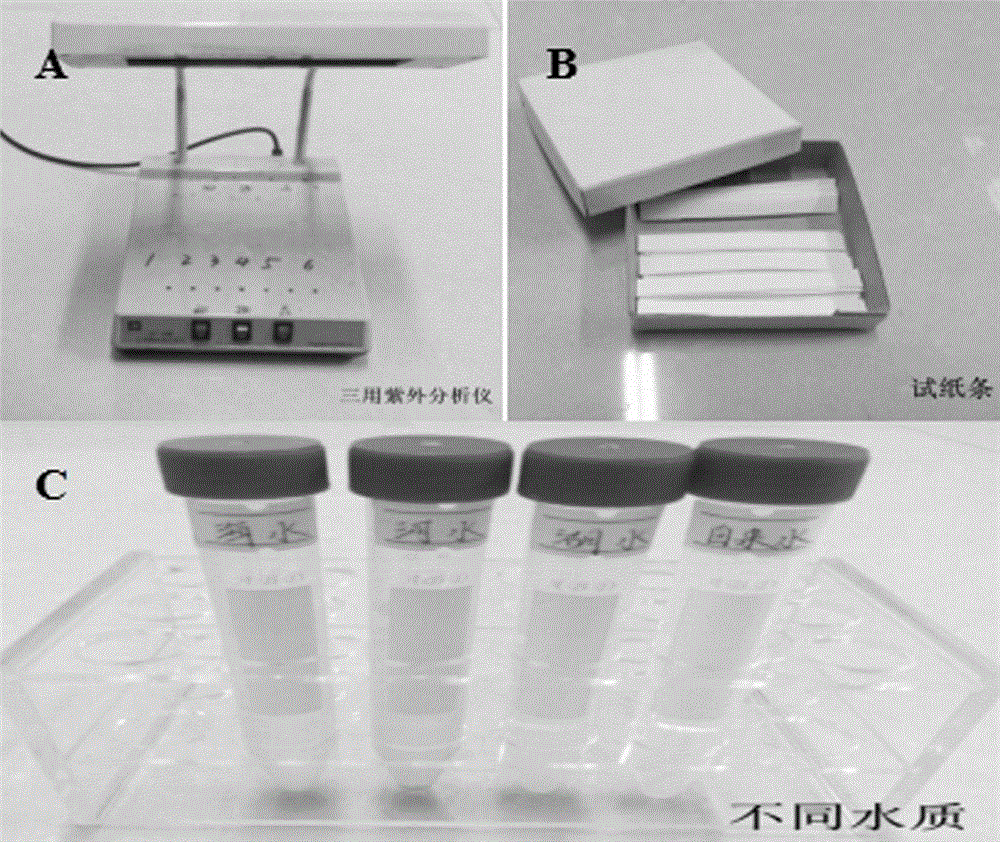

CTS-ZnO fluorescent test paper and preparation method and application thereof

ActiveCN105241859APresenting an integrated designQuantitative method is intuitiveFluorescence/phosphorescenceSeleninic acidWater quality

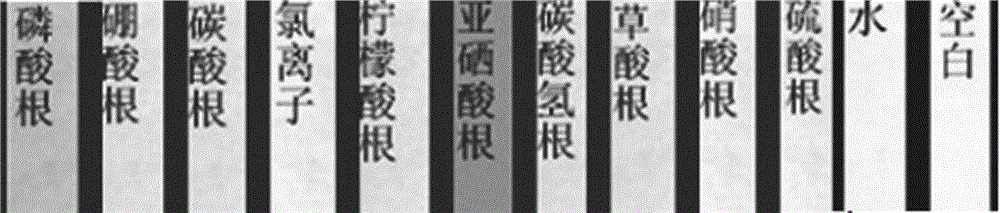

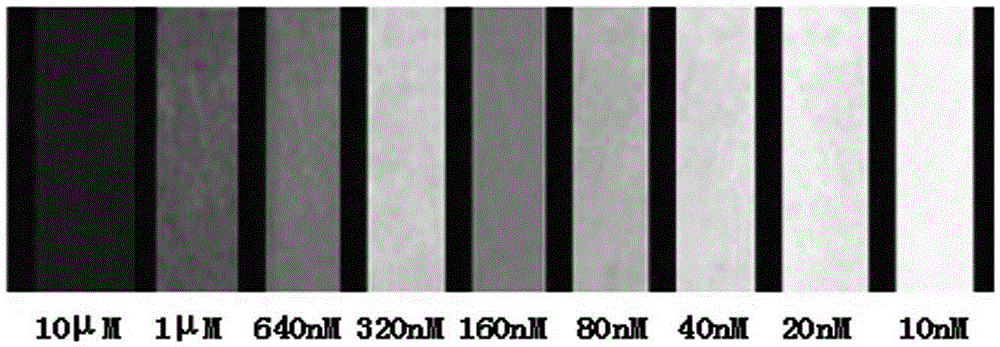

The invention discloses a CTS-ZnO fluorescent test paper comprising a test paper matrix material impregnated and loaded with silanization nano zinc oxide, wherein the load capacity of the silanization nano zinc oxide is 0.010 mg / mm<2>, and also provides a preparation method and application of the test paper. A silanization nano zinc oxide material with fluorescence characteristics and high water stability is prepared and solidified on the surface of the test paper matrix material to prepare the CTS-ZnO fluorescent test paper; and a portable fluorescence intensity measurement instrument is employed to determine the concentration of seleninic acid ions. The employed fluorescent test paper strip is cheap, portable and shows the integrated design characteristics; the quantitative method is intuitive and fast, and fluorescence intensity changes can be observed through the visual discoloration; and the concentration of seleninic acid ions in the solution to be tested can be determined directly. The method has the advantages of simple operation, short detection time and high sensitivity, and adapts to rapid, sensitive and trace rapid test of seleninic acid ion content in all kinds of water and on-site application.

Owner:QUFU NORMAL UNIV

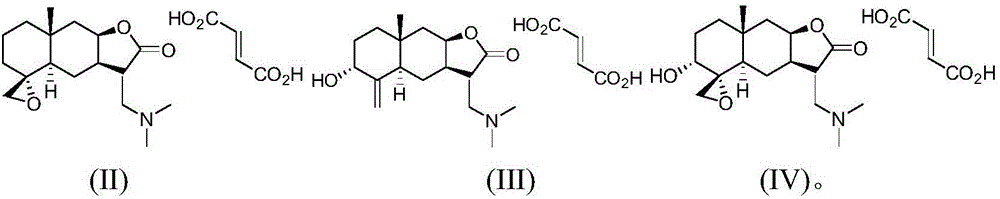

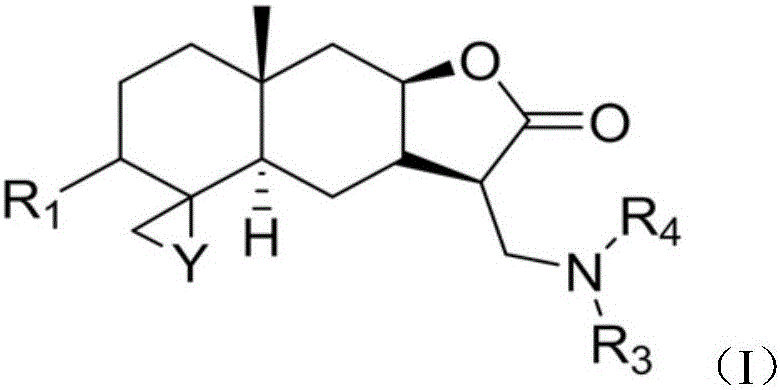

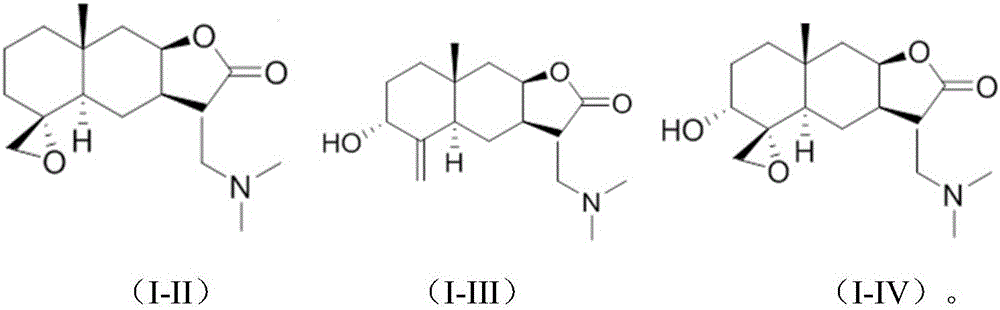

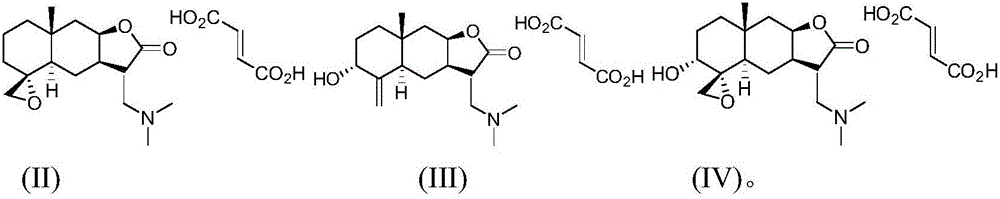

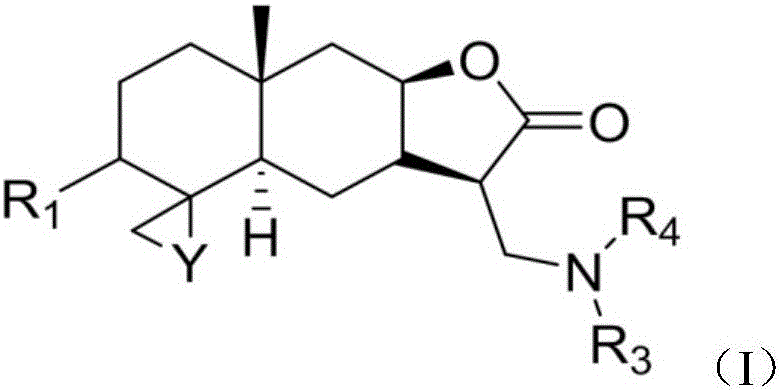

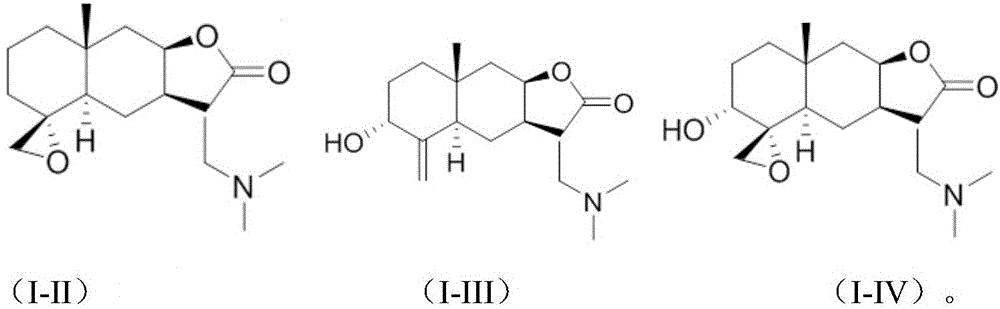

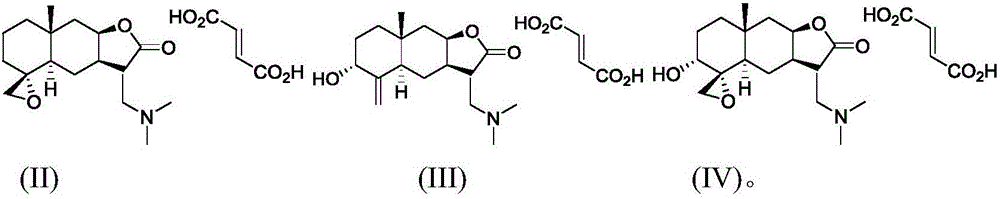

Isoalantolactone derivative and salt thereof

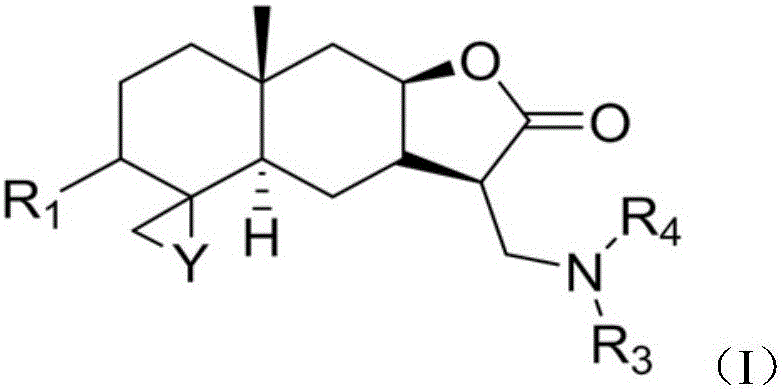

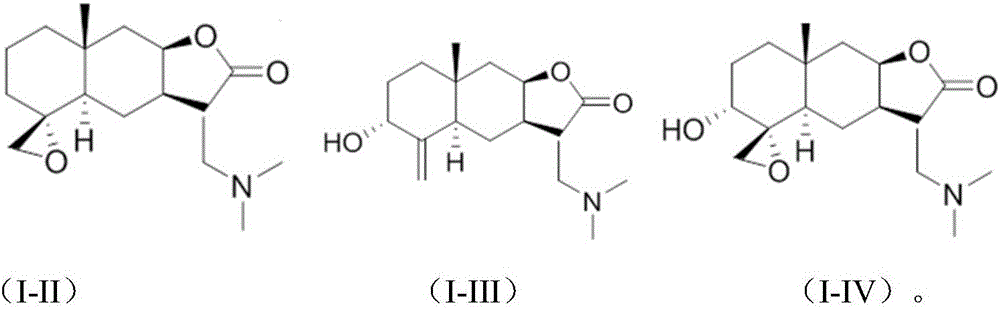

InactiveCN106478569AImprove tumor inhibition rateProlong lifeOrganic active ingredientsAntipyreticBenzoic acidPhosphomolybdic acid

The invention relates to isoalantolactone derivatives and salts thereof and provides an isoalantolactone derivative as shown in a formula (I). Salification acids are selected from inorganic acids or organic acids; the inorganic acids are selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, boric acid, seleninic acid, phosphomolybdic acid, phosphorous acid and sulphurous acid; the organic acids are selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-acid, oxalic acid, methylsulfonic acid, pentanoic acid, oleic acid, lauric acid, p-toluene sulfonic acid, 1-naphthalenesulfonic acid, 2-naphthalenesulfonic acid, phthalic acid, tartaric acid, malonic acid, succinic acid, fumaric acid, glycolic acid, mercaptan acid, glycine, sarcosine, sulfonic acid, nicotinic acid, methylpyridine acid, isonicotinic acid, benzoic acid or substituted benzoic acid.

Owner:NANKAI UNIV

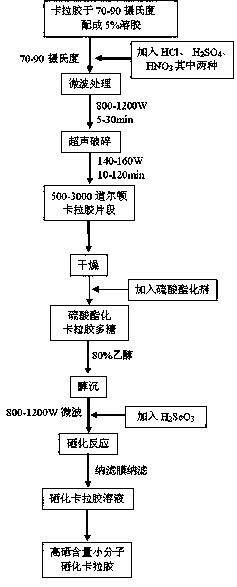

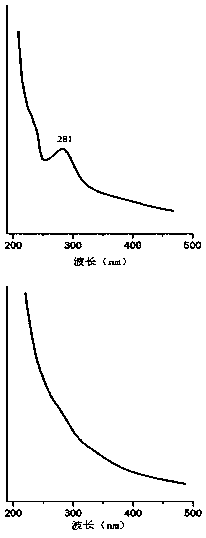

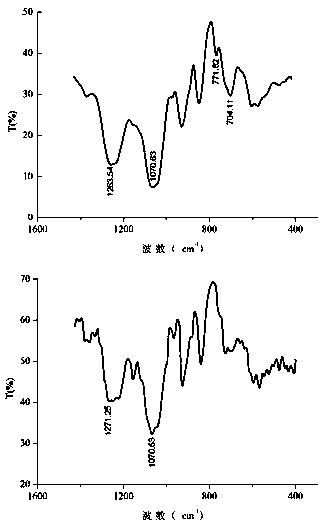

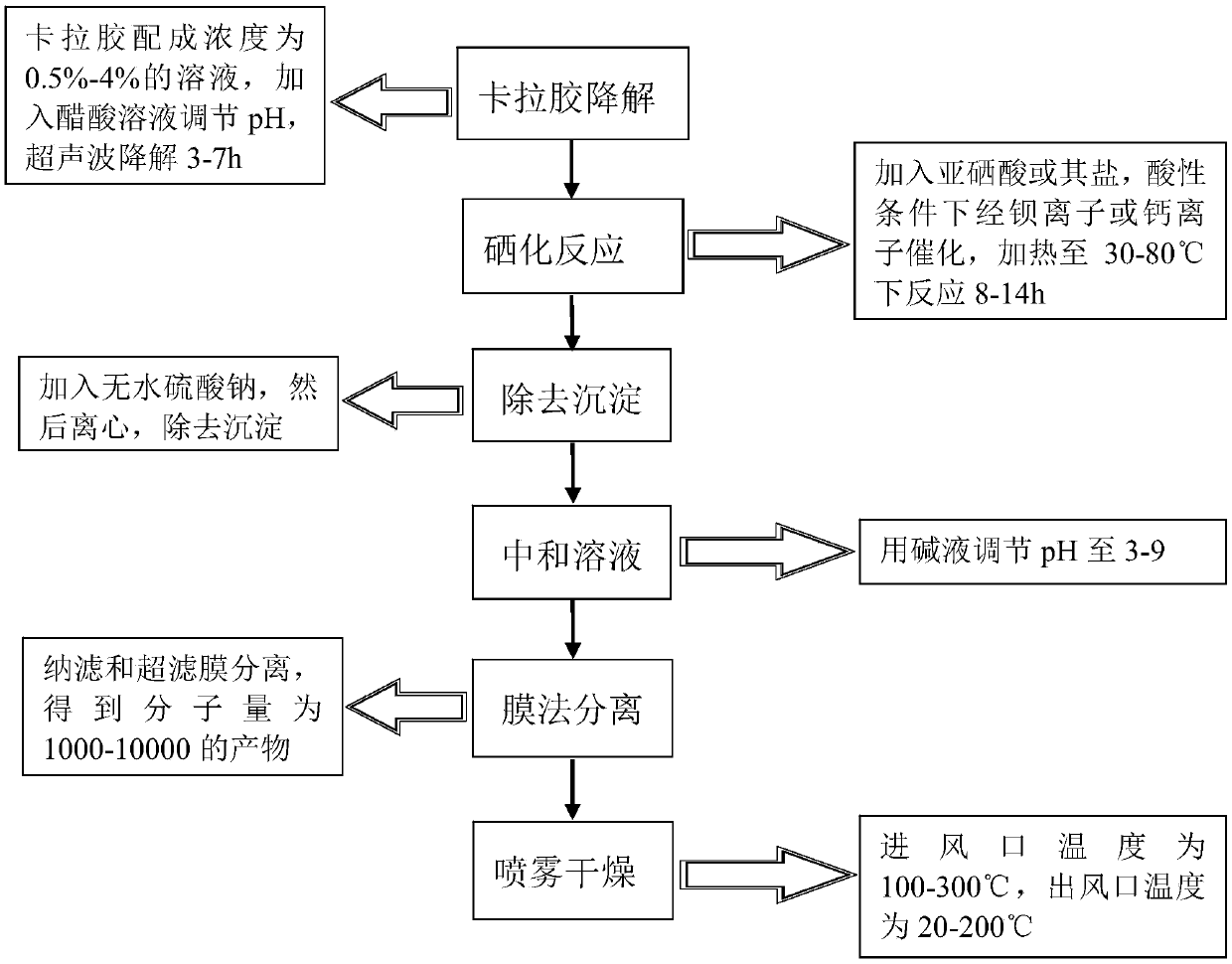

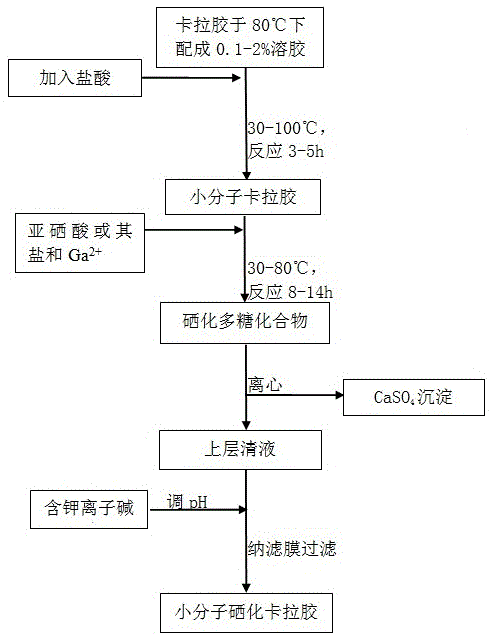

Preparation method of micromolecular selenylation carrageenan with high selenium content

ActiveCN108276603AShorten the timeImprove biological activityPlastic recyclingFood ingredient functionsBarium dichlorideUltrasonic assisted

The invention discloses a preparation method of micromolecular selenylation carrageenan with a high selenium content. The preparation method particularly comprises the following steps: performing specific-power ultrasonic treatment and ultrasonic assistance on carrageenan macromolecules to rapidly realize quantitative degradation of carrageenan molecule segments, wherein the molecular weight of most of the carrageenan is 500 to 3000 Daltons, and the carrageenan degradation time is greatly shortened when being compared with the traditional carrageenan degradation time; performing sulphating reaction to esterify carrageenan polysaccharide, and adding barium chloride and seleninic acid and performing microwave and ultrasonic assistance to promote selenylation reaction, so that the time is greatly shortened when being compared with the time of the traditional process, rapid and efficient selenylation effect can be achieved, the selenylation carrageenan with high selenium content and low molecular weight is finally prepared, the bioavailability of the selenylation carrageenan is improved, and the efficiency of absorbing the selenium by the organism is improved.

Owner:青岛鑫康达生物科技有限公司

Binder-free selenium cathode material with self-supporting structure and preparation method thereof

ActiveCN106571460AReduce weightHigh specific capacityNon-aqueous electrolyte accumulator electrodesElemental selenium/telluriumAnhydrous ethanolSeleninic acid

The invention relates to a binder-free selenium cathode material with self-supporting structure and a preparation method thereof. The preparation method comprises the following steps: Step 1) dissolving selenium dioxide in deionized water to obtain a uniform seleninic acid solution, and dissolving a reducing agent in the seleninic acid solution to obtain an uniformly-mixed solution, wherein molar concentration of selenium dioxide is 0.01-1 mol / liter, and molar concentration of the reducing agent is 0.01-0.5 mol / liter; Step 2) putting the solution obtained in the Step 1) and a conductive network structured substrate in a reaction vessel and heating at the temperature of 50-250 DEG C for 1-96 h; and Step 3) washing the sediment-attached conductive network structured substrate with anhydrous ethanol and deionized water at least once, and drying at the temperature of 40-100 DEG C so as to obtain the binder-free selenium cathode material with a self-supporting structure. The invention has characteristics as follows: the process is simple; cost is low; and the morphology is controllable. The preparation method of the invention is a preparation method suitable for large-scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Application of isoalantolactone derivative and salt thereof in preparation of medicines for treating lung fibration

ActiveCN106496243AGood treatment effectOrganic active ingredientsOrganic chemistryBenzoic acidPhosphomolybdic acid

The invention relates to an application of an isoalantolactone derivative and a salt thereof in the preparation of medicines for treating lung fibration, and provides an isoalantolactone derivative represented by formula (I). An acid for forming the salt is an inorganic acid or an organic acid, the inorganic acid is selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, boric acid, seleninic acid, phosphomolybdic acid, phosphorous acid and sulfurous acid, and the organic acid is selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-lactic acid, oxalic acid, methanesulfonic acid, pentanoic acid, oleic acid, lauric acid, p-methyl benzenesulfonic acid, 1-naphthalenesulfonic acid, 2-naphthalenesulfonic acid, phthalic acid, tartaric acid, propane diacid, succinic acid, fumaric acid, glycollic acid, thioglycollic acid, glycine, sarcosine, sulfonic acid, nicotinic acid, methylpyridine acid, isonicotinic acid, benzoic acid and substituted benzoic acid.

Owner:NANKAI UNIV

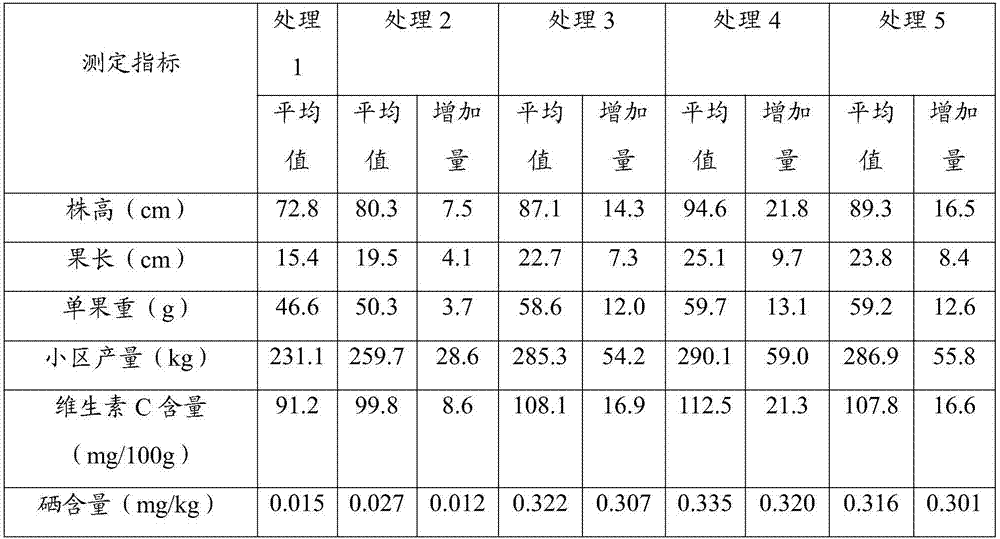

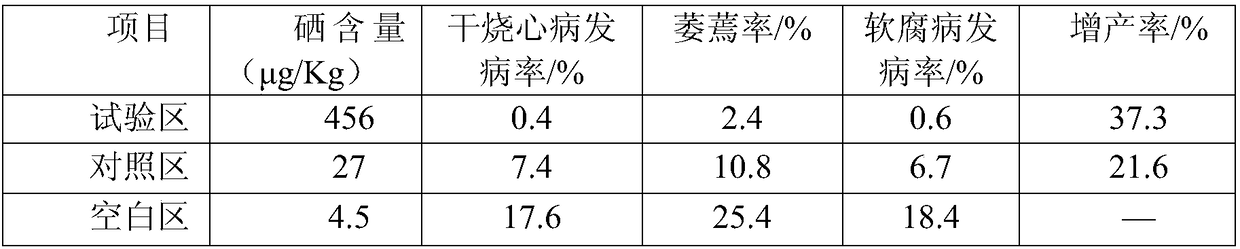

Method for Radix Platycodonis polysaccharide regulated preparation of nutritional liquid fertilizer containing nano-selenium

InactiveCN106977272AEfficient use ofAvoid reunionMagnesium fertilisersNitrogenous fertilisersSilicon dioxideHydrolysis

The invention discloses a method for the Radix Platycodonis polysaccharide regulated preparation of a nutritional liquid fertilizer containing nano-selenium. The method comprises the following steps: preparing a nano-selenium solution from Radix Platycodonis polysaccharides and seleninic acid by using an ascorbic acid reduction technology; preparing a soybean meal composite amino acid stock solution from soybean meal by using a sulfuric acid hydrolysis technology, adsorbing and decolorizing the stock solution by active carbon modified through 0.25% KOH solution treatment, filtering the stock solution, sterilizing the obtained filtrate by cobalt60 to prepare a soybean meal composite amino acid solution; and uniformly mixing magnesium sulfate, zinc sulfate, manganese sulfate, ferrous sulfate, borax, copper sulfate, sodium molybdate, silica, Arabic gum and water with the nano-selenium solution and the soybean meal composite amino acid solution to prepare the nutritional liquid fertilizer containing nano-selenium. The soybean seed composite amino acid solution and trace elements are compounded to make the trace elements exist in a chelated state, so the utilization rate of the trace elements is increased, the absorption of the plants to macro-elements is promoted, the crop yield is increased, and the crop quality is improved.

Owner:GUANGZHOU JUCHAN MODERN AGRI RES INST CO LTD

Selenium-enriched plant nutrient solution containing polyglutamic acid and preparation method thereof

InactiveCN108191523AFavorable for chelation reactionLow viscosityBio-organic fraction processingMagnesium fertilisersPhosphateManganese

The invention provides a selenium-enriched plant nutrient solution containing polyglutamic acid and preparation method thereof. The nutrient solution is prepared from acid polyglutamic acid fermentation liquor, potassium nitrate, calcium nitrate, sulfuric acid, ferrous sulfate, manganese sulfate, zinc sulfate, boric acid, phosphate, alum and the like; the acid polyglutamic acid fermentation liquoris prepared by adding the seleninic acid in the polyglutamic acid fermentation liquor until the fermentation liquid pH is 2-4. The polyglutamic acid fermentation liquor is directly used as the raw material, the nutrient substances in the fermentation liquor are reserved, and the resource is sufficiently utilized, wherein the polyglutamic acid is easy to form hydrogel, so that the covered fertilizer and microelements have obvious sustained-releasing effect, the nutrient absorbing capacity of the crops can be enhanced, the fertilizer efficiency is improved, and the fertilizing amount is reduced; the bacillus subtilis has good preventing effect on the plant disease, and the use of the pesticide can be reduced.

Owner:SHANDONG FREDA BIOTECH

Cancer wrine examination reagent

InactiveCN1420351ARapid responseThe content of effective detectable substances is smallMaterial analysis by observing effect on chemical indicatorSeleninic acidCancer Early Detection

A reagent for urinoscopy of cancer, especially the early-phase cancer is a 5-20% solution whose primary component is seleninic acid. Its advantage is high correctness.

Owner:康彦珍 +2

Preparation method of selenium carrageenan

PendingCN110357978AHarm reductionSimplify operating proceduresFood ingredient functionsWater bathsIce water

The invention discloses a preparation method of selenium carrageenan. The preparation method comprises the following steps that carrageenan is degraded by ultrasonic under the condition of acidic ice-water bath, and is reacted with seleninic acid or selenite under catalysis of barium ions or calcium ions, sodium sulfate sediment is added to remove the barium ions or the calcium ions, separation isachieved through a separation membrane after neutralizing, and finally maltodextrin spray drying is added to prepare selenium carrageenan powder. According to the preparation method, the carrageenanis degraded by the ultrasonic, more rapidness, mildness and environment-friendly are achieved; organic macromolecule selenium carrageenan is separated from micromolecule selenium carrageenan and otherinorganic substances more efficient and environmental-friendly throughseparation membrane filtration; and according to using of the spray drying, the particle size is more uniform, the production link is more sanitary, and the product purity is high.

Owner:QINGDAO PENGYANG BIOLOGICAL ENG

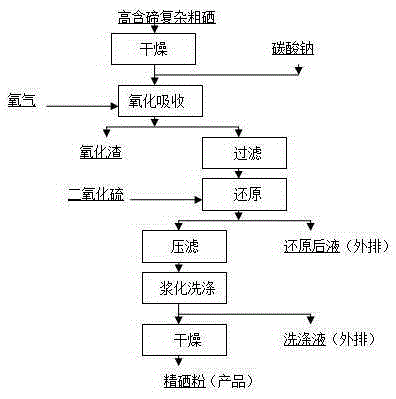

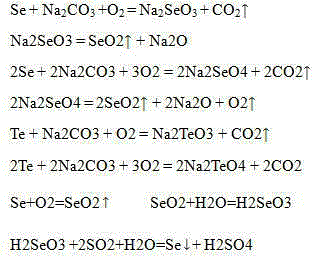

Method for separating tellurium in crude selenium refining process

Owner:JINCHUAN GROUP LIMITED

Method for treating selenium-containing sewage

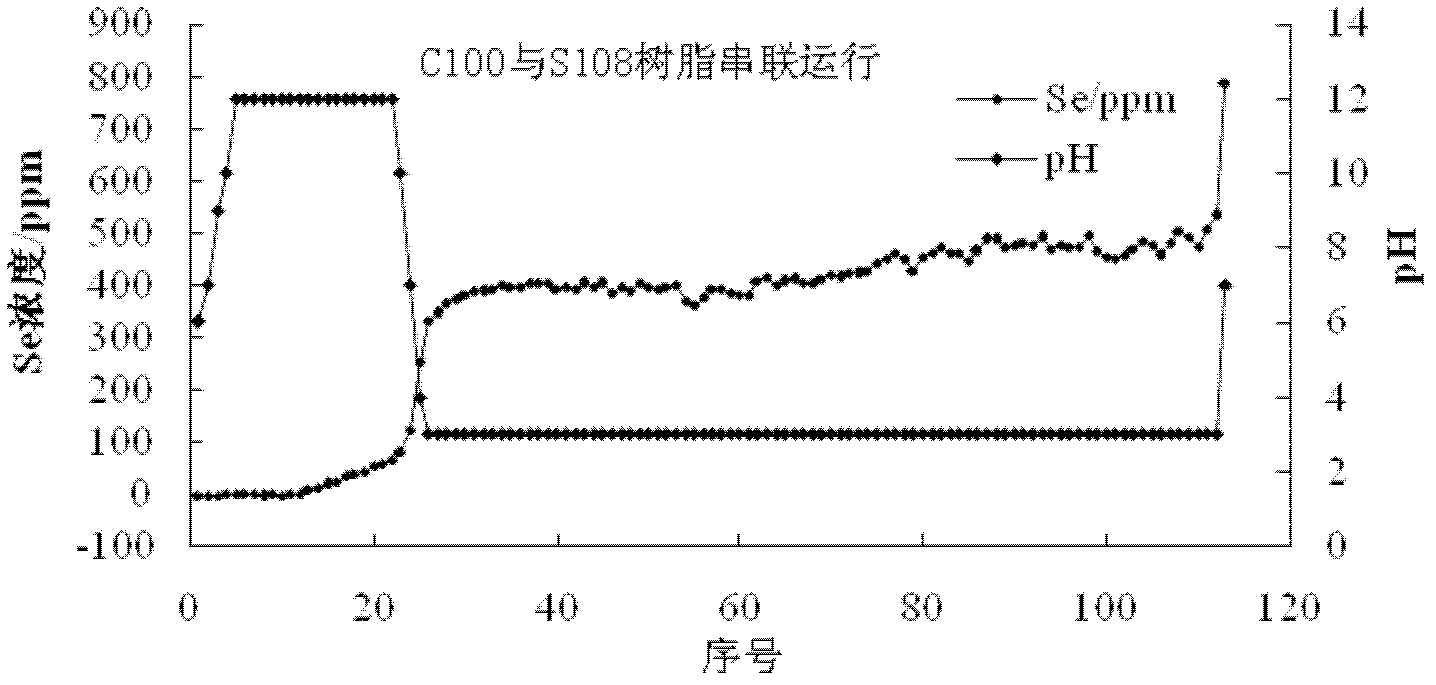

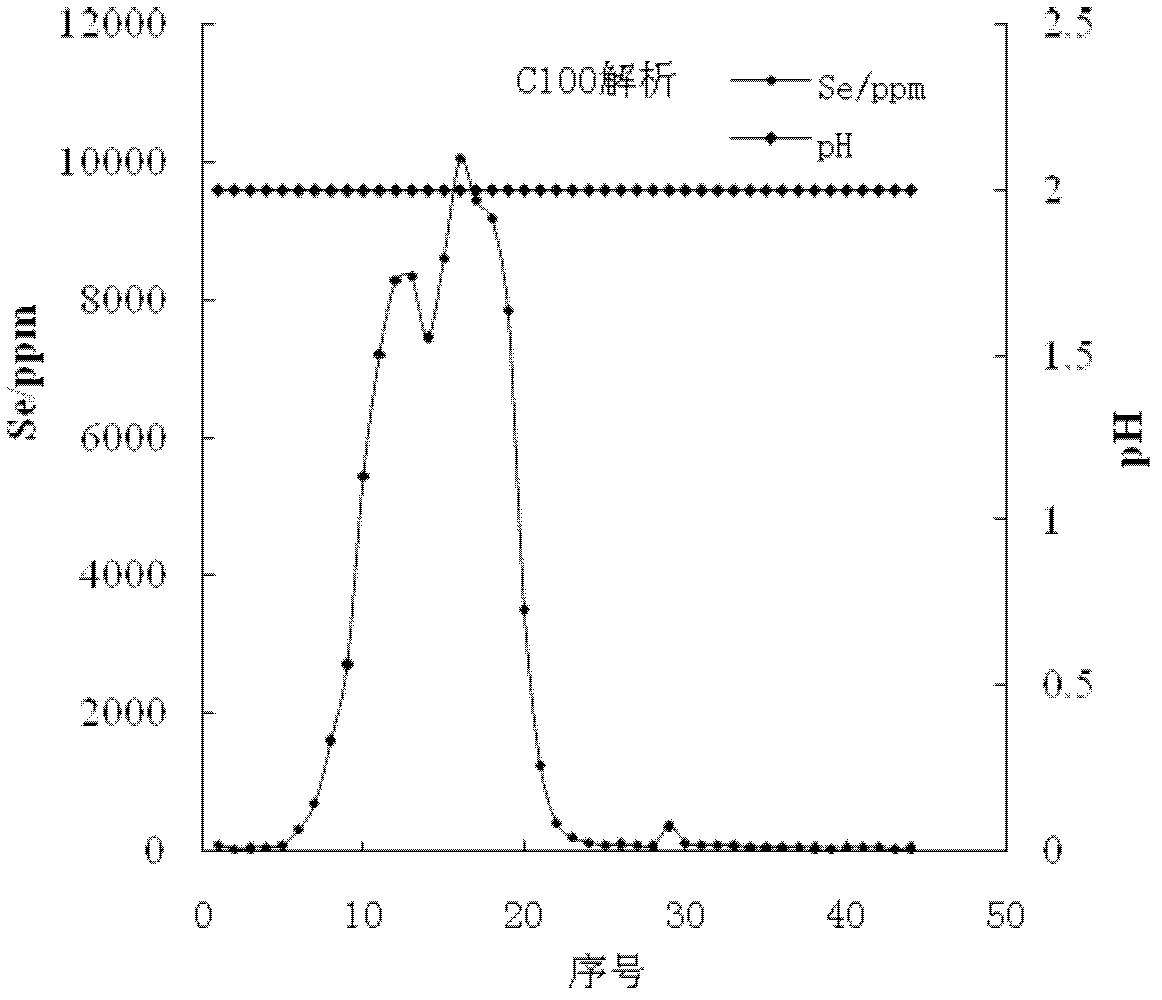

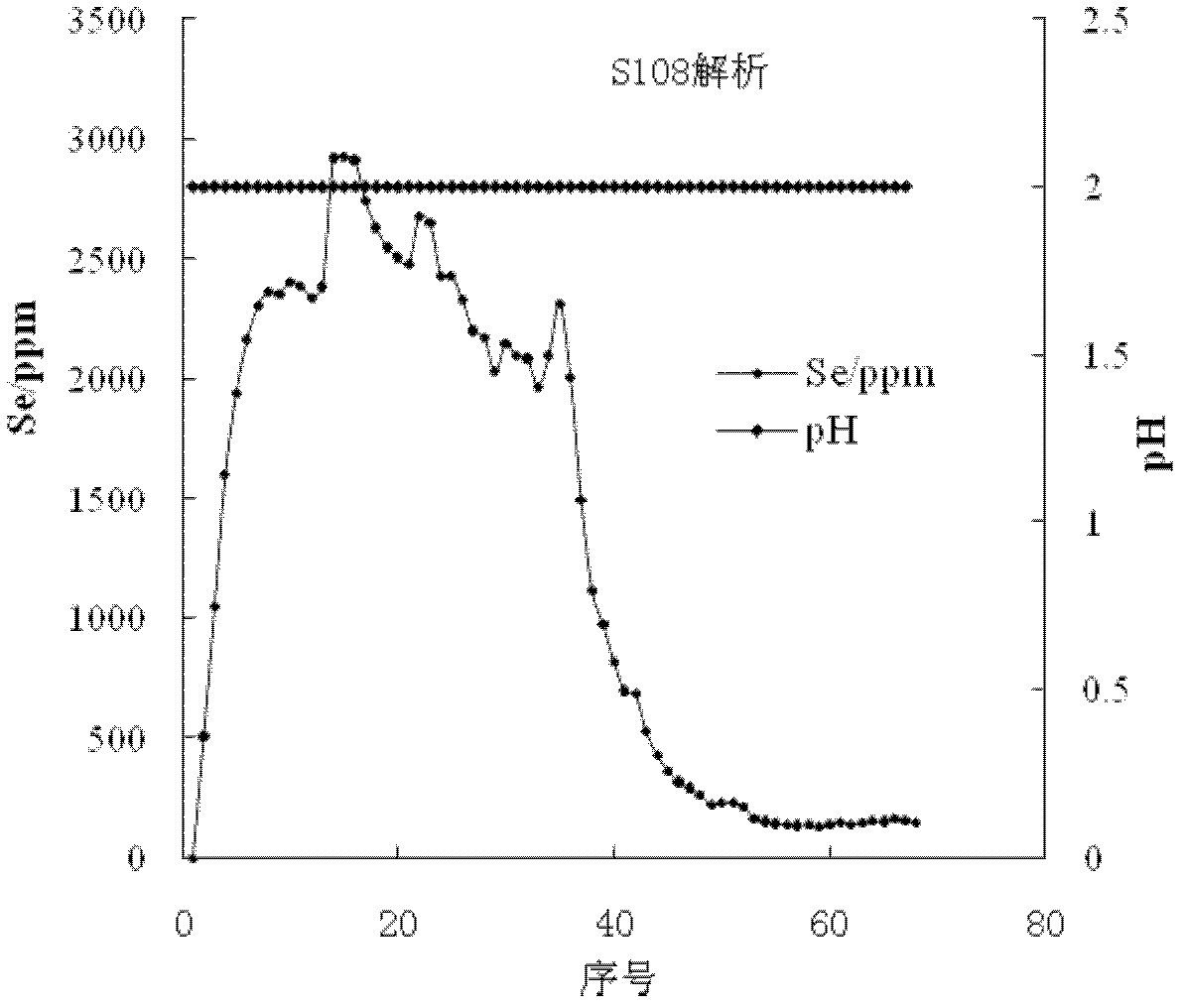

InactiveCN103183427AEasy to handleAchieve separationMultistage water/sewage treatmentWater/sewage treatment by neutralisationSeleninic acidSewage discharge

The invention provides a method for treating selenium-containing sewage, which comprises the following steps: regulating the pH value of the selenium-containing sewage to 7-8 to serve as the raw sewage, wherein selenium in the raw sewage exists in the form of seleninic acid ion or selenate radical icon; supplying the raw sewage to a first adsorption column, wherein the first adsorption column contains C100 resin, performs a first adsorption treatment on the raw sewage and discharges the first treated sewage; supplying the first treated sewage discharged from the first adsorption column to a second adsorption column, wherein the second adsorption column contains C108 resin or A420 resin, performs a second adsorption treatment on the first treated sewage and discharges the second treated sewage. The method for treating selenium-containing sewage can effectively treat selenium-containing sewage, including micro-content selenium sewage, low-content selenium sewage and high-content selenium sewage, and can remove quadrivalent selenium or hexavalent selenium in the sewage, so as to separate two valency states of selenium.

Owner:FIRST RARE MATERIALS CO LTD

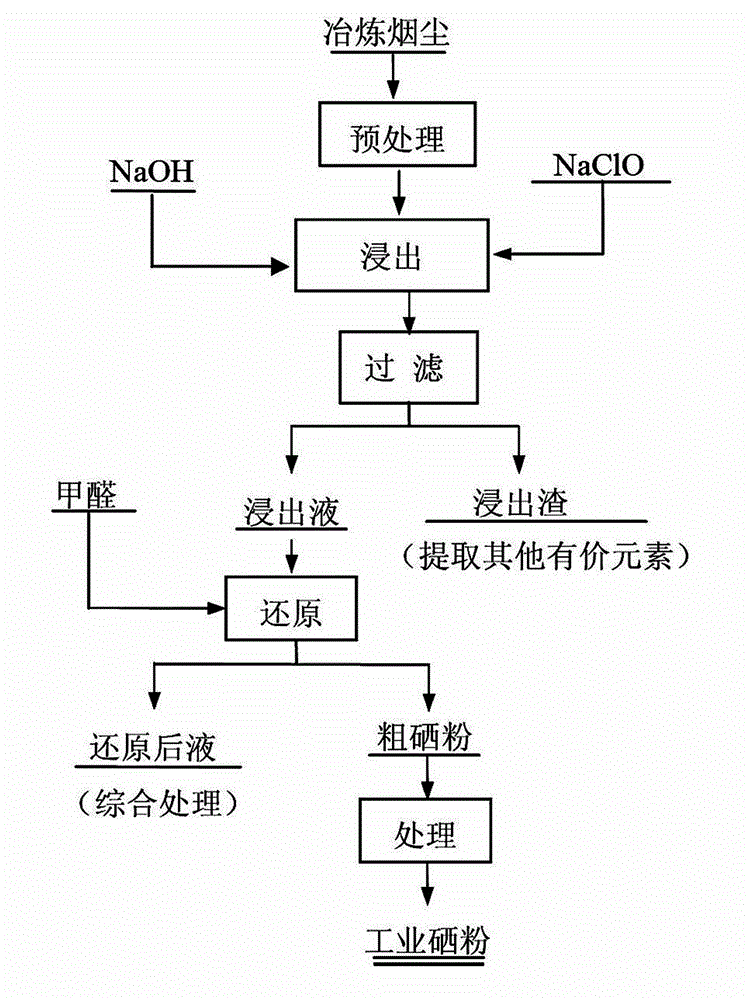

Method for extracting selenium from nickel-molybdenum ore smelting smoke dust in alkali system

ActiveCN102745656AHigh recovery rateEmission reductionElemental selenium/telluriumPregnant leach solutionSeleninic acid

The invention discloses a method for extracting selenium from nickel-molybdenum ore smelting smoke dust in an alkali system. The method comprises the following steps of: pre-treating the nickel-molybdenum ore smelting smoke dust; performing oxidation leaching on the pre-treated nickel-molybdenum ore smelting smoke dust in an alkali leaching system; and performing selenium reduction reaction on oxidation-leached seleninic acid radical-containing leachate by taking at least one of formaldehyde and diammonium under an alkali condition to highly separate seleninic acid radical ions from other ions in the leachate to obtain high-purity selenium powder. The method is short in process flow, easy to operate, low in energy consumption, high in metal recovery rate and low in production cost, and a low-carbon and environment-friendly smelting aim can be fulfilled.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Preparation method of plant selenium enrichment enhancer

ActiveCN104604930APromote absorptionEasy to getBiocidePlant growth regulatorsBiotechnologyCarrageenan

The invention discloses a preparation method of a plant selenium enrichment enhancer. The preparation method comprises the following steps of degrading carrageenan, reacting with seleninic acid or selenite so as to obtain the plant selenium enrichment enhancer taking selenium carrageenan as a selenium source. The preparation method is characterized in that HC1 replaces HNO3 to degrade carrageenan so that micromolecule carrageenan with the molecular weight lower than 1000 can be obtained, and a nano filtration membrane is used for filtering to control the proportion of carrageenan products with micromolecular weight; meanwhile, calcium salt is adopted for replacing barium salt to act as a catalyst of de-sulfation, and participates into the reaction to prevent of the use of the toxic barium salt. The raw material carrageenan of the plant selenium enrichment enhancer is extracted from seaweed, and is easily available; moreover, the preparation technology is simple, is easy to operate, is high in safety, and is low in production cost; the modular weight of the prepared product is below 1000; the plant selenium enrichment enhancer is high in activity, and is easy absorption and utilization by plants.

Owner:QINGDAO PENGYANG BIOLOGICAL ENG

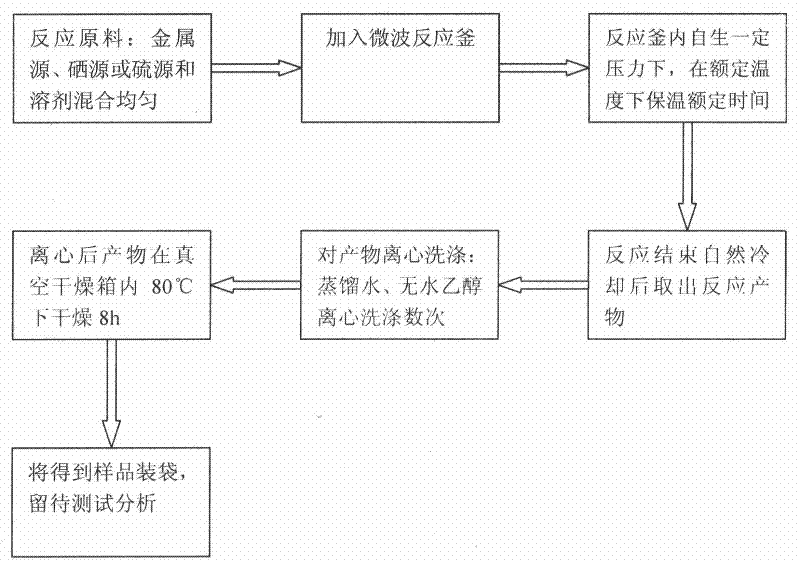

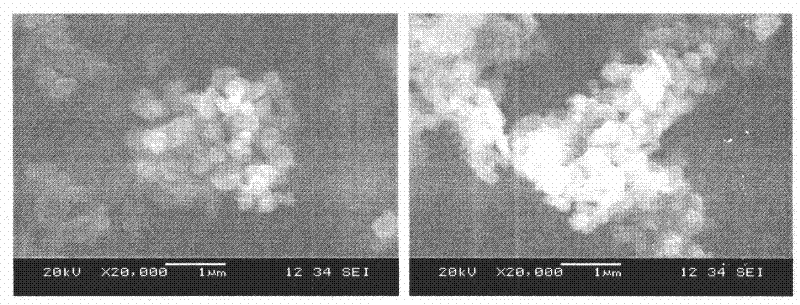

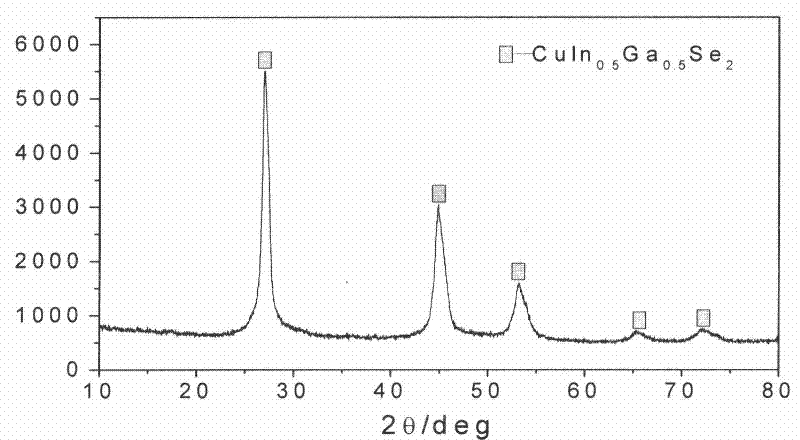

Microwave-assisted solvothermal synthesis method of I-III-VI semiconductor material nano-powder

InactiveCN102249199AEasy to operateSmall grain sizeSelenium/tellurium compundsNanotechnologyEthylenediamineSemiconductor materials

The invention discloses a microwave-assisted solvothermal synthesis method of I-III-VI semiconductor material nano-powder. The method comprises the following steps: adding metal salt and a sulfur source or selenium source into a beaker based on the mole ratio of an expected product, adding a solvent, evenly mixing and then transferring the obtained mixed solution to a microwave reaction kettle; after the reaction kettle is closed, heating the mixed solution to rated temperature in a microwave field, and performing heat preservation for rated time; and centrifugally washing the final product to obtain the target powder. In the method, the solvent is one or more of water, ethylenediamine, ethylene glycol, diamine and ethanol; the metal salt is the metal salt of Cu, In, Ga and Al; the sulfur source is thiourea or sulfur powder; and the selenium source is selenium powder or seleninic acid. The microwave-assisted solvothermal synthesis method has the beneficial effects that based on the heating and activation effect of the microwave field, reaction temperature is lowered and reaction time is shortened; and part of reaction that can not be made in the traditional high-pressure solvothermal synthesis process can be performed smoothly. The obtained semiconductor material nano-powder has the advantages of smaller grain size, pure phases, accurately controlled stoichiometric ratio of the phases and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

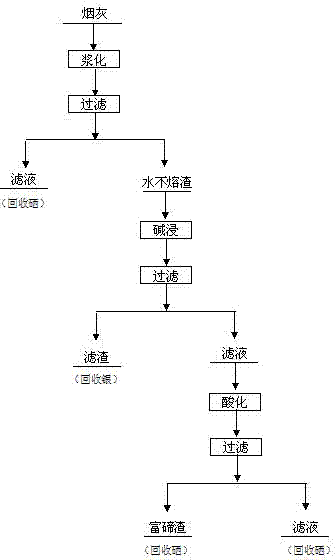

Method for extracting selenium and tellurium from pyrometallurgy smelting soot

The invention relates to a method for extracting selenium and tellurium from pyrometallurgy smelting soot, and relates to a method for extracting selenium and tellurium from pyrometallurgy smelting soot collected by a dust collection system in the pyrometallurgy treatment process of copper anode slime. The method is characterized by comprising the following steps: (1) adding water to the pyrometallurgy smelting soot for slurrying and dissolution, filtering to obtain a seleninic acid solution, and extracting crude selenium through direct reduction; (2) adding a sodium hydroxide solution to filter residues to leach selenium and tellurium, and filtering again; (3) adding sulfuric acid to a filtrate, regulating the pH value to obtain a selenium-containing filtrate to extract crude selenium through reduction, and extracting tellurium by using tellurium-rich filter residues as a raw material. According to the method provided by the invention, the direct recovery rates of extracting selenium and tellurium from the soot are 95% and 80% respectively, and the crude selenium contains more than 93% selenium, and the tellurium-rich residues contain more than 50% of tellurium after reduction. In addition, the soot from which selenium and tellurium are recovered is fully enriched in precious metal elements, the grade reaches about 15%, and the soot can be mixed with the copper anode slime to be dried and then treated by pyrometallurgy.

Owner:JINCHUAN GROUP LIMITED

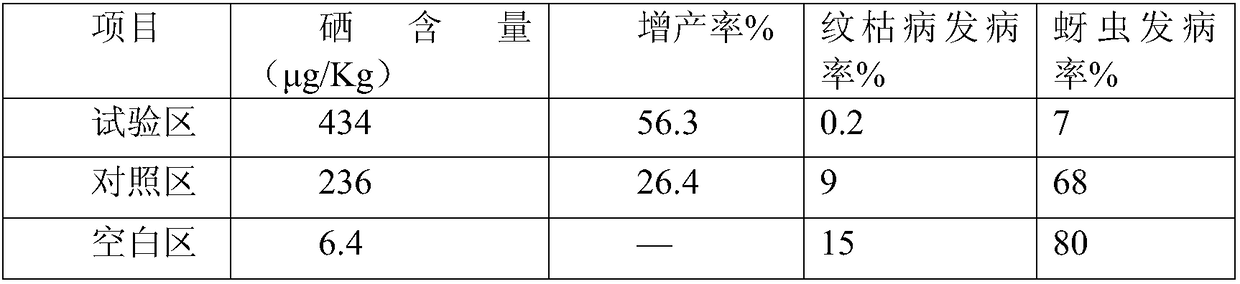

Method for planting selenium-enriched crops

ActiveCN109247203APermanent productionFertilising methodsCultivating equipmentsAlkaline earth metalSeleninic acid

The invention discloses a method for planting selenium-enriched crops. The method comprises the following steps 1, a seleninic acid solution is mixed with an alkaline earth metal hydroxide solution orsuspension to be subjected to a reaction, or alkaline earth metal selenite powder and water are mixed to generate an alkaline earth metal selenite suspension or sol; 2, the alkaline earth metal selenite suspension or sol is uniformly sprayed to the surface of a plough covered with no water, then, ploughing and raking are performed on the plough, and then the selenium-enriched crops are planted. The method has the advantages that water insoluble selenite is adopted for performing disposable selenium supplementing on soil short of selenium, selenium can be stored into soil for a long time, andthe selenium-enriched crops can be planted for 300 years or longer according to a conventional tillage method; plants and excrement of people, livestock and poultry eating selenium-enriched agricultural products can be returned to the plough, and the selenium-enriched agricultural products can be permanently produced under the condition that selenium circulation is formed.

Owner:唐谟堂

Potassium-boron-selenium fertilizer capable of promoting growth of fruit trees and degrading residual pesticide

InactiveCN101863697APromote growthIncrease selenium contentFertilizer mixturesFruit treeSeleninic acid

The invention discloses a potassium-boron-selenium fertilizer capable of promoting the growth of fruit trees and degrading residual pesticide. Seleninic acid is neutralized by potassium hydroxide, so that potassium selenite is obtained; diboron trioxide is dissolved in water, and is mixed with the potassium selenite, and thereby potassium-boron-selenium reagent with the PH value between 7.0 and 8.8 is prepared. The potassium-boron-selenium fertilizer has the multiple fertilizer effects of selenium fertilizer and conventional potash fertilizer and boron fertilizer, and when the potassium-boron-selenium fertilizer is sprayed on the surfaces of the leaves of fruit trees, not only can the fruit-setting rate be increased, but also residual pesticide can be degraded and the selenium content of fruits can be increased.

Owner:于百涛

Method for preparing yolk-shell structure Co9Se8 nano-particles

ActiveCN107628591AEasy to prepareReduce processing costsMaterial nanotechnologyCell electrodesYolkNitrate

The invention provides a method for preparing yolk-shell structure Co9Se8 nano-particles. The process comprises the following steps: 1, respectively adding cobalt-nitrate hexahydrate (Co(NO3)2.6H2O) and glycerol into isopropyl alcohol to prepare a mixed solution, and performing ultrasonic stirring; 2, transferring the stirred mixed solution into a reaction kettle for hydrothermal treatment at 180DEG C for 3-9 hours, and centrifugally washing the powder generated in reactions to obtain a Co spherical precursor; and 3, preparing a mixed solution from the Co spherical precursor and deionized water, sequentially adding seleninic acid and hydrazine hydrate solution, stirring for 1-5 minutes, transferring the mixed solution into the reaction kettle for hydrothermal treatment at 140-200 DEG C for 12-36 hours, and centrifugally washing the powder after the reaction is completed to obtain the yolk-shell structure Co9Se8 nano-particles. The yolk-shell structure Co9Se8 nano-particles prepared bycontrolling reaction conditions of growth and selenylation of the precursor has a simple method, short production cycle and regular powder shape, and has an excellent application prospect in the field of ionic batteries.

Owner:UNIV OF SCI & TECH BEIJING

Isoalantolactone derivatives and their application in preparation of drugs for treating inflammatory bowel diseases

InactiveCN106474109AGood treatment effectOrganic active ingredientsOrganic chemistryBenzoic acidPhosphomolybdic acid

Isoalantolactone derivatives and their application in preparation of drugs for treating inflammatory bowel diseases are provided, and an isoalantolactone derivative shown as in formula (I) is provided; a salt-forming acid is an inorganic acid or organic acid, the inorganic acid is selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, bromic acid, seleninic acid, phosphomolybdic acid, phosphorus acid and sulfurous acid, and the organic acid is selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-acid, oxalic acid, methylsulfonic acid, pentanoic acid, oleic acid, lauric acid, p-methylbenzene sulfonic acid, 1-naphthalene sulfonic acid, 2-naphthalene sulfonic acid, phthalic acid, tartaric acid, malonic acid, succinic acid, fumaric acid, glycolic acid, mercapturic acid, glycine, creatine, sulfonic acid, nicotinic acid, picolimic acid, isonicotinic acid, and benzoic acid or substituted benzoic acid.

Owner:天承南运(天津)科技有限公司

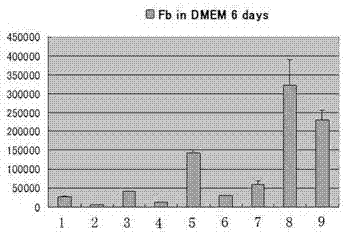

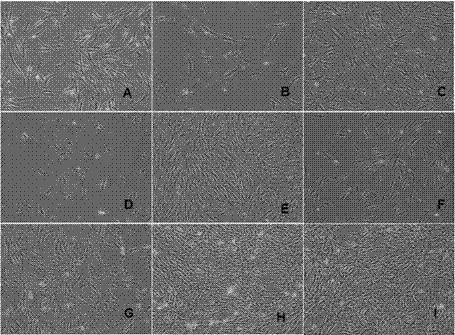

Medium without animal source components for cultivating human mesenchymal stem cells

InactiveCN107475185AReduce dependenceReduced characteristicsSkeletal/connective tissue cellsFiberProgesterones

The invention relates to a medium without animal source components for cultivating human mesenchymal stem cells. The medium comprises the following components: 1-100[mu]g / ml of recombinant human insulin, 1-50ng / ml of basic fibroblast growth factor, 1-50[mu]g / ml of human transferrin, 1-80[mu]g / ml of seleninic acid, 1-300[mu]g / ml of serine, 1-200[mu]g / ml of choline chloride, 1-60[mu]g / ml of adenine, 1-100[mu]g / ml of single acetamide, 0.01-10mmol / ml of o-phosphorylethanolamine 1-40pg / ml of progesterone, 1-50pg / ml of three iodine thyroid, 1-100[mu]l / ml of human blood plasma. The medium has substantially better culture efficiency than traditional mediums in cultivating human adipose-derived stem cells and human umbilical cord mesenchymal stem cells, and the medium has characteristics of maintenance of good stem cell characters, cell proliferation capability, and high biological performance; the medium reduces dependence of stem cells for fetal calf serum, reduces bad influences of fetal calf serum for stem cell characteristics and differentiation, thoroughly removes fetal calf serum, avoids pollution risk of virus due to bad quality of animal serum, and more accords with clinic applications.

Owner:杨旅军

Biological synthesizing method of nano-selenium

ActiveCN107640748AUniform sizeGood dispersionMaterial nanotechnologyElemental selenium/telluriumWater bathsEnvironmental resistance

The invention discloses a biological synthesizing method of nano-selenium. The biological synthesizing method comprises the following steps of using pure lemon juice; adding seleninic acid, magnetically stirring, adjusting the pH (potential of hydrogen) value by ammonia water, and vibrating by ultrasonic waves; heating in a water bath, and magnetically stirring; finally, centrifuging, so as to obtain the nano-selenium material. The biological synthesizing method has the advantages that by using the seleninic acid and the fresh lemon juice as the raw materials, the raw materials are pure plant,and the nano-selenium can be prepared at room temperature; the green and environment-friendly effects are realized, the reaction is moderate, and the template and catalyst are not needed.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com