Binder-free selenium cathode material with self-supporting structure and preparation method thereof

A self-supporting structure and positive electrode material technology, applied to structural parts, battery electrodes, element selenium/tellurium, etc., to achieve good cycle performance, uniform appearance, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a high-performance selenium cathode material with no binder and self-supporting structure and a preparation method thereof. The phase and morphology of the high-performance binder-free, self-supporting selenium cathode material can be controlled by adjusting the experimental conditions, and the morphology is uniform and the size distribution is uniform; the preparation method uses a conductive network structure as the lining Using selenium dioxide as the selenium source, the selenium dioxide is reduced to elemental selenium with a suitable reducing agent under hydrothermal conditions, and deposited on the conductive network structure substrate, thereby preparing a binder-free, self- Supported selenium cathode material. The present invention mainly lies in that, using selenium dioxide and a suitable reducing agent as raw materials, by controlling the reaction temperature, reaction time, type of reducing agent and reactant concentration of the syste...

Embodiment 1

[0042] 1 mmol of selenium dioxide was dissolved in 40 ml of deionized water to obtain a uniform selenous acid solution, and then 2 mmol of ethylenediaminetetraacetic acid was dissolved in the above selenous acid solution, and stirred at room temperature for 60 minutes. At the same time, the carbon fiber paper was cut into long strips of suitable size, ultrasonicated in absolute ethanol for 10 minutes, repeated ultrasonication 3 times, and then rinsed with absolute ethanol. Then the above mixed solution and carbon fiber paper were placed in a reaction kettle, and hydrothermally reacted at 150° C. for 24 hours. After the reaction, the obtained carbon fiber paper with deposits was washed several times with absolute ethanol and deionized water, and dried in an oven at 60° C. for several hours to obtain a selenium material with no binder and a self-supporting structure.

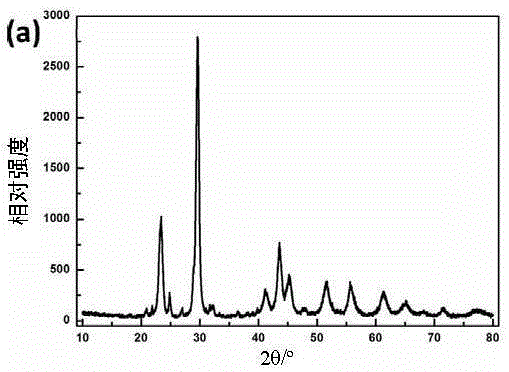

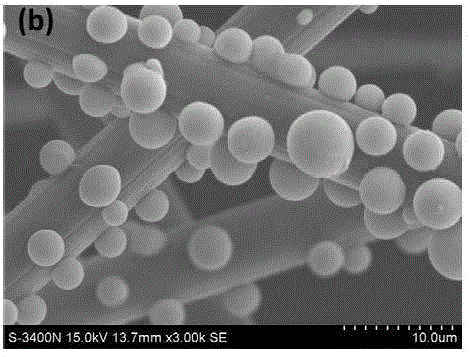

[0043] The samples were characterized by XRD and SEM, respectively as Figure 1a , as shown in 1b. It can be s...

Embodiment 2

[0048] 1 mmol of selenium dioxide was dissolved in 40 ml of deionized water to obtain a uniform selenous acid solution, and then 2 mmol of ethylenediaminetetraacetic acid was dissolved in the above selenous acid solution, and stirred at room temperature for 60 minutes. At the same time, the carbon fiber paper was cut into long strips of suitable size, ultrasonicated in absolute ethanol for 10 minutes, repeated ultrasonication 3 times, and then rinsed with absolute ethanol. Then the above mixed solution and carbon fiber paper were placed in a reaction kettle, and hydrothermally reacted at 180° C. for 24 hours. After the reaction, the obtained carbon fiber paper with deposits was washed several times with absolute ethanol and deionized water, and dried in an oven at 60° C. for several hours to obtain a selenium material with no binder and a self-supporting structure.

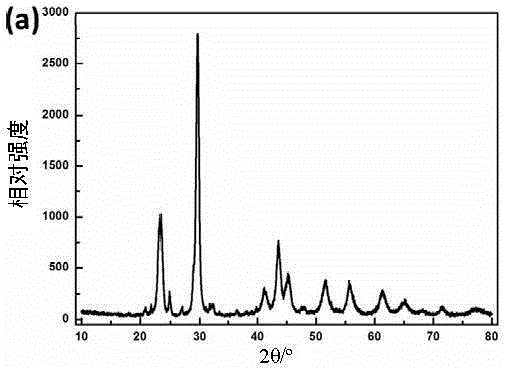

[0049] The samples were characterized by XRD and SEM, respectively as Figure 2a , as shown in 2b. It can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com