Preparation method of selenium carrageenan

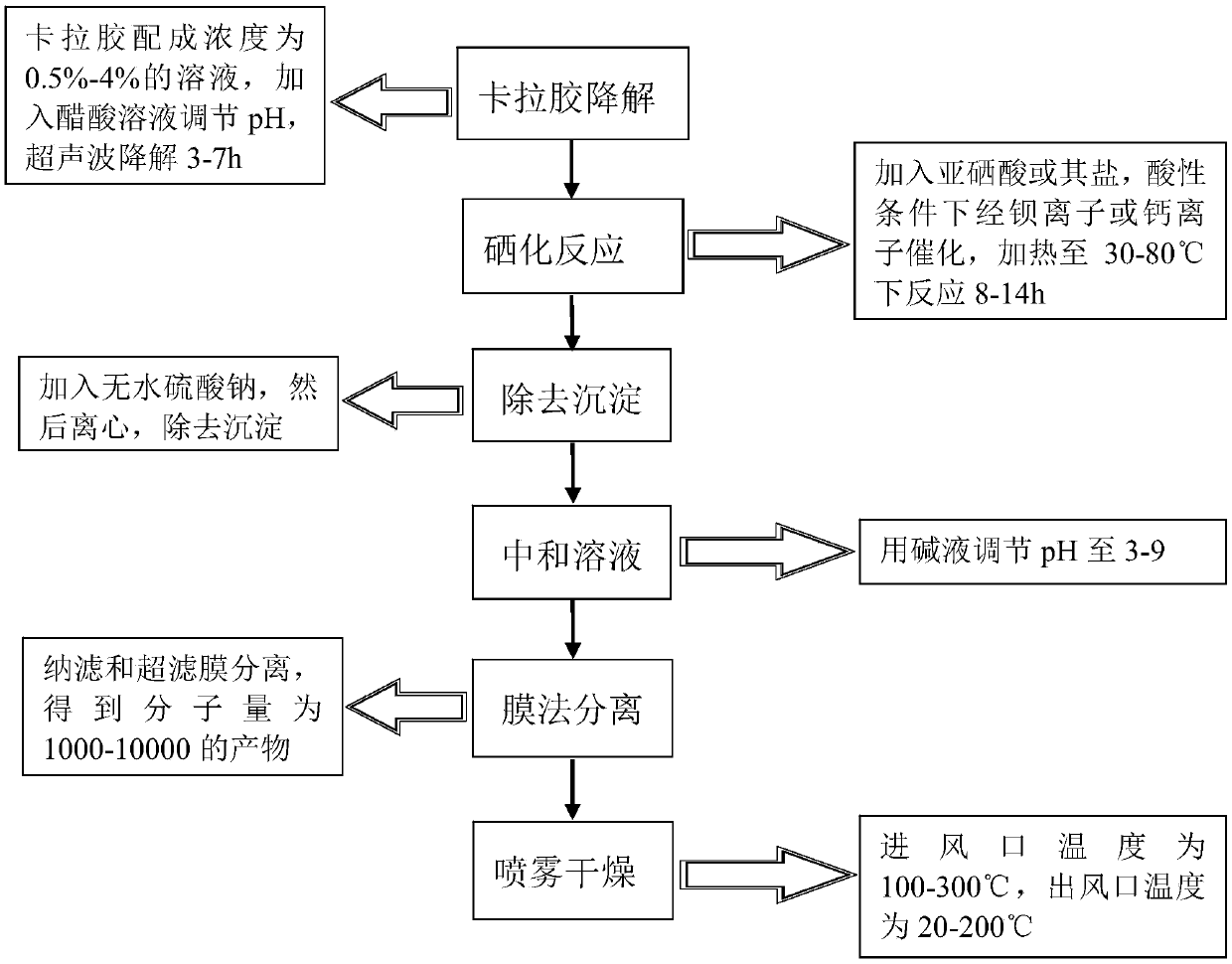

A technology of selenized carrageenan and carrageenan, which is applied in the preparation of selenized carrageenan and the field of preparation of selenized polysaccharide compounds, can solve the problems of incomplete separation of organic substances and inorganic substances, low selenium content of selenized carrageenan, The quality of the final product is not high, and the effect of excellent powder properties, uniform powder particle size, and hygienic production process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Degradation of carrageenan: Make 1.0kg of carrageenan (Shanghai Beilian Biotechnology Co., Ltd., white uniform powder) into a solution with a mass concentration of 0.5% with deionized water, and then add 5M acetic acid solution to adjust the pH value of the solution to 4.0 , to make the solution acidic, and use an ultrasonic wave with a power of 300W to carry out the degradation reaction for 7 hours under the adjustment of an ice bath at 2°C;

[0035] (2) Selenization reaction: add 0.16kg sodium selenite and 0.32kg BaCl to the carrageenan sol 2 , heated to 30°C and reacted for 14 hours to generate selenized carrageenan; after the reaction was completed, the reaction solution was lowered to room temperature;

[0036] (3) Remove barium ions: add 0.25 kg of anhydrous sodium sulfate to the reaction solution cooled to room temperature in step (2), so that the barium ions in the reaction solution are formed as precipitates; centrifuge the reaction solution to remove the b...

Embodiment 2

[0041] (1) Degradation of carrageenan: After making 1.5kg of carrageenan (Shanghai Beilian Biotechnology Co., Ltd., white uniform powder) into a solution with a mass concentration of 2% with deionized water, add 5M acetic acid solution to adjust the pH value of the solution to 3.0 , to make the solution acidic, and use an ultrasonic wave with a power of 500W to carry out the degradation reaction for 5 hours under the adjustment of an ice bath at 5°C;

[0042] (2) Selenization reaction: add 0.68kg sodium selenite and 1.5kg BaCl to the carrageenan sol 2 , heated to 50°C and reacted for 10 hours to generate selenized carrageenan; after the reaction was completed, the reaction solution was lowered to room temperature;

[0043] (3) Remove barium ions: add 1.25 kg of anhydrous sodium sulfate to the reaction solution cooled to room temperature in step (2), so that the barium ions in the reaction solution are generated as precipitates; the reaction solution is centrifuged to remove th...

Embodiment 3

[0048] (1) Degradation of carrageenan: After making 1.8kg of carrageenan (Shanghai Beilian Biotechnology Co., Ltd., white uniform powder) into a solution with a mass concentration of 2.5% with deionized water, add 3M acetic acid solution to adjust the pH value of the solution to 3.5 , to make the solution acidic, and use an ultrasonic wave with a power of 600W to carry out the degradation reaction for 4.5h under the adjustment of an ice bath at 3°C;

[0049] (2) Selenization reaction: add 0.8kg sodium selenite and 1.75kg BaCl to the carrageenan sol 2 , heated to 70°C and reacted for 7 hours to generate selenized carrageenan; after the reaction was completed, the reaction solution was lowered to room temperature;

[0050] (3) Remove barium ions: add 1.56 kg of anhydrous sodium sulfate to the reaction solution cooled to room temperature in step (2), so that the barium ions in the reaction solution are generated as a precipitate; the reaction solution is centrifuged to remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com