Method capable of improving selenium content for preparing polysaccharide selenite

A polysaccharide selenite content technology, applied in the field of polysaccharide selenite preparation, can solve the problems of complex selenium polysaccharide synthesis process, heavy metal organic solvent pollution, low selenium content of products, etc., to avoid food safety problems, Easy post-processing and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

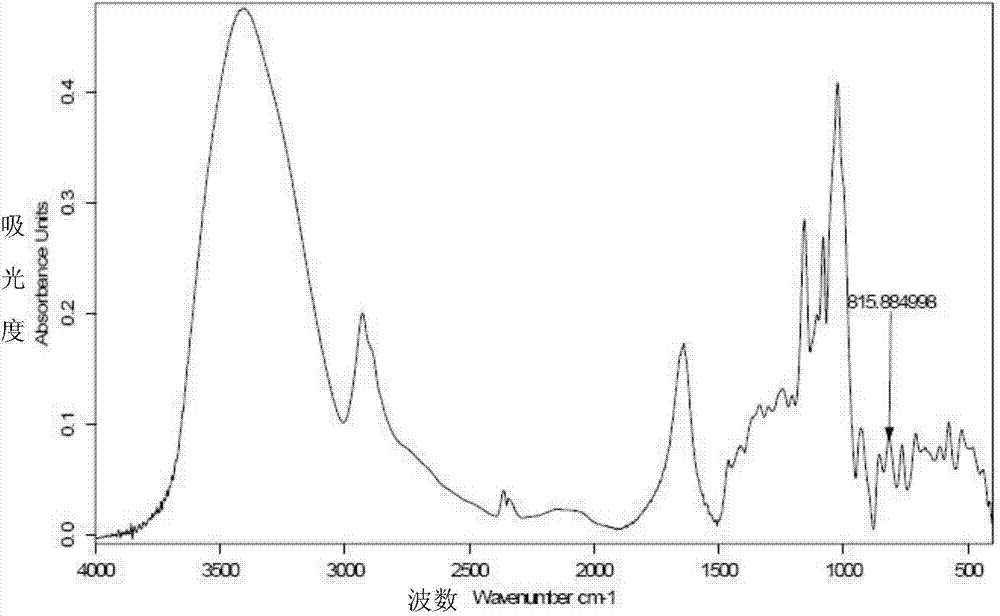

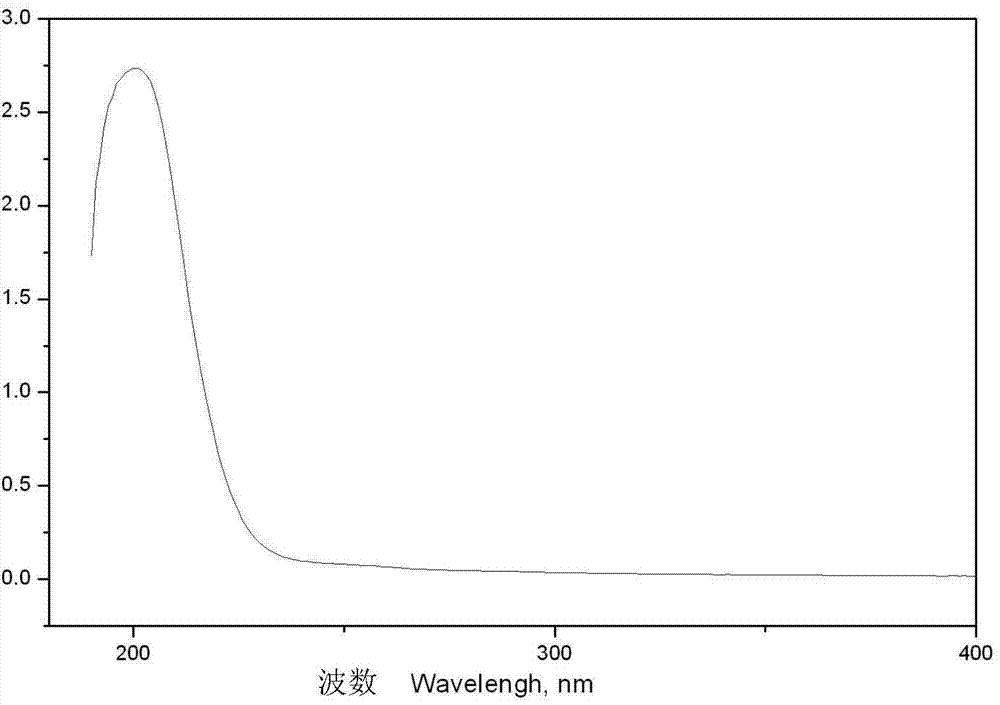

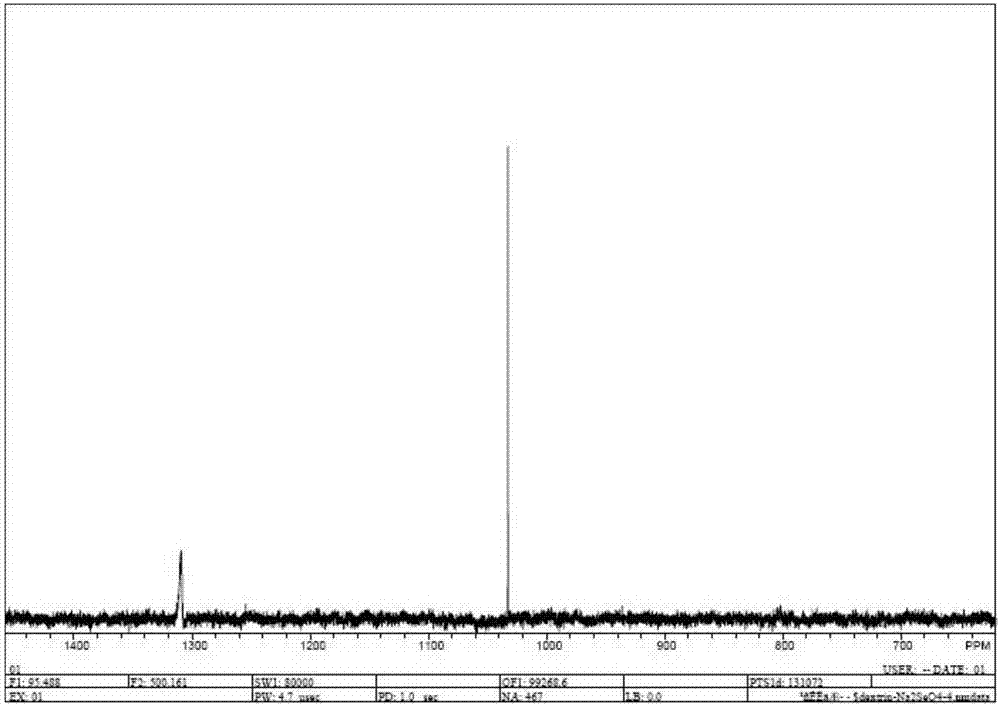

[0034] Example 1: Preparation of starch selenite

[0035] 1) First add 33g of 100-200 mesh potato starch into the reaction vessel, spray 18g of sodium selenite solution with a concentration of 65% (mass fraction) into the reaction vessel evenly with a spray device, and keep stirring under nitrogen protection, The stirring speed was 40 rev / min, and the temperature was raised to 130° C. to carry out the esterification reaction for 18 hours;

[0036] 2) After the reaction, dissolve the reaction product with a small amount of distilled water and put it into a dialysis bag, and carry out dialysis treatment with distilled water until the solution in the dialysis bag is detected with 2% ascorbic acid and no red appears, stop dialysis, and the solution in the dialysis bag is at 60 ℃. , Concentrate under reduced pressure to 1 / 20 of the original volume under the condition of 0.09Mpa.

[0037]3) The concentrated solution was freeze-dried at -60°C and 9Pa for 24 hours to obtain starch se...

Embodiment 2

[0039] Embodiment 2: the preparation of chitosan selenite

[0040] 1) First add 100g of 50-100 mesh chitosan into the reaction vessel, and use a spray device to evenly spray 50g of selenous acid solution with a concentration of 60% (mass fraction) into the reaction vessel, and continue stirring under nitrogen protection. The stirring speed is 60 rpm, and the temperature is raised to 145°C for esterification reaction for 22 hours;

[0041] 2) After the reaction is over, dissolve the reaction product with a small amount of distilled water and put it into a dialysis bag, and perform distilled water dialysis until the solution in the dialysis bag is tested with 2% ascorbic acid and no red color appears, stop dialysis, and the solution in the dialysis bag is at 55°C , Concentrated under reduced pressure to 1 / 30 of the original volume under the condition of 0.08Mpa.

[0042] 3) The concentrated solution is spray-dried, and the inlet temperature of the spray dryer is controlled to 1...

Embodiment 3

[0044] Embodiment 3: the preparation of polysaccharide selenite

[0045] 1) First add 25g of 60-80 mesh pachyrhythm to the reaction vessel, and use a spray device to evenly spray 10g of sodium selenite solution with a concentration of 70% (mass fraction) into the reaction vessel, and continue stirring under the protection of nitrogen. The stirring speed is 30 rpm, and the temperature is raised to 120° C. for 20 hours of esterification;

[0046] 2) After the reaction is over, dissolve the reaction product with a small amount of distilled water and put it into a dialysis bag, and perform distilled water dialysis until the solution in the dialysis bag is tested with 2% ascorbic acid and no red color appears, stop dialysis, and the solution in the dialysis bag is at 55°C , Concentrated under reduced pressure to 1 / 15 of the original volume under the condition of 0.09Mpa.

[0047] 3) The concentrated solution was freeze-dried at -55°C and 6Pa for 30 hours to obtain pachyphyllin sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com