Preparation method of micromolecular selenylation carrageenan with high selenium content

A technology of selenized carrageenan and small molecules, which is applied in the functions of food ingredients, food ingredients, food science, etc., can solve the problems of low biological activity, unfavorable absorption, low selenium content, etc., and achieve high biological activity, easier absorption, The effect of low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

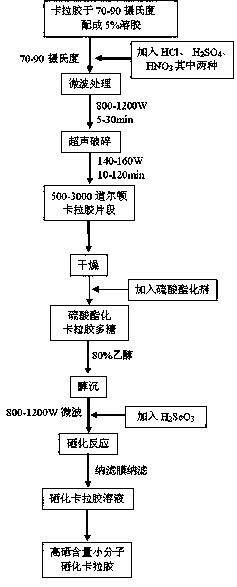

Method used

Image

Examples

Embodiment 1

[0038] Degradation of carrageenan: 50g of carrageenan is made into a 5% sol at 70°C, and a mixed acid solution of nitric acid and hydrochloric acid is added under stirring, the H+ concentration is 0.8mol / L, and the temperature is maintained, and 1000w microwave is continued for 10 minutes to make the solution molecules resonate Reach the active state, use the ultrasonic breaker for resonance, degrade for 30 minutes, adjust the pH to neutral,

[0039] Refining of small molecule carrageenan fragments: use nanofiltration membrane with a molecular weight cut-off of 3000 Daltons to remove molecular fragments with a molecular weight greater than 3000, retain the filtrate, and filter the filtrate through a nanofiltration membrane with a molecular weight of 500 Daltons to filter out molecular fragments with a molecular weight lower than 500 small molecule fragments and inorganic salts to obtain a small molecule carrageenan solution with a molecular weight of 500-3000 Daltons, and dry t...

Embodiment 2

[0054] Degradation of carrageenan: 6g carrageenan is made into a 5% sol at 80°C, and a mixed acid solution of nitric acid and sulfuric acid is added under stirring. In the active state, use a sonicator for resonance, degrade for 60 minutes, adjust the pH to neutral,

[0055] Refining small molecule carrageenan fragments: use nanofiltration membrane with a molecular weight cut-off of 3000 Daltons to remove molecular fragments with a molecular weight greater than 3000, retain the filtrate, and pass the filtrate through a nanofiltration membrane with a molecular weight of 500 Daltons to filter out molecular fragments with a molecular weight lower than 500 small molecule fragments and inorganic salts to obtain a small molecule carrageenan solution with a molecular weight of 500-3000 Daltons, and freeze-dry to obtain 6.7 g of small molecule carrageenan fragments;

[0056] Sulfation reaction: Prepare the esterification agent according to the chlorosulfonic acid-pyridine method, add ...

Embodiment 3

[0063] Degradation of carrageenan: 80g of carrageenan is made into a 5% sol at 90°C, and a mixed acid solution of nitric acid and sulfuric acid is added under stirring, the H+ concentration is 1.5mol / L, and the temperature is kept, and the 1200w microwave is continued for 30 minutes to make the solution molecules resonate Reach the active state, use the ultrasonic breaker for resonance, degrade for 120 minutes, adjust the pH to neutral,

[0064] Refining small molecule carrageenan fragments: use nanofiltration membrane with a molecular weight cut-off of 3000 Daltons to remove molecular fragments with a molecular weight greater than 3000, retain the filtrate, and pass the filtrate through a nanofiltration membrane with a molecular weight of 500 Daltons to filter out molecular fragments with a molecular weight lower than 500 small molecule fragments and inorganic salts to obtain a small molecule carrageenan solution with a molecular weight of 500-3000 Daltons, and freeze-dry to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com