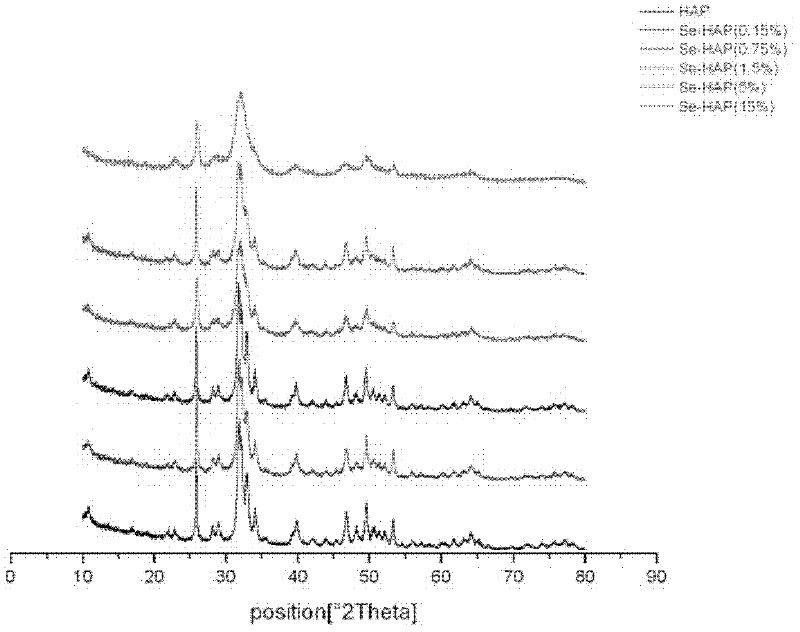

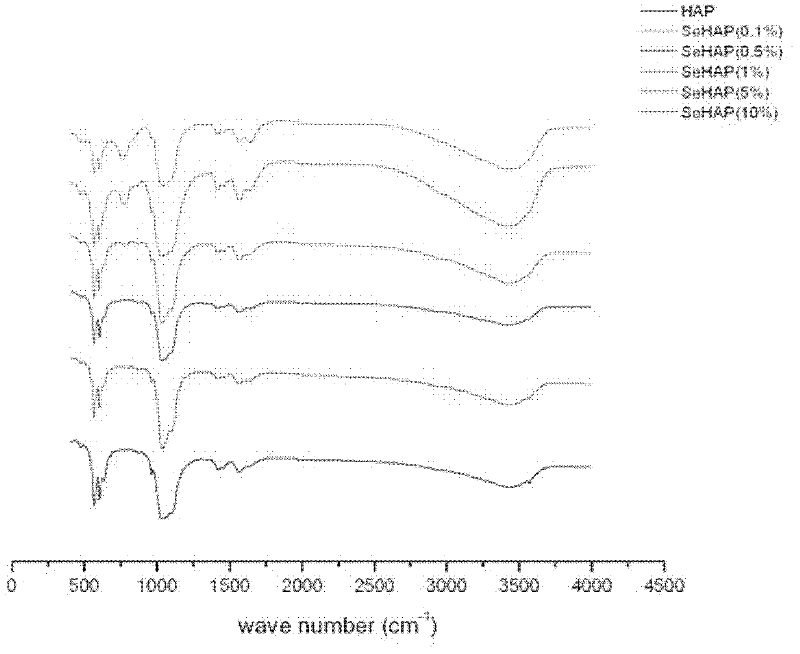

Selenium-doped hydroxyapatite and preparation method thereof

A technology of hydroxyapatite and apatite, which is applied in the direction of chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc., to achieve the effect of simple process, high output and convenient large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

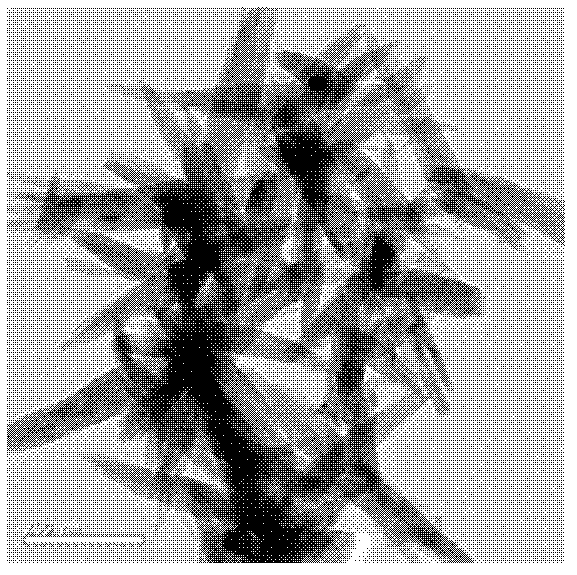

Image

Examples

Embodiment 1

[0035] Select and analyze pure calcium nitrate, diamine hydrogen phosphate, and sodium selenite, and synthesize 0.1% selenium-doped nano-scale hydroxyapatite through this preparation method. The specific steps are:

[0036] (1) Add 12.398g analytically pure calcium nitrate to 140ml distilled water; 4.156g analytically pure diammonium hydrogen phosphate into 320ml distilled water, 0.0083g analytically pure sodium selenite into 20ml distilled water, stir until completely dissolved;

[0037] (2) Adjust the pH value of the calcium nitrate solution to 9 with ammonia water, and use a thermostatic magnetic stirrer to raise its temperature to 80°C;

[0038] (3) Under the conditions described in step (2), slowly drop the diammonium hydrogen phosphate solution in step (1) into the calcium nitrate solution, and control the dropping rate so that the dropping process lasts for 30 minutes;

[0039] (4) In step (3), when the reaction continues for 15 minutes, slowly drop 3 ml of sodium polyacrylate ...

Embodiment 2

[0045] Select and analyze pure calcium nitrate, diammonium hydrogen phosphate, sodium selenite, and synthesize 1% selenium-doped nano-scale hydroxyapatite through this preparation method. The specific steps are:

[0046] (1) Add 7.085g analytically pure calcium nitrate to 280ml distilled water; 2.540g analytically pure disodium hydrogen phosphate into 280ml distilled water, and 0.047g analytically pure sodium selenite into 40ml distilled water. Stir until completely dissolved

[0047] (2) Adjust the pH value of the calcium nitrate solution to 9 with ammonia water, and use a thermostatic magnetic stirrer to raise its temperature to 80°C;

[0048] (3) While maintaining the conditions described in step (2), slowly drop the diammonium hydrogen phosphate solution in step (1) into the calcium nitrate solution. Control the dripping speed so that the dripping process lasts for 30 minutes;

[0049] (4) In step (3), when the reaction continues for 15 minutes, slowly drop 1.5 ml of sodium poly...

Embodiment 3

[0055] Select and analyze pure calcium nitrate, diammonium hydrogen phosphate, sodium selenite, and synthesize 1% selenium-doped nano-scale hydroxyapatite through this preparation method. The specific steps are:

[0056] Choose to analyze pure calcium nitrate, diammonium hydrogen phosphate, sodium selenite. The process of synthesizing 5% selenium-doped hydroxyapatite through this process is:

[0057] (1) Add 3.542g analytically pure calcium nitrate into 140ml distilled water; 1.150g analytically pure diammonium hydrogen phosphate into 140ml distilled water, and 0.115g analytically pure sodium selenite into 20ml distilled water. Stir until completely dissolved

[0058] (2) Adjust the pH value of the calcium nitrate solution to 9.5 with ammonia water, and use a constant temperature magnetic stirrer to raise its temperature to 80°C;

[0059] (3) While maintaining the conditions described in step (2), slowly drop the diammonium hydrogen phosphate solution in step (1) into the calcium ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com