Microwave-assisted solvothermal synthesis method of I-III-VI semiconductor material nano-powder

An auxiliary solvent, thermal synthesis technology, applied in nanotechnology, chemical instruments and methods, selenium/tellurium compounds, etc., can solve the problems of difficult to control product stoichiometric ratio, high reaction temperature, and high equipment requirements, and achieve strong reaction activation ability. , Reduce the reaction temperature, the effect of precise control of the stoichiometric ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

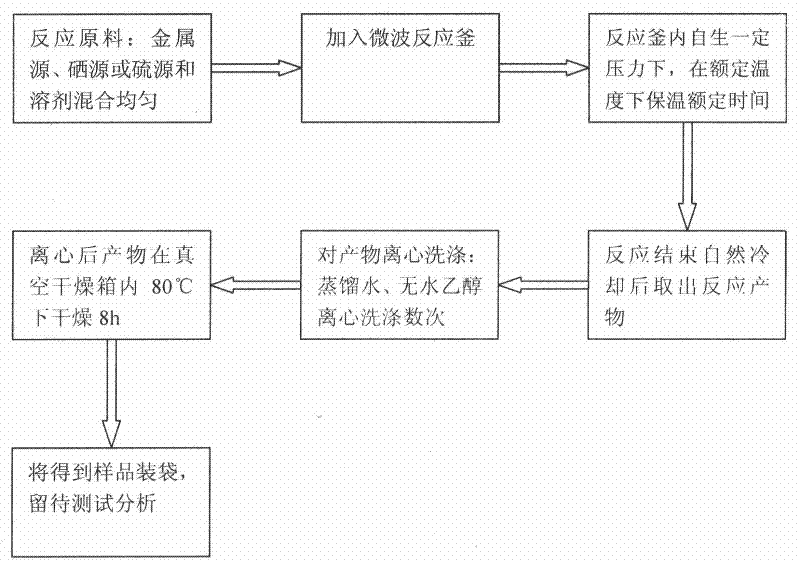

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: (CuIn 0.5 Ga 0.5 Se 2 Synthesis of powder)

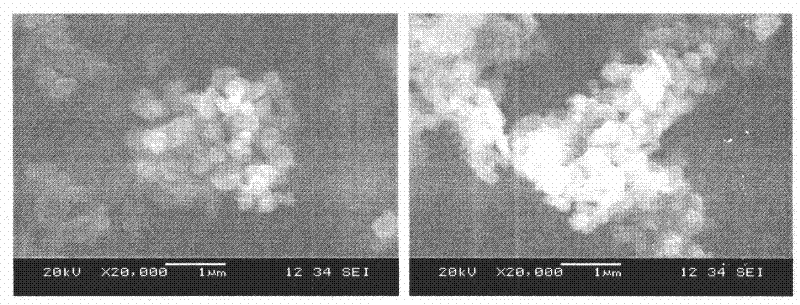

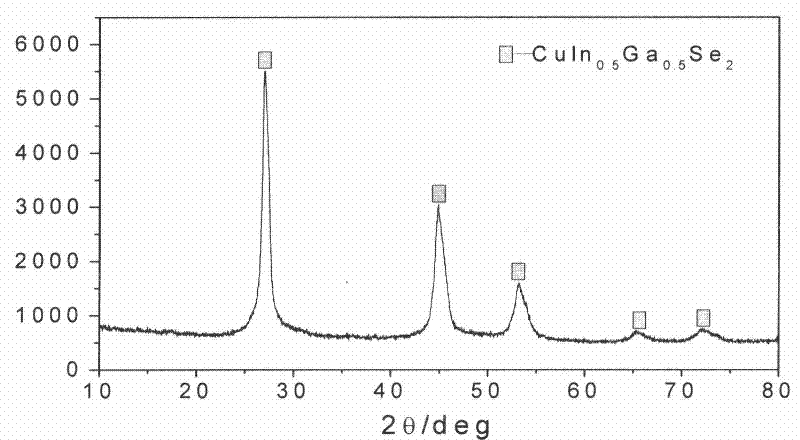

[0019] with CuCl 2 2H 2 O, InCl 3 4H 2 O, GaCl 3 , Se powder as raw material, respectively weighed 0.17045g CuCl in molar ratio 1:0.5:0.5:2 2 2H 2 O, 0.146575 g InCl 3 4H 2 O, 0.08804 g GaCl 3 , 0.15792g Se powder, put into the microwave reactor, add ethylenediamine 20ml; close the reactor and put it into the microwave instrument, set the microwave parameters: heating power 400W, heating time 15min, reaction temperature 230℃, The reaction time is 120min. After the reaction is over, cool naturally to below 100°C, transfer the reaction solution from the microwave reactor to a centrifuge tube, carry out centrifugal washing and separation of the product, and wash it several times with distilled water and absolute ethanol. Dry in a vacuum oven at 80°C for 8 hours to obtain CuIn 0.5 Ga 0.5 Se 2 Nano powder. The sample was analyzed by XRD as pure CuIn 0.5 Ga 0.5 Se 2 , by SEM analysis, the powder pr...

Embodiment 2

[0020] Embodiment 2: (CuIn 0.7 Ga 0.3 Se 2 Synthesis of powder)

[0021] with CuCl 2 2H 2 O, InCl 3 4H 2 O, GaCl 3 , Se powder as raw material, respectively weighed 0.17045g CuCl according to the molar ratio of 1:0.3:0.7:2 2 2H 2 O, 0.087945 g InCl 3 4H 2 O, 0.123256 g GaCl 3, 0.15792g Se powder, put into the microwave reactor, add ethylenediamine 20ml; close the reactor and put it into the microwave instrument, set the microwave parameters: heating power 400W, heating time 15min, reaction temperature 230℃, The reaction time is 60min. After the reaction is over, cool naturally to below 100°C, transfer the reaction solution from the microwave reactor to a centrifuge tube, carry out centrifugal washing and separation of the product, and wash it several times with distilled water and absolute ethanol. Dry in a vacuum oven at 80°C for 8 hours to obtain CuIn 0.7 Ga 0.3 Se 2 Nano powder. The sample was analyzed by XRD as pure CuIn 0.3 Ga 0.7 Se 2 , by SEM analysi...

Embodiment 3

[0022] Embodiment 3: (CuInS 2 Synthesis of powder)

[0023] with CuCl 2 2H 2 O, InCl 3 4H 2 O, thiourea (CH 4 N 2 S) is raw material, weigh 0.17045g CuCl by molar ratio 1:1:2 2 2H 2 O, 0.29318g InCl 3 4H 2 O, 0.15224g thiourea, put into the microwave reactor, add 20ml of ethylene glycol; close the reactor and put it into the microwave instrument, set the microwave parameters: heating power 400W, heating time 10min, reaction temperature 190°C , The reaction time is 60min. After the reaction is over, cool naturally to below 100°C, transfer the reaction solution from the microwave reactor to a centrifuge tube, carry out centrifugal washing and separation of the product, and wash it several times with distilled water and absolute ethanol. Vacuum dry at 80°C for 8 hours in a vacuum oven to obtain CuInS 2 Nano powder. The sample was analyzed as CuInS by XRD 2 , according to SEM analysis, the powder particles are mainly composed of spherical and flake, and the particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com