Patents

Literature

97results about How to "Pure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

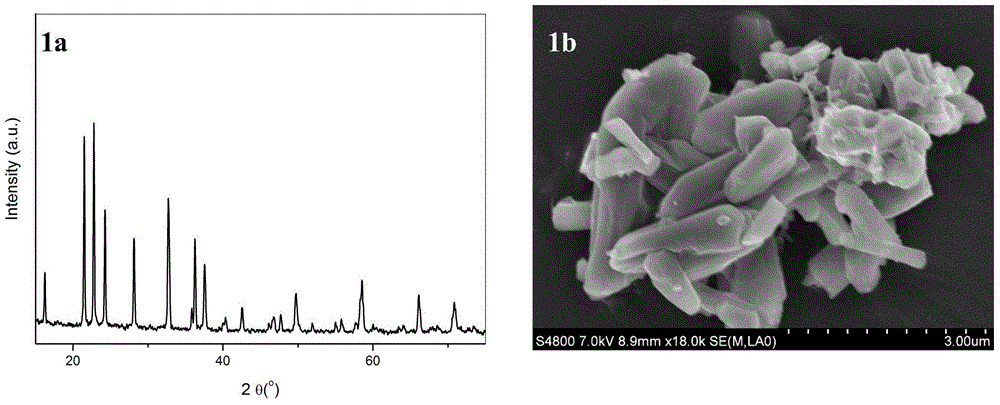

Method for preparing neodymium-doped yttrium aluminum garnet micro/nano powder by spray freeze-drying

InactiveCN102173775AEvenly dopedEfficient preparationDrying solid materials without heatFreeze-dryingRare earth

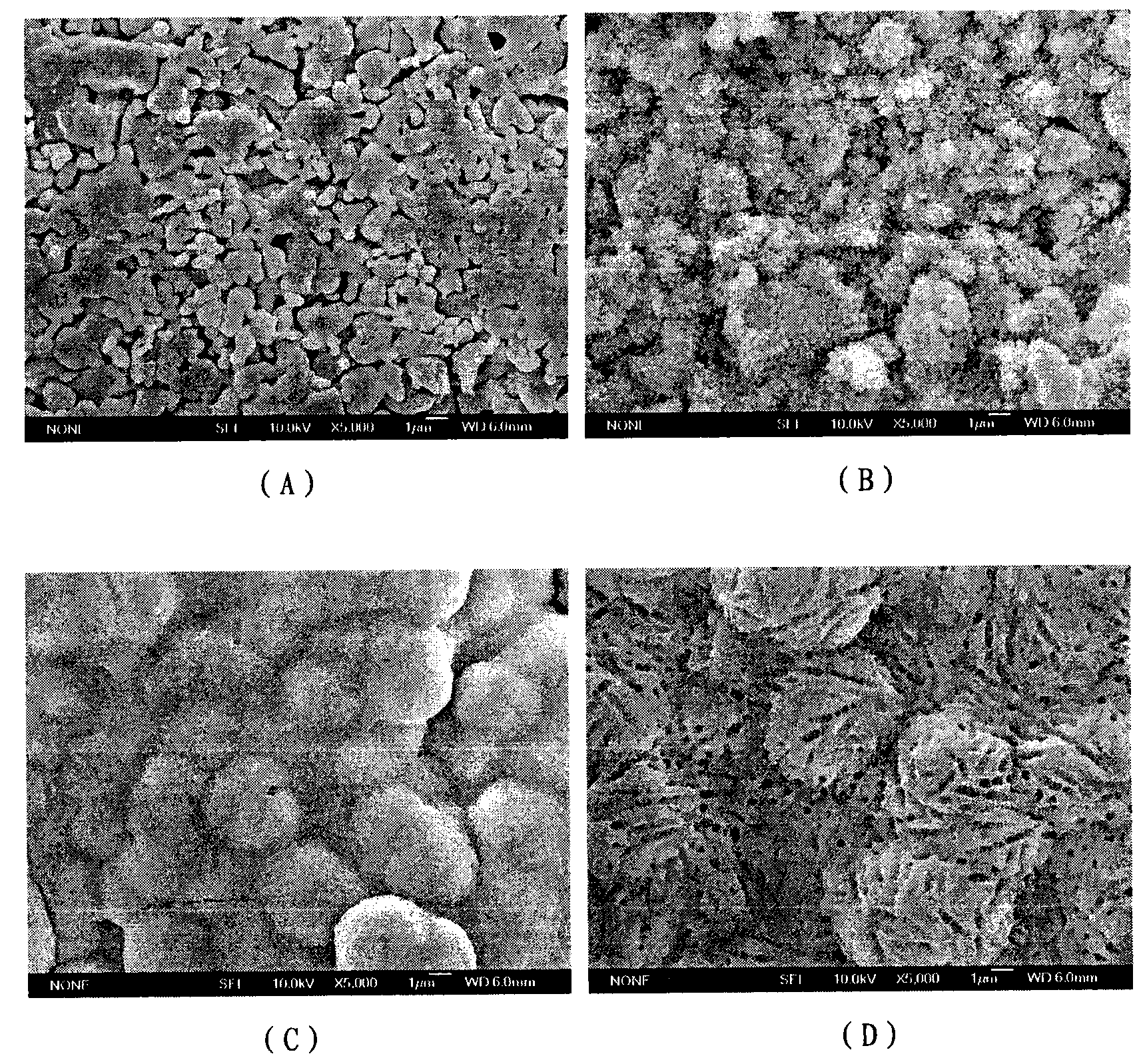

The invention discloses a method for preparing neodymium-doped yttrium aluminum garnet micro / nano powder by spray freeze-drying, which comprises the following steps: dissolving soluble salts of yttrium, aluminum and neodymium, which are used as raw materials; mixing the raw materials according to the stoichiometric proportion; and by using ammonia water or acetic acid as a pH regulator and the mixture of liquid nitrogen and liquid ethane as a freezing agent, granulating by spray freeze-drying, and calcining to obtain the uniform neodymium-doped yttrium aluminum garnet micro / nano powder. The method disclosed by the invention is simple, has the advantage of low cost, and can be used for scale-up production of the raw material of rare-earth-doped transparent ceramics.

Owner:SHANDONG UNIV

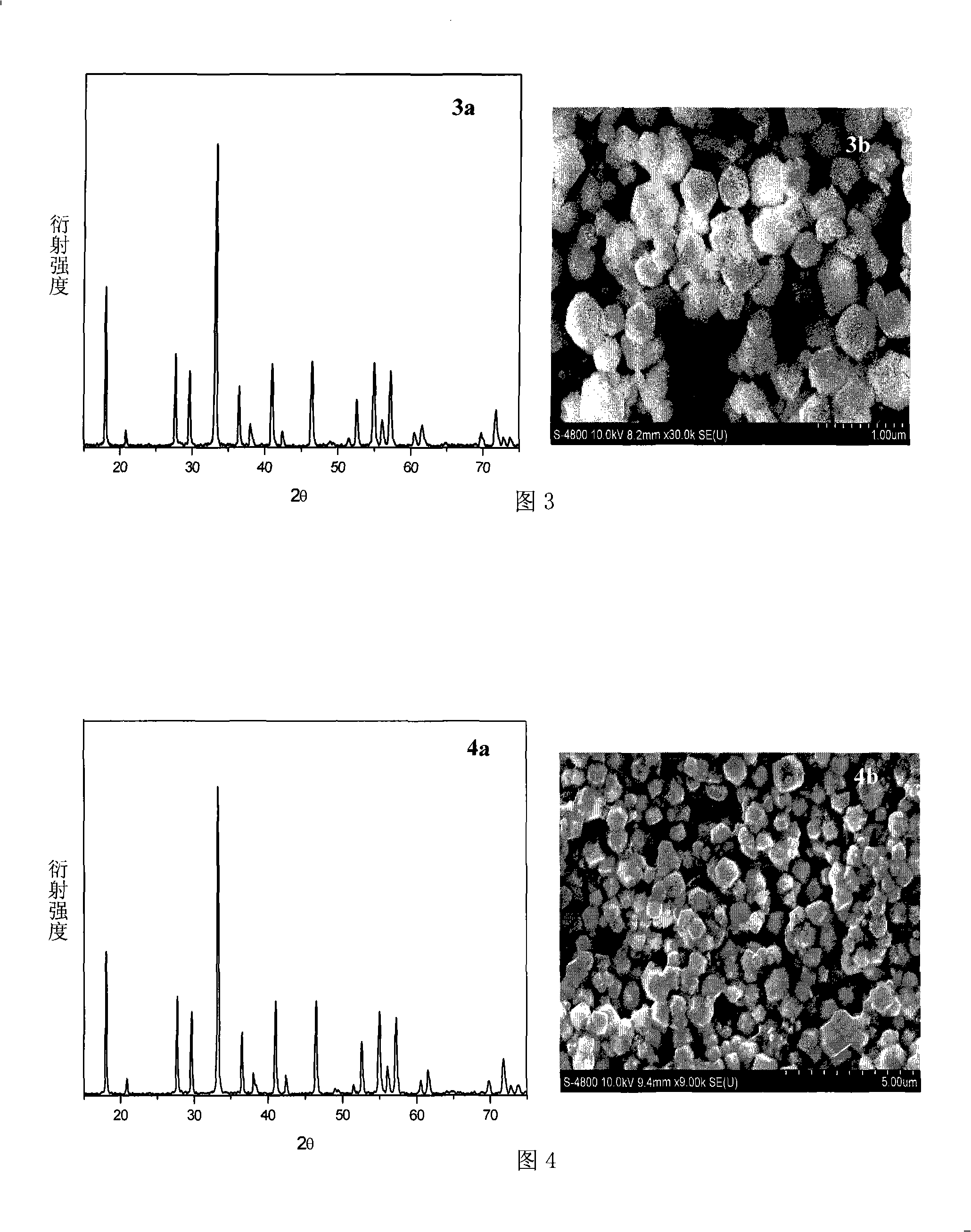

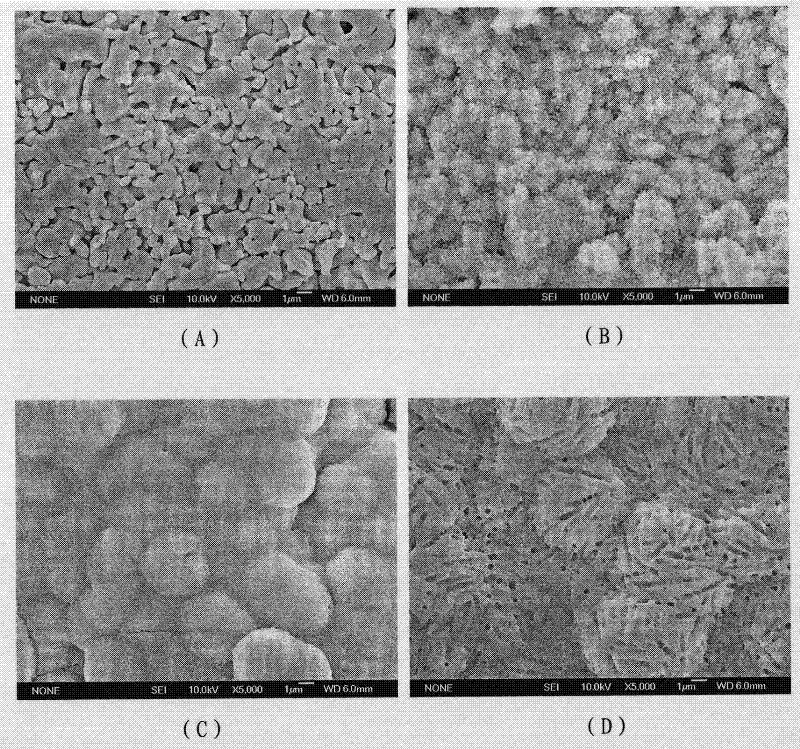

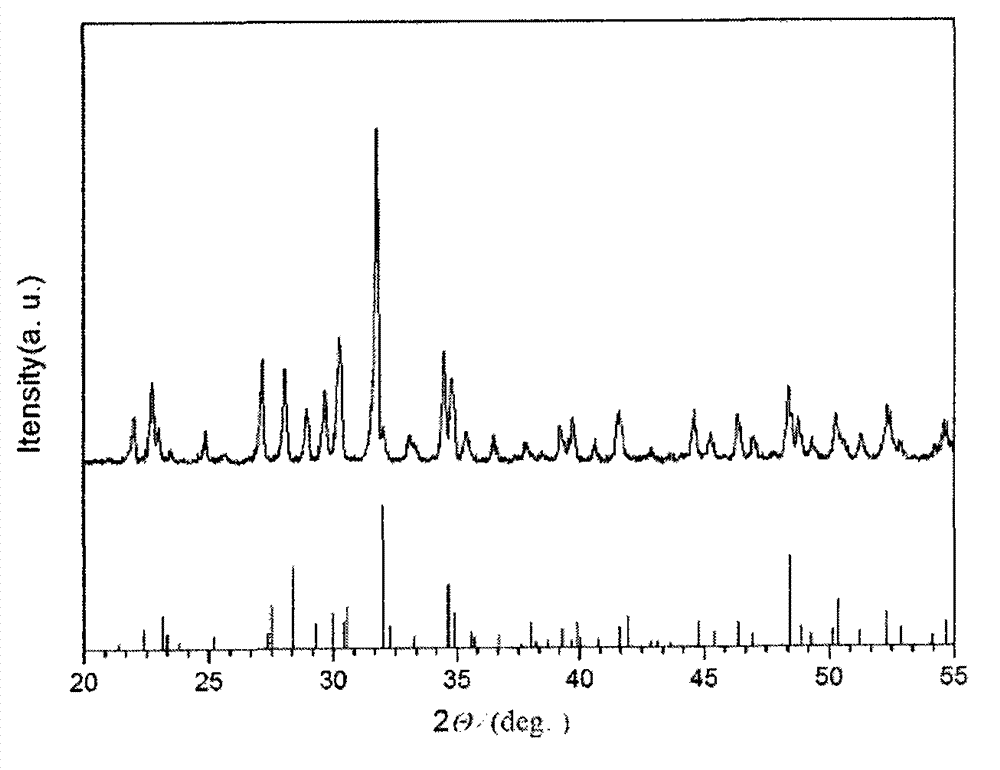

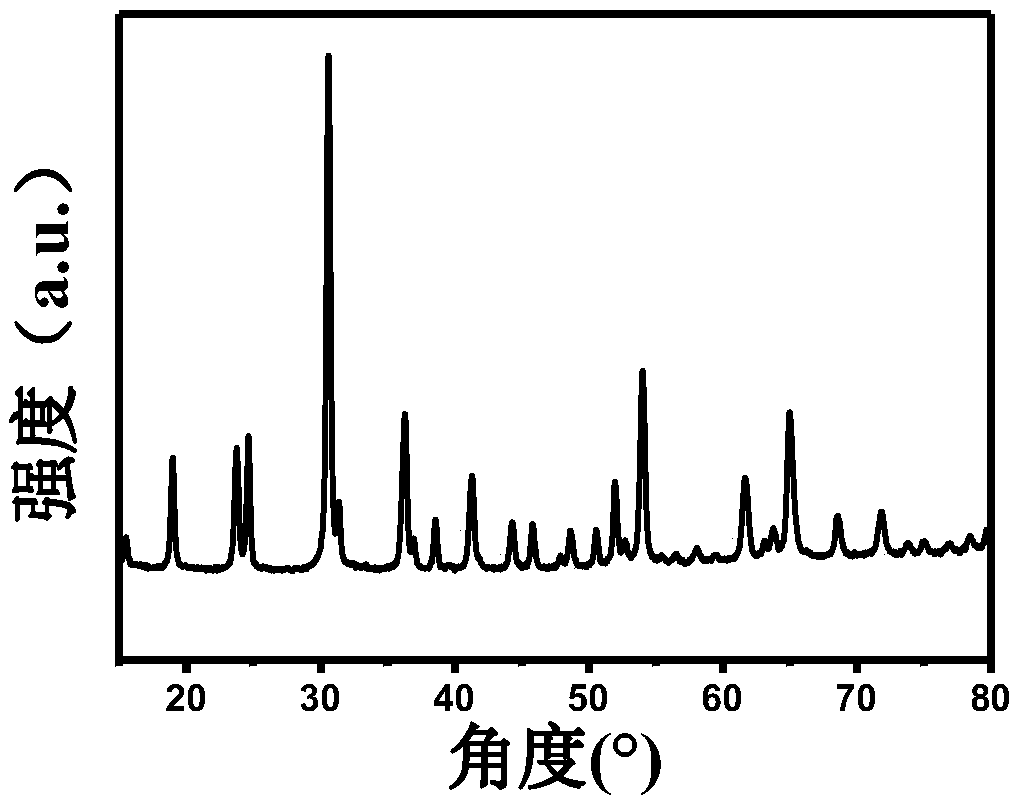

Process for synthesizing YAG single crystal nano-powder

InactiveCN101311373AEasy to synthesizeEfficient use ofPolycrystalline material growthFrom normal temperature solutionsInorganic saltsSpherical polyhedron

The invention discloses a method for compounding YAG single crystal nanometer powder, wherein routine inorganic salt is used as raw material to obtain a solid precursor material by a coprecipitation; supercritical water and sub-critical water are used as reaction media; the YAG single crystal nanometer powder material is compounded under the pressure of 8-30MPa and the temperature of 300 - 420 DEG C. The YAG nanometer powder material compounded by the method of the invention has the advantages that the phase is pure; the feature of the grain is a regular approximate spherical polyhedron; the distribution of the grain size is appropriate; foundation is established for preparing YAG transparent pottery laser material or device and promoting the study and development of novel laser material.

Owner:SHANDONG UNIV

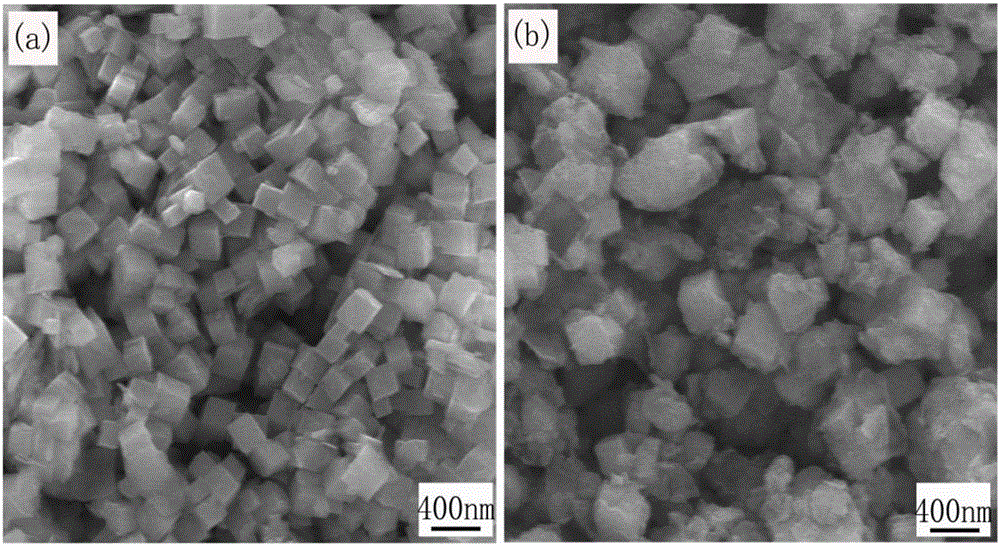

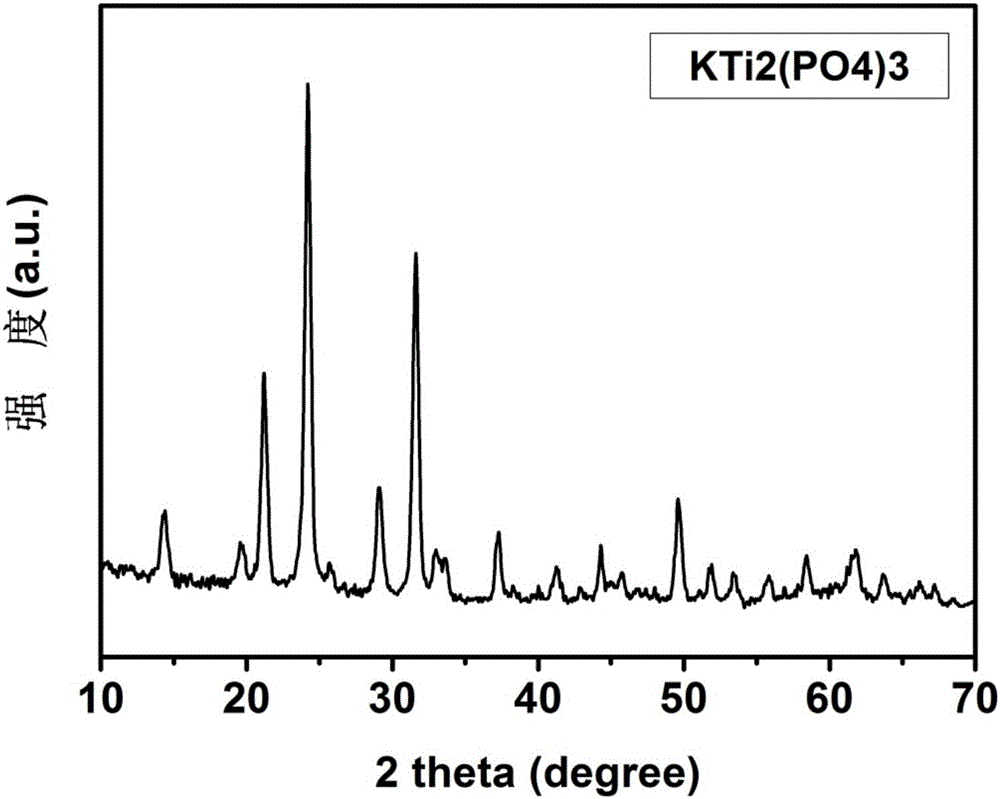

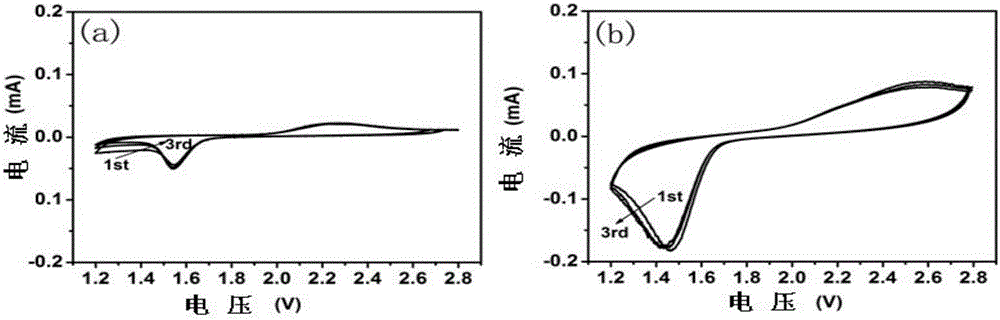

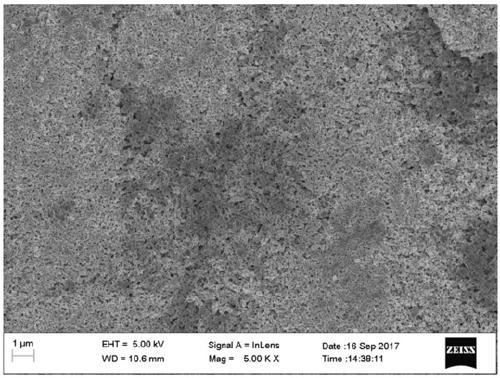

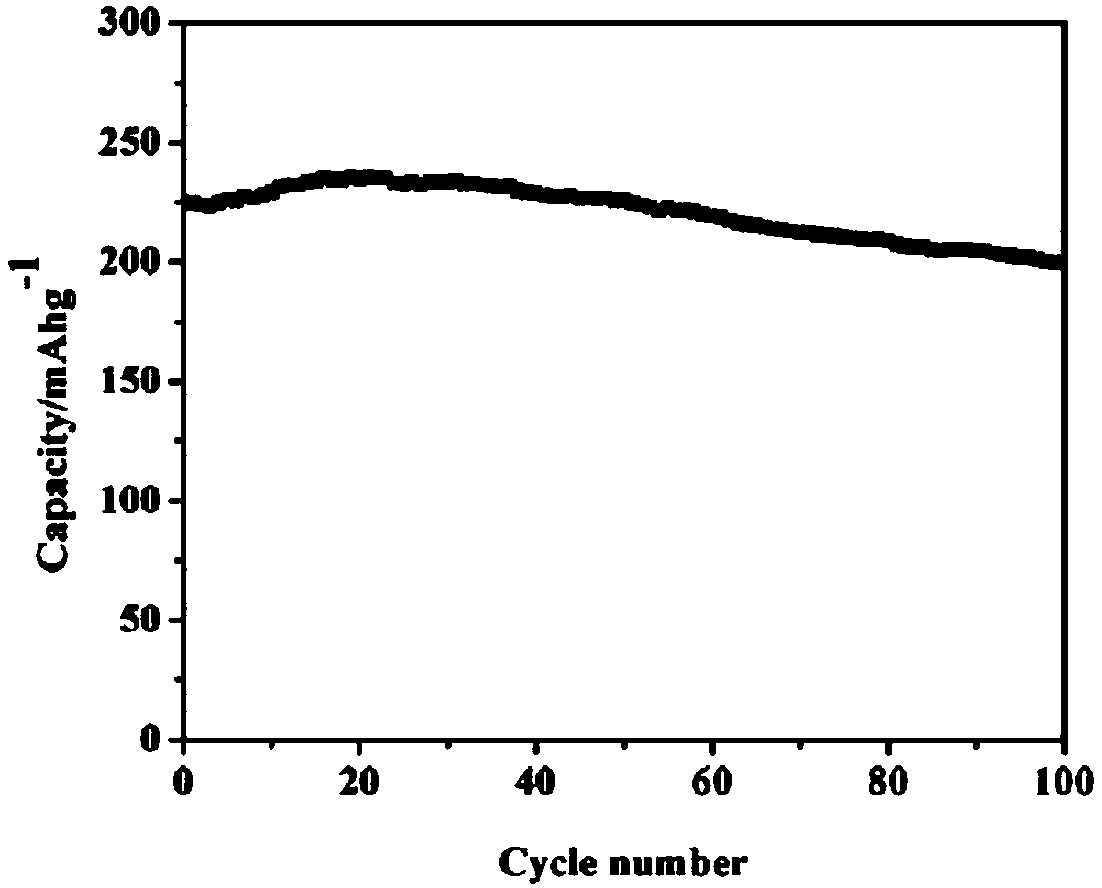

Polyanion compound KTi2(PO4)3, preparation of carbon coating thereof and application of product of polyanion compound KYi(PO4)3

The invention discloses a polyanion compound KYi(PO4)3, a preparation method of a carbon coating thereof and application of a product of the polyanion compound KYi(PO4)3 and the polyanion compound KYi(PO4)3 as a potassium ion battery electrode material. The method has the advantages that operation is easy and convenient, a solvothermal method is adopted, and synthesis is easy; the reaction temperature is low, reactions are mild, and the yield is high; raw materials are TiO2, KH2PO4.2H2O, H3PO4 and deionized water with the stable chemical properties, and the cost is low; no harmful gas is generated in the reaction process, and no pollution is caused. Various methods show that the product is uniform in morphology, the phase is pure, and no impurity is generated. The KYi2(PO4)3 and KTi2(PO4)3 / C with the nanoscale cube structures are applied to a potassium ion battery, and tests show that the electrochemical performance of the potassium ion battery is good, and the electrochemical performance of KTi2(PO4)3 / C is better.

Owner:SOUTHWEST UNIV

Tea making process for jasmine black tea

InactiveCN102742688AEasy to controlImprove qualityPre-extraction tea treatmentMaterials preparationSpare time

The invention relates to a tea making process for jasmine black tea. The process is characterized by being carried out according to the following process steps of 1, material preparation: the material preparation step concretely comprises smalls steps of a) selecting materials and b) selecting flowers; 2, making process: the making process concretely comprises small steps of a ) thinly paving finely selected tea leaves on selected positions of a withering region; b) carrying out twisting; c) placing the tea leaves into a fermentation chamber to be fermented; d) carrying out baking; and e) carrying out heating scenting; 3, cooling; and 4 package. The process provided by the invention has the advantages that the production process is conveniently controlled, the quality of made products is good, the flower consumption in the making process is proper, the products have the characteristics of attractive appearance, pure flavor, flower fragrance, transplant and bright soup color and the like, in addition, the tea flavor and the flower fragrance are proper, the aftertaste is fragrant and sweet, a unique flavor is realized, and the tea belongs to high-grade tea products for people in the work spare time.

Owner:福建春伦集团有限公司

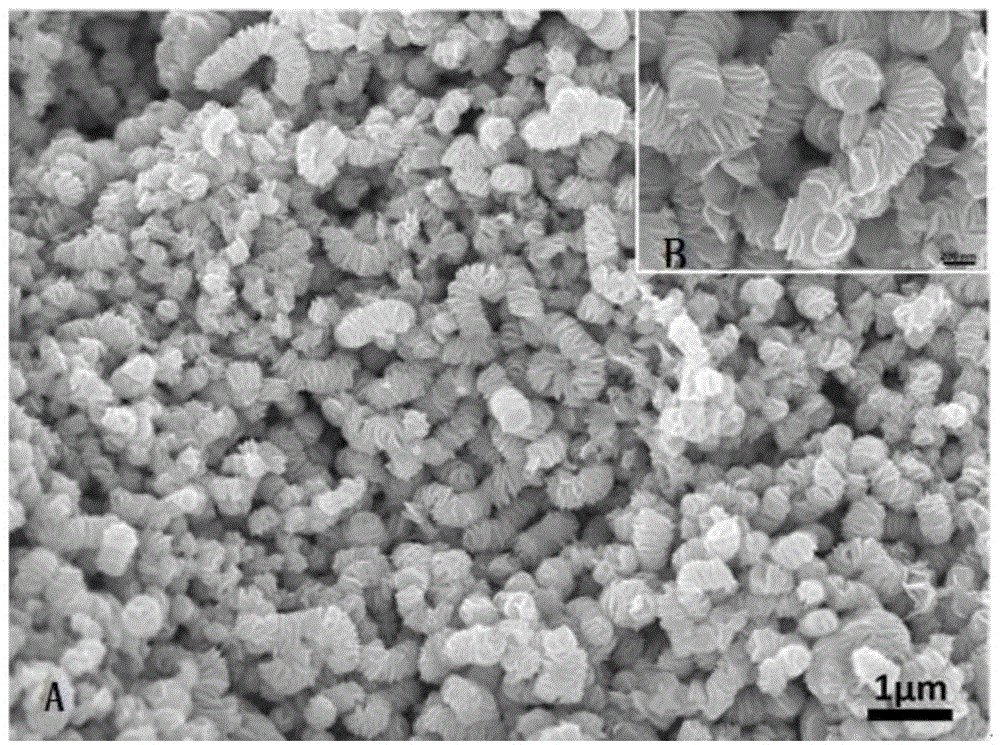

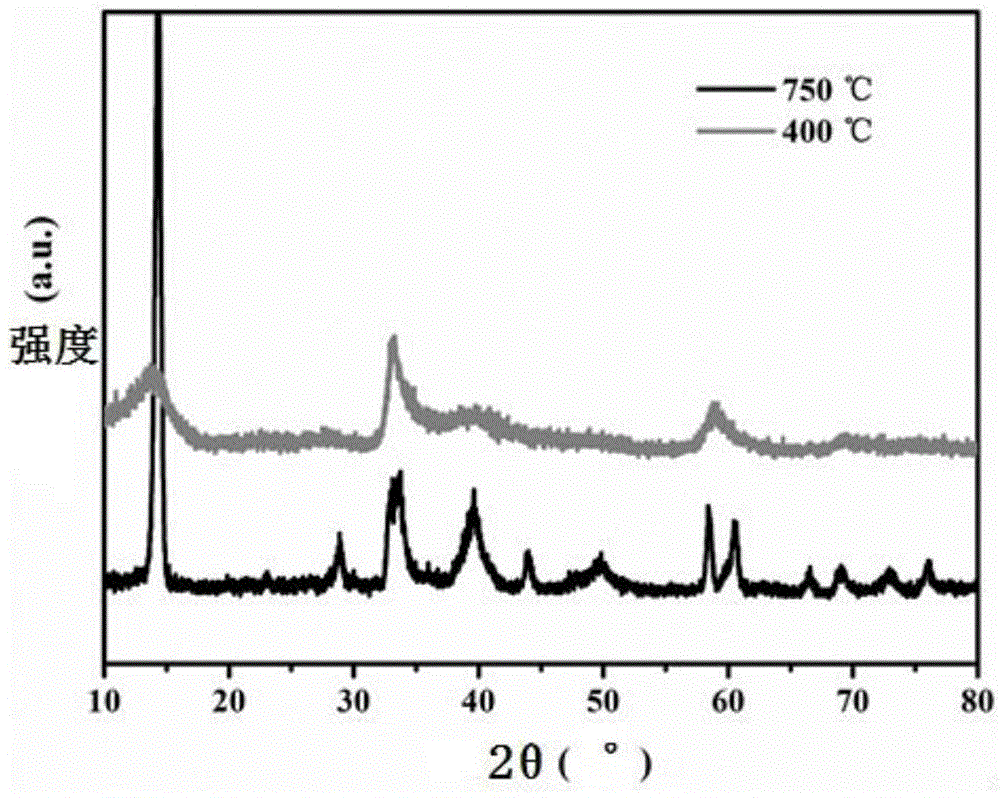

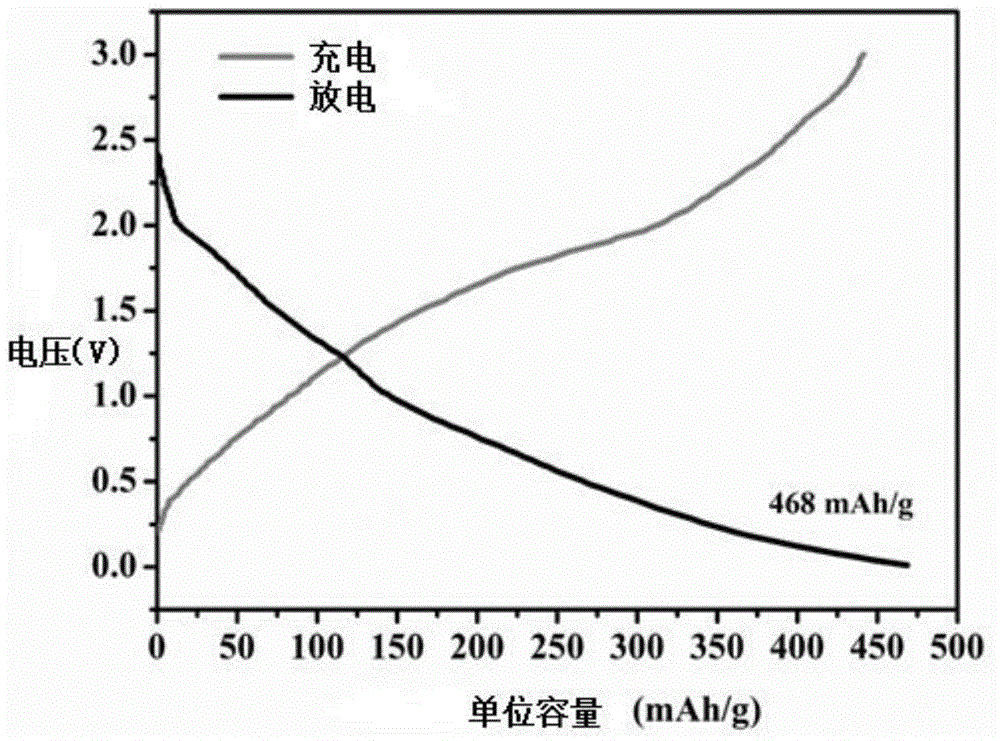

Solvothermal method for preparing three-dimensional nanometer layered structure WS2 and electrochemical application thereof

ActiveCN104828867ASimple and fast operationMild reaction conditionsCell electrodesNanotechnologyNitrogen gasSolvent

The invention relates to a solvothermal method for preparing a three-dimensional nanometer layered structure WS2 and an electrochemical application thereof. The method comprises the following steps: adding tungstic acid and S powder into a mixed solution of octylamine and n-hexyl alcohol, and rapidly stirring at room temperature, so that the components are fully mixed; transferring the fully stirred mixed solution into a hydro-thermal synthesis reactor, reacting under the constant temperature of 180-240 DEG C for 24 hours, filtering and collecting the reaction solution after the reaction solution is cooled to room temperature, cleaning by using ethanol and deionized water, drying, and performing heat treatment on the obtained solid products in a nitrogen atmosphere under the condition of 400-750 DEG C for 2 hours, thereby obtaining the three-dimensional nanometer layered structure WS2. The three-dimensional nanometer layered structure WS2 is applied to lithium ion battery and electro-catalysis hydrogen evolution reaction, good electrochemical performance can be obtained under the condition that mixing and coating are absent, and when the current density is 20mA / g, the discharge capacity of the lithium battery is 468mAh / g; and moreover, a hydrogen evolution initial potential more correct than WS2 in the prior art is obtained under the scanning speed of 10mV / s.

Owner:SOUTHWEST UNIVERSITY

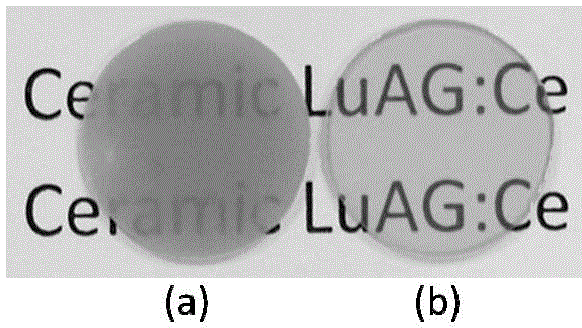

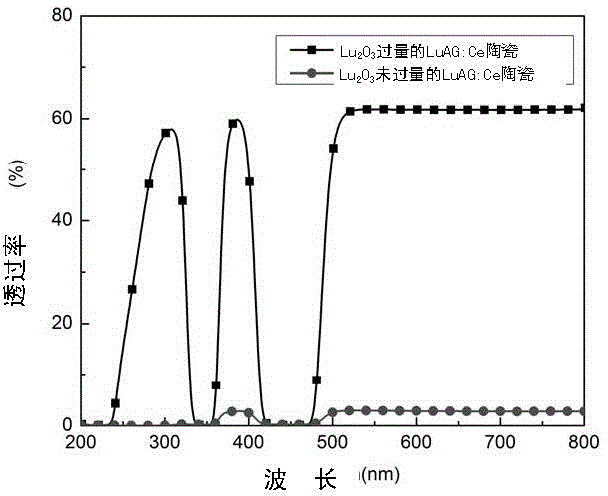

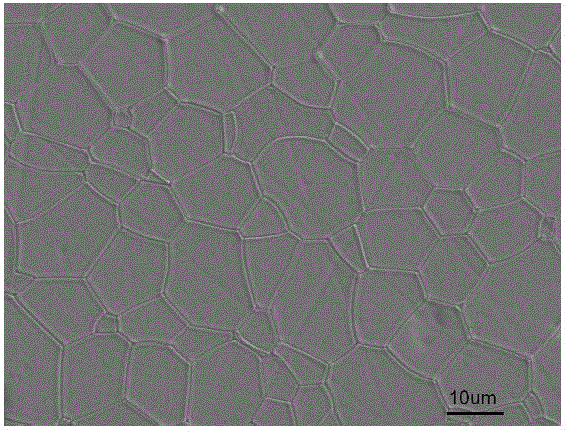

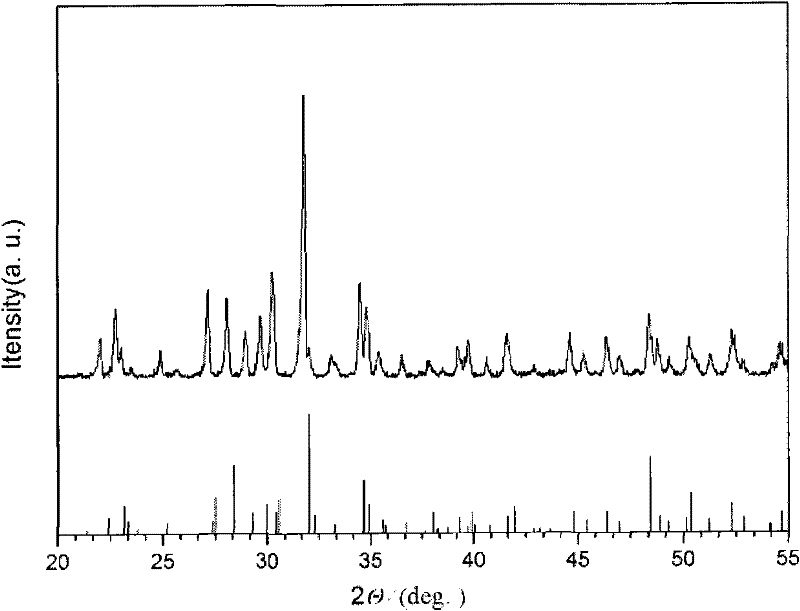

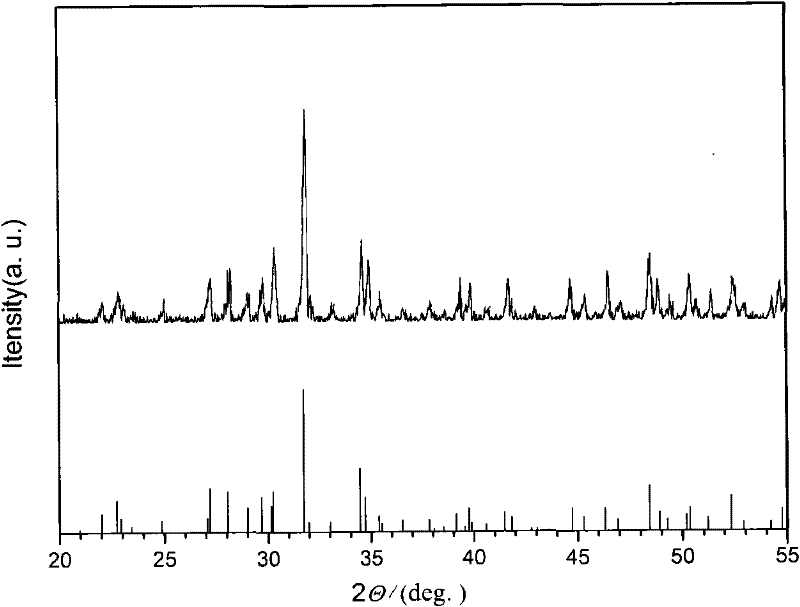

Lutetium-aluminum garnet scintillation ceramic in non-stoichiometric ratio and preparation method for ceramic

The invention relates to a lutetium-aluminum garnet scintillation ceramic in a non-stoichiometric ratio and a preparation method for ceramic. The general formula of the lutetium-aluminum garnet scintillation ceramic is [Lu(1-x)(1+y)REx]3Al5O12, wherein RE is one of rare earth activated ions Ce, Pr, Eu, Nd, Sm, Gd, Ho, Yb, Tm, Dy and Er; x is greater than or less than or equal to 0.05, and y is greater than or less than or equal to 0.04.

Owner:中科西卡思(苏州)科技发展有限公司

Calcium silicon phosphate biomaterial and its preparation method and use

ActiveCN102276247ASimple processLow costImpression capsDentistry preparationsCalcium biphosphateApatite

The invention relates to a calcium phosphate silicate biomaterial, and a preparation method and a purpose thereof. The calcium phosphate silicate biomaterial is characterized in that a soluble silicon source, a soluble phosphor source and a soluble calcium source are used as raw materials, and water is used as a solvent; a sol-gel method is employed to synthesize pure phase calcium phosphate silicate (Ca5(PO4)2SiO4) powder, which is compressed for moulding and sintered into a calcium phosphate silicate (Ca5(PO4)2SiO4) ceramic block. After soaking the Ca5(PO4)2SiO4 ceramic block in a simulated body fluid (SBF) for 1 day, bone-like apatite can be precipitated on a surface of the ceramic block, and the apatite layer becomes thicker with increasing of a soaking time. The Ca5(PO4)2SiO4 prepared in the invention has good biological performance, is a potential biological and medical material and can be used as a bone restoration and filling material and a restoration material in dentistry.

Owner:上海积力威尔生物科技合伙企业(有限合伙)

Calcium silicophosphate biomaterial, and preparation method and use thereof

The invention relates to a calcium silicophosphate biomaterial, and a preparation method and a use thereof. Pure-phase calcium silicophosphate (Ca5(PO4)2SiO4) powder is synthesized through adopting a sol-gel method and treating a soluble silicon source, a soluble phosphorus source and a soluble calcium source as raw materials and water as a solvent, and the calcium silicophosphate powder is subjected to compression molding and is sintered to obtain a calcium silicophosphate (Ca5(PO4)2SiO4) ceramic block. The surface of the ceramic is deposited with a bone-like apatite layer after the calcium silicophosphate (Ca5(PO4)2SiO4) ceramic block is immersed in a stimulation body fluid for 1 day, and the thickness of the apatite layer increases with the prolongation of the immersion time. The calcium silicophosphate (Ca5(PO4)2SiO4) material prepared in the invention has good biological performances, is a most potential biological and medical material, and can be used as a material for bone tissue restoration and filling, and dental restoration.

Owner:上海积力威尔生物科技合伙企业(有限合伙)

High pure anhydrous composite rare earth halide and preparation method thereof

ActiveCN106745163AImprove uniformityEvenly distributedRare earth metal compoundsRare-earth elementHalogen

The invention relates to a method for preparing a high pure anhydrous composite rare earth halide. The composite rare earth halide has a general formula of A2BMX6, wherein A represents Rb or Cs, B represents Li or Na, M represents one or two of rare earth elements of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc and Y, and X represents one of halogen elements of Cl, Br and I. The method comprises (1) preparing a mixed solution, (2) concentrating the mixed solution, (3) dehydrating the mixed solution and (4) removing ammonium, wherein in the step (1), ammonium halide NH4X is used as a dehydrating agent. In addition, the invention also provides the high pure anhydrous composite rare earth halide obtained by the method. The high pure anhydrous composite rare earth halide does not contain crystal water and oxide impurities, has high purity and good uniformity, and can meet the application requirements of scintillating crystals and scintillating ceramics.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

Red long-afterglow phosphor material and its prepn process

InactiveCN1974716ALow costRapid preparation technologyLuminescent compositionsAluminateParticle-size distribution

The present invention relates to one kind of red long afterglow phosphor material and its preparation process. The matrix of the phosphor powder is aluminate in the chemical expression of SraAlbO6:cEu2+, dDy3+, where, a=3-c-d, b is 1.9-2.1, c is 0.1-0.2, and d is 0.05-0.1. It is prepared through a nanometer pseudoboehmite sol-gel and microwave ignition process including hot air spray pelletizing of composite RE sol, ignition of dry gel in reducing atmosphere inside a microwave oven and cooling to room temperature to obtain the red long afterglow phosphor material. The red long afterglow phosphor material has the advantages of pure physical phase, homogeneous granularity distribution, loose powder, low material cost, simple preparation process and easy industrial production.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Fireproof product for cement rotary kiln transition belt

InactiveCN1919797AImprove performanceHigh compressive strength at room temperatureCement rotary kilnCoesite

The invention discloses a fireproof composition product of cement rotary kiln transmitting belt through dried method, which comprises the following parts: 50-79% alumina clinker aggregate with Al2O3 not less than 90% and bulk density not less than 3.0g / cm3, 5-20% silicon carbide, 3-15% clay with Al2O3 not less than 32%, 3-15% alumina, wherein the silicon carbide, clay and alumina are added at 0.1-10mm fined powder pattern, which possesses 63-75% Al2O3,8-32.5% SiO2 and 4.5-19% SiC for sintered components.

Owner:YIXING REFRACTORY EQUIP & MATERIAL FACTORY

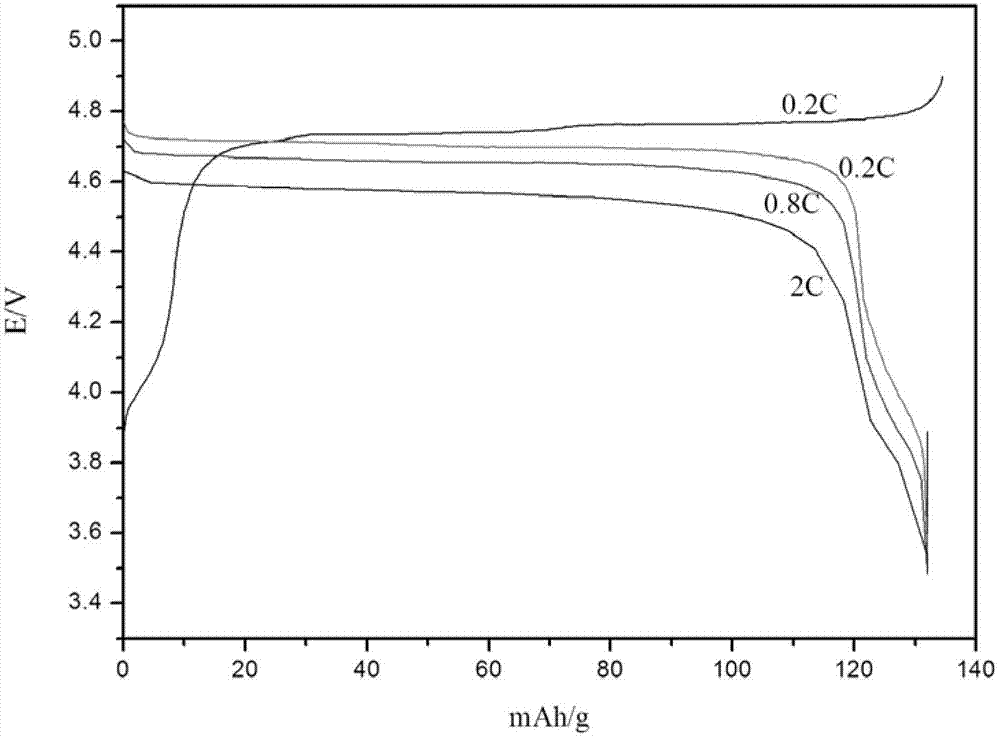

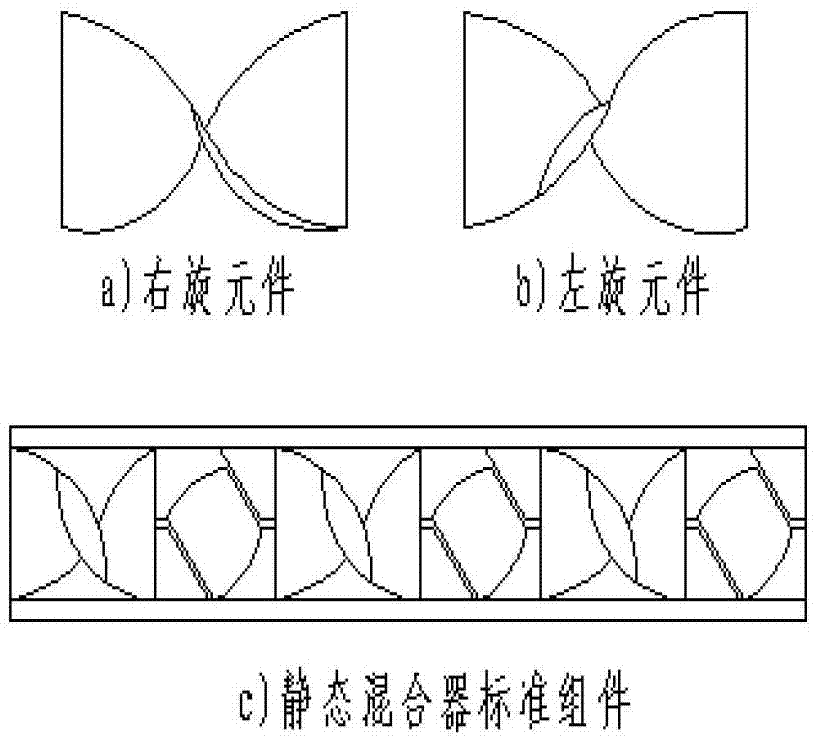

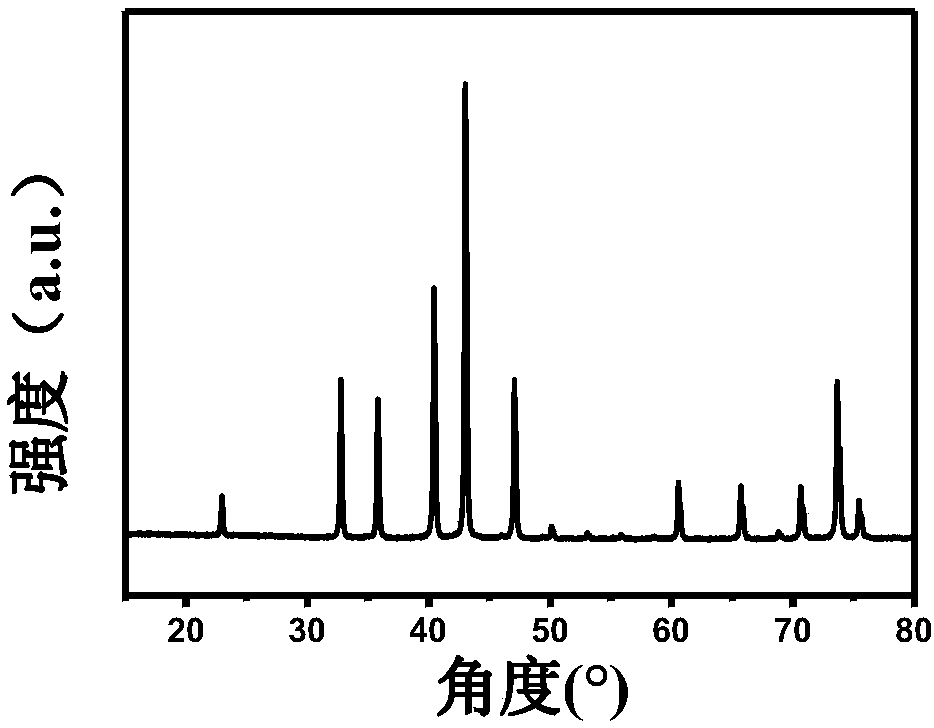

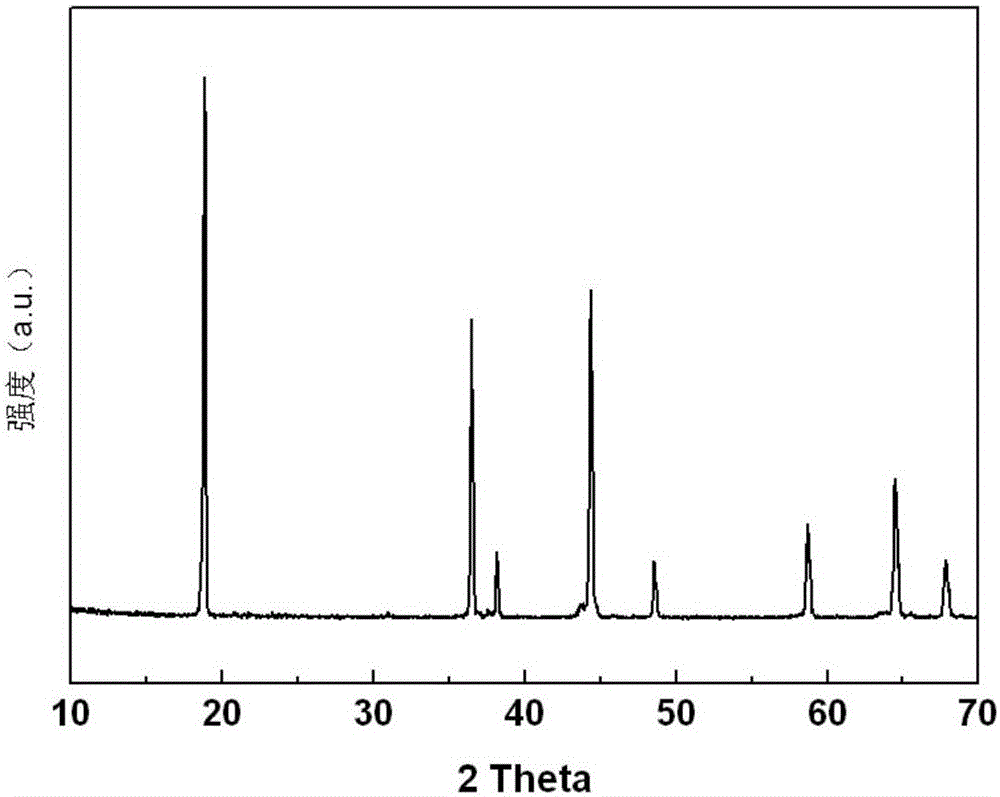

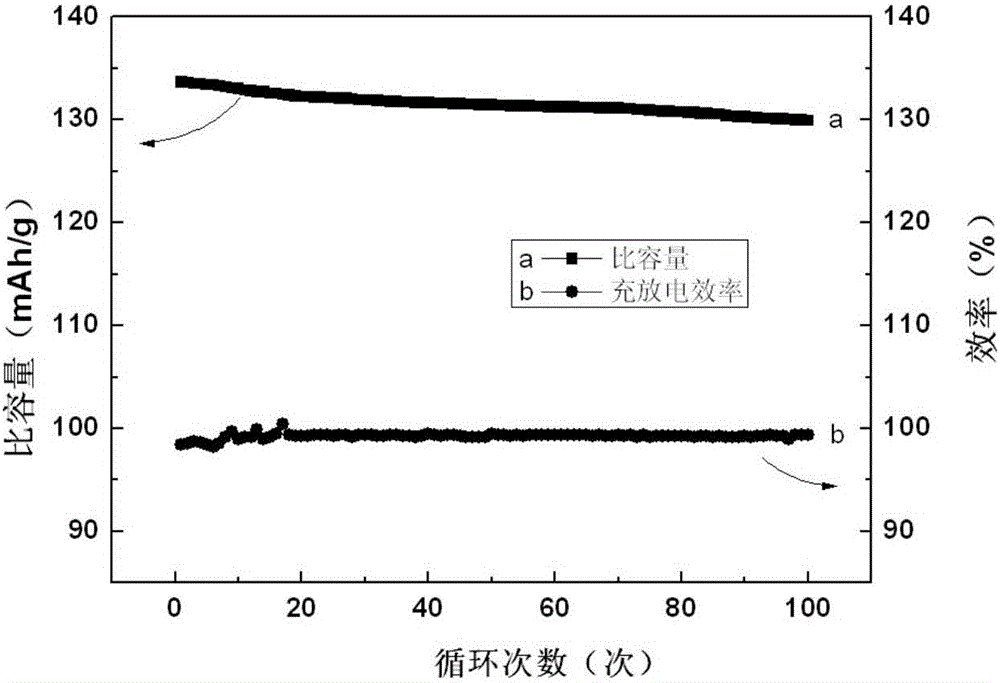

Method for preparing nickel lithium manganate having spinel structure by static mixer type reactor

The invention discloses a method for preparing nickel lithium manganate (LiN0.5Mn1.5O4) having a spinel structure by a static mixer type reactor, which comprises the following steps: a mixing solution of a nickel source and a manganese source as well as a carbonate solution is placed according to equal volume flow from one end of the static mixer type reactor, a liquid phase mixing reaction is carried out in the static mixer type reactor to generate an emulsion, the emulsion is aged and a membrane is washed to remove the impurity ion, and a nickel manganese composite carbonate precursor powder is obtained through spray drying, the precursor powder is coasted at the temperature of 400-500 DEG C for 5-10 hours to obtain a nickel manganese composite oxide, the lithium source is added in the nickel manganese composite oxide according to mol ratio of Li<+> to Ni<2+> to Mn<4+> being 1.05: 0.5: 1.5, and performing ball milling and uniformly mixing, and sintering at the temperature of 800-950 DEG C for 8-15 hours to obtain the finished product. The obtained material has the advantages of pure phase, good crystallization, small particle size, narrow particle size distribution and low raw material price, the technology is simple and a continuous industrial production is easy to be carried out, 0.2C initial discharge specific capacity can reach 130mAh / g, and 0.5C multiplying power 50 times circulation capacity maintenance rate is more than 98%.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

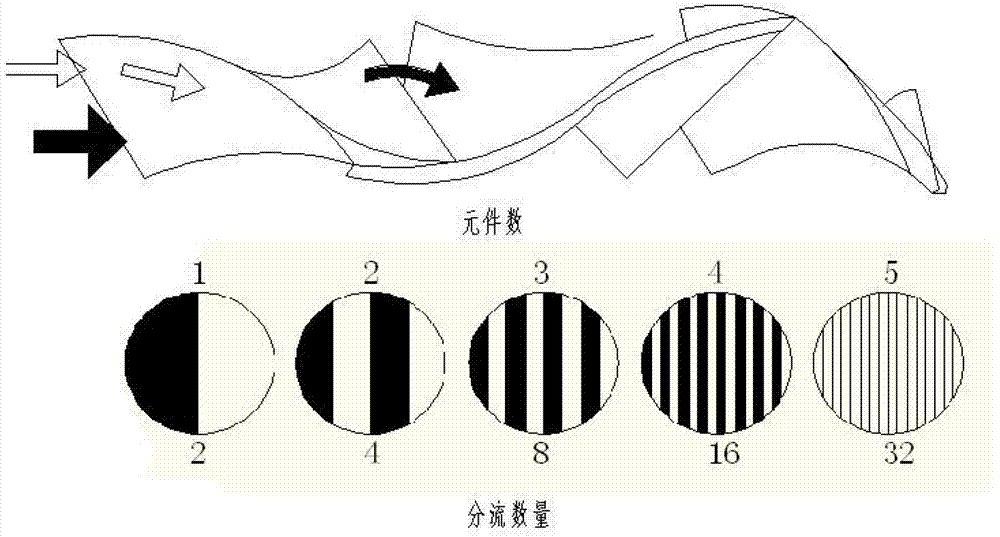

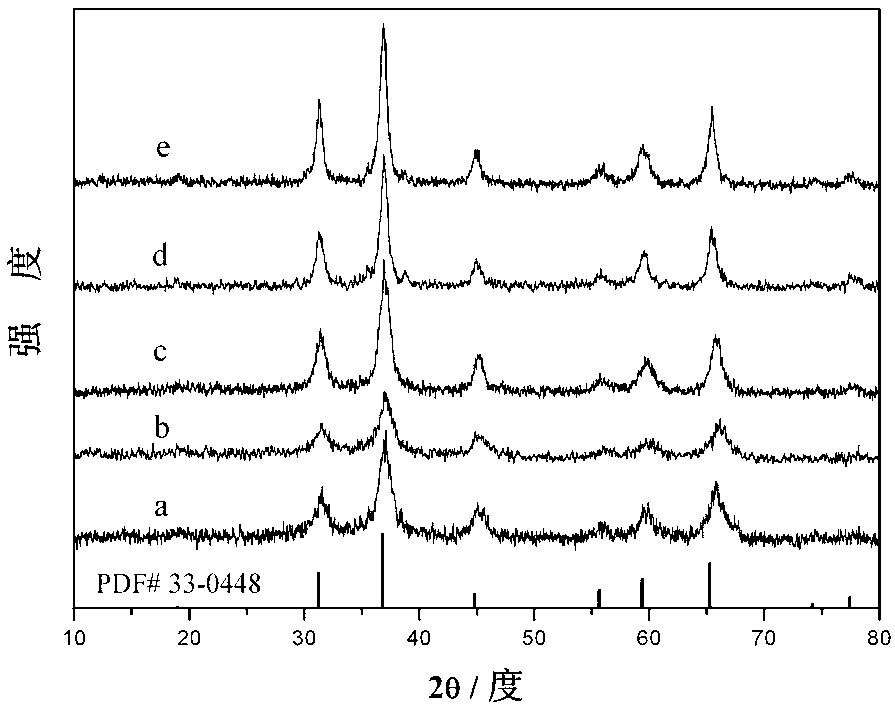

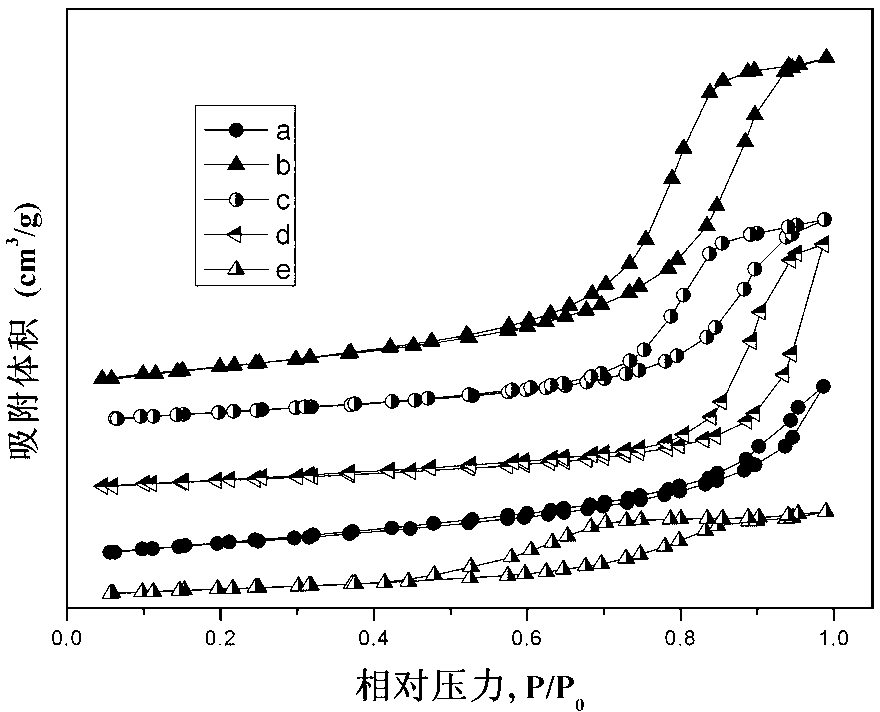

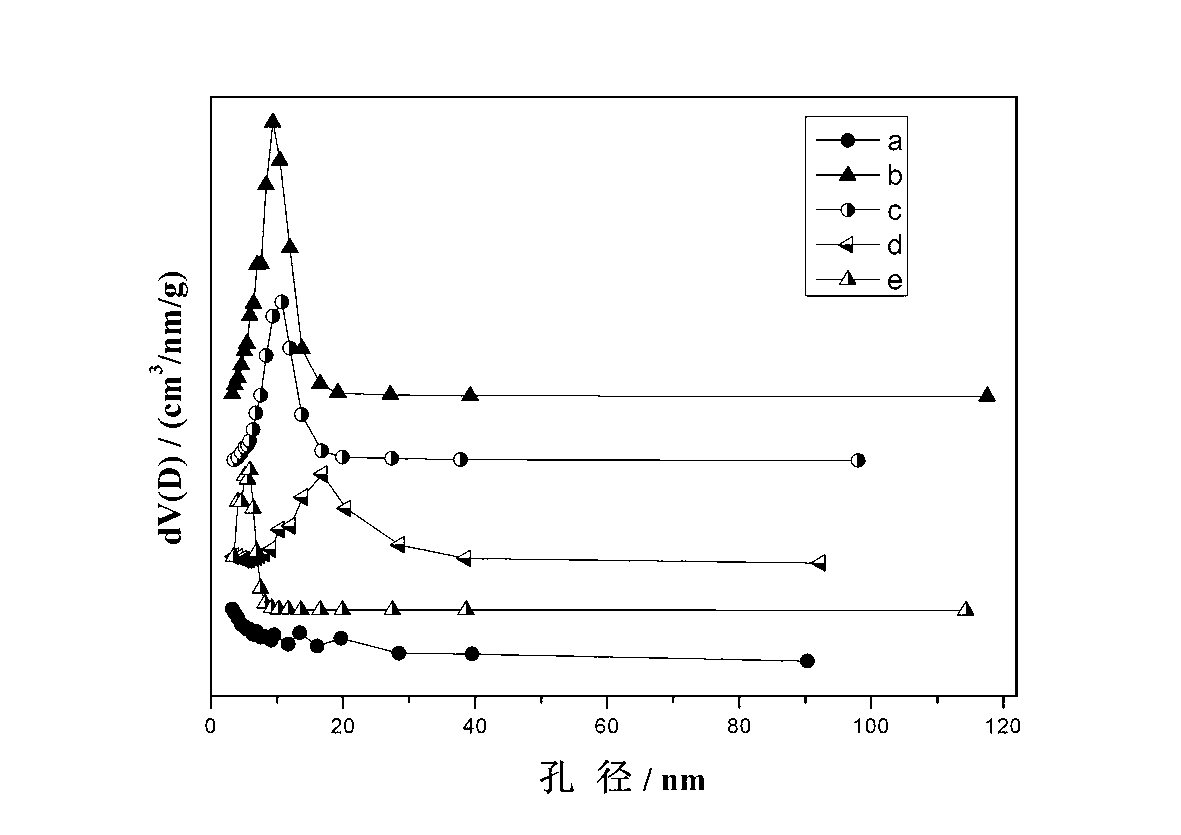

Synthetic method of pore size-adjustable nanometer mesoporous CuAl2O4 spinel

The invention discloses a synthetic method of pore size-adjustable nanometer mesoporous CuAl2O4 spinel. The synthetic method is characterized by comprising the following steps of: reacting for 24 hours at the constant temperature of 80 DEG C by using Cu(NO3)2.3H2O and Al(NO3)3.9H2O as raw materials, using n-butylamine and dodecanol as co-template, and using water and alcohol as solvent; washing the product by water and alcohol, centrifugally separating and drying the washed product to obtain a copper-aluminum hydroxide coprecipitation precursor; roasting the precursor for 2 hours in a muffle furnace of 800 DEG C to obtain mesoporous CuAl2O4 spinel. The synthetic method of pore size-adjustable nanometer mesoporous CuAl2O4 spinel disclosed by the invention is reasonable in design, simple in process, smaller in product particle dimension, large in specific surface area, concentrated in pore size distribution and adjustable within a range of 5nm-17nm.

Owner:UNIV OF JINAN

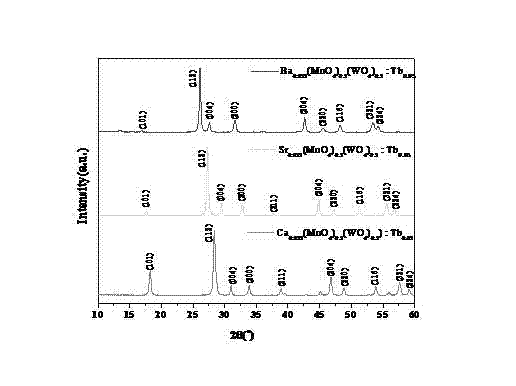

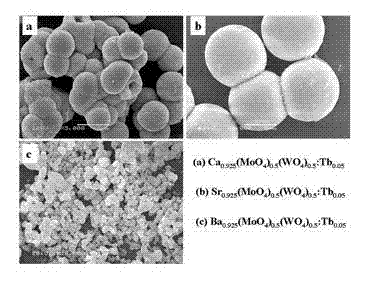

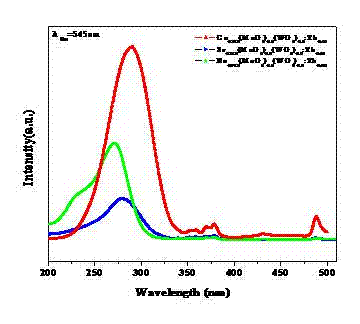

Preparation method of chemical solution of terbium-doped tungsten molybdate green fluorescent microcrystalline

InactiveCN102382643APracticalSolve the above problemsLuminescent compositionsChemical solutionMolybdate

The invention relates to a preparation method of a chemical solution of terbium-doped tungsten molybdate green fluorescent microcrystalline. The green microcrystalline provided by the invention can be expressed by a general formula A0.925(WO4)0.5(MoO4)0.5:Tb3+0.05, wherein A=Ca, Sr and Ba. The preparation method comprises the following steps of: preparing the molar ratio of various raw materials required by a certain amount of target system, A0.925(WO4)0.5(MoO4)0.5:Tb3+0.05 microcrystalline, weighing a certain consistency and relative volume of A(NO3)2, TbCl3 solutions in a polytertrafluoroethylene beaker, respectively adding the relative amounts of Na2MoO4 and Na2WO4 solutions, stirring at the room temperature for 15-30min, and putting the polytertrafluoroethylene beaker into a high-pressure reaction kettle; naturally cooling down to the room temperature after carrying out a hydrothermal reaction under 80-180 DEG C for 15-30h; and centrifugalizing and cleaning in deionized water sediments, and baking the sediments under 100-150 DEG C to obtain the A0.925(WO4)0.5(MoO4)0.5:Tb3+0.05 solid solution luminescent microcrystalline. The invention has the advantages of environment protection, energy conservation, simple preparation processes and devices and low reaction temperature. The terbium-doped tungsten molybdate green fluorescent microcrystalline prepared by the preparation method disclosed by the invention has the advantages of pure phase, uniform granularity, suitable grain size, regular appearance, highly pure and bright green and excellent practicability.

Owner:SICHUAN NORMAL UNIVERSITY

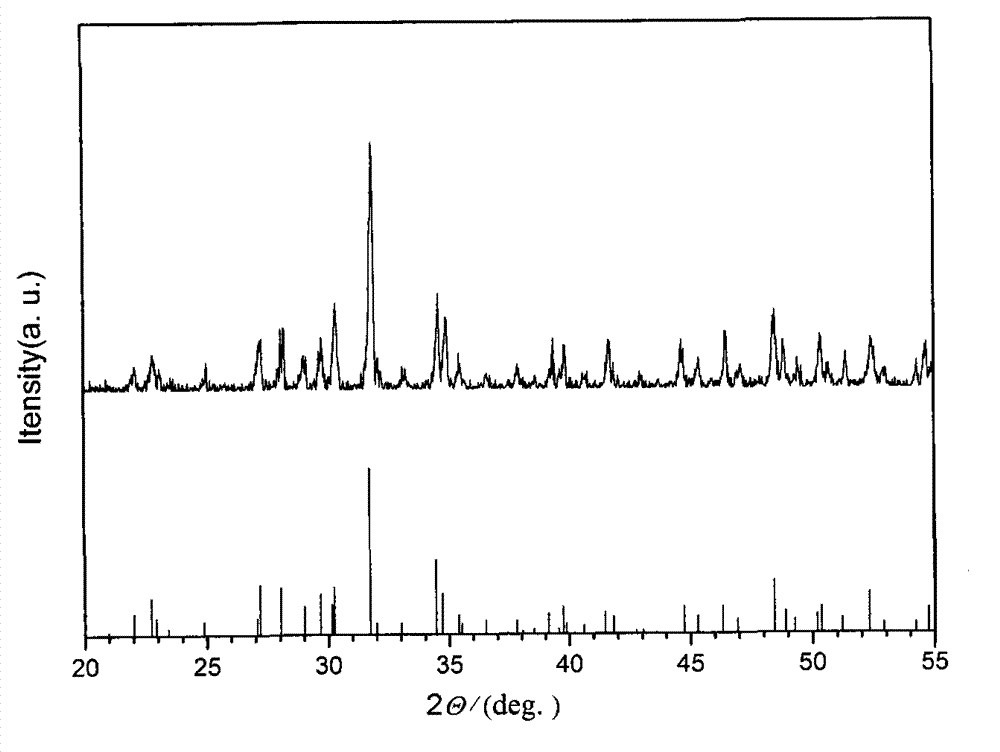

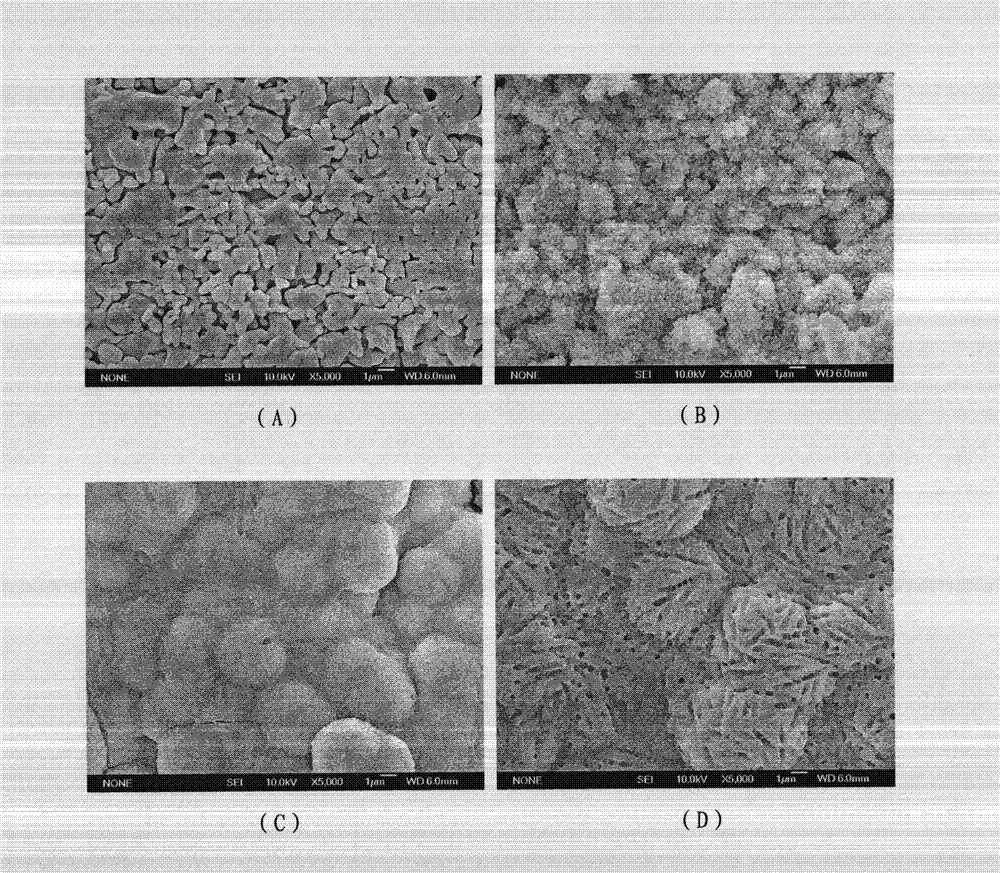

Method for synthesizing lithium vanadate Li3VO4 monocrystal micrometer powder with high-temperature and high-pressure mixed solvent thermal system

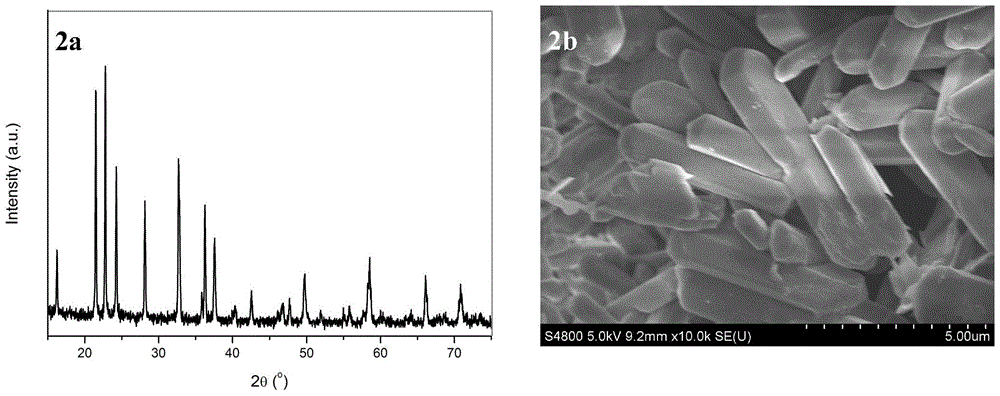

ActiveCN105731539AEasy to synthesizePromoting the development of technological fields such as applicationsVanadium compoundsSingle crystalHigh pressure

The invention discloses a method for synthesizing lithium vanadate Li3VO4 monocrystal micrometer powder with a high-temperature and high-pressure mixed solvent thermal system.The method comprises the steps that solid lithium carbonate powder and solid vanadium pentoxide serve as raw materials, a high-temperature and high-pressure mixed solvent serves as a reaction medium, and the lithium vanadate Li3VO4 monocrystal micrometer powder is synthesized with the condition ranges of 2-9 MPa, 200-350 DEG C and 1-4 h.The method has a unique advantage, the lithium vanadate Li3VO4 monocrystal micrometer powder can be quickly, easily and conveniently obtained, the physical phase is pure, the particle size ranges from 1 micrometer to 20 micrometers, and the dispersibility is good.The synthesizing method is easy, convenient and safe to implement, equipment is convenient to use and simple, the reaction process is easy to control, energy conservation and environment protection are achieved, and the method is especially suitable for industrialized mass production.

Owner:SHANDONG UNIV

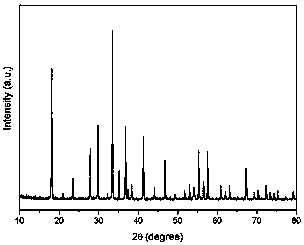

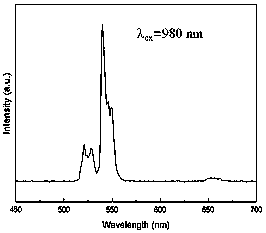

Er3+/ Yb3+ co-doping calcium fluoraluminate green up-conversion luminescent material and preparation method thereof

InactiveCN108384536ASimple preparation processNo damageLuminescent compositionsFluorescenceGreen-light

The invention belongs to the technical field of inorganic luminescent materials, and particularly relates to an Er3+ / Yb3+ co-doping calcium fluoraluminate green up-conversion luminescent material triggered by near-infrared light and a preparation method thereof. The method adopts a high temperature solid phase method to prepare the Er3+ / Yb3+ co-doping calcium fluoraluminate, high-purity raw materials of Er2O3, Yb2O3, Al2O3, CaF2 and CaCO3 are evenly mixed in proportion, sintering is carried out to obtain the Er3+ / Yb3+ co-doping calcium fluoraluminate luminescent material. The luminescent material emits green light located at about 550 nanometers under the stimulation of 980-nanometer near-infrared light, and the up-conversion luminescent efficiency is higher; the luminescent material has better stability, is environmentally-friendly, has low cost, and can be widely applied to the fields of three-dimensional volumetric display, biomolecule fluorescent labeling probe, optical fiber amplifier and the like; the preparation method is easy in operation and industrial production, and the production cost is low.

Owner:CHANGCHUN UNIV OF SCI & TECH

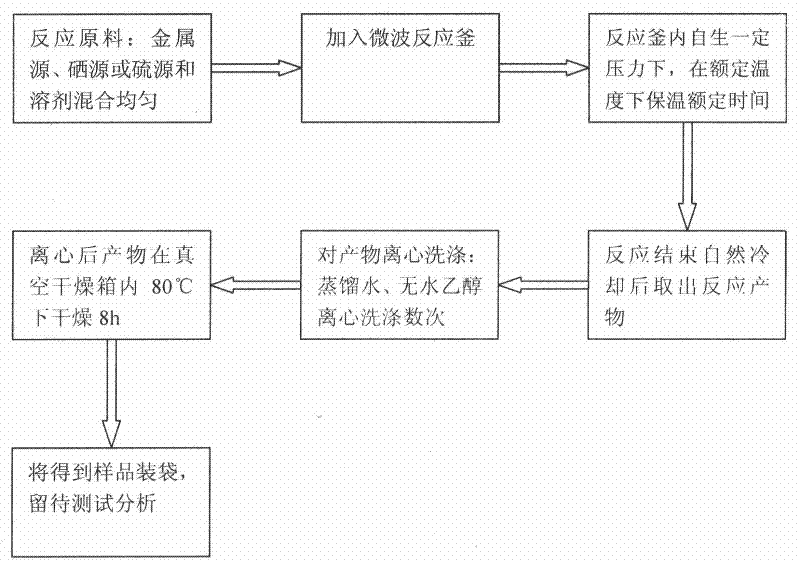

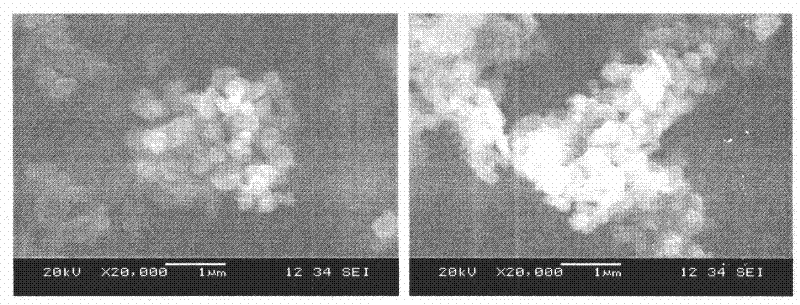

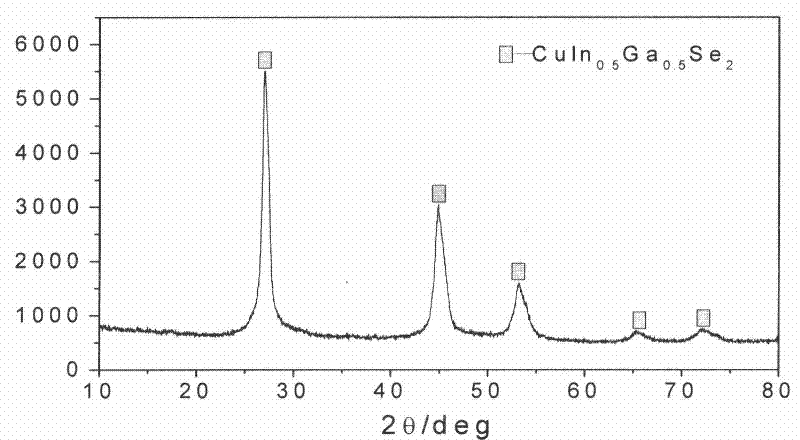

Microwave-assisted solvothermal synthesis method of I-III-VI semiconductor material nano-powder

InactiveCN102249199AEasy to operateSmall grain sizeSelenium/tellurium compundsNanotechnologyEthylenediamineSemiconductor materials

The invention discloses a microwave-assisted solvothermal synthesis method of I-III-VI semiconductor material nano-powder. The method comprises the following steps: adding metal salt and a sulfur source or selenium source into a beaker based on the mole ratio of an expected product, adding a solvent, evenly mixing and then transferring the obtained mixed solution to a microwave reaction kettle; after the reaction kettle is closed, heating the mixed solution to rated temperature in a microwave field, and performing heat preservation for rated time; and centrifugally washing the final product to obtain the target powder. In the method, the solvent is one or more of water, ethylenediamine, ethylene glycol, diamine and ethanol; the metal salt is the metal salt of Cu, In, Ga and Al; the sulfur source is thiourea or sulfur powder; and the selenium source is selenium powder or seleninic acid. The microwave-assisted solvothermal synthesis method has the beneficial effects that based on the heating and activation effect of the microwave field, reaction temperature is lowered and reaction time is shortened; and part of reaction that can not be made in the traditional high-pressure solvothermal synthesis process can be performed smoothly. The obtained semiconductor material nano-powder has the advantages of smaller grain size, pure phases, accurately controlled stoichiometric ratio of the phases and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

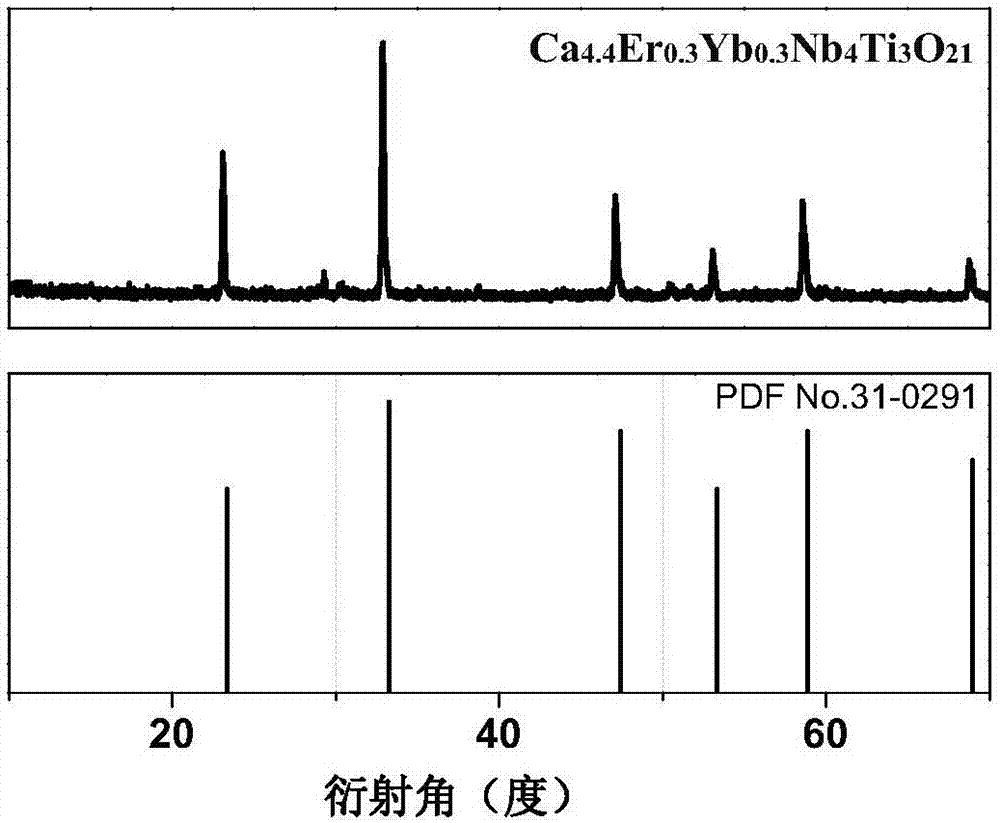

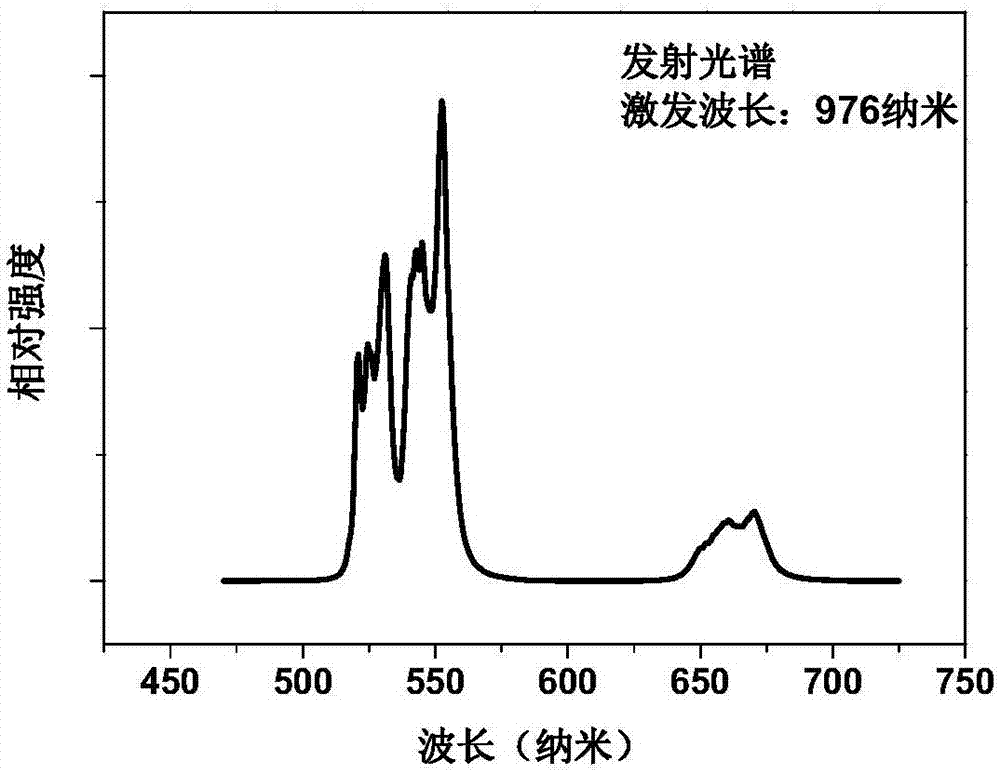

Green titanium niobate up-conversion luminescent material, and preparation method and application thereof

ActiveCN106905964AEfficient deliveryHigh Luminescence PurityLuminescent compositionsFiberLuminous intensity

The invention discloses a green titanium niobate up-conversion luminescent material, and a preparation method and application thereof. The green titanium niobate up-conversion luminescent material has a general chemical formula of Ca<5-5x>Er<5x>Yb<5y>Nb<4>Ti<3>O<21>, wherein x is the doping mol ratio of Er<3+> ions, y is the doping mol ratio of Yb<3+> ions, and the sum of x and y is no less than 0.001 and no more than 0.20. The green titanium niobate up-conversion luminescent material prepared in the invention has uniform particles, and under the excitation of light with a wavelength of 976 nm, the material emits green light with a wavelength of about 550 nm and has high luminescent intensity and high up-conversion luminescent efficiency. The green titanium niobate up-conversion luminescent material has good stability, no toxicity and no pollution and can be widely applied to fields like infrared radiation detection, optical fiber communication technology, fiber amplifiers, three-dimensional stereo display and biomolecular fluorescent marking. The preparation method is simple, safe, low in production cost, not restricted by raw material supply and easy for operation and industrial production.

Owner:NANJING TONGLI CRYSTAL MATERIALS RES INST CO LTD

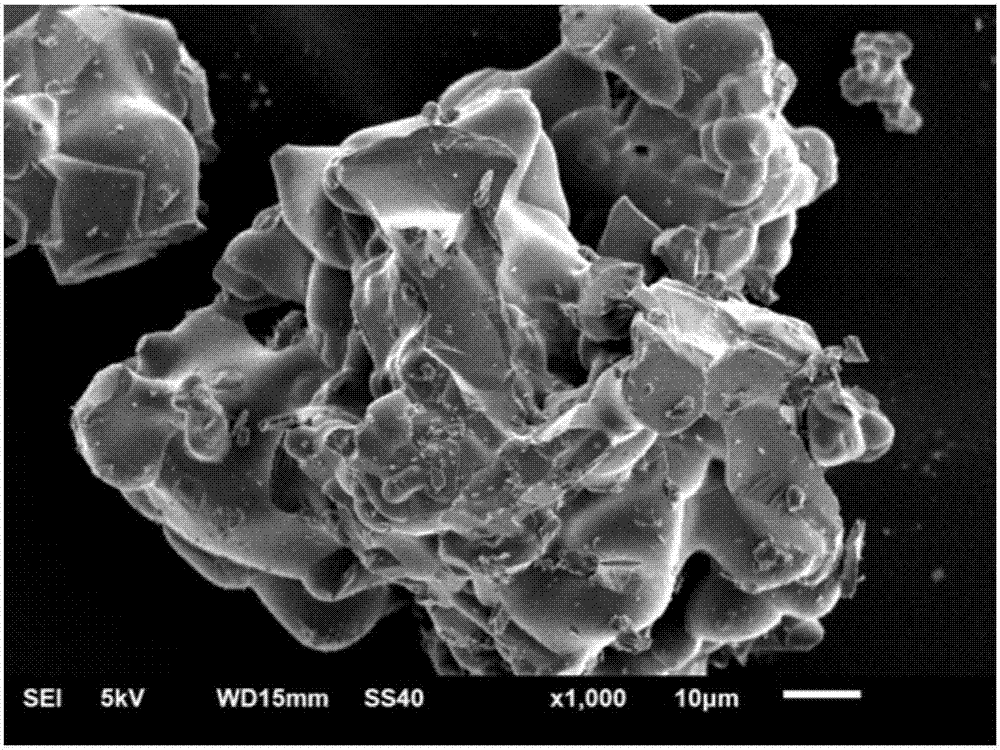

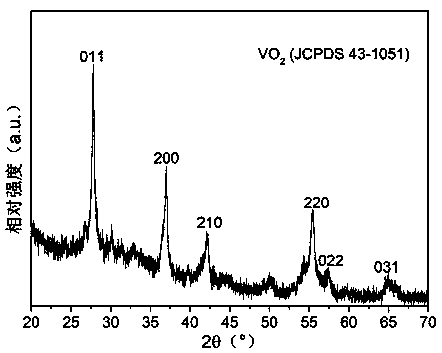

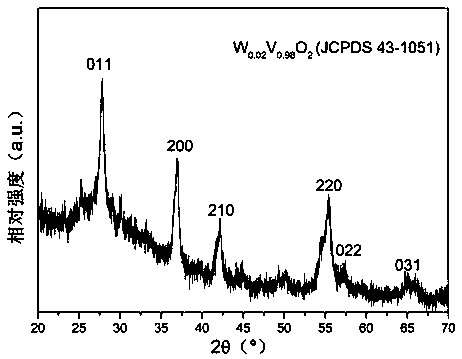

Preparation method of doped vanadium dioxide nano-powder

The invention discloses a preparation method of doped vanadium dioxide nano-powder. The method comprises the following steps that according to the preparation quantity of the product V1-xMxO2 (whereinM is one or two of doping elements of W and Mo, and x is greater than and equal to 0 and is smaller than and equal to 0.25) and the molar ratios of the doping elements to vanadium in the chemical formula of the product, a W / Mo-source reactant and ammonium metavanadate with the corresponding mass are weighed, according to 0.5-6 times of the mole number of the metal elements in the product, solid organic acid and ammonium salt of the solid organic acid are weighed and added into a ball-milling tank of a ball-milling machine for ball-milling for 0.5-5 hours, a ball-milling product is dried in the air at 60-120 DEG C for 0.5-8 hours, calcined at the atmosphere of specific gas at 200-800 DEG C for 0.5-6 hours and cooled to room temperature, and then the final product is obtained. The preparedpowder is even in particle and pure in phase, moreover, equipment is simple, the raw materials are easy to get, the yield is high, time is short, the cost is low, large-scale preparation is easy, andthus the method has very good industrial application prospects.

Owner:NANCHANG UNIV

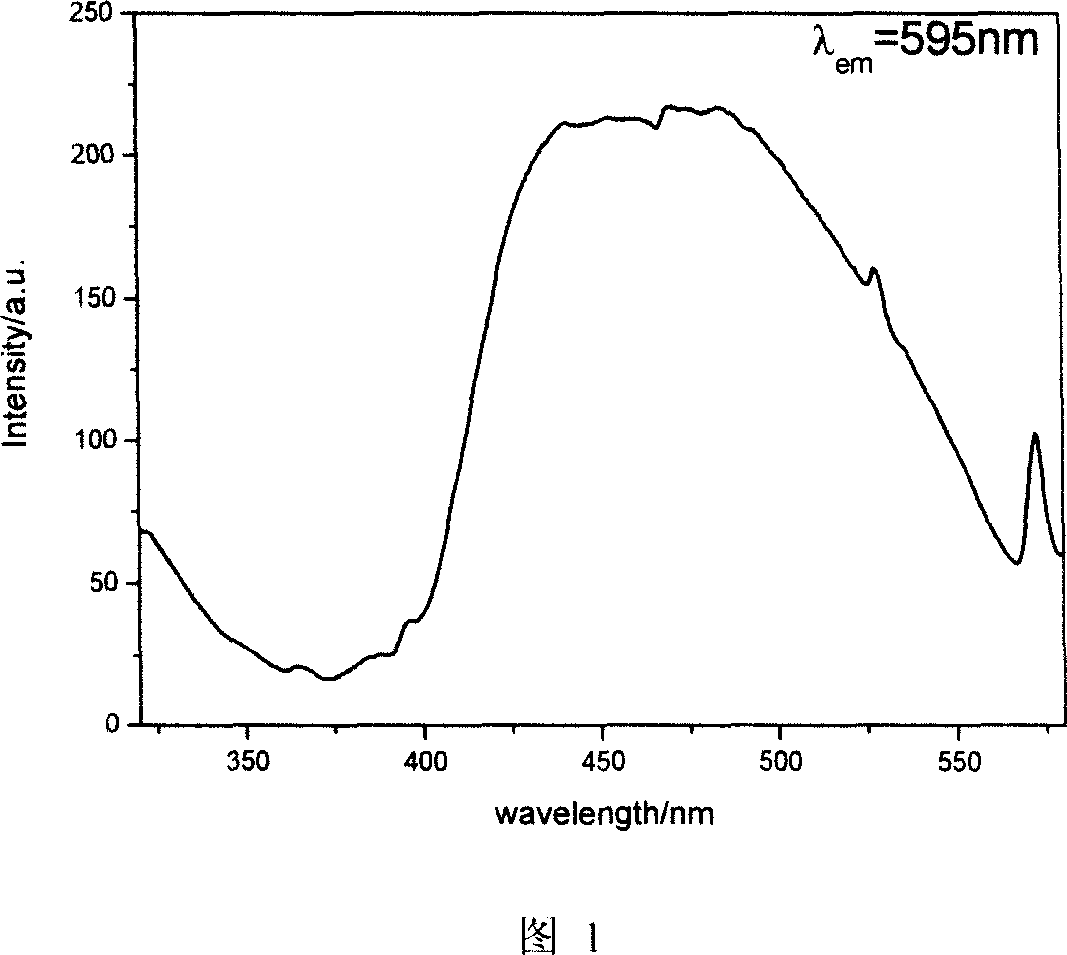

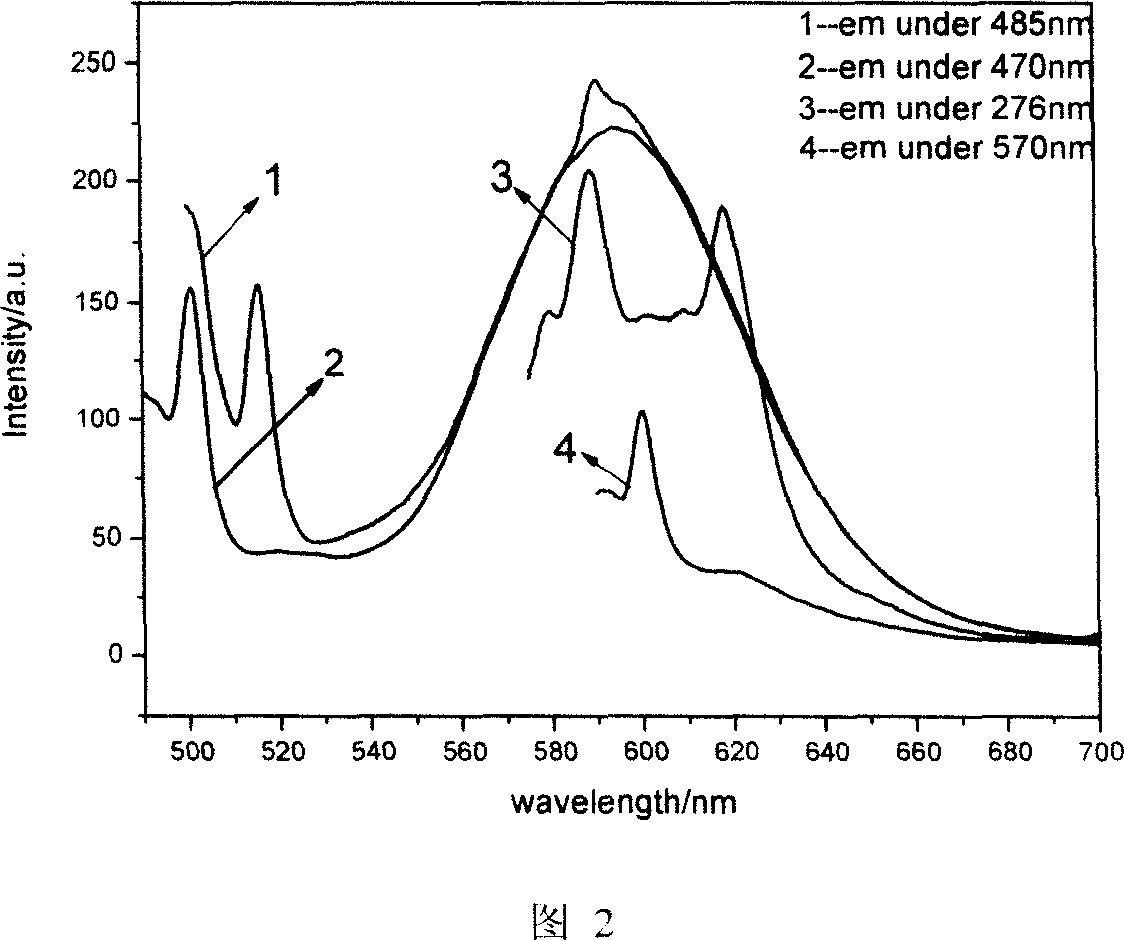

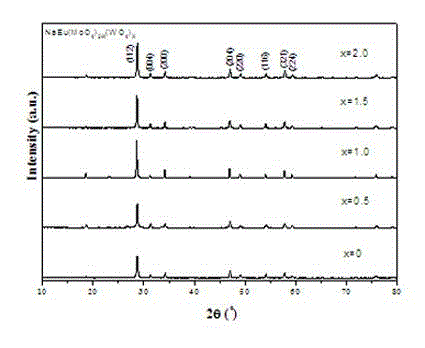

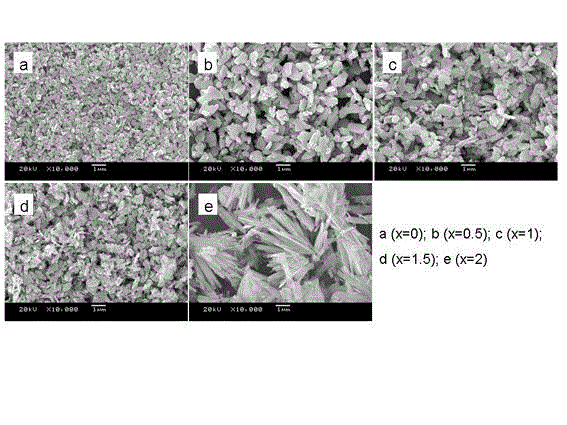

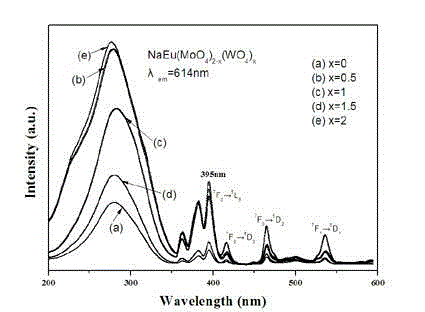

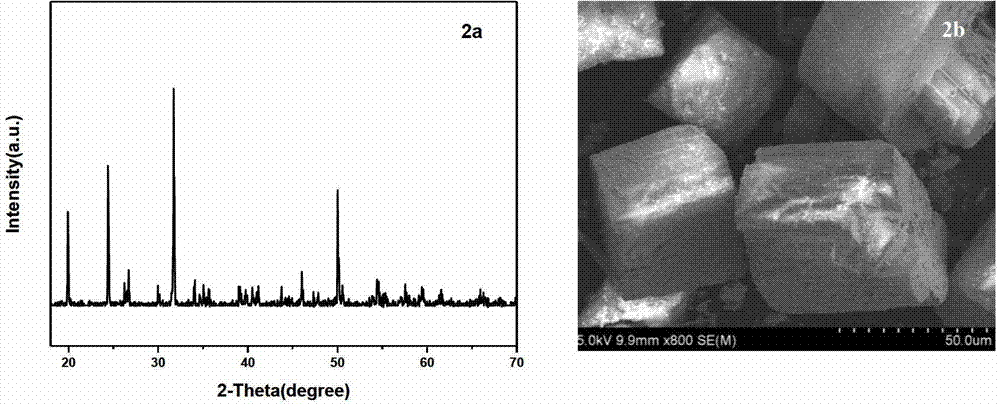

NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals and chemical solution preparation method thereof

InactiveCN102942925ASolve the above problemsImprove practicalityLuminescent compositionsChemical solutionProcess equipment

The invention belongs to the field of scheelite-structure luminescent materials, relates to a research on novel composite tungsten molybdate phosphors which are NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals, and especially relates to a chemical solution preparation method of the NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals. The NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals have a general formula of NaEu(MoO4)2-x(WO4)x, wherein x is greater than or equal to 0 and less than or equal to 2. The chemical solution preparation method comprises the following steps of weighing Na2MoO4 and Na2WO4 solutions having corresponding volumes according to a mole ratio of all raw materials for preparation of a certain amount of the NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals as a target system, putting the weighed Na2MoO4 and Na2WO4 solutions into a Teflon beaker with a stirrer, respectively adding a corresponding amount of an EuCL3 solution into the Teflon beaker, stirring at a normal temperature for 15 to 30 minutes, adjusting a pH value to 6-9, putting the Teflon beaker into a high-pressure reactor, carrying out a hydrothermal reaction process at a temperature of 80 to 160 DEG C for 15 to 30 hours, naturally cooling to a room temperature, carrying out centrifugal separation of precipitates, washing by deionized water, and drying at a temperature of 100 to 150 DEG C to obtain the NaEu(MoO4)2-x(WO4)x-type fluorescent microcrystals. The chemical solution preparation method adopts simple process equipment and allows a low reaction temperature. Rare earth-doped tungsten molybdate fluorescent microcrystals obtained by the chemical solution preparation method have a pure phase, a uniform and appropriate particle size and regular morphology, can emit high purity and high brightness red light, and have good practicality.

Owner:SICHUAN NORMAL UNIV

Bimetallic nitride Co3W3N, preparation method and application thereof

ActiveCN109019533ASimple processHigh catalytic activityNitrogen compoundsCell electrodesIonic crystalHigh oxygen

The invention discloses a bimetallic nitride Co3W3N, a preparation method and application thereof. The Co3W3N is prepared by subjecting a cobalt salt and a tungsten salt of equal molar ratio to hydrothermal reaction and then performing nitriding synthesis. The Co3W3N is applied to the electrochemical catalysis field. The bimetallic nitride Co3W3N provided by the invention is a intermetallic mold filling compound, has the properties of covalent compounds, ionic crystals and transition metals, has high oxygen reduction catalytic activity and nitrogen reduction catalytic activity, the catalytic activity is close to that of commercial Pt / C, also the phase is pure, the stability is strong and the methanol resistance is excellent. At the same time, the preparation method is simple, effective andcontrollable, is easy to operate, low in cost and high in yield, and the problems of poor cycle stability and easy agglomeration of particles caused by thermal decomposition of the bimetallic nitrideto form a mixture of metal elements and metal nitrides can be effectively avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

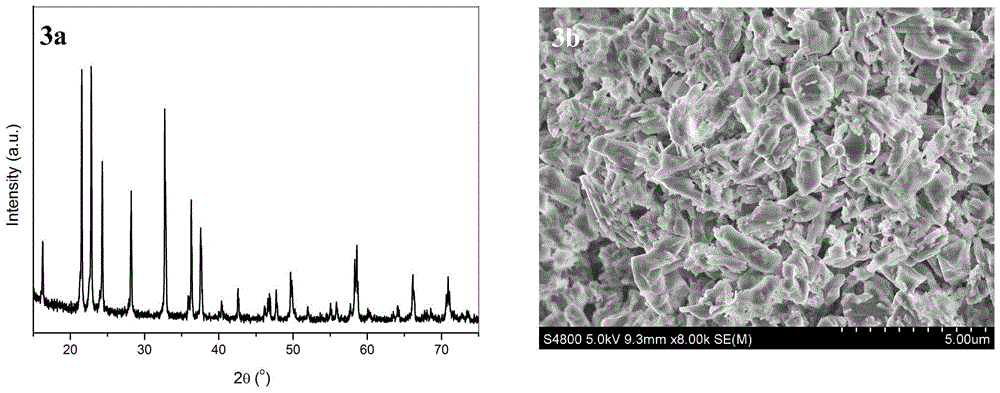

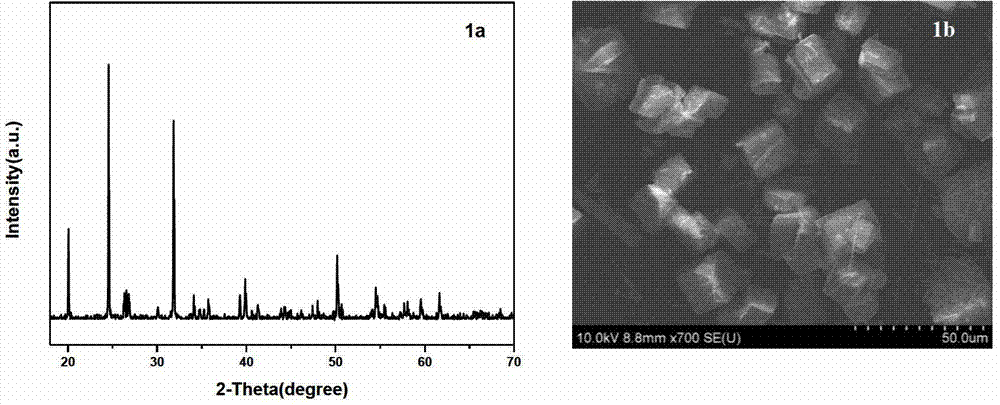

Method for synthesizing tellurium molybdate magnesium single crystal micro powder by using supercritical water system

InactiveCN103031592ASafe preparationEasy to preparePolycrystalline material growthFrom normal temperature solutionsDispersityHigh pressure water

The invention discloses a method for synthesizing a tellurium molybdate magnesium single crystal micro powder by using a supercritical water system. With solid magnesium oxide powder, a tellurium dioxide powder and a molybdenum trioxide powder as raw materials and high temperature and high pressure water as a reaction medium, the tellurium molybdate magnesium single crystal micro powder material is synthesized in a sealed pressure container within a condition range of 380 DEG C and 23-25 MPa. The tellurium molybdate magnesium single crystal micro powder material synthesized by the method disclosed by the invention has the advantages of pure phase, comparatively structured particle morphology, particle size range of 15-50 microns, uneasily agglomerated particles and better dispersity. The synthesizing method disclosed by the invention is also suitable for synthesizing a plurality of multibasic oxide single crystal micro materials containing the molybdenum and tellurium and provides a simple, convenient, rapid, safe and environment-friendly preparation process route for novel multibasic oxides containing the molybdenum and tellurium.

Owner:SHANDONG UNIV

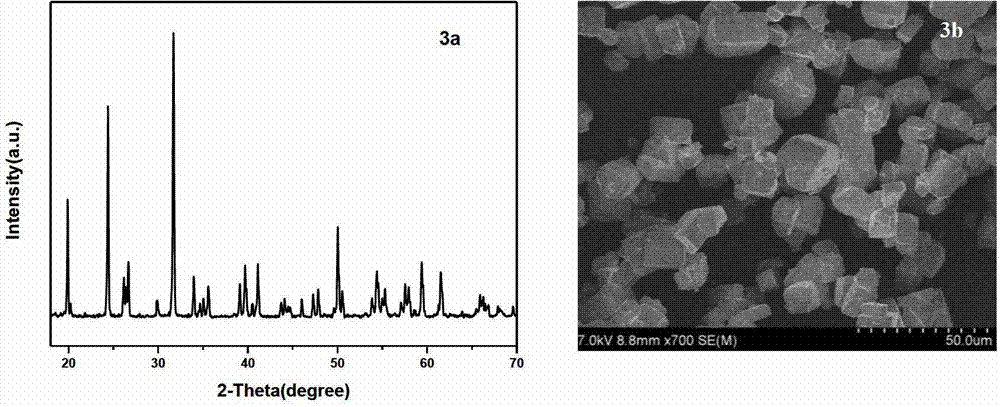

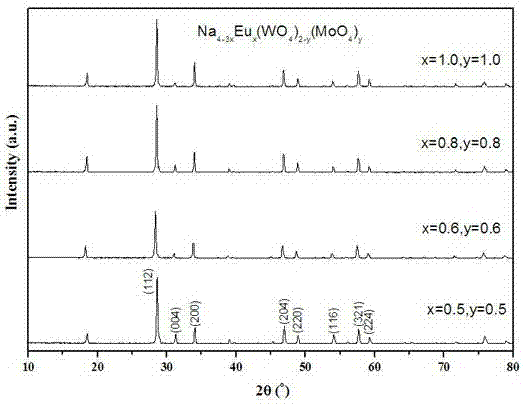

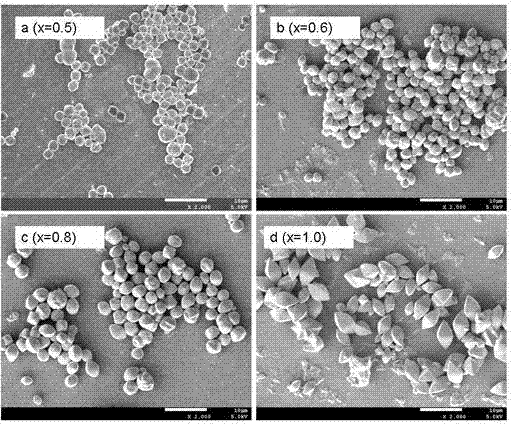

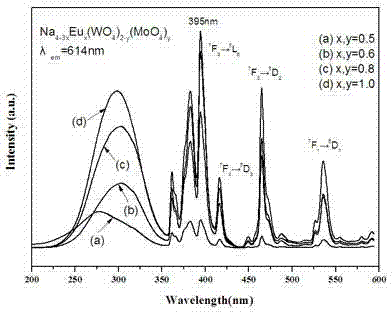

Na4-3xEux(WO4)2-y(MoO4)y serial fluorescent microcrystal and chemical solution preparation method

InactiveCN102851029ASmall sizeImprove practicalityPolycrystalline material growthFrom normal temperature solutionsChemical solutionFluorescence

The invention relates to research of a novel composite tungsten molybdenate phosphor, and especially relates to a novel fluorescent microcrystal prepared by a chemical solution method. The microcrystal provided by the invention can be expressed by a general formula of Na4-3xEux(WO4)2-y(MoO4)y, wherein 0<x<4 / 3 and 0<y<2. The preparation method comprises the following steps: according to a molar ratio of raw materials required for the preparation of a certain amount of Na4-3xEux(WO4)2-y(MoO4)y, measuring corresponding volumes of Na2MoO4 and Na2WO4 solutions in a polytetrafluoroethylene beaker, respectively adding a corresponding amount of EuCl3 solution, stirring at normal temperature for 15-30 min, adjusting the pH to 6-9, and finally putting the polytetrafluoroethylene beaker into a high pressure reaction vessel; performing a hydrothermal reaction at 80-160 DEG C for 15-30 hours, naturally cooling to room temperature; centrifuging the precipitates for separation, washing with deionized water, and drying at 100-150 DEG C to obtain the Na4-3xEux(WO4)2-y(MoO4)y microcrystal. The preparation method of the invention is simple in preparation process, low in reaction temperature. The prepared tungsten molybdenate fluorescent microcrystal is pure in phase, uniform in granularity, appropriate in particle size, and regular in morphology, can exhibit red light with high purity and brightness, and has good practicality.

Owner:SICHUAN NORMAL UNIVERSITY

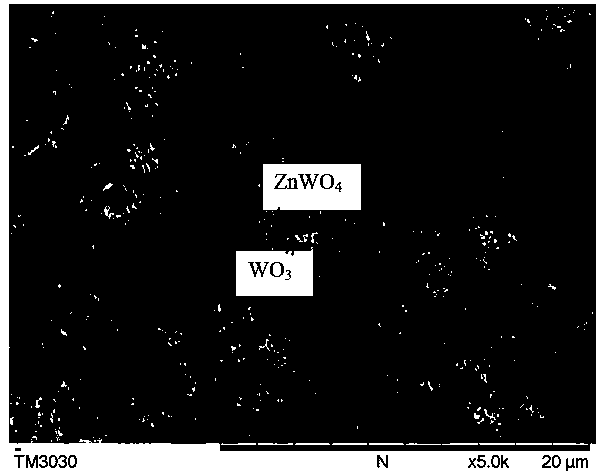

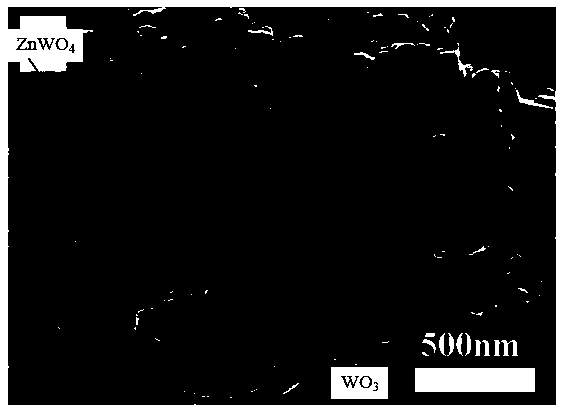

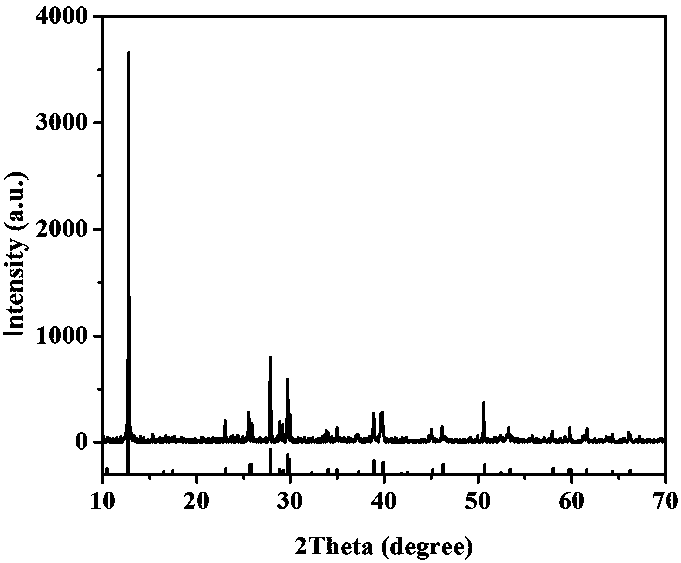

Method for preparing tungsten trioxide/tungstic acid composite photocatalytic material through in-situ self growth

ActiveCN109126769AComponent distribution is evenCan be industrially prepared with phase purityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsTungstateWater soluble

The invention discloses a method for preparing a tungsten trioxide / tungstic acid composite photocatalytic material through in-situ self growth. The method comprises the following steps: by taking water-soluble tungstate and zinc salt as raw materials, preparing nano tungstic acid powder by using a hydrothermal method, carrying out in-situ medium reduction on the tungstic acid powder in the presence of H2 so as to prepare W / WO3 / ZnWO4 composite powder, and finally carrying out a thermal treatment process to oxidize W into WO3, thereby obtaining in-situ self growth W / WO3 / ZnWO4 composite powder. The method is simple to operate, in-situ self growth of WO3 is carried out on the surface of ZnWO4, the phenomenon that in the prior art components are not uniformly distributed when the W / WO3 / ZnWO4 composite powder is prepared can be effectively solved, and the stability of properties of the composite powder can be ensured.

Owner:JIANGXI UNIV OF SCI & TECH

Preparation method of positive pole material Na1.1V3O7.9 of lithium ion battery

InactiveCN108264085AMaterials are cheap and readily availableReduce manufacturing costCell electrodesSecondary cellsAluminium-ion batteryElectrical battery

The invention relates to a preparation method of a positive pole material Na1.1V3O7.9 of a lithium ion battery. The preparation method can prepare the positive electrode material Na1.1V3O7.9 with goodelectrochemical performances through a sol-gel method through heat treatment at different temperatures.

Owner:QILU UNIV OF TECH

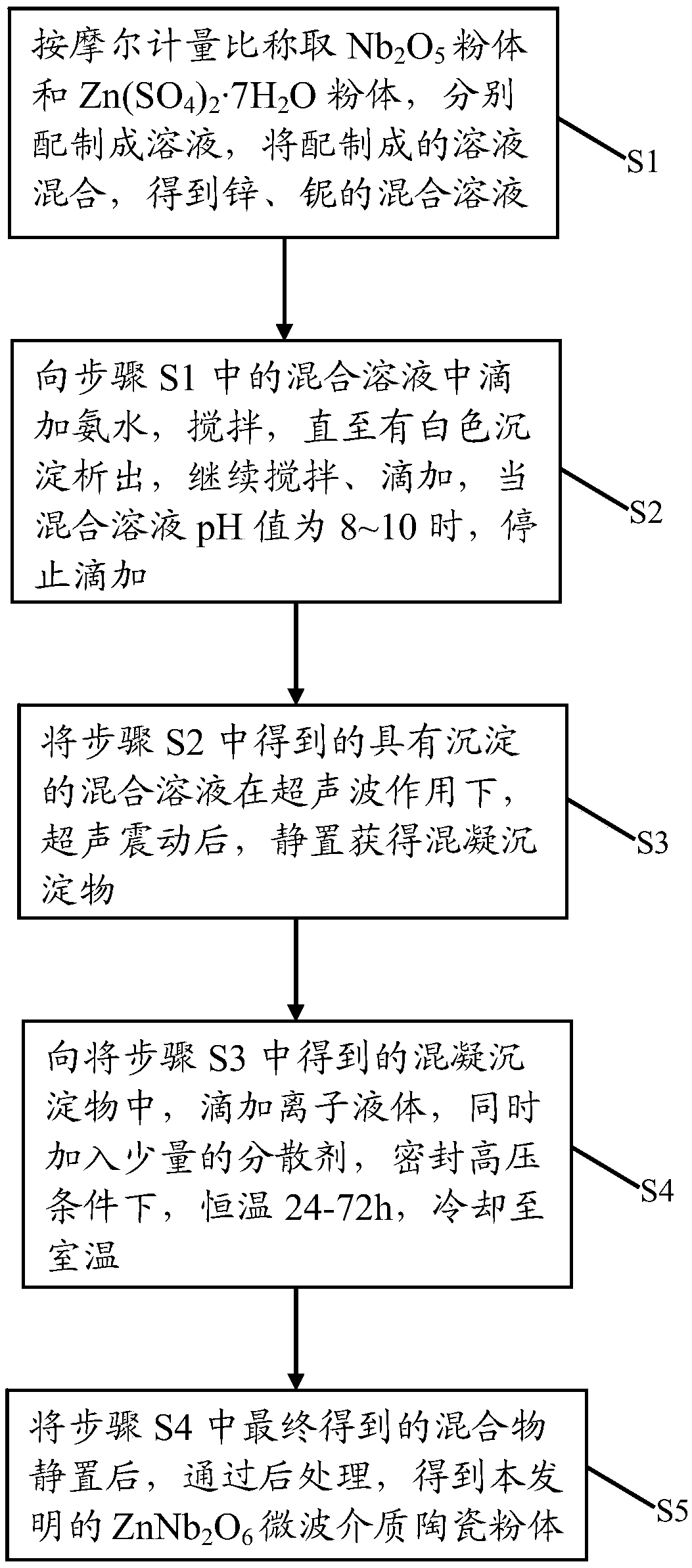

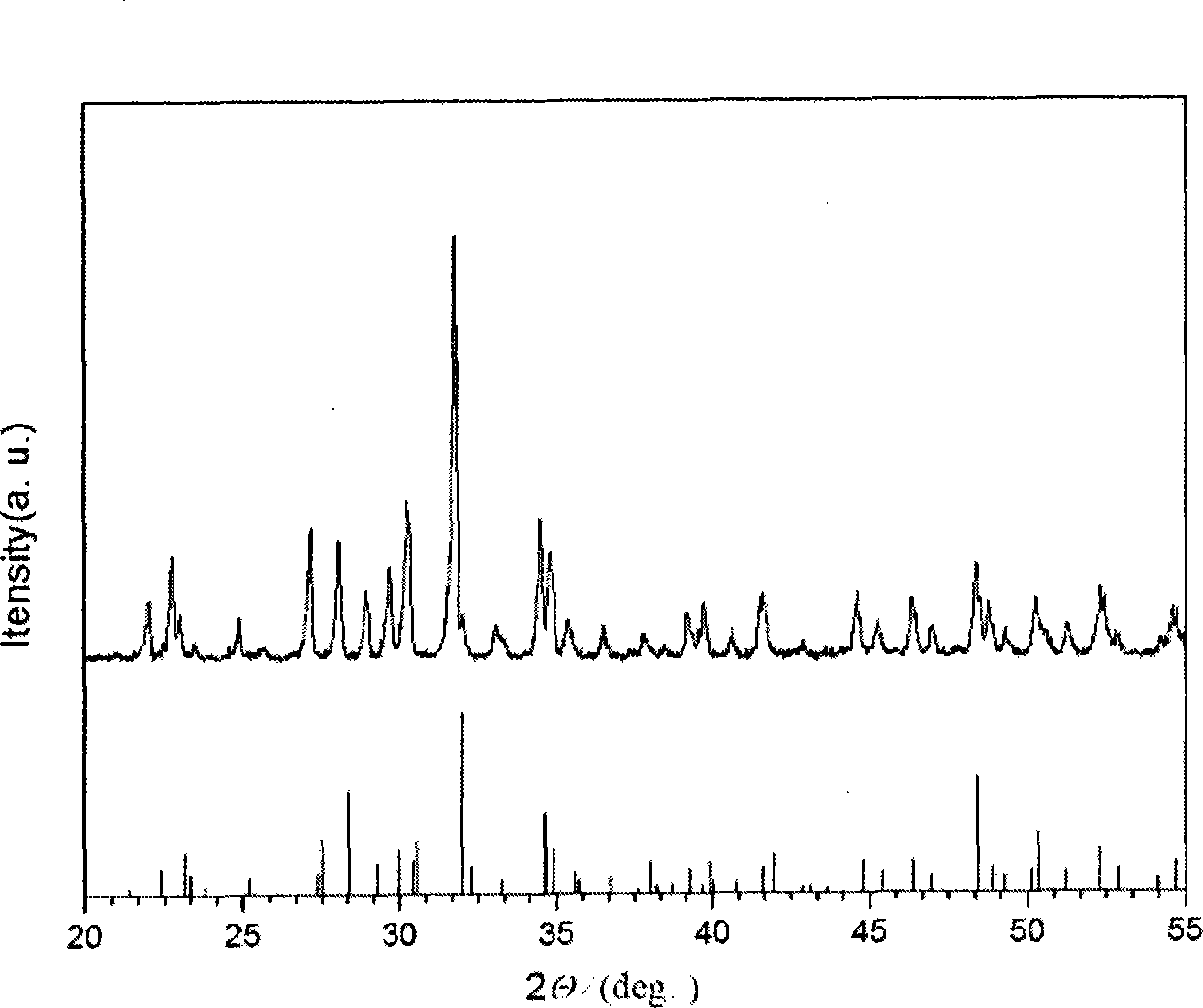

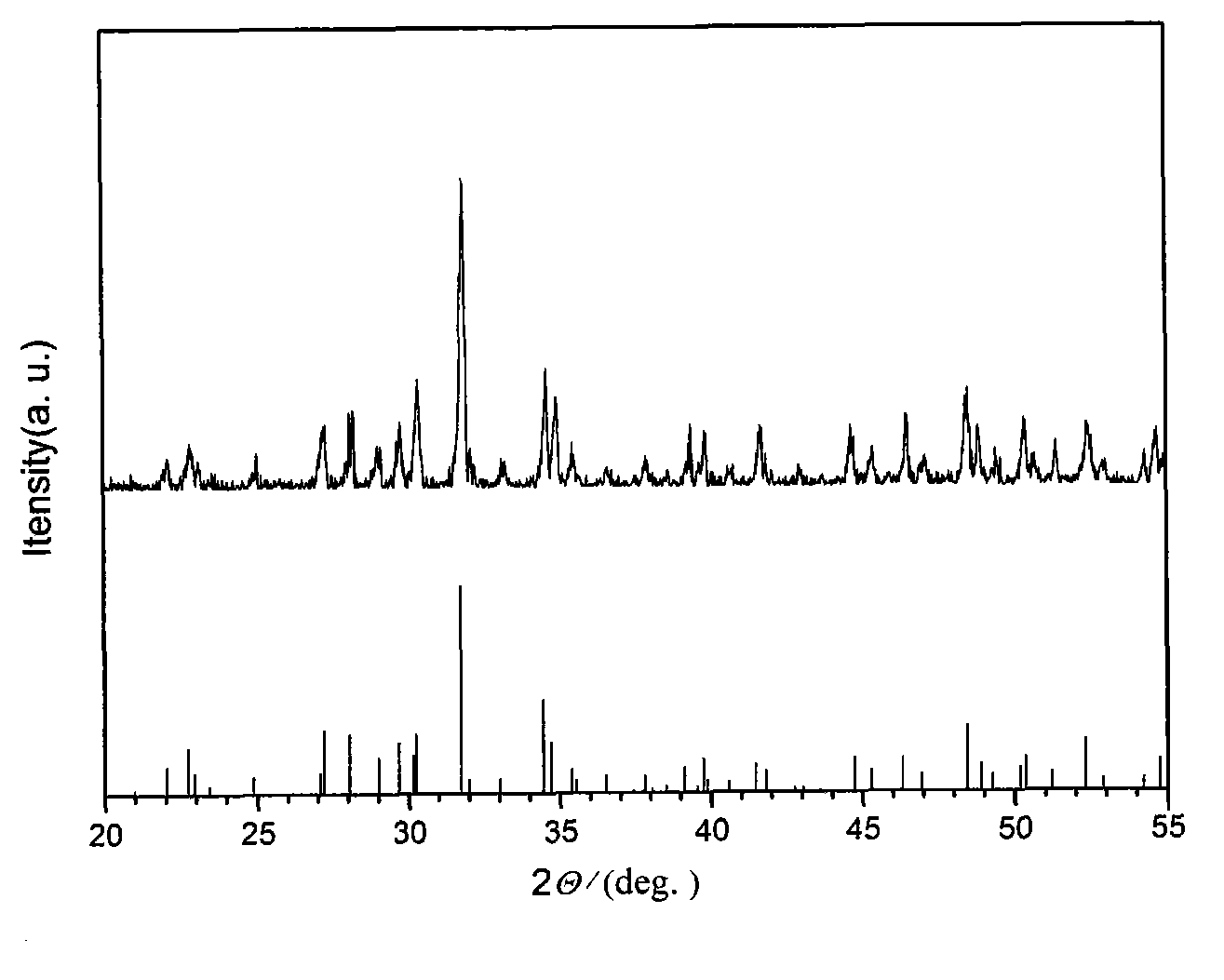

Preparation method for ZnNb2O6 microwave dielectric ceramic powder

InactiveCN105502497ASynthesis temperature is lowExcellent dielectric propertiesNiobium compoundsMicrowaveMetallurgy

The invention discloses a preparation method for ZnNb2O6 microwave dielectric ceramic powder. The preparation method comprises the steps of precursor preparation, a precipitation reaction, a hydrothermal reaction and pumping-filtration drying. Through the preparation method for the ZnNb2O6 microwave dielectric ceramic powder, the resultant temperature of the ZnNb2O6 microwave dielectric ceramic powder can be lowered, ultramicro ZnNb2O6 ceramic powder with excellent microcosmic properties can be obtained, and then the dielectric properties of microwave dielectric ceramic can be improved.

Owner:KUNSHAN BRANCH INST OF MICROELECTRONICS OF CHINESE ACADEMY OF SCI

Carbon nanotube composite barium titanate wave absorbing nano-material and preparation method therefor

Provided are a carbon nanotube composite barium titanate wave absorbing nano-material and a preparation method therefor. The wave absorbing nano-material is composed of carbon nanotube powder and barium titanate according to a weight ratio of 0.026-0.111 through combination. Carbon nanotube powder is dispersed in a mixed solution of concentrated sulfuric acid and nitric acid with a volume ratio of 3:1 and pretreatment is carried out; tetrabutyl titanate is dissolved in absolute ethyl alcohol, and a solution A with a concentration of 0.5-1mol / L; barium acetate is dissolved in deionized water, polyvinylpyrrolidone is added as a dispersant, and a solution B with a concentration of 1-1.5mol / L; glacial acetic acid and the solution B are added in the solution A in order and transparent sol is prepared; carbon nanotube powder after pretreatment is weighed and dispersed in the transparent sol, and the mass ratio of the carbon nanotube powder to barium titanate is 0.026-0.111; the mixture is placed in a water bath kettle, heat insulation is carried out for 24h, and the mixture is ground into powder; the above powder is placed in a tubular furnace with nitrogen as a protection atmosphere, calcination is carried out for 2h, and the finished product is obtained. The prepared carbon nanotube composite barium titanate wave absorbing nano-material is advantaged by light weight, wide wave absorbing frequency band and strong wave performances.

Owner:TIANJIN UNIV

Preparation method of barium sodium niobate cylindrical monocrystal particle

InactiveCN1493718ASimple processImprove efficiencyPolycrystalline material growthFrom solid stateCeramicCrystallite

A process for preparing the cylindrical monocrystal particles of sodium barium niobate by salt smelting method features that the raw materials (BaCO3 and Nb2O3) and the medium (NaCl) are used to synthesize said cylindrical monocrystal particles in the high-temp fused Na salt. Its advantages are high efficiency and high purity and reaction activity of said particles used to prepare the ceramics with texture structure.

Owner:SHANGHAI UNIV

Silicon calcium phosphate biomaterial, preparation method and uses thereof

ActiveCN103253932ASimple processLow costImpression capsDentistry preparationsCalcium biphosphateBone tissue

The invention relates to a silicon calcium phosphate biomaterial, a preparation method and uses thereof, wherein a soluble silicon source, a soluble phosphorus source and a soluble calcium source are adopted as raw materials, water is adopted as a solvent, a sol-gel method is adopted to synthesize pure phase silicon calcium phosphate (Ca5(PO4)2SiO4) powder, the silicon calcium phosphate powder is subjected to pressing forming and sintering to obtain silicon calcium phosphate (Ca5(PO4)2SiO4) ceramic blocks, the silicon calcium phosphate (Ca5(PO4)2SiO4) ceramic blocks are soaked in a simulated body fluid (SBF) for 1 day, a bone-like apatite layer is deposited on the surface of the ceramic, and a apatite layer thickness can be increased along with soaking time prolonging. The prepared silicon calcium phosphate (Ca5(PO4)2SiO4) material has good biology performances, is a potential biological and medical material, and can be used as a material for bone tissue repair and filling, and dental repair.

Owner:上海积力威尔生物科技合伙企业(有限合伙)

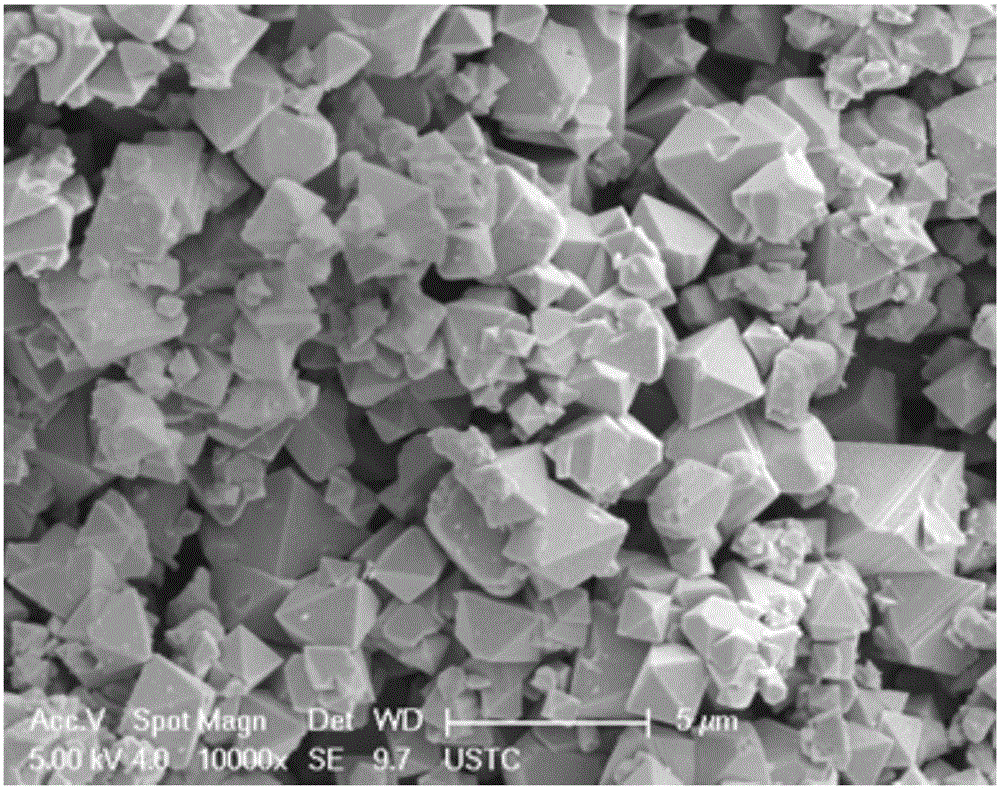

A kind of preparation method of composite material coating lithium nickel manganese oxide

ActiveCN105374997BPurePromote crystallizationCell electrodesSecondary cellsAir atmospherePolyethylene glycol

The invention discloses a preparation method for a nickel lithium manganate coated composite material. The preparation method comprises the following steps of adding a composite solution of a calcium salt, a zircon salt and a titanium salt into a pure-phase nickel lithium manganate precursor suspension liquid, simultaneously adding polyethylene glycol (PEG) as a dispersing agent and citric acid as a complexing agent, adjusting pH with ammonia water, carrying out mechanical stirring and constant-temperature waterbath reaction, taking out and ageing the composite solution, and carrying out filtering, washing and drying to obtain a Cao-ZrO2-TiO2 coated nickel lithium manganate precursor, wherein the composite solution is prepared from Li, Ca, Zr and Ti according to the ratio of 2:x:x:x, and x is equal to (0.01-0.1); and carrying out calcination and annealing processing in an air atmosphere to obtain the CaO-ZrO2-TiO2 coated nickel lithium manganate composite material. The material obtained according to the preparation method is pure in phase, well crystallization is achieved, the process is simple, continuous industrial production is easily realized, moreover, the initial discharging specific capacity at 0.2C reaches over 130mAh / g, and the cycle capacity retention rate at 0.2C after rate of 100 times is over 97%.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com