Method for preparing nickel lithium manganate having spinel structure by static mixer type reactor

A technology of tubular reactor and spinel structure, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of unfavorable large-scale production, large drying shrinkage, and high difficulty in industrialization, and achieve easy continuous industrial production, Effect of narrow particle size distribution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Configure a nickel sulfate solution with a concentration of 0.1mol / L and a manganese sulfate solution with a concentration of 0.1mol / L, and then mix them to make the solution A to be reacted. The molar ratio of nickel ions and manganese ions is required to be 1:3; Carbonate 0.2mol / L solution and ammonia solution are mixed to prepare solution B to be reacted;

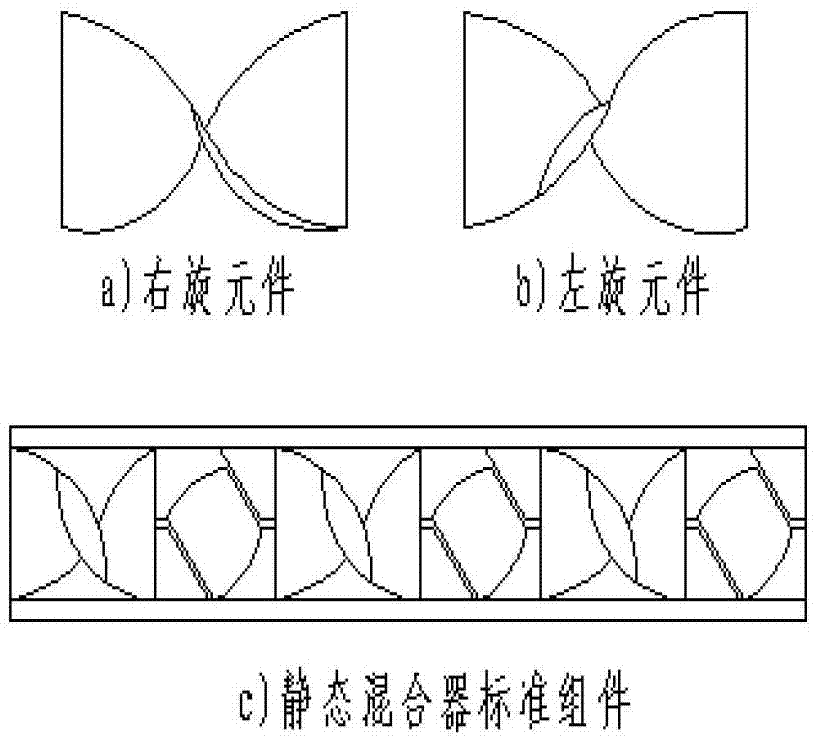

[0031] (2) Use two feeding pumps to inject solution A and B in step (1) from one end of the static mixing tube reactor at an equal volume flow rate of 1L / min, and carry out a mixing reaction to generate an emulsion. By adjusting the B solution The amount of ammonia water in the medium, the pH value in the reactor is controlled between 8.5~9.5;

[0032] (3) After aging the emulsion in step (2) for 2 hours, perform membrane washing to obtain a slurry solution for removing impurity ions;

[0033] (4) obtain nickel-manganese composite carbonate precursor powder after step (3) is removed the slurry liquid spray dr...

Embodiment 2

[0038] (1) Configure a nickel nitrate solution with a concentration of 0.5mol / L and a manganese nitrate solution with a concentration of 0.5mol / L, and then mix them to form the solution A to be reacted. The molar ratio of nickel ions and manganese ions is required to be 1:3; Ammonium carbonate 1mol / L solution and ammonia solution are mixed to make solution B to be reacted;

[0039] (2) Use two feeding pumps to inject solution A and B in step (1) from one end of the static mixing tubular reactor by 2.5L / min equal volume flow rate, carry out mixing reaction to generate emulsion, by adjusting B The amount of ammonia water in the solution, the pH value in the reactor is controlled between 9.0~10.0;

[0040] (3) After aging the emulsion in step (2) for 2 hours, perform membrane washing to obtain a slurry solution for removing impurity ions;

[0041] (4) obtain nickel-manganese composite carbonate precursor powder after step (3) is removed the slurry liquid spray drying of impurity...

Embodiment 3

[0046] (1) Configure a nickel chloride solution with a concentration of 1mol / L and a manganese chloride solution with a concentration of 1mol / L, and then mix them to form the solution A to be reacted. The molar ratio of nickel ions and manganese ions is required to be 1:3; Sodium bicarbonate 4mol / L solution and ammonia solution are mixed to make solution B to be reacted;

[0047] (2) Use two feeding pumps to inject solution A and B in step (1) from one end of the static mixing tube reactor by 5L / min equal volume flow, carry out mixing reaction to generate emulsion, and adjust B solution The amount of ammonia water in the medium, the pH value in the reactor is controlled between 9.5~10.5;

[0048] (3) After aging the emulsion in step (2) for 2 hours, perform membrane washing to obtain a slurry solution for removing impurity ions;

[0049] (4) obtain nickel-manganese composite carbonate precursor powder after step (3) is removed the slurry liquid spray drying of impurity ion; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com