A kind of preparation method of composite material coating lithium nickel manganese oxide

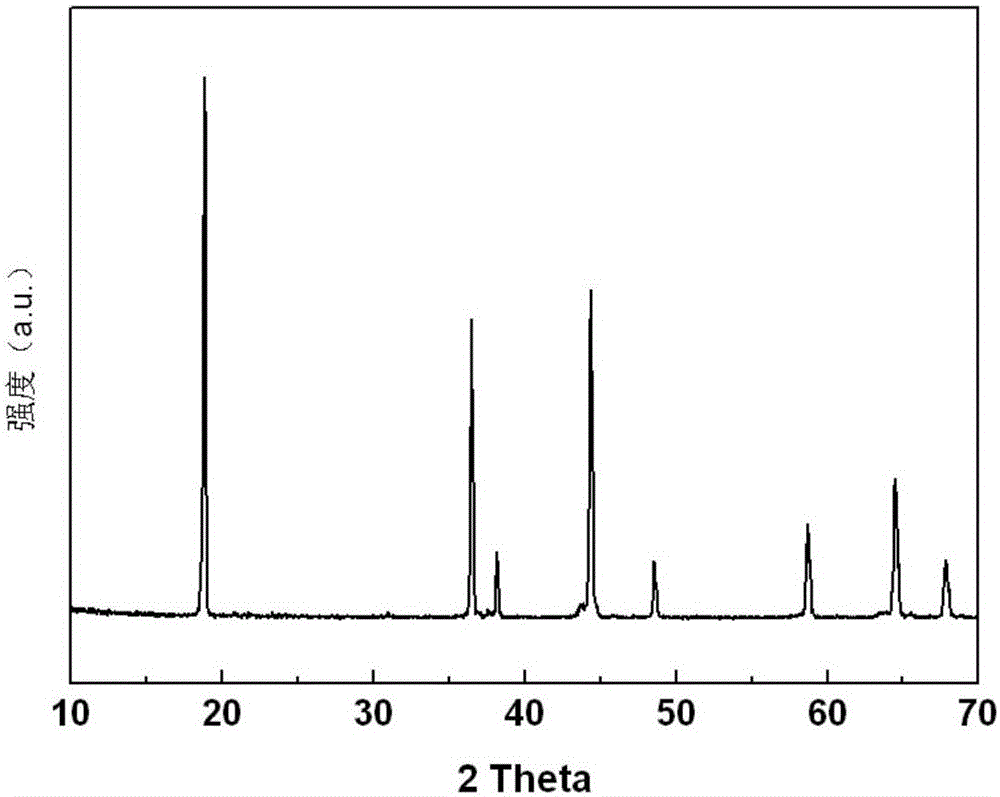

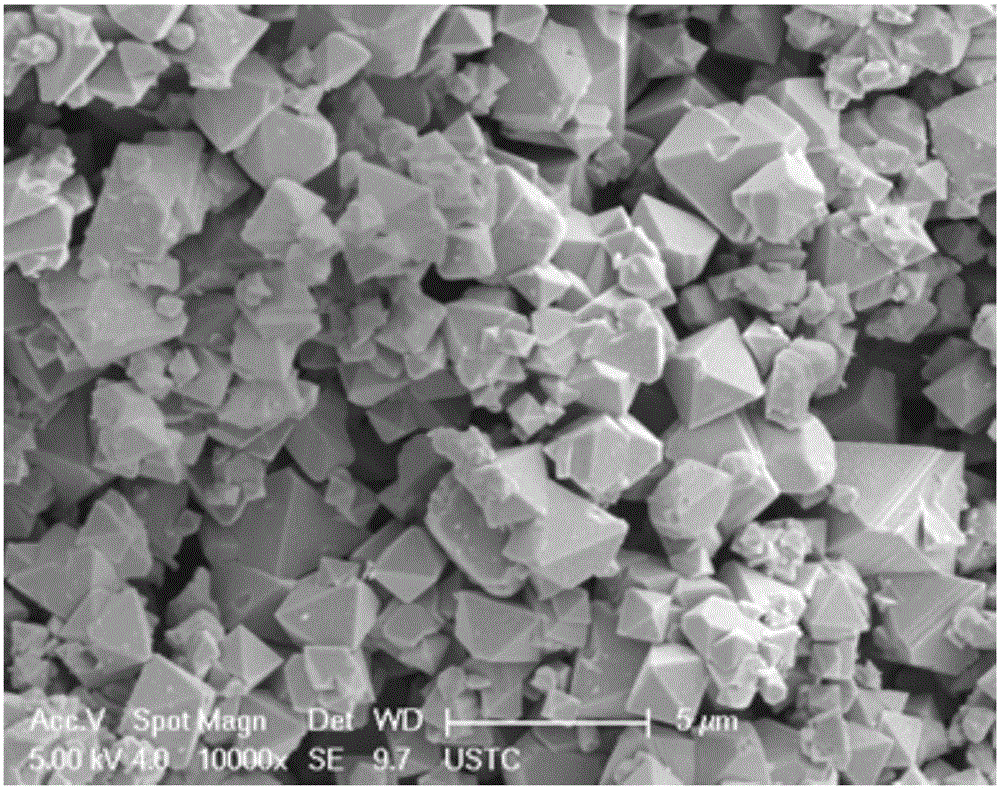

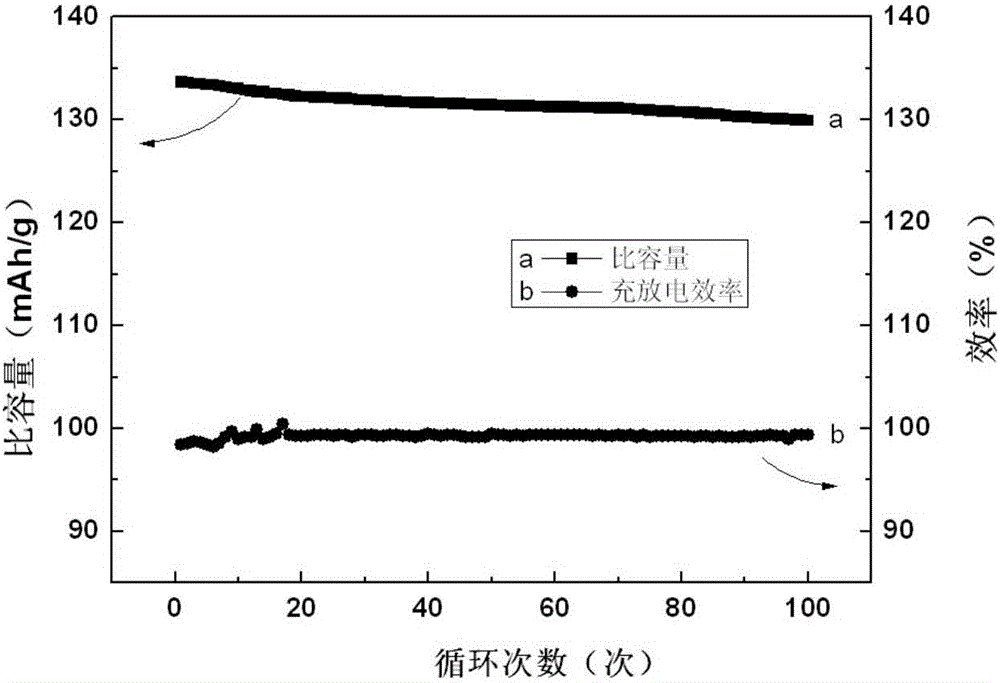

A technology of lithium nickel manganese oxide and composite materials, which is applied in the field of battery material preparation, can solve problems such as restricting battery performance, and achieve the effects of inhibiting the dissolution of manganese, good crystallization, and guaranteed capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of pure-phase lithium nickel manganese oxide precursor: Accurately weigh lithium carbonate, nickel sulfate, and manganese sulfate according to the Li:Ni:Mn element ratio of 2:1:3, and disperse them by ball milling with isopropanol for 1 h. The obtained slurry was vacuum-dried at 80°C, pre-fired in an air atmosphere of 400°C for 3 hours after grinding, cooled naturally, taken out, and ground to obtain a pure-phase lithium nickel manganese oxide precursor;

[0023] (2) ultrasonically disperse the pure-phase lithium nickel manganese oxide precursor in isopropanol, and stir to obtain the lithium nickel manganese oxide precursor suspension;

[0024] (3) According to Li: Ca: Zr: Ti = 2: 0.01: 0.01: 0.01, weigh calcium acetate, zirconium hydroxide, and tetrabutyl titanate, add them to the suspension of lithium nickel manganese oxide in step (2), add 1% PEG as dispersant and 1% citric acid complexing agent, add ammonia water dropwise to adjust pH to 9, stir mech...

Embodiment 2

[0028] (1) Preparation of pure-phase lithium nickel manganese oxide precursor: Accurately weigh lithium acetate, nickel nitrate, and manganese nitrate according to Li:Ni:Mn element ratio of 2:1:3, and disperse them by ball milling with absolute ethanol for 2 hours. The obtained slurry was vacuum-dried at 85°C, pre-fired in an air atmosphere of 450°C for 3.5 hours after grinding, cooled naturally, taken out, and ground to obtain a pure-phase lithium nickel manganese oxide precursor;

[0029] (2) ultrasonically disperse the pure-phase lithium nickel manganese oxide precursor in absolute ethanol, and stir to obtain the lithium nickel manganese oxide precursor suspension;

[0030] (3) By Li: Ca: Zr: Ti=2: 0.02: 0.02: 0.02, take calcium carbonate, zirconium nitrate, titanium tetrachloride, add in step (2) lithium nickel manganese oxide suspension, mass fraction is 2% PEG as a dispersant, 3% citric acid as a complexing agent, add ammonia water dropwise to adjust the pH to 9.2, mecha...

Embodiment 3

[0034] (1) Preparation of pure-phase lithium nickel manganese oxide precursor: Accurately weigh lithium nitrate, nickel chloride, and manganese nitrate according to Li:Ni:Mn element ratio of 2:1:3, and disperse them by ball milling with acetone for 3 hours to obtain The slurry was vacuum-dried at 90°C, pre-fired in an air atmosphere of 500°C for 4.5 hours after grinding, cooled naturally and then ground to obtain a pure-phase lithium nickel manganese oxide precursor;

[0035] (2) ultrasonically disperse the pure-phase lithium nickel manganese oxide precursor in acetone, and stir to obtain the lithium nickel manganese oxide precursor suspension;

[0036] (3) According to Li: Ca: Zr: Ti = 2: 0.03: 0.03: 0.03, weigh calcium oxalate, zirconium n-propoxide, and titanium tetrachloride, add them to the suspension of lithium nickel manganese oxide in step (2), add PEG with a mass fraction of 3% was used as a dispersant, citric acid with a mass fraction of 4% was used as a complexing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com