Silicon calcium phosphate biomaterial, preparation method and uses thereof

A technology of calcium silicophosphate and biological materials, which is applied in pharmaceutical formulations, dental preparations, press mold cups, etc., to achieve the effect of simple and easy process, pure phase and uniform material composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Mix 22.4 ml of tetraethyl orthosilicate with 4 ml of nitric acid at a concentration of 2 mol / L, add 9.6 ml of deionized water and 5.8 ml of absolute ethanol, stir at room temperature for 2 hours, then add 34.2 ml of phosphoric acid Triethyl ester, continue to stir for 2 hours, then add 118.1 grams of calcium nitrate tetrahydrate, and stir for 4 hours to obtain a silicon calcium phosphate sol; age the sol at 60°C for 48 hours to obtain a gel; put the gel at 120°C Dry for 120 hours to obtain xerogel;

[0067] (2) Grinding the xerogel into powder, calcining at 1400°C, the heating rate is 2°C / min, and the holding time at 1400°C is 6 hours to obtain silicon calcium phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder.

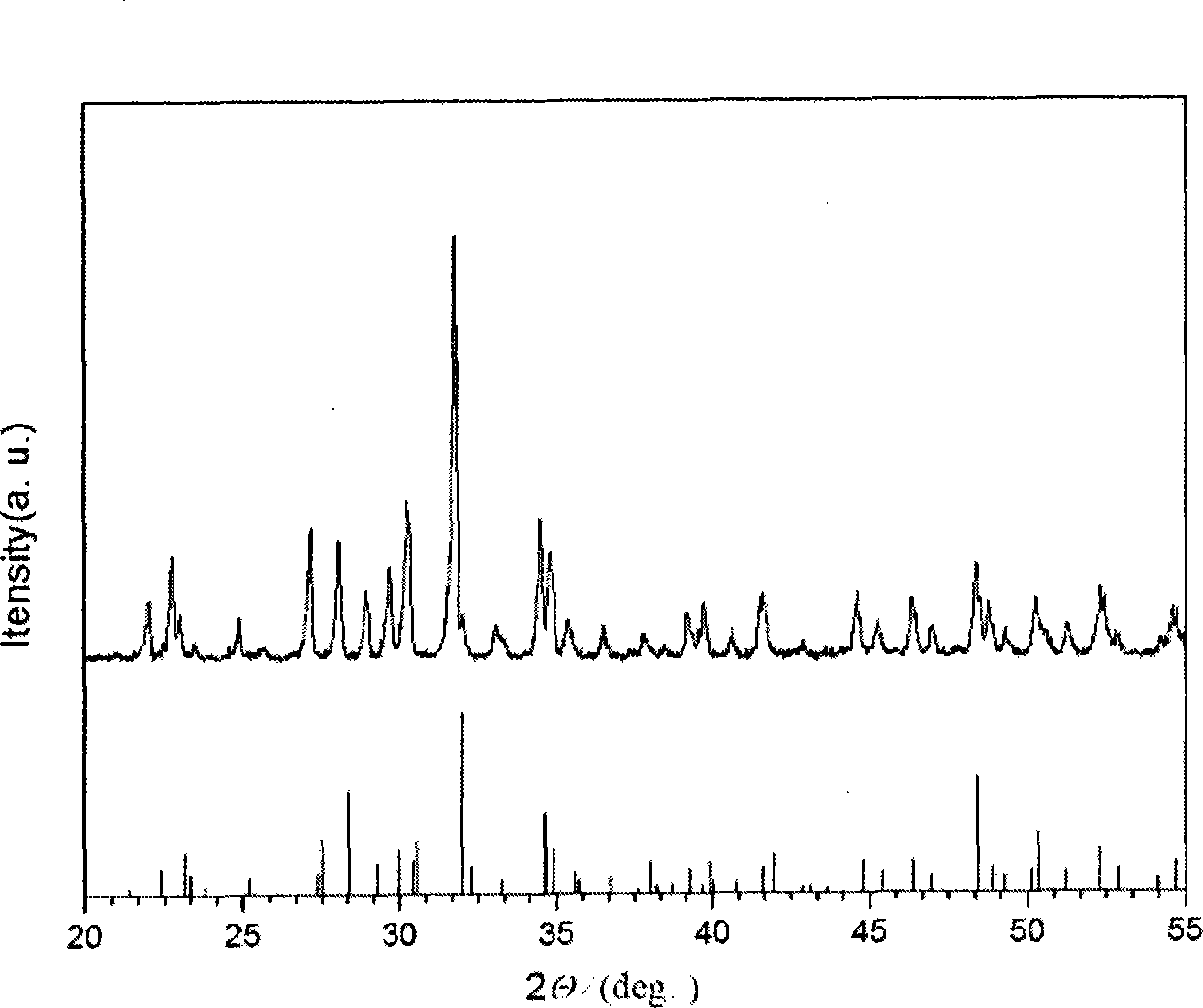

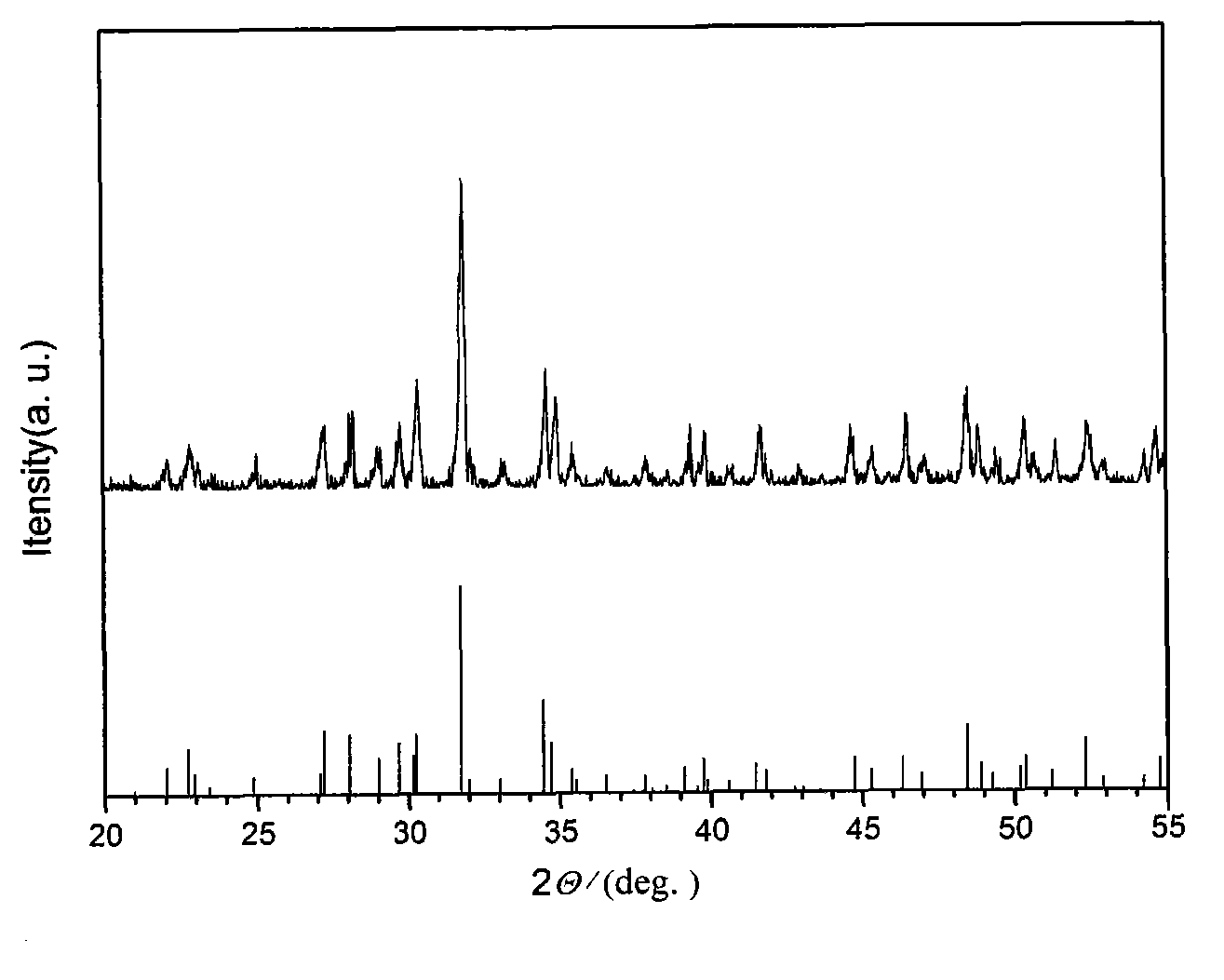

[0068] The prepared powder was subjected to XRD test, and the diffraction peak of the powder was related to Ca 5 (PO 4 ) 2 SiO 4 The standard card (PDF No.40-0393) coincides (such as figure 1 ), indicating that the crystal phase of the synthesized powder is ...

Embodiment 2

[0070] (1) Mix 44.8 milliliters of tetraethyl orthosilicate with 8 milliliters of nitric acid at a concentration of 2 mol / liter, add 19.2 milliliters of deionized water and 11.6 milliliters of absolute ethanol, stir at room temperature for 3 hours, then add 68.4 milliliters of phosphoric acid Triethyl ester, continue to stir for 4 hours, then add 236.2 grams of calcium nitrate tetrahydrate, and stir for 6 hours to obtain a silicon calcium phosphate sol; age the sol at 60°C for 72 hours to obtain a gel; put the gel at 120°C Dry for 168 hours to obtain xerogel;

[0071] (2) Grinding the xerogel into powder, calcining at 1400°C, the heating rate is 2°C / min, and the holding time at 1400°C is 6 hours to obtain silicon calcium phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder;

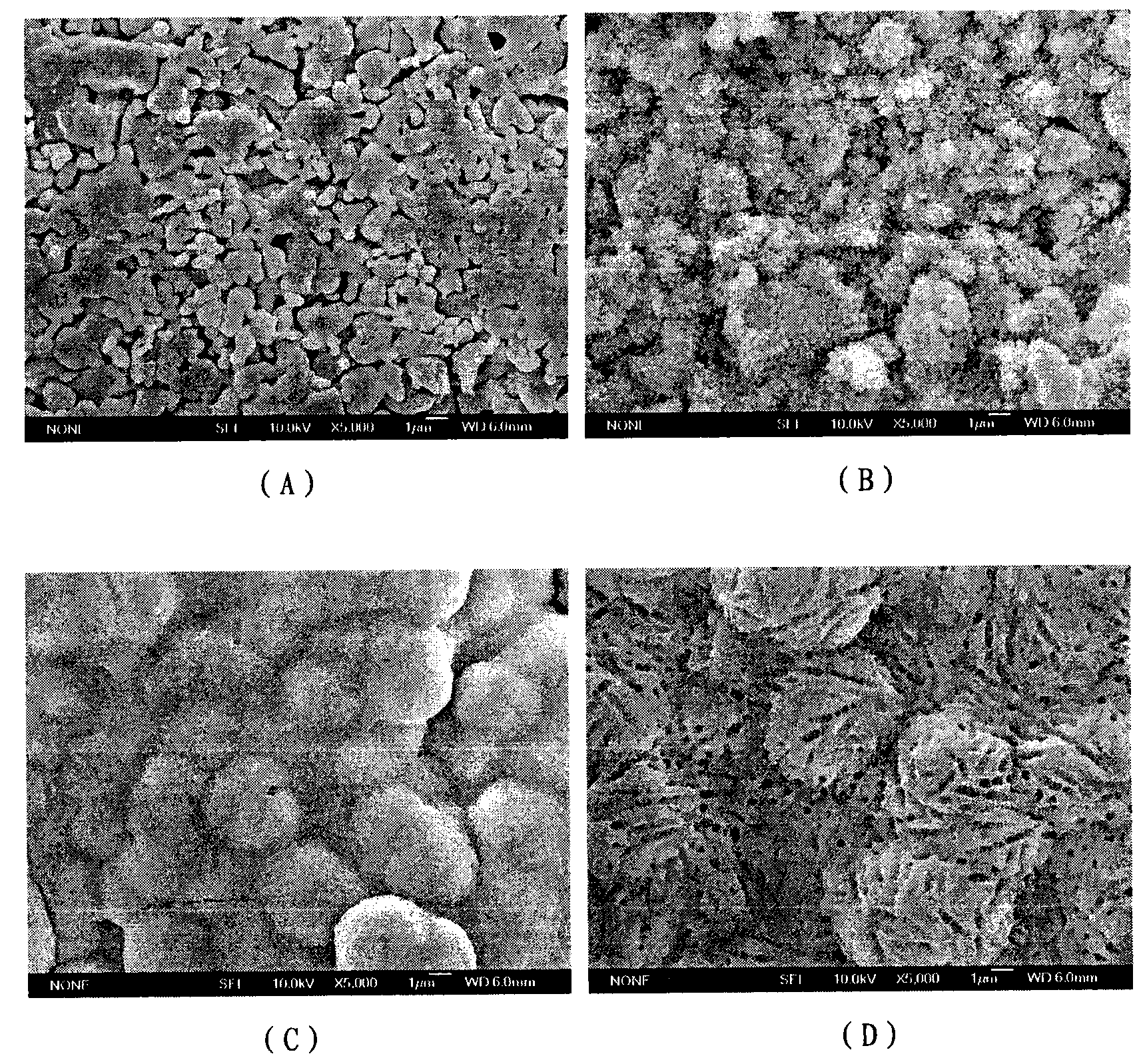

[0072] (3) Grind and sieve the calcium silicon phosphate powder, then weigh 0.2 gram of powder, and dry press it under 8 MPa to form a ceramic green body with a diameter of 10 mm and a thickness of 1 mm; place th...

Embodiment 3

[0075](1) Mix 44.8 milliliters of tetraethyl orthosilicate with 8 milliliters of nitric acid at a concentration of 2 mol / liter, add 19.2 milliliters of deionized water and 11.6 milliliters of absolute ethanol, stir at room temperature for 3 hours, then add 68.4 milliliters of phosphoric acid Triethyl ester, continue to stir for 4 hours, then add 236.2 grams of calcium nitrate tetrahydrate, and stir for 6 hours to obtain a silicon calcium phosphate sol; age the sol at 60°C for 72 hours to obtain a gel; put the gel at 120°C Dry for 168 hours to obtain xerogel;

[0076] (2) Grinding the xerogel into powder, calcining at 1400°C, the heating rate is 2°C / min, and the holding time at 1400°C is 6 hours to obtain silicon calcium phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder;

[0077] (3) Grinding and sieving the silicon calcium phosphate powder, and adding a polyvinyl alcohol aqueous solution with a concentration of 6wt% in the sieved powder, the addition quality of the polyvinyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com