Red long-afterglow phosphor material and its prepn process

A long afterglow phosphor, red technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of easy decomposition into miscellaneous phases, difficult to maintain the composition and structure of the matrix phase, and achieve uniform particle size distribution and low cost of raw materials. , Preparation technology for fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

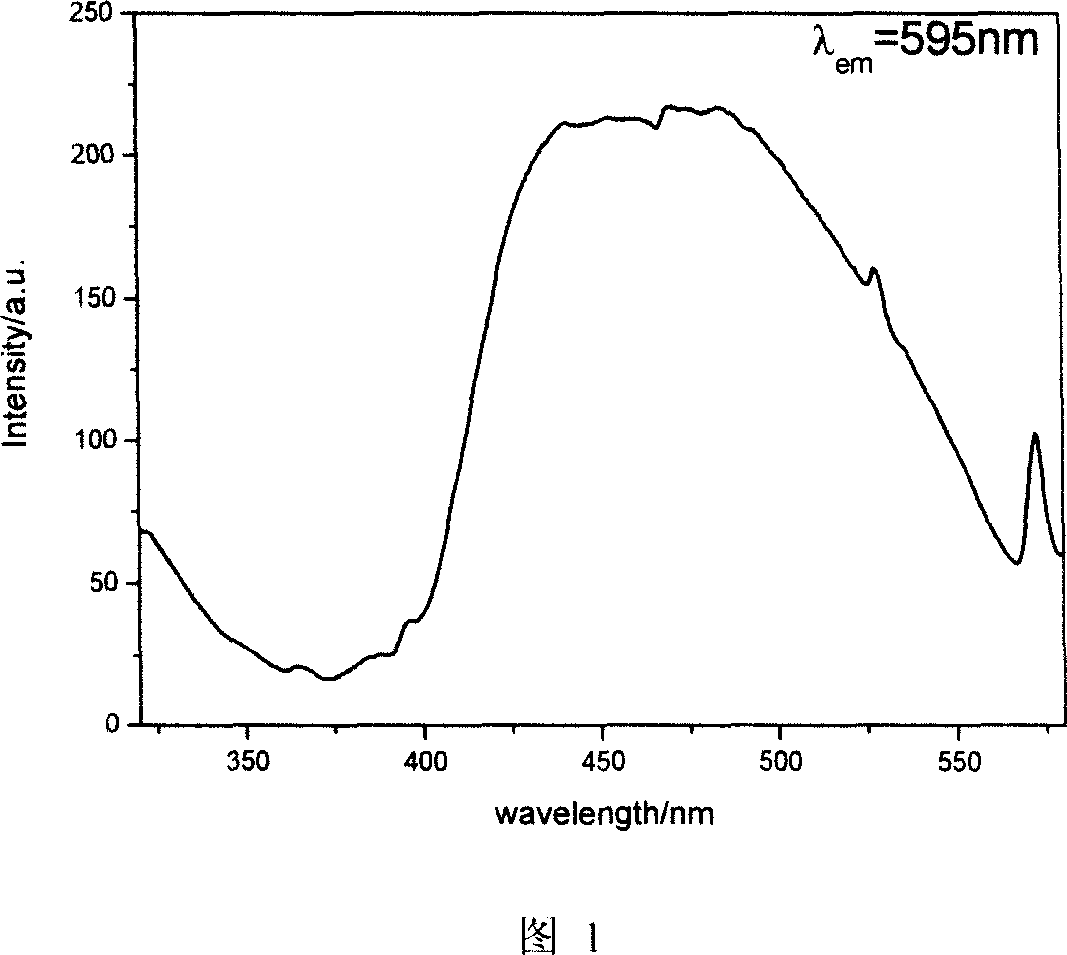

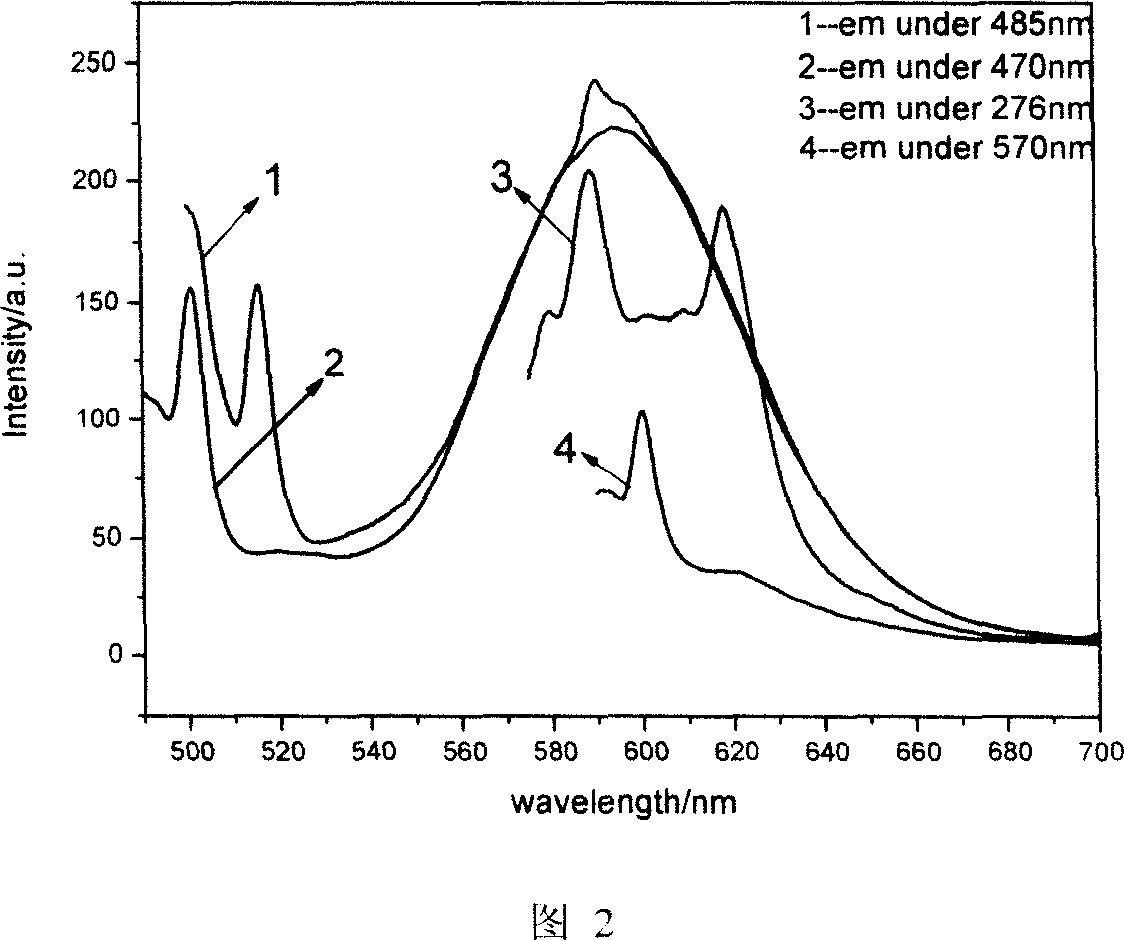

Image

Examples

preparation example Construction

[0011] The preparation steps of the red long-lasting phosphor material of the present invention include: preparation of rare earth composite sol, preparation of dry gel particles, and rapid microwave burning. According to the stoichiometric ratio, strontium (Sr), europium (Eu) and dysprosium (Dy) elements in the form of strontium nitrate, europium nitrate and dysprosium nitrate, all of which have a purity of 99.99%, are added to the nano pseudoboehmite sol together ; Add boric acid (H 3 BO 3 ), the amount is 0.1-1% of the total solid content added above. After mechanical stirring or ultrasonic dispersion, the rare earth composite sol is obtained; the composite sol is sprayed and granulated by hot air to obtain dry gel particles; the dry gel particles are burned in a microwave oven filled with a reducing atmosphere to obtain red long-lasting phosphors Material. in:

[0012] Nano pseudo-boehmite is based on the AlOOH phase, the size is 40nm-80nm, and the purity is 95%-97%. T...

example 1

[0017] According to the chemical formula Sr a Al b o 6 :cEu 2+ , dDy 3+ , get b=2, c=0.2, d=0.1, take by weighing the nano pseudo-boehmite (with AlOOH, purity 95%) powder of 100 grams of raw materials, weigh the corresponding Sr(NO 3 ) 2 (purity 99%), Eu(NO 3 ) 3 ·6H 2 O (purity 99.99%) and Dy (NO 3 ) 3 ·6H 2 O (purity 99.99%) and 1 gram of boric acid (H 3 BO 3 , purity 99%), put into the beaker together; Add deionized water according to the mass ratio of pseudo-boehmite: water=3%: 97%, mechanically stir; Be 30% dilute nitric acid solution dropwise with concentration, until pH = 2, continue stirring for 2 hours to obtain a rare earth composite sol. The rare earth composite sol is granulated by hot air spraying, the heating air temperature is 120°C, and the drying air volume is 80m 3 / h, the material flow is 2L / h, to obtain granular xerogel particles; the xerogel particles are packed in a 200ml corundum crucible and placed in a microwave oven, activated carbon par...

example 2

[0019] According to the chemical formula Sr a Al b o 6 :cEu 2+ , dDy 3+ , get b=2, c=0.1, d=0.0.05, take by weighing the nano pseudoboehmite (with AlOOH, purity 95%) powder of 100 grams of raw materials, weigh the corresponding Sr(NO 3 ) 2 (purity 99%), Eu(NO 3 ) 3 ·6H 2 O (purity 99.99%) and Dy (NO 3 ) 3 ·6H 2 O (purity 99.99%) and 0.5 grams of boric acid (H 3 BO 3 , purity 99%), put into a beaker together; Add deionized water according to the mass ratio of pseudo-boehmite: water=5%: 95%, mechanically stir; Be 30% dilute nitric acid solution dropwise with concentration, until pH = 1, continue stirring for 3 hours to obtain a thin composite sol. The rare earth composite sol is granulated by hot air spraying, the heating air temperature is 110°C, and the drying air volume is 100m 3 / h, the material flow is 3L / h, to obtain granular xerogel particles; the xerogel particles are packed in a 200ml corundum crucible and placed in a microwave oven, activated carbon parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com