Na4-3xEux(WO4)2-y(MoO4)y serial fluorescent microcrystal and chemical solution preparation method

A technology of chemical solutions and microcrystals, applied in chemical instruments and methods, solutions from normal temperature liquid solvents, single crystal growth, etc.

Inactive Publication Date: 2013-01-02

SICHUAN NORMAL UNIVERSITY

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to use a chemical solution method, that is, a hydrothermal synthesis method, to prepare a new type of tungstomolybdate solid solution fluorescent microcrystal, so as to solve the above-mentioned problems existing in existing phosphors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

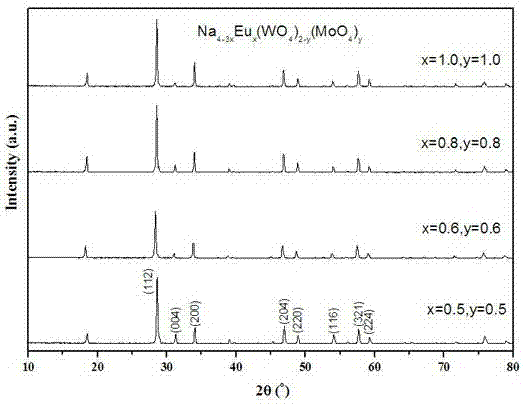

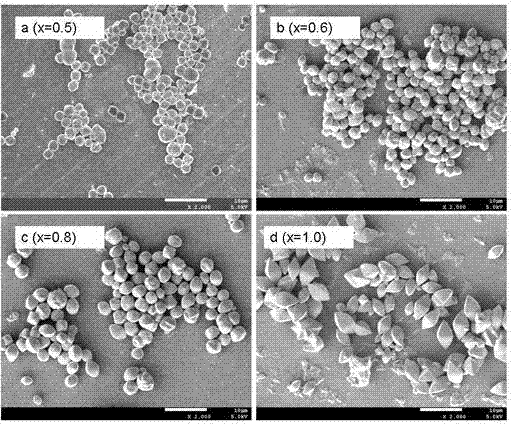

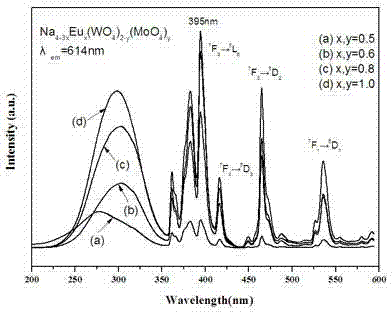

The invention relates to research of a novel composite tungsten molybdenate phosphor, and especially relates to a novel fluorescent microcrystal prepared by a chemical solution method. The microcrystal provided by the invention can be expressed by a general formula of Na4-3xEux(WO4)2-y(MoO4)y, wherein 0<x<4 / 3 and 0<y<2. The preparation method comprises the following steps: according to a molar ratio of raw materials required for the preparation of a certain amount of Na4-3xEux(WO4)2-y(MoO4)y, measuring corresponding volumes of Na2MoO4 and Na2WO4 solutions in a polytetrafluoroethylene beaker, respectively adding a corresponding amount of EuCl3 solution, stirring at normal temperature for 15-30 min, adjusting the pH to 6-9, and finally putting the polytetrafluoroethylene beaker into a high pressure reaction vessel; performing a hydrothermal reaction at 80-160 DEG C for 15-30 hours, naturally cooling to room temperature; centrifuging the precipitates for separation, washing with deionized water, and drying at 100-150 DEG C to obtain the Na4-3xEux(WO4)2-y(MoO4)y microcrystal. The preparation method of the invention is simple in preparation process, low in reaction temperature. The prepared tungsten molybdenate fluorescent microcrystal is pure in phase, uniform in granularity, appropriate in particle size, and regular in morphology, can exhibit red light with high purity and brightness, and has good practicality.

Description

technical field [0001] The invention relates to the research of a novel composite tungstomolybdate phosphor, in particular to the preparation of the novel fluorescent microcrystal by a chemical solution method. Background technique The unique 4f electron layer structure and rich energy levels of rare earth elements make them have spectral properties unmatched by general elements, and provide many luminescent materials and laser materials with superior performance for the national economy and high-tech. Rare earth luminescent materials have the advantages of strong absorption capacity, high conversion rate, can emit spectrum from ultraviolet to infrared, strong emission ability in the visible region, stable physical properties, etc., so they are widely used in lighting sources, color TVs, medical equipment, industrial transportation It has extremely important and extensive applications in many fields such as aviation, aerospace, national defense and military affairs. Whit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K11/78C30B29/32C30B7/10

Inventor 吴云高道江赖欣毕剑赵燕秦丹刘梦娇吴思

Owner SICHUAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com