Method for preparing tungsten trioxide/tungstic acid composite photocatalytic material through in-situ self growth

A composite photocatalysis and tungsten trioxide technology, applied in the field of photocatalytic materials, can solve the problems of uneven distribution and difficult control of the synthesis process, and achieve the effects of uniform distribution of components, pure phase, and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

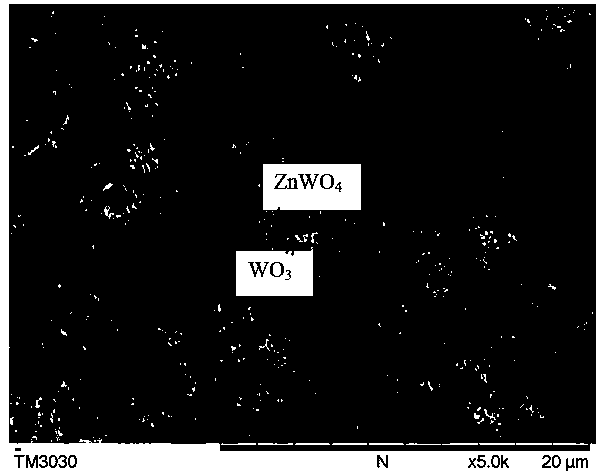

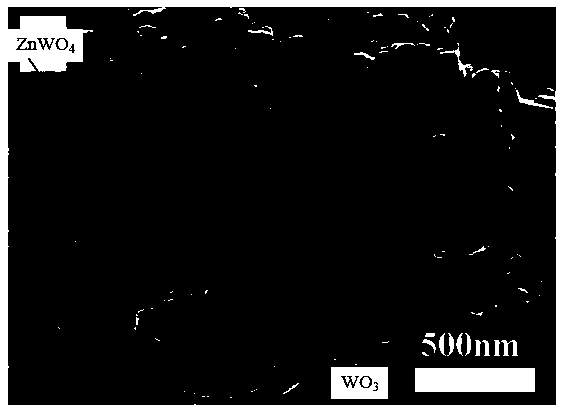

Image

Examples

Embodiment 1

[0023] The method for preparing tungsten trioxide / zinc tungstate composite photocatalytic material by in-situ self-growth, specifically according to the following steps:

[0024] Step 1, configure zinc chloride solution and sodium tungstate solution; dissolve zinc chloride in deionized water to prepare a zinc chloride solution with a concentration of 0.2mol / L, and dissolve sodium tungstate in deionized water to prepare Sodium tungstate solution with a concentration of 0.2mol / L;

[0025]Step 2. Add the zinc chloride solution into the reaction kettle, and add the surfactant polyvinylpyrrolidone. The concentration of polyvinylpyrrolidone in the zinc chloride solution is 0.1g / L. After stirring for 30 minutes, add it dropwise with the zinc chloride solution Equimolar sodium tungstate solution, closed reaction vessel, and carried out hydrothermal reaction, the temperature of hydrothermal reaction in the reaction kettle is 130°C, and the reaction time is 12h, to prepare ZnWO 4 Preci...

Embodiment 2

[0029] The method for preparing tungsten trioxide / zinc tungstate composite photocatalytic material by in-situ self-growth, specifically according to the following steps:

[0030] Step 1. Configure zinc acetate solution and ammonium metatungstate solution; dissolve zinc acetate in deionized water to prepare a zinc acetate solution with a concentration of 0.6mol / L, and dissolve ammonium metatungstate in deionized water to prepare a concentration of 0.6mol / L ammonium metatungstate solution;

[0031] Step 2, adding the zinc acetate solution to the reaction kettle, and adding the surfactant cetyltrimethylammonium bromide, the concentration of cetyltrimethylammonium bromide in the zinc acetate solution is 2.55g / L , after stirring for 45 minutes, add dropwise ammonium metatungstate solution equimolar to zinc acetate solution, seal the reaction vessel, and carry out hydrothermal reaction. 4 Precipitate, filter and dry to obtain ZnWO with a particle size of 65nm 4 For powder, the dry...

Embodiment 3

[0035] The method for preparing tungsten trioxide / zinc tungstate composite photocatalytic material by in-situ self-growth, specifically according to the following steps:

[0036] Step 1, configure zinc sulfate solution and ammonium metatungstate solution; dissolve zinc sulfate in deionized water to prepare a zinc sulfate solution with a concentration of 1mol / L, and dissolve ammonium metatungstate in deionized water to prepare a concentration of 1mol / L ammonium metatungstate solution;

[0037] Step 2. Add the zinc sulfate solution into the reaction kettle, and add the surfactant disodium edetate, the concentration of disodium edetate in the zinc sulfate solution is 5g / L, stir for 60 minutes and then add dropwise Equimolar ammonium metatungstate solution and zinc sulfate solution, sealed reaction vessel, and carried out hydrothermal reaction, the temperature of hydrothermal reaction in the reaction kettle is 200 ℃, the reaction time is 4h, to prepare ZnWO 4 Precipitate, filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com