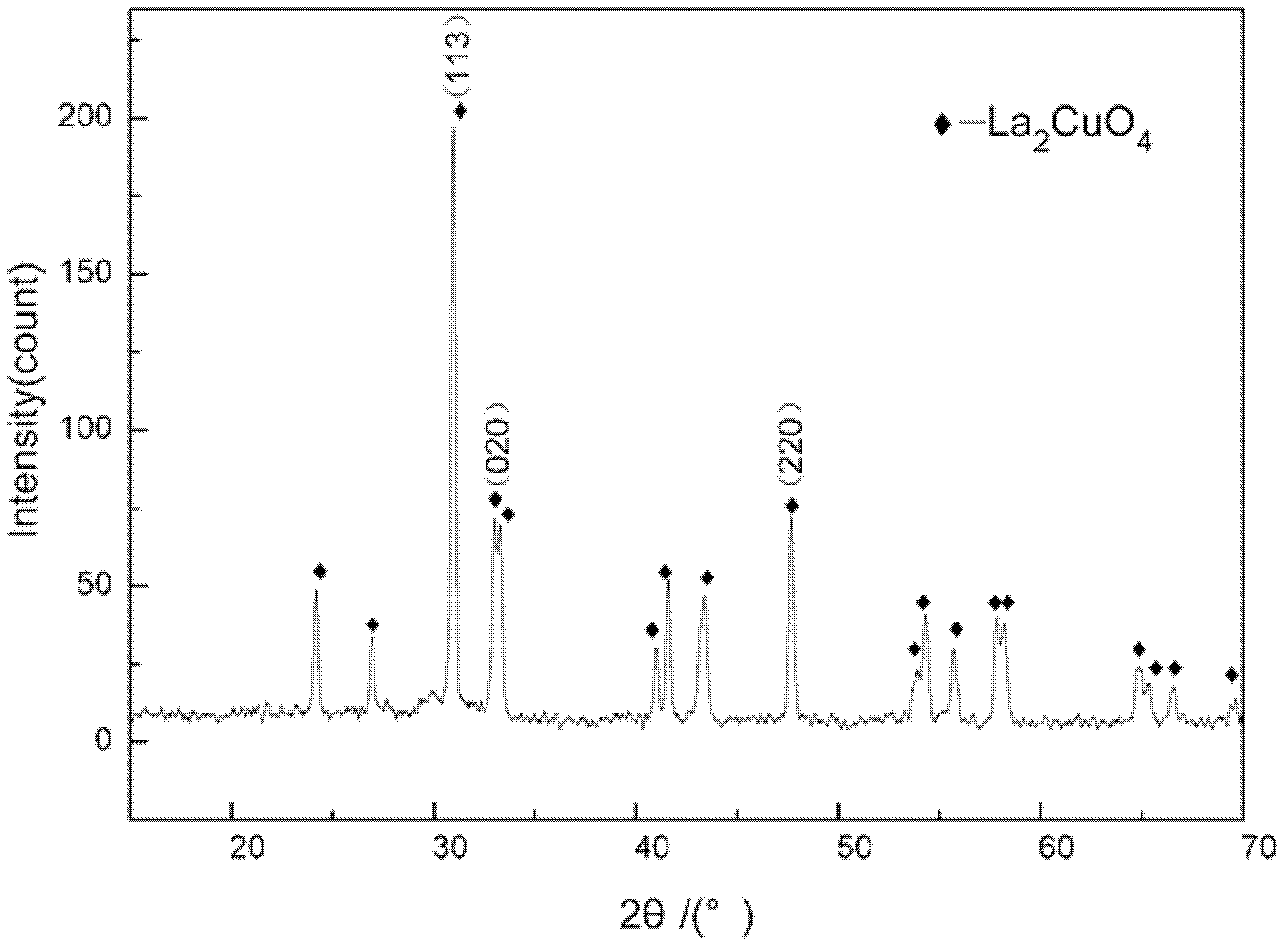

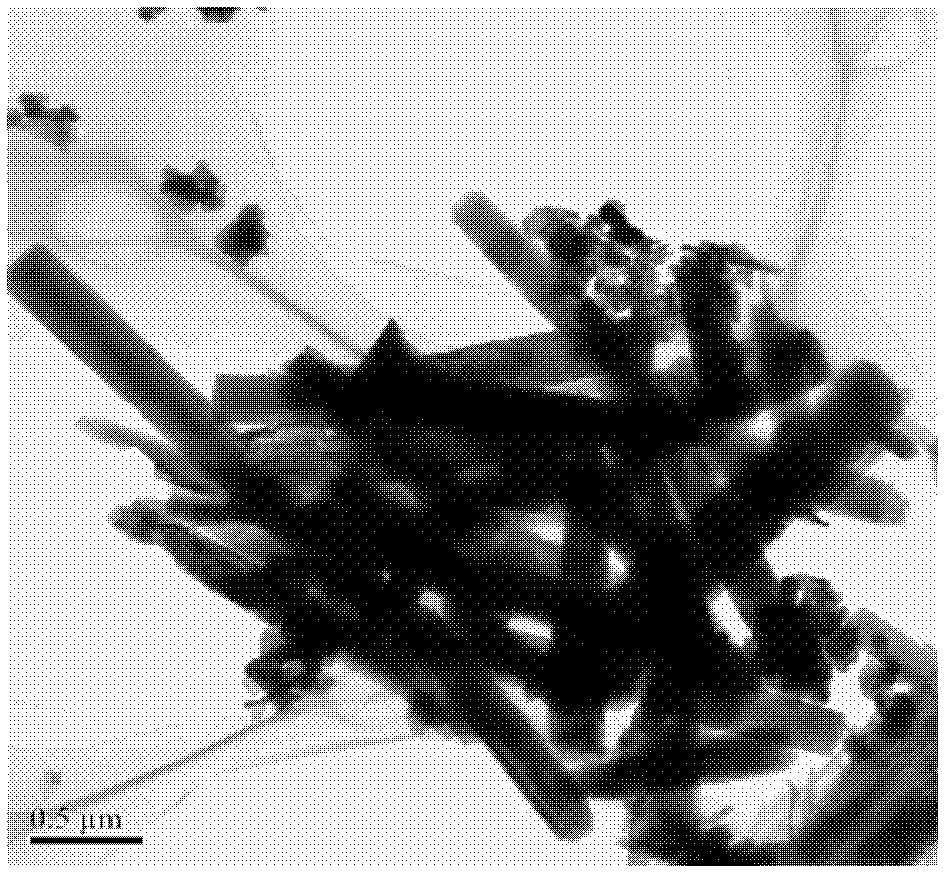

Method for preparing special-shaped lanthanum cuprate (La2CuO4) powder bodies by sol-gel method

A gel method, lanthanum cuprate technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve the problems of fast reaction process, long reaction period, and easy sintering of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Analytical pure lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and copper nitrate (Cu(NO 3 ) 3 ·3H 2 O) dissolve with deionized water, be mixed with the solution A that total metal ion concentration is 0.5mol / L;

[0019] 2) Add glycine to solution A at a molar ratio of 1.2:1 to the sum of glycine and metal ions, and then add lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and copper nitrate (Cu(NO 3 ) 3 ·3H 2 The total mass of O is 2% stearic acid as a dispersant, and urea is used to adjust pH=2.5, and stirred at a constant temperature of 80° C. to form a blue transparent solution B;

[0020] 3) The sol formed after the solution B was left to age for 10 hours was placed in a blast drying oven and dried at a constant temperature of 90°C to obtain a xerogel;

[0021] 4) Grind the dry gel into powder with a mortar, put it into a muffle furnace, raise the temperature from room temperature to 650 °C at a rate of 5 °C / min, keep it warm for 3 hours, cool down to room temperatur...

Embodiment 2

[0024] 1) Analytical pure lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and copper nitrate (Cu(NO 3 ) 3 ·3H 2 O) dissolve with deionized water, be mixed with the solution A that total metal ion concentration is 1mol / L;

[0025] 2) According to the molar ratio of the sum of glycine and metal ions being 2:1, add glycine to solution A and then add lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and copper nitrate (Cu(NO 3 ) 3 ·3H 2 The total mass of O is 3% of the dispersant EDTA, and urea is used to adjust the pH=3, and it is stirred at a constant temperature of 80° C. to form a blue transparent solution B;

[0026] 3) The sol formed after the solution B was left to age for 15 hours was placed in a blast drying oven and dried at a constant temperature of 100°C to obtain a xerogel;

[0027] 4) Grind the dry gel into powder with a mortar, put it into a muffle furnace, raise the temperature from room temperature to 700 °C at a rate of 5 °C / min, keep it warm for 2 hours, cool to room tem...

Embodiment 3

[0029] 1) Analytical pure lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and copper nitrate (Cu(NO 3 ) 3 ·3H 2 O) dissolve with deionized water, be mixed with the solution A that total metal ion concentration is 1.5mol / L;

[0030] 2) Add glycine to solution A at a molar ratio of 0.8:1 to the sum of glycine and metal ions, and then add lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and copper nitrate (Cu(NO 3 ) 3 ·3H 2 The total mass of O is 6% dispersant oxalic acid, and the pH is adjusted to 1.5 with urea, and stirred at a constant temperature of 50 ° C to form a blue transparent solution B;

[0031] 3) The sol formed after the solution B was allowed to stand and age for 2 hours was placed in a blast drying oven and dried at a constant temperature of 70°C to obtain a xerogel;

[0032] 4) Grind the dry gel into powder with a mortar, put it into a muffle furnace, raise the temperature from room temperature to 500 °C at a rate of 5 °C / min, keep it warm for 6 hours, cool down to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com