Calcium silicophosphate biomaterial, and preparation method and use thereof

A biological material, a technology of calcium silicophosphate, applied in the field of calcium silicophosphate biological material, calcium silicophosphate biological material and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (1) Mix 22.4 ml of tetraethyl orthosilicate with 4 ml of nitric acid at a concentration of 2 mol / L, add 9.6 ml of deionized water and 5.8 ml of absolute ethanol, stir at room temperature for 2 hours, then add 34.2 ml of phosphoric acid Triethyl ester, continue to stir for 2 hours, then add 118.1 grams of calcium nitrate tetrahydrate, and stir for 4 hours to obtain a silicon calcium phosphate sol; age the sol at 60°C for 48 hours to obtain a gel; put the gel at 120°C Dry for 120 hours to obtain xerogel;

[0075] (2) Grinding the xerogel into powder, calcining at 1400°C, the heating rate is 2°C / min, and the holding time at 1400°C is 6 hours to obtain silicon calcium phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder.

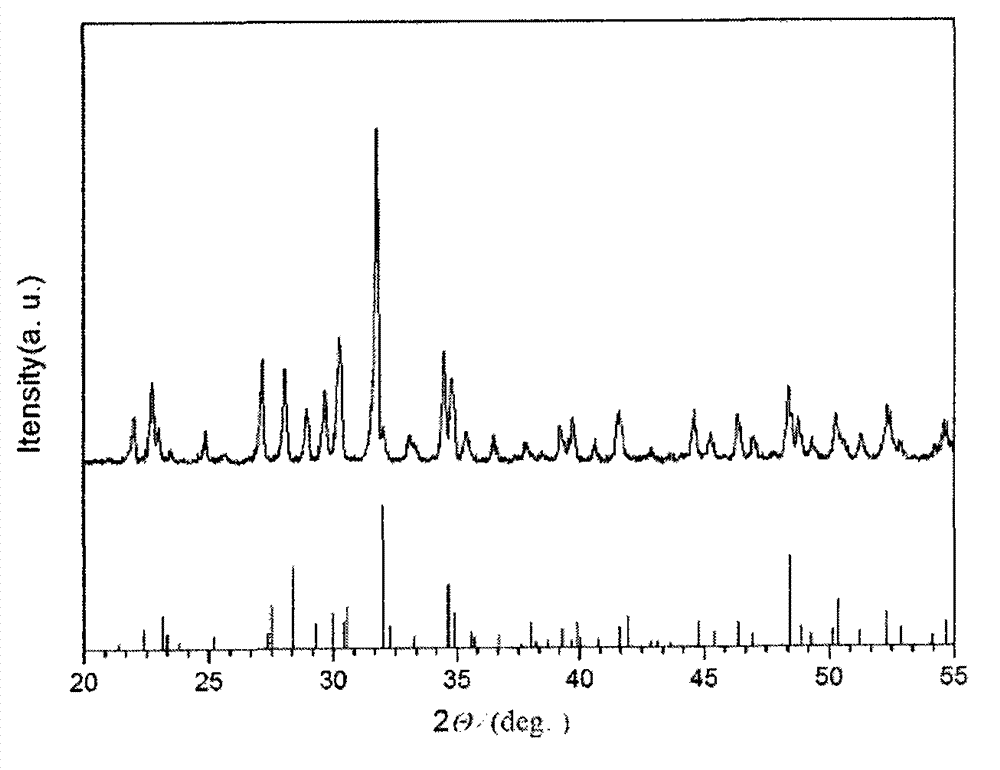

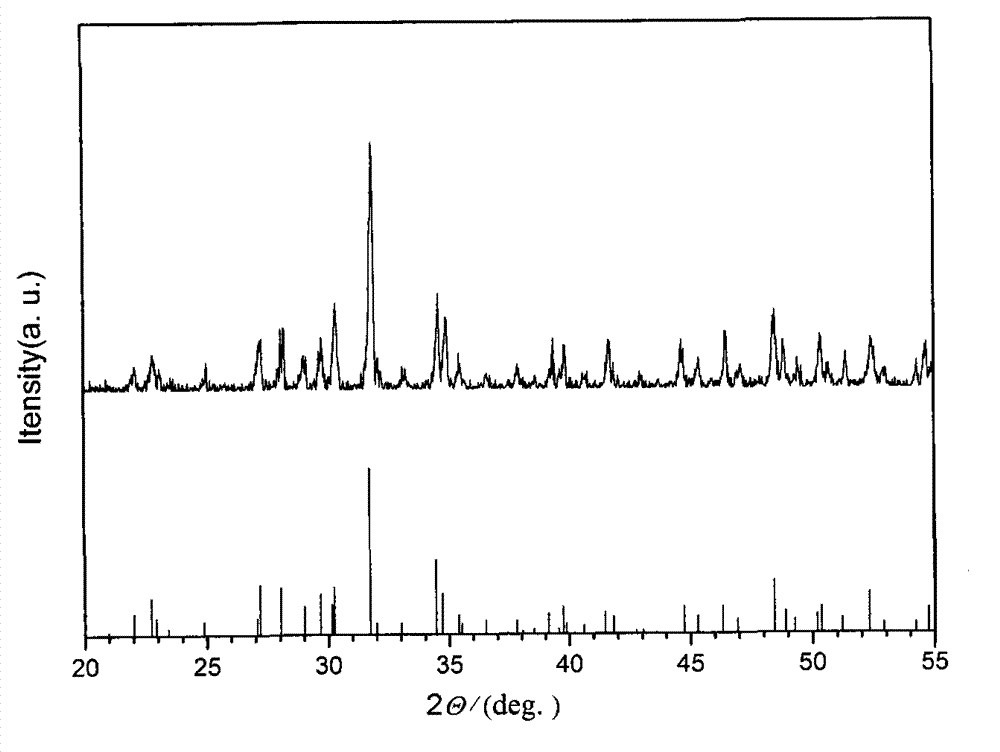

[0076] The prepared powder was subjected to XRD test, and the diffraction peak of the powder was related to Ca 5 (PO 4 ) 2 SiO 4 The standard card (PDF No.40-0393) coincides (such as figure 1 ), indicating that the crystal phase of the synthesized powder is ...

Embodiment 2

[0078] (1) Mix 44.8 milliliters of tetraethyl orthosilicate with 8 milliliters of nitric acid at a concentration of 2 mol / liter, add 19.2 milliliters of deionized water and 11.6 milliliters of absolute ethanol, stir at room temperature for 3 hours, then add 68.4 milliliters of phosphoric acid Triethyl ester, continue to stir for 4 hours, then add 236.2 grams of calcium nitrate tetrahydrate, and stir for 6 hours to obtain a silicon calcium phosphate sol; age the sol at 60°C for 72 hours to obtain a gel; put the gel at 120°C Dry for 168 hours to obtain xerogel;

[0079] (2) Grinding the xerogel into powder, calcining at 1400°C, the heating rate is 2°C / min, and the holding time at 1400°C is 6 hours to obtain silicon calcium phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder;

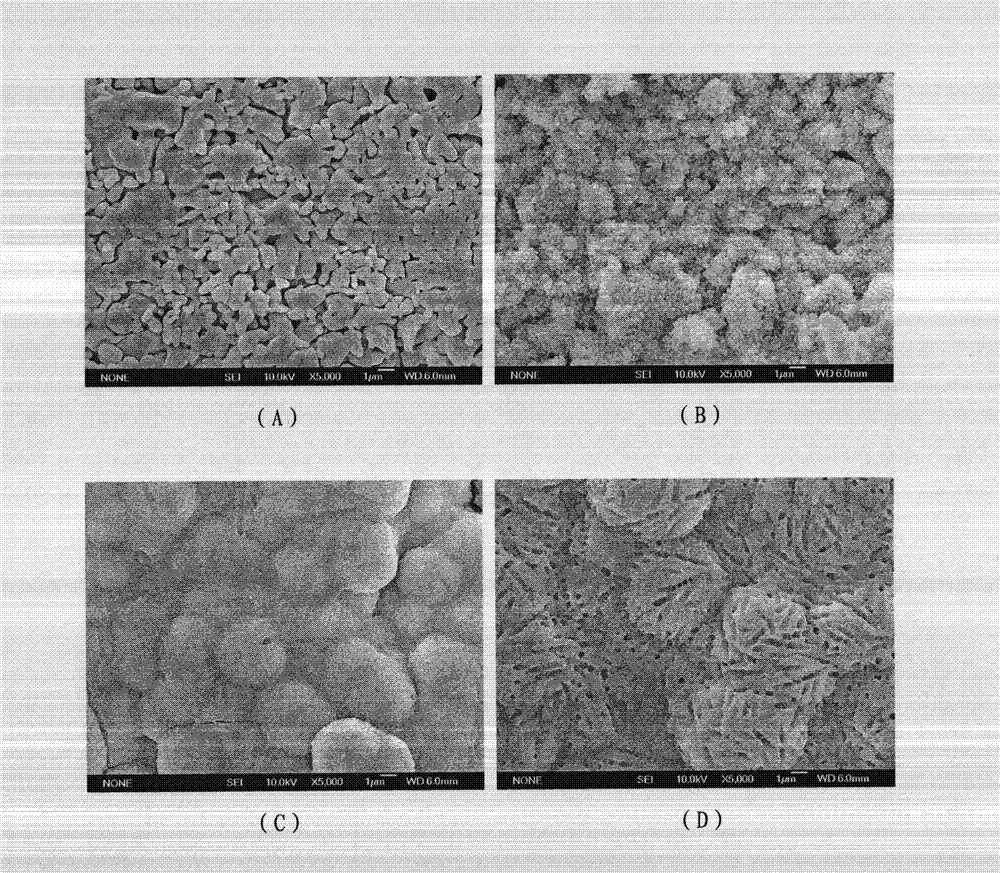

[0080] (3) Grind and sieve the calcium silicon phosphate powder, then weigh 0.2 gram of powder, and dry press it under 8 MPa to form a ceramic green body with a diameter of 10 mm and a thickness of 1 mm; place th...

Embodiment 3

[0083] (1) Mix 44.8 milliliters of tetraethyl orthosilicate with 8 milliliters of nitric acid at a concentration of 2 mol / liter, add 19.2 milliliters of deionized water and 11.6 milliliters of absolute ethanol, stir at room temperature for 3 hours, then add 68.4 milliliters of phosphoric acid Triethyl ester, continue to stir for 4 hours, then add 236.2 grams of calcium nitrate tetrahydrate, and stir for 6 hours to obtain a silicon calcium phosphate sol; age the sol at 60°C for 72 hours to obtain a gel; put the gel at 120°C Dry for 168 hours to obtain xerogel;

[0084] (2) Grinding the xerogel into powder, calcining at 1400°C, the heating rate is 2°C / min, and the holding time at 1400°C is 6 hours to obtain silicon calcium phosphate (Ca 5 (PO 4 ) 2 SiO 4 ) powder;

[0085] (3) Grinding and sieving the silicon calcium phosphate powder, and adding a polyvinyl alcohol aqueous solution with a concentration of 6wt% in the sieved powder, the addition quality of the polyvinyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com