Method for synthesizing lithium vanadate Li3VO4 monocrystal micrometer powder with high-temperature and high-pressure mixed solvent thermal system

A technology for synthesizing lithium vanadate and mixed solvents, which is applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., to achieve the effects of simplifying synthesis steps, easy control of product particle morphology, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

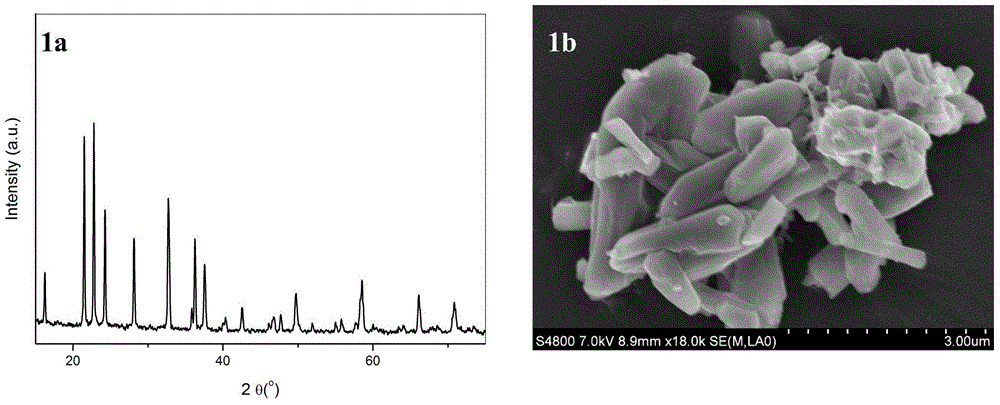

Embodiment 1

[0036] 1. Ingredients:

[0037] Mix 60ml of acetone and 40ml of ultrapure water evenly, mix 0.6651g of lithium carbonate and 0.5457g of vanadium pentoxide and disperse them in the above mixed solvent. Then join in the high-temperature and high-pressure reactor (volume is 250 milliliters) that has temperature measurement, pressure measurement device, seal.

[0038]2. Use high temperature and high pressure mixed solvent thermal system to implement constant temperature reaction:

[0039] Put the sealed reaction kettle into a muffle furnace, heat it to 280°C (the pressure inside the container reaches 9MPa), and keep the temperature constant for 2 hours.

[0040] 3. Cooling:

[0041] The reaction kettle was naturally cooled to room temperature (20° C. to 25° C.), and the reaction kettle was taken out from the muffle furnace.

[0042] 4. Washing:

[0043] The product was taken out from the reaction kettle, and the product was filtered through a vacuum filter (0.45 micron in aper...

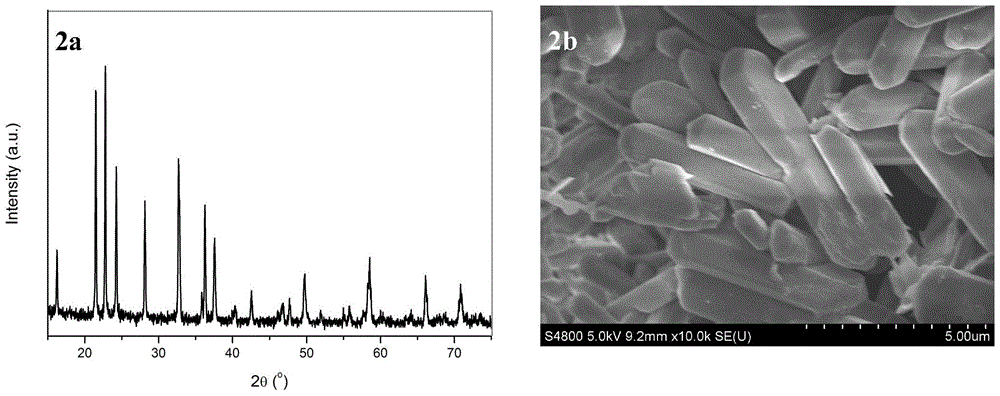

Embodiment 2

[0048] 1. Ingredients:

[0049] Mix 60ml of acetone and 40ml of ultrapure water evenly, mix 0.6651g of lithium carbonate and 0.5457g of vanadium pentoxide and disperse them in the above mixed solvent. Then join in the high-temperature and high-pressure reactor (volume is 250 milliliters) that has temperature measurement, pressure measurement device, seal.

[0050] 2. Use high temperature and high pressure mixed solvent thermal system to implement constant temperature reaction:

[0051] Put the sealed reaction vessel into a muffle furnace, heat it to 250°C (the pressure inside the vessel reaches 6.2MPa), and keep the temperature constant for 1 hour.

[0052] 3. Cooling:

[0053] The reaction kettle was naturally cooled to room temperature (20° C. to 25° C.), and the reaction kettle was taken out from the muffle furnace.

[0054] 4. Washing:

[0055] The product was taken out from the reaction kettle, and the product was filtered through a vacuum filter (0.45 micron in apert...

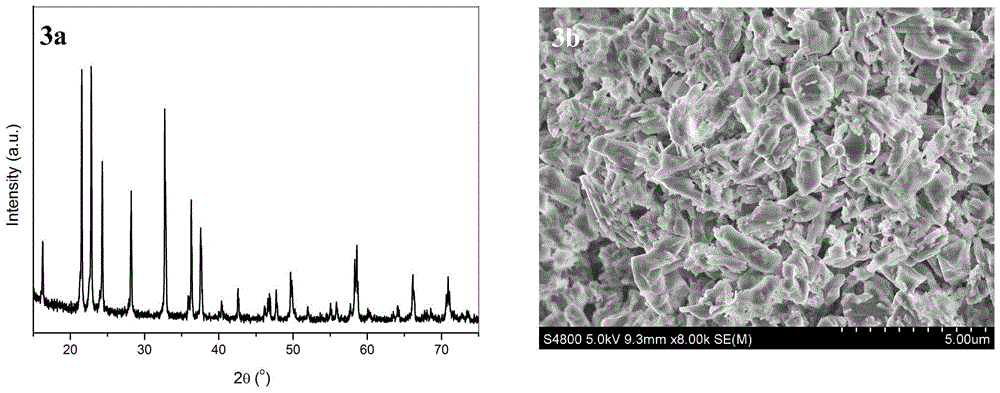

Embodiment 3

[0060] 1. Ingredients:

[0061] Mix 50ml of acetone and 50ml of ultrapure water evenly, mix 0.6651g of lithium carbonate and 0.5457g of vanadium pentoxide and disperse them in the above mixed solvent. Then join in the high-temperature and high-pressure reactor (volume is 250 milliliters) that has temperature measurement, pressure measurement device, seal.

[0062] 2. Use high temperature and high pressure mixed solvent thermal system to implement constant temperature reaction:

[0063] Put the sealed reaction kettle into a muffle furnace, heat it to 250°C (the pressure inside the container reaches 6MPa), and keep the temperature constant for 1 hour.

[0064] 3. Cooling:

[0065] The reaction kettle was naturally cooled to room temperature (20° C. to 25° C.), and the reaction kettle was taken out from the muffle furnace.

[0066] 4. Washing:

[0067] The product was taken out from the reaction kettle, and the product was filtered through a vacuum filter (0.22 micron in aper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com