Er3+/ Yb3+ co-doping calcium fluoraluminate green up-conversion luminescent material and preparation method thereof

A technology of calcium heterofluoroaluminate and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of poor thermal stability of fluoride, and achieve good thermal stability, strong tissue penetration ability, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

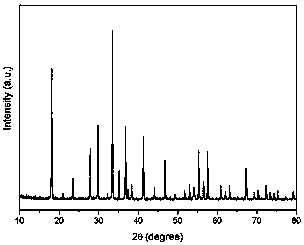

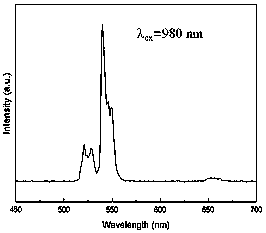

Image

Examples

example 1

[0023] (1) Weighing CaCO 3 (99.99%) 1.1771g, Al 2 o 3 (99.99%) 0.71372g, CaF 2 (99.99%) 0.07808g, Er 2 o 3 (99.99%)0.00459g, Yb 2 o 3 (99.99%) 0.04256g is placed in a mortar, grinds with ethanol as a dispersant, and grinds to make the raw materials fully mix and then dry;

[0024] (2) pre-burning the dried raw materials at 850°C for 2 hours, and then grinding for 1 hour;

[0025] (3) calcining the fully mixed raw materials at 1200° C. for 10 hours in an air atmosphere;

[0026] (4) After grinding, the Er excited by near-infrared light is obtained 3+ / Yb 3+ Co-doped calcium fluoroaluminate upconversion luminescent material (Ca 11.98 al 14 o 32 f 2 :Er 0.002 / Yb 0.018 )

Embodiment 2

[0028] (1) Weighing CaCO 3 (99.99%) 1.1963g, Al 2 o 3 (99.99%) 0.71372g, CaF 2 (99.99%) 0.07808g, Er 2 o 3 (99.99%)0.00459g, Yb 2 o 3 (99.99%) 0.047g is placed in a mortar, grinds with ethanol as a dispersant, and grinds to make the raw materials fully mix and then dry;

[0029] (2) pre-burning the dried raw materials at 900°C for 2 hours, and then grinding for 1 hour;

[0030] (3) calcining the fully mixed raw materials at 1250° C. for 6 hours in an air atmosphere;

[0031] (4) After grinding, the Er excited by near-infrared light is obtained 3+ / Yb 3+ Co-doped calcium fluoroaluminate upconversion luminescent material (Ca 11.996 al 14 o 32 f 2 :Er 0.002 / Yb 0.002 )

example 3

[0033] (1) Weighing CaCO 3 (99.99%) 2.3494g, Al 2 o 3 (99.99%) 1.42744g, CaF 2 (99.99%) 0.15616g, Er 2 o 3 (99.99%)0.00918g, Yb 2 o 3 (99.99%) 0.0946g is placed in a mortar and grinds with ethanol as a dispersant, and the grinding is drying after the raw materials are fully mixed;

[0034] (2) pre-burning the dried raw materials at 850°C for 2 hours, and then grinding for 1 hour;

[0035] (3) calcining the fully mixed raw materials at 1300° C. for 10 hours in an air atmosphere;

[0036] (4) After grinding, the Er excited by near-infrared light is obtained 3+ / Yb 3+ Co-doped calcium fluoroaluminate upconversion luminescent material (Ca 11.978 al 14 o 32 f 2 :Er 0.002 / Yb 0.02 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com