Polyanion compound KTi2(PO4)3, preparation of carbon coating thereof and application of product of polyanion compound KYi(PO4)3

A polyanion and compound technology, applied in the field of potassium ion battery materials, to achieve the effect of no impurities in the phase, low reaction temperature, and pure phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] polyanionic compound KTi 2 (PO 4 ) 3 The preparation steps are as follows:

[0031] 1) Weigh 0.5g of anatase titanium dioxide (TiO2) with an average particle size of 25nm 2 ), 0.5g potassium dihydrogen phosphate dihydrate (KH 2 PO 4 2H 2 O), measure volume 0.5mL85% phosphoric acid (H 3 PO 4 ), 0.5mL deionized water and thoroughly grind and mix well.

[0032] 2) Transfer the mixture obtained above to the liner of a polytetrafluoroethylene reactor, put it into a stainless steel shell, tighten it, and react in a constant temperature oven at 180-240°C for 24h.

[0033] 3) After cooling to room temperature, the product was collected by filtration, washed three times with ethanol and deionized water, and the obtained powder was vacuum-dried at 60°C for 12 hours to obtain KTi 2 (PO 4 ) 3 .

Embodiment 2

[0035] Carbon-encapsulated polyanionic compound KTi 2 (PO 4 ) 3 The preparation steps are as follows:

[0036] Get the dried KTi of Example 1 2 (PO 4 ) 3 Carry out high-energy planetary ball milling with a certain amount of sucrose (mass ratio 8:2) for 6-24 hours, and put the resultant into a tube furnace in an argon atmosphere for annealing at 300-600°C for 2-6 hours to obtain carbon coating KTi 2 (PO 4 ) 3 , KTi 2 (PO 4 ) 3 / C.

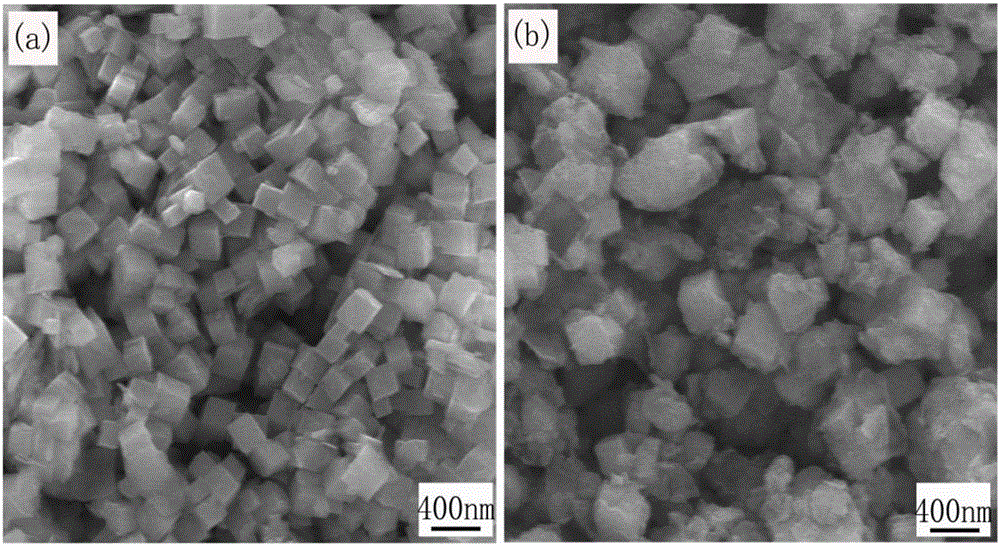

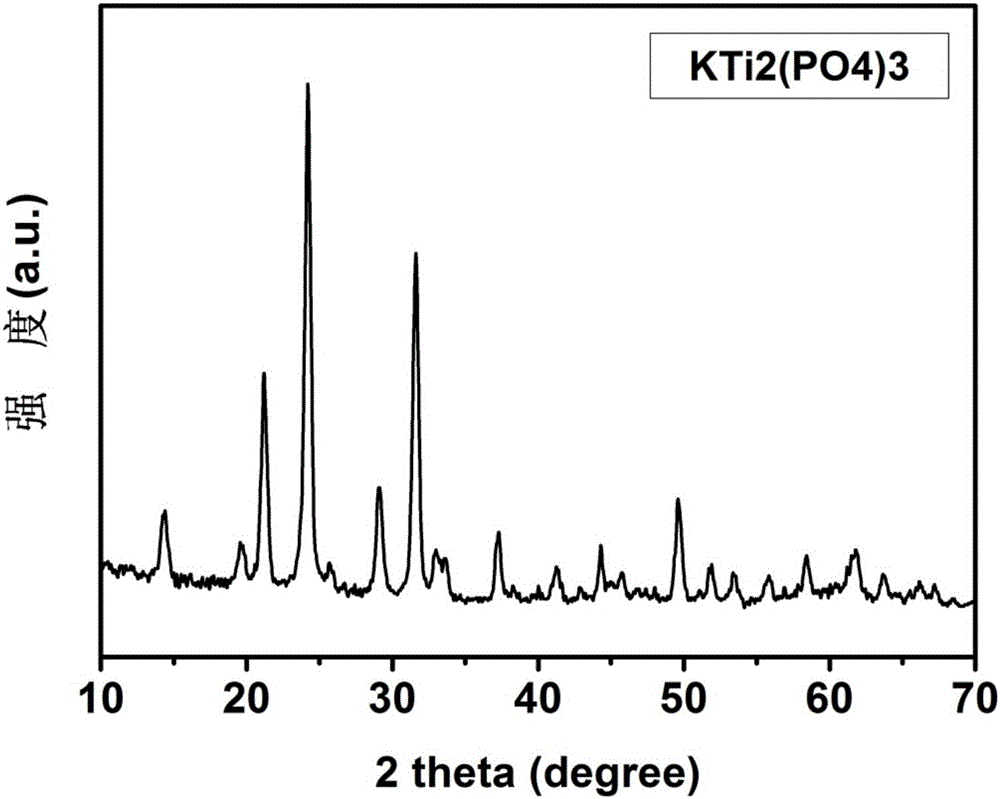

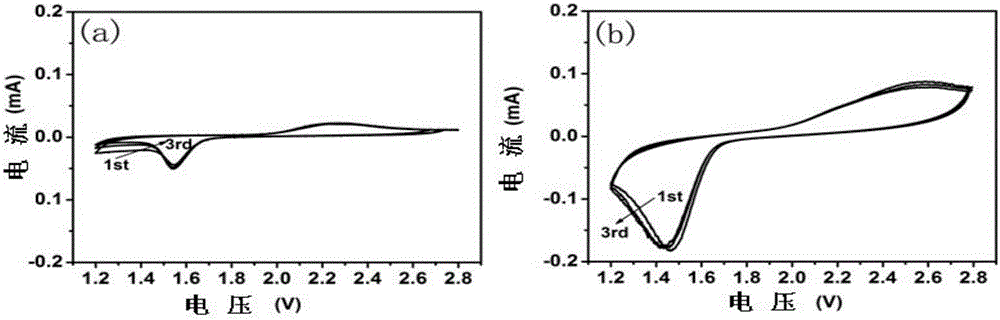

[0037] KTi prepared respectively by embodiment 1 and embodiment 2 2 (PO 4 ) 3 and KTi 2 (PO 4 ) 3 / C carries out electron microscope scanning to obtain such as figure 1 The scanning electron microscope picture shown, wherein (a) represents the KTi with nano-scale cubic structure 2 (PO 4 ) 3 The scanning electron microscope image; (b) shows the nano-scale cubic structure KT i2 (PO 4 ) 3 / C SEM image. Depend on figure 1 It can be seen that KTi 2 (PO 4 ) 3 The cubic structure is uniform in shape and has a small size, KT i2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com