Method for extracting selenium and tellurium from pyrometallurgy smelting soot

A technology of pyromelting and soot, applied in the direction of elements such as selenium/tellurium, which can solve the problems of harsh working environment, low direct recovery rate, and easy flying and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

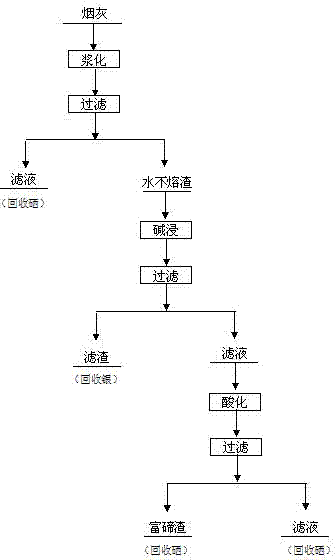

Image

Examples

Embodiment 1

[0016] Put 300kg of soot into the pulping tank, add water for pulping and dissolving, the liquid-solid ratio of water and soot is 4:1, raise the temperature to 75°C for stirring and pulping, react for 1 hour and then filter, the filtrate is selenous acid solution for reduction Extract crude selenium, add 3mol / L sodium hydroxide solution to the filter residue to leach selenium and tellurium, the liquid-solid ratio of sodium hydroxide solution to water-insoluble residue is 6:1, heat up to 80°C and stir, react for 2 hours, filter again, and the filtrate Add 10% dilute sulfuric acid, adjust the pH value to 5, stir, react for 1 hour to separate selenium and tellurium, filter, and reduce the filtrate to extract crude selenium. By calculation, the direct recovery rate of selenium is 95.08%, the direct recovery rate of tellurium is 81.2%, the selenium content of crude selenium after reduction is 95.12%, and the tellurium content of tellurium-rich slag is 52.48%.

Embodiment 2

[0018] Put 300kg of soot into the pulping tank, add water for pulping and dissolving, the liquid-solid ratio of water and soot is 5:1, heat up to 75°C for stirring and pulping, react for 0.5h and then filter, the filtrate is selenous acid solution, carry out Reductively extract crude selenium, add 4mol / L sodium hydroxide solution to the filter residue to leach selenium and tellurium, the liquid-solid ratio of sodium hydroxide solution to water-insoluble residue is 8:1, heat up to 80°C for stirring, react for 2 hours, filter again, and the filtrate Add 15% dilute sulfuric acid to the solution, adjust the pH value to 5.5, stir, react for 1 hour to separate selenium and tellurium, filter, and reduce the filtrate to extract crude selenium. By calculation, the direct recovery rate of selenium is 95.23%, the direct recovery rate of tellurium is 81.45%, the selenium content of crude selenium after reduction is 95.35%, and the tellurium-rich slag contains 53.25% tellurium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com