Patents

Literature

37results about How to "Reduced phenolic content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

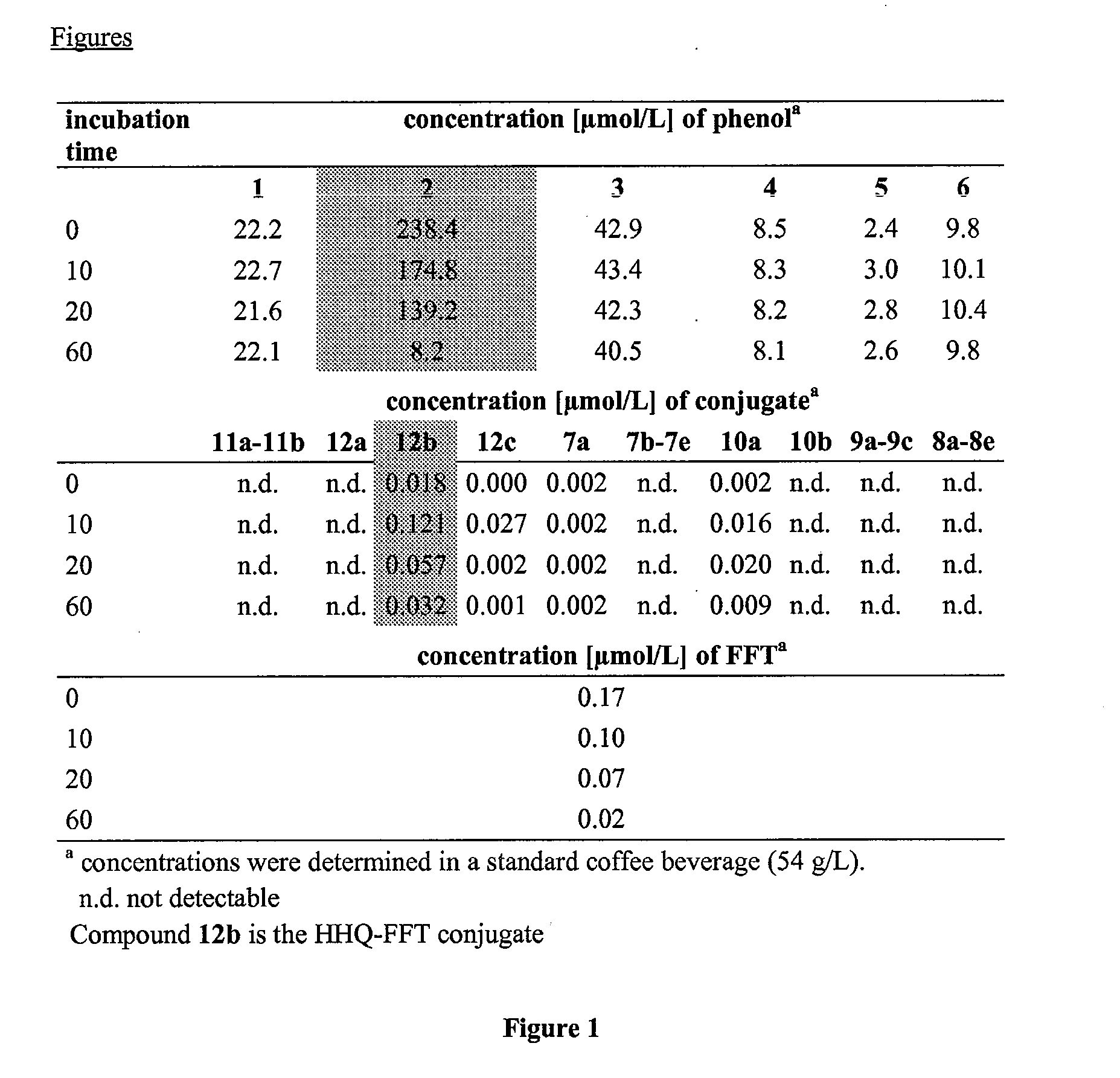

Aroma stabilizing method

InactiveUS20100040733A1Aroma stabilityReduce the amount requiredMilk preparationAlcoholic beverage preparationDecompositionPolyphenol

The present invention provides a method for stabilising the aroma of aroma-rich foodstuffs and their products by reducing the amount of phenols derived from decomposition of polyphenols contained therein. The invention also describes aroma-stabilized foodstuffs as well as their products having a desirable flavour.

Owner:NESTEC SA

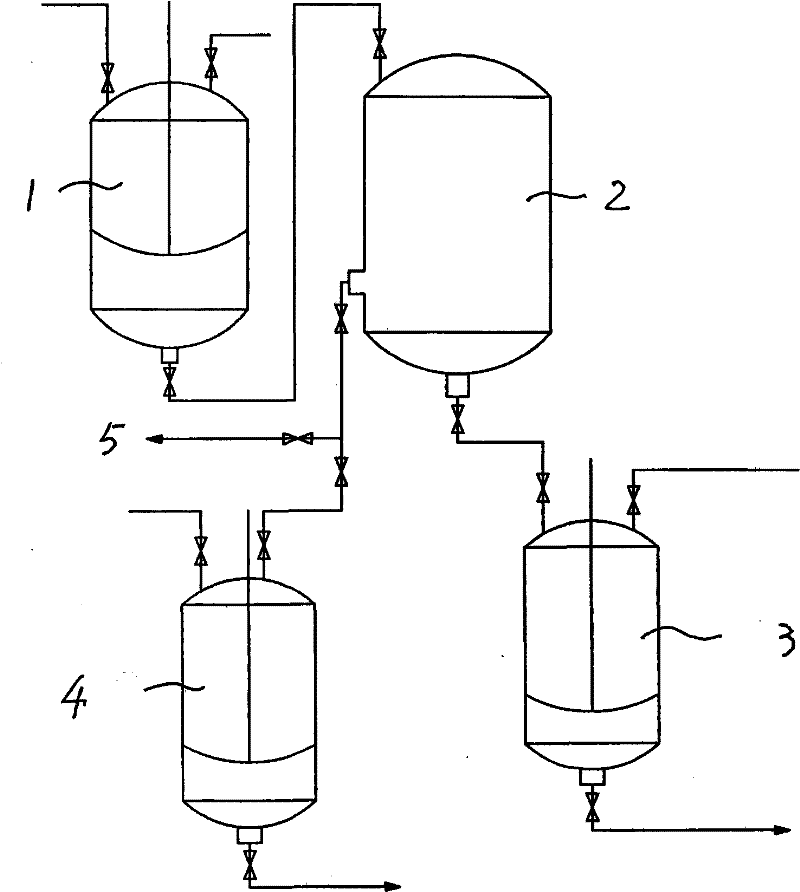

Comprehensive utilization method of phenolic resin wastewater

InactiveCN101906196AShort production processHigh yieldMultistage water/sewage treatmentCarbonyl compound separation/purificationFree phenolWater soluble

The invention discloses a comprehensive utilization method of phenolic resin wastewater, belonging to the technical field of processing wastewater produced in the fine chemical engineering industry. The comprehensive utilization method comprises the steps of: adding the phenolic resin wastewater, an acid catalyst and formaldehyde in a condensation polymerization kettle according to the proportion, raising the temperature until the phenolic resin wastewater, the acid catalyst and the formaldehyde are boiled, preserving temperature for reaction; then reducing the temperature in the kettle, pumping materials in the condensation polymerization kettle into a settlement separation kettle by using a pump to reduce the temperature and settle and demix; flowing a lower layer resin material of a settlement formed by demixing into a resin synthesis kettle through a pipeline, adding the acid catalyst and the formaldehyde, raising temperature and boiling for reaction, vacuum dewatering to obtain thermoplastic phenolic resin; and injecting one part of wastewater with content of the free phenol formed after the settlement formed in the condensation polymerization kettle, which is reduced to be below 1 percent, into a water borne resin synthesis kettle to be used for reducing water soluble resin, absorbing the formaldehyde in a primary and a secondary absorption towers one part of which is injected with industrial formaldehyde, and forming the industrial formaldehyde. The invention realizes the purpose that the phenolic resin industrial wastewater achieves zero emission.

Owner:河北泽田化工有限公司

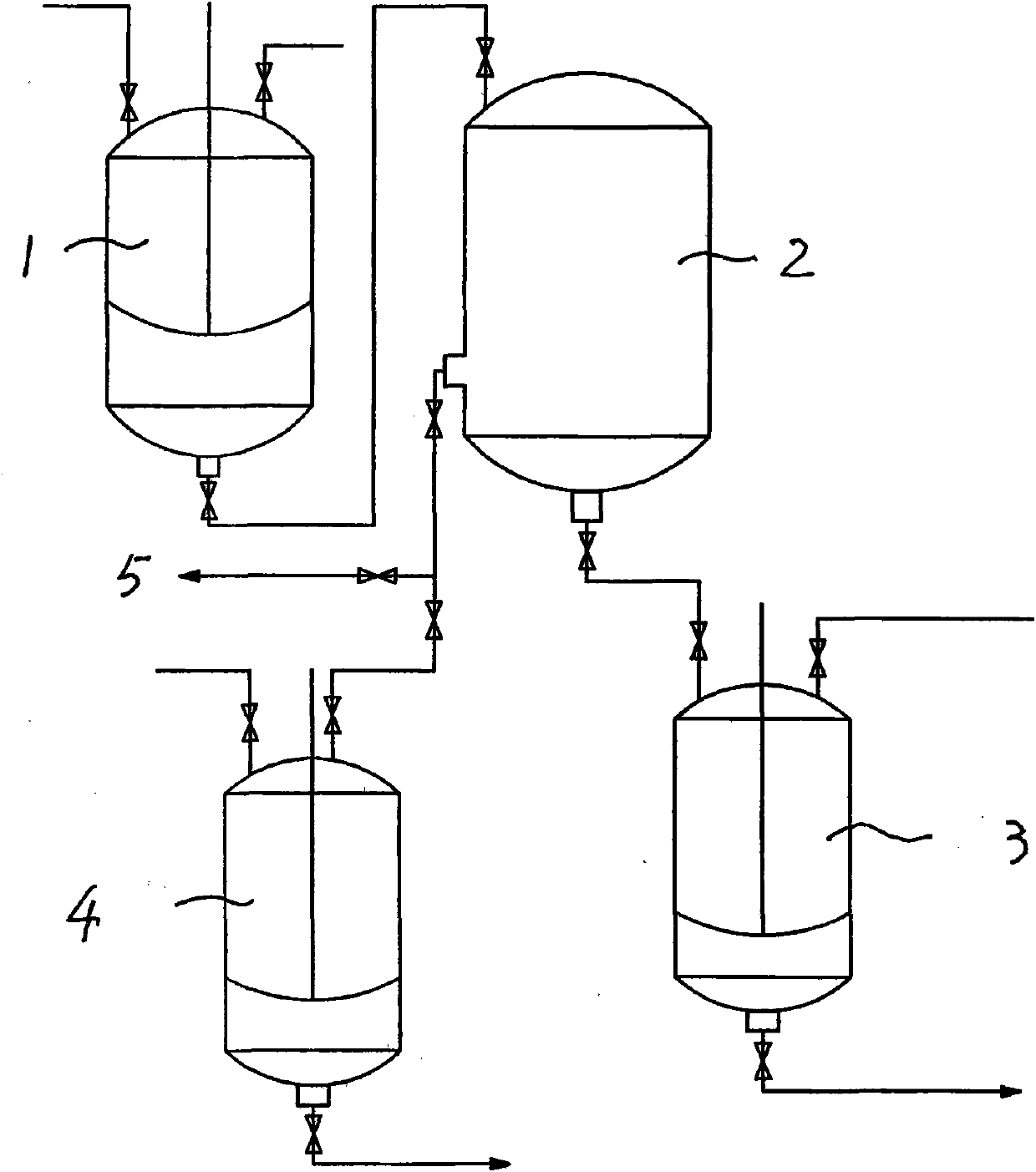

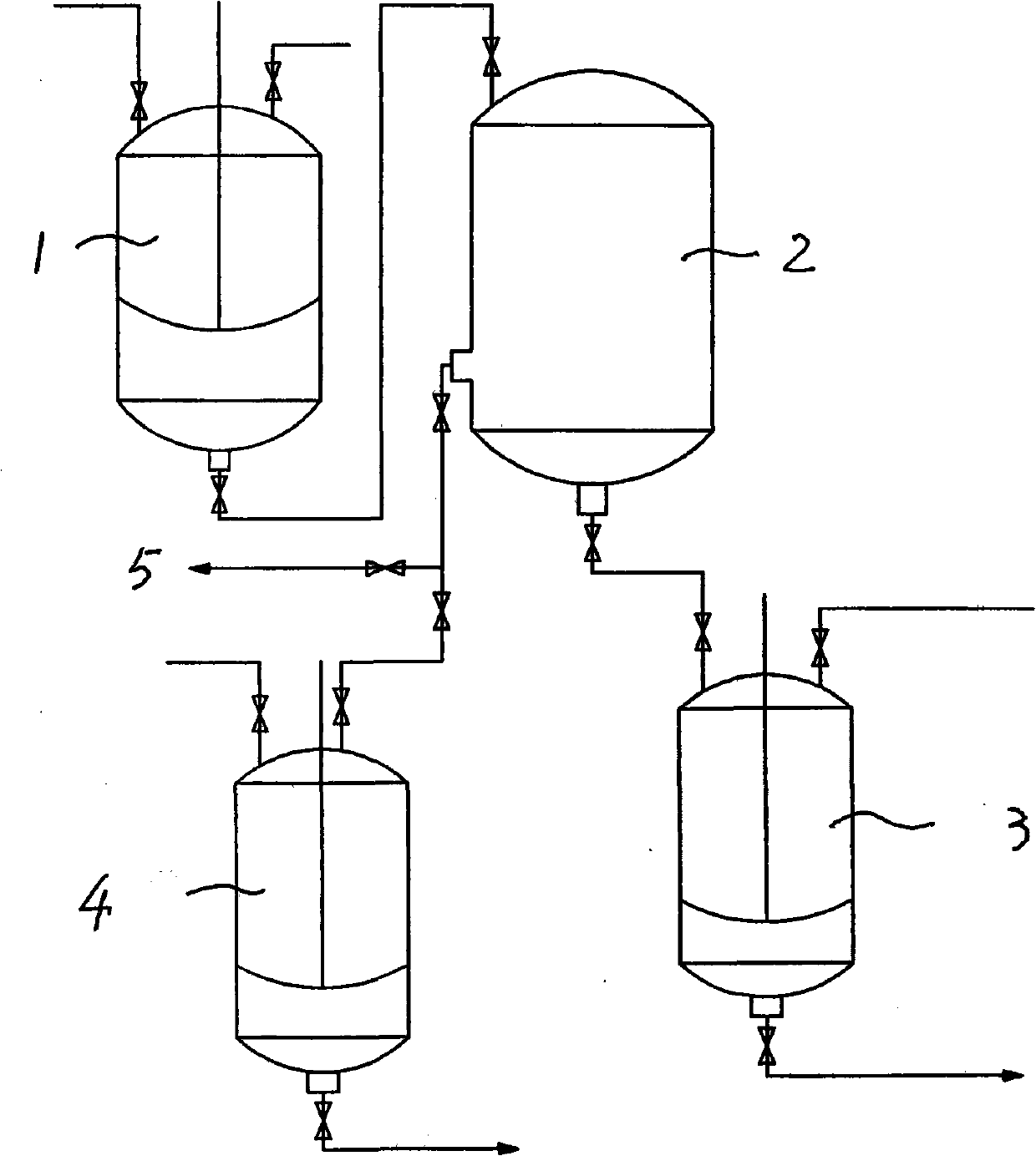

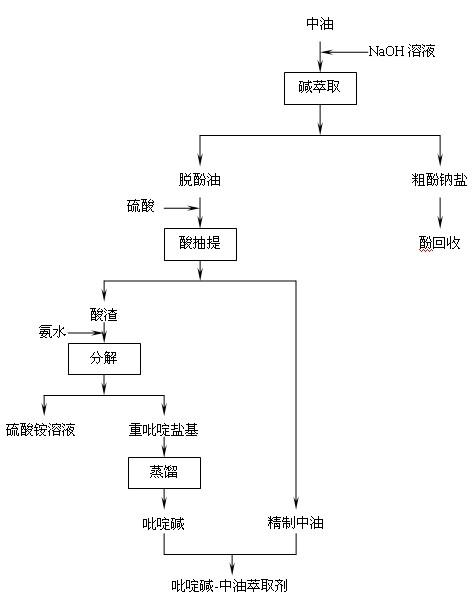

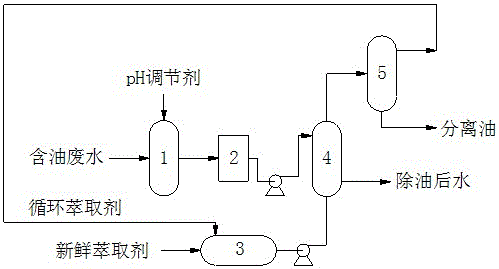

Oil dephenolizing extractant in brown coal tar, and preparation method and application thereof

InactiveCN102351270AReduce lossMeet the requirements of industrial recyclingWater contaminantsLiquid solutions solvent extractionHigh concentrationLiquid waste

The invention discloses a preparation method of an oil dephenolizing extractant in brown coal tar, which not only can realize recycling comprehensive utilization of oil in the brown coal tar, but also can recover phenolic materials to provide basic production raw materials for organic chemical industry production. The method comprises the following steps of: carrying out alkali wash refining and acid wash refining on oil in the brown coal tar by using an NaOH solution and sulfuric acid to generate refined medium oil, and then carrying out chemical decomposition on acid sludge subjected to acid washing by using an ammonia water solution to separate out crude pyridine liquor; distilling the crude pyridine liquor to obtain pyridine base; and at last, adding pyridine base fraction into the refined medium oil according to proportion to obtain the oil dephenolizing extractant in brown coal tar. The oil dephenolizing extractant is used for processing high concentration waste water containing phenol, wherein the dephenolizing efficiency reaches 95% and the dephenolized extractant is carried out with reextraction for regenerating by using the NaOH solution with the regeneration efficiency of higher than 99%, and cycle use of the extractant can be realized. The dephenolizing extractant disclosed by the invention has low preparation cost, simple operation process, no waste liquor discharge in the preparation process of the extractant, and little extractant loss in waste water processing procedure, and is capable of realizing industrial continuous operation.

Owner:KUNMING UNIV OF SCI & TECH

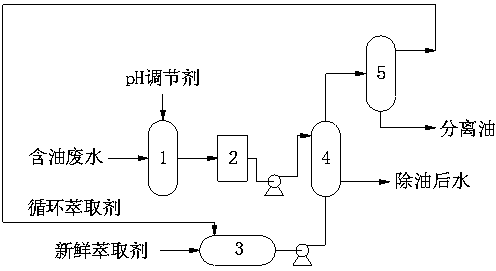

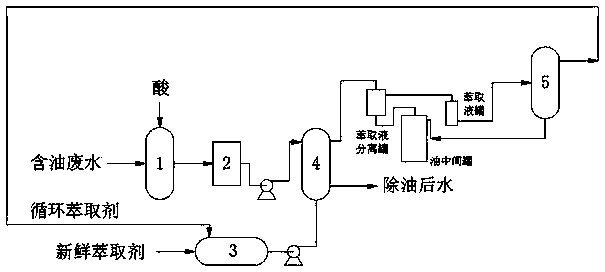

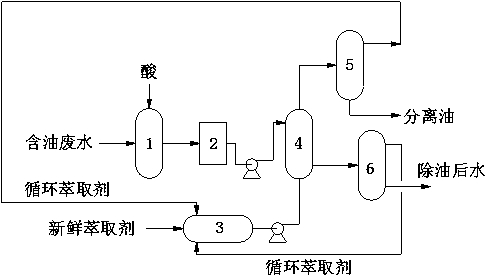

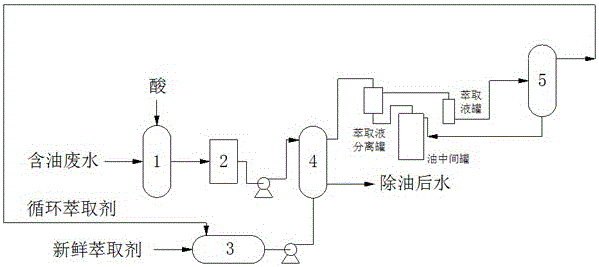

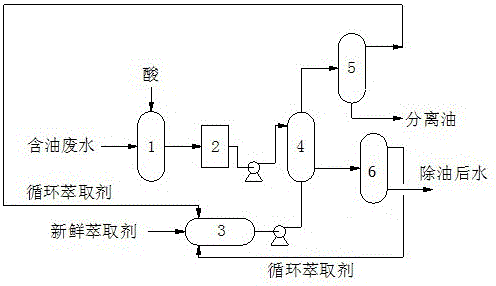

Method for oil and phenol removal from wastewater in field of coal chemical industry

ActiveCN103964543ASimple handlingSimplify timeFatty/oily/floating substances removal devicesLiquid separationWastewaterPre treatment

The invention discloses a method for oil and phenol removal from wastewater in field of coal chemical industry. The method is characterized in that in the wastewater containing oil and phenol generated in the coal chemical industry process, as the oil mostly is soluble oil, through combining wastewater pretreatment, extraction and oil and phenol removal and extraction agent recovery with related processes, a good oil and phenol removal effect is achieved, and the content of the soluble oil is effectively reduced. The invention further provides an extraction agent cyclohexane; and through a site test, the oil removal rate reaches 94.71-97.30 percent, the oil removal rate of the soluble oil reaches 87.08-92.81 percent, and the phenol removal rate reaches 96.94-98.21 percent, therefore, the effect is remarkable.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Phenolic resin adhesive

InactiveCN108659755ARaw materials are easy to getSimple processAldehyde/ketone condensation polymer adhesivesSolubilityPlasticizer

The invention provides a phenolic resin adhesive. The phenolic resin adhesive of the invention is water-soluble resin and has short curing time, low phenol content and good usage performance. A preparation method for the phenolic resin adhesive is characterized by comprising the following steps: adding metered phenol, formaldehyde and a plasticizer into a 500-mL three-necked flask equipped with aspherical condenser, a thermometer and a stirring device, adjusting a pH value to 8 by using Ba(OH)2, carrying out stirring and heating to 40 DEG C, and after a catalyst, the plasticizer, phenol and the like are dissolved completely, carrying out slow heating to a desired reaction temperature; carrying out a reaction at a certain temperature until the water-solubility of resin is 1: 1 (wherein water-solubility refers to the amount, in term of ml, of water added into 1 g of resin at 20 DEG C to allow the resin to become turbid), and terminating the reactionat the time; carrying out cooling to 60 DEG C and removing water at a vacuum degree of 0.9 Pa to allow solid content to reach 70%, wherein reddish brown transparent liquid is obtained and has viscosity of about 0.5 Pa-s (20 DEG C).

Owner:ZIBO SRING ADHESIVE CO LTD

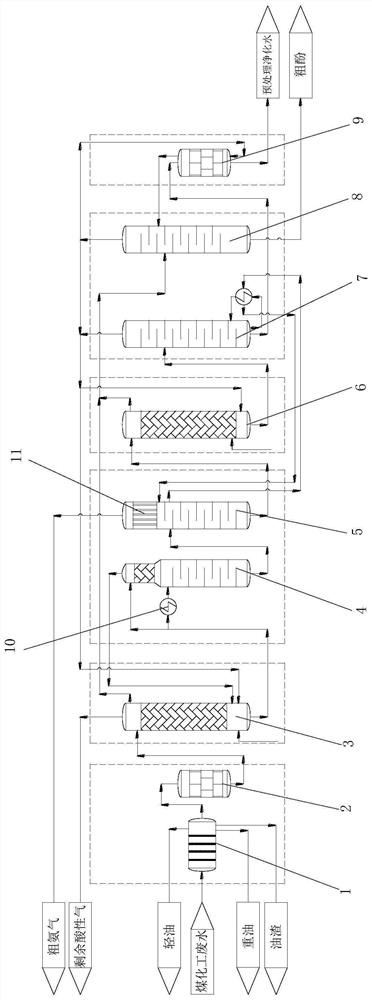

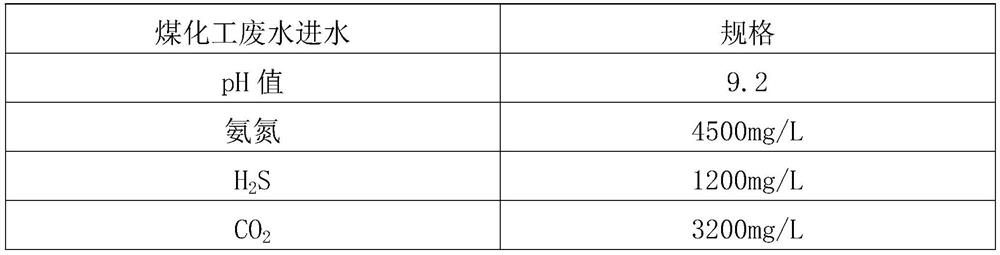

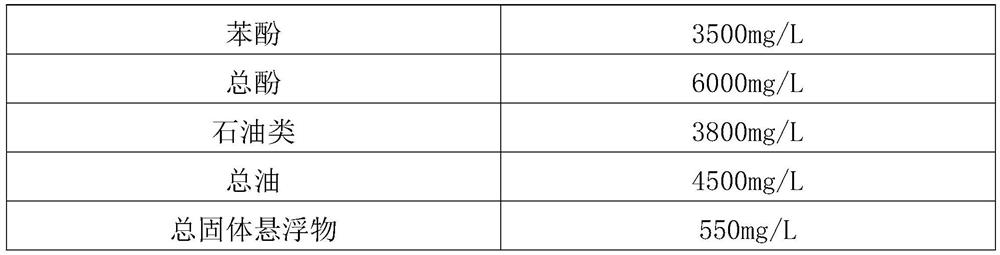

Coal chemical industry wastewater pretreatment method

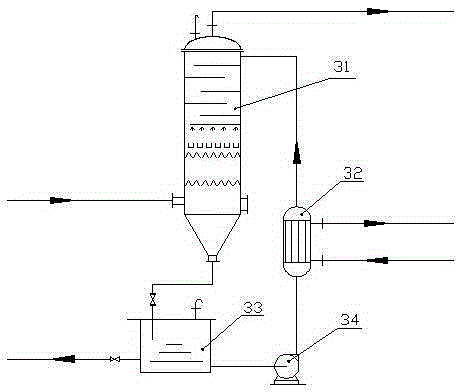

PendingCN112624466AReduce oil contentSolve the problem of pollutionFatty/oily/floating substances removal devicesWater contaminantsPretreatment methodPollution

The invention discloses a coal chemical industry wastewater pretreatment method, which belongs to the technical field of coal chemical industry wastewater treatment, and comprises the following steps of: oil removal and solid removal, pre-deoiling, deacidification and deamination, extraction and dephenolization, solvent / phenol recovery and deep dephenolization. According to the coal chemical industry wastewater pretreatment method, heavy oil, light oil, oil residues, ammonia, acidic components and phenol in the wastewater are removed, the operation load of a subsequent biochemical treatment section is reduced, and favorable conditions are created for biochemical treatment of the wastewater; floating oil, dispersed oil, emulsified oil and dissolved oil in the wastewater are removed in advance before deacidification and deamination, so that the problem of pollution and blockage of a deacidification and deamination system is solved; through deep dephenolization, the phenol content of the pretreated purified water is further reduced, and the impact resistance of a subsequent biochemical treatment section is improved; and the recycled heavy oil, light oil, oil residues, acid gas, crude ammonia gas and crude phenol are sent out as products, and recycling treatment and comprehensive utilization of the coal chemical industry wastewater are achieved.

Owner:陕西德信祥能源科技有限公司

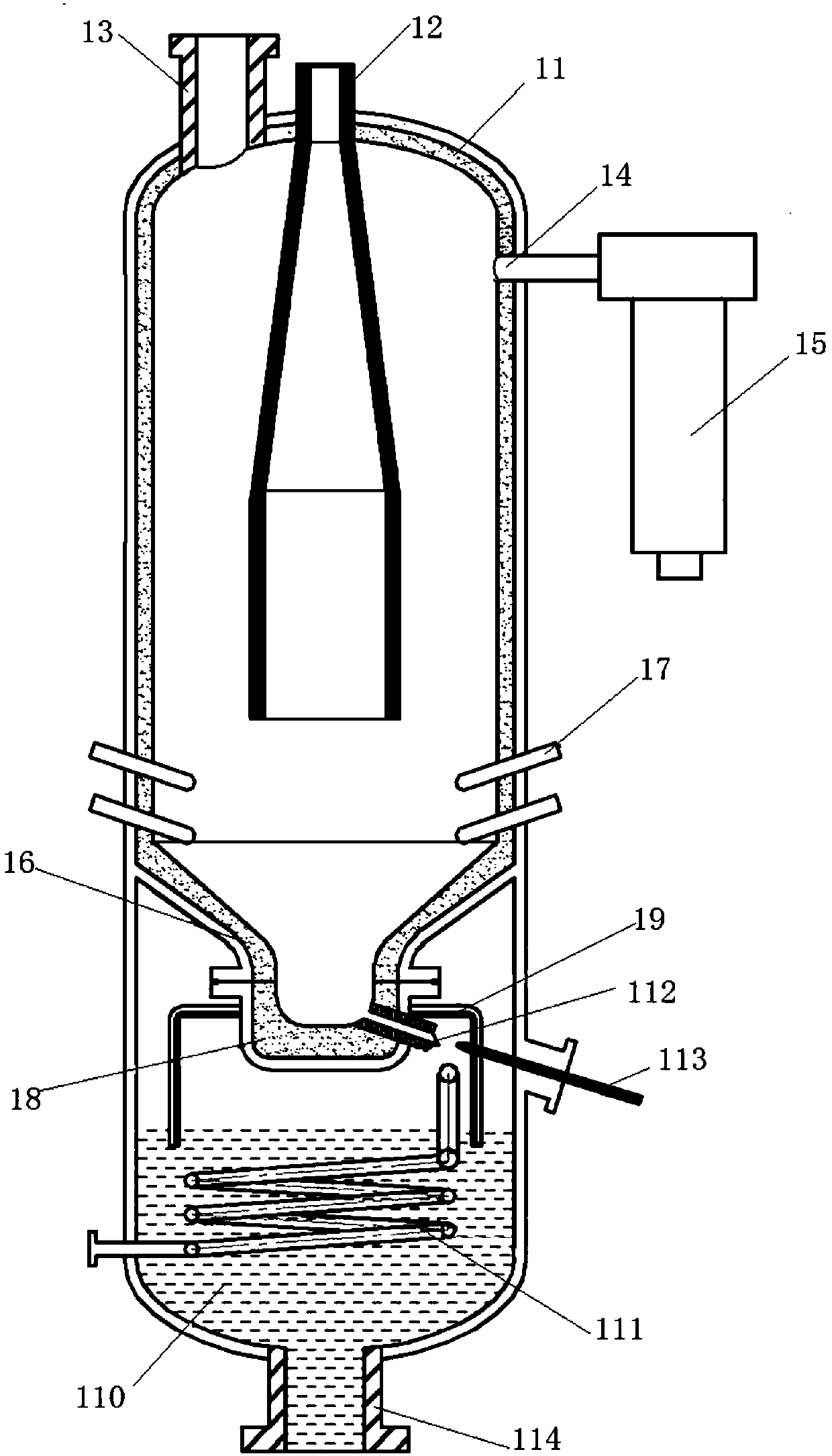

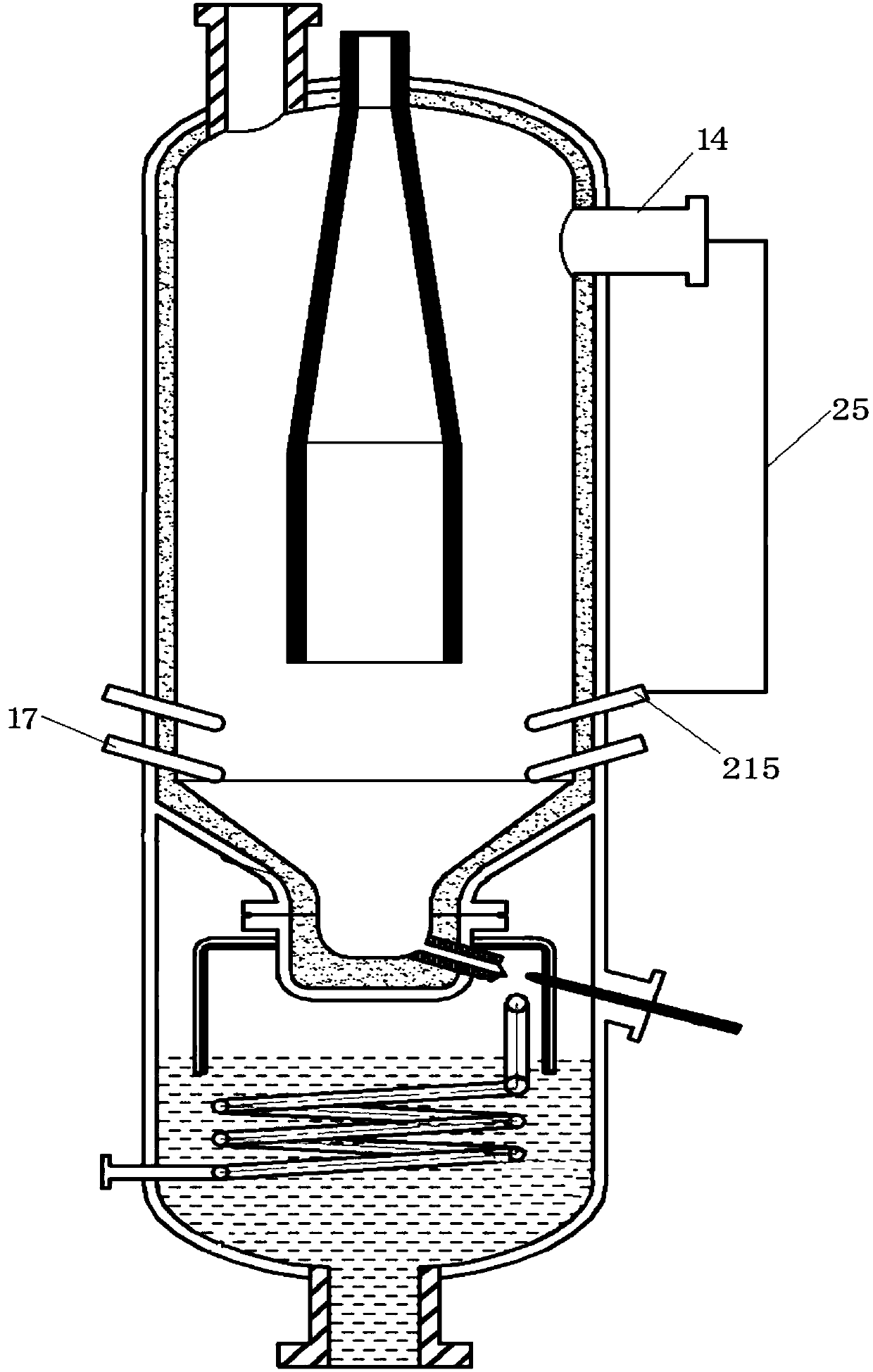

Fixed bed slag gasification furnace

ActiveCN107674712AReduce processingReduced phenolic contentGasification processes detailsGasification with fuel pre-distillationSlagFixed bed

The invention relates to a fixed bed slag gasification furnace which comprises a furnace body. A special outlet pipe is arranged in the furnace body along the axial direction of the furnace body, thespecial outlet pipe comprises an upper small-diameter section, a middle extension section and a lower large-diameter section, the upper small-diameter section penetrates the top of the furnace body toform a high-temperature coal gas outlet, fire-resistant materials are arranged on the inner surface of the special outlet pipe, an annular cavity is formed between the side wall of the special outletpipe and the side wall of the furnace body, a feeding port communicated with the annular cavity is formed in the top of the furnace body, a low-temperature coal gas outlet communicated with the annular cavity is formed in the side wall of the furnace body, a funnel-shaped slag tank with uniform wall thickness is arranged at the bottom of the furnace body, a slag storage tank is firmly connected at the bottom of the slag tank, a plurality of gasifying agent sprayers are circumferentially and uniformly arranged on the side wall of the lower portion of the furnace body, and an included angle between each gasifying agent sprayer and a horizontal plane ranges from 0 degree to 90 degrees.

Owner:CCTEG CHINA COAL RES INST

A method for deoiling and dephenolizing waste water in the field of coal chemical industry

ActiveCN103964543BSimplify timeLow costFatty/oily/floating substances removal devicesLiquid separationWastewaterPre treatment

The invention discloses a method for oil and phenol removal from wastewater in field of coal chemical industry. The method is characterized in that in the wastewater containing oil and phenol generated in the coal chemical industry process, as the oil mostly is soluble oil, through combining wastewater pretreatment, extraction and oil and phenol removal and extraction agent recovery with related processes, a good oil and phenol removal effect is achieved, and the content of the soluble oil is effectively reduced. The invention further provides an extraction agent cyclohexane; and through a site test, the oil removal rate reaches 94.71-97.30 percent, the oil removal rate of the soluble oil reaches 87.08-92.81 percent, and the phenol removal rate reaches 96.94-98.21 percent, therefore, the effect is remarkable.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

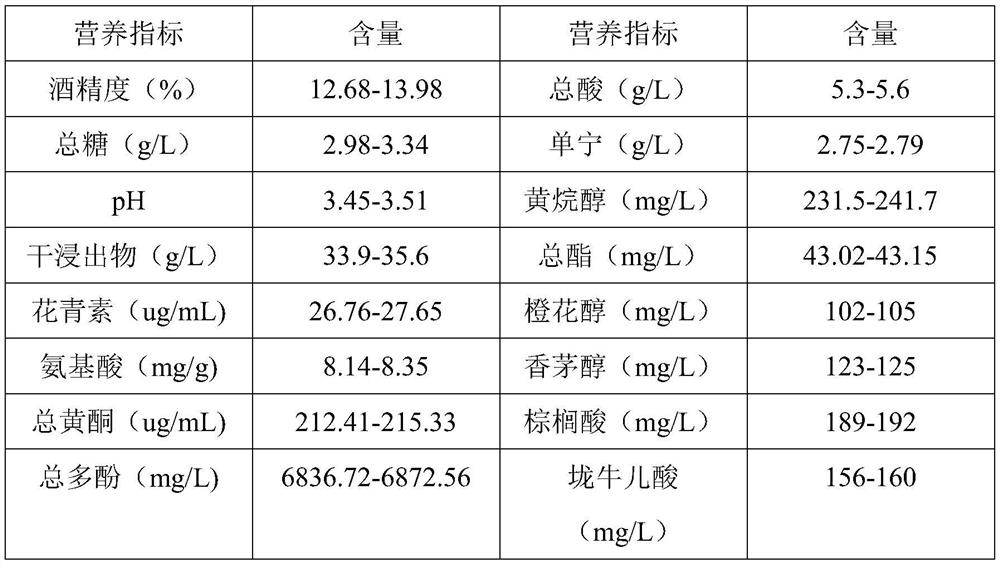

Flavored aronia melanocarpa wine and preparation method thereof

InactiveCN113355193AFull of nutritionStrong aromaAlcoholic beverage preparationFermentationBiotechnologyNutritive values

The invention discloses flavored aronia melanocarpa wine and a preparation method thereof, and belongs to the technical field of wine brewing. The flavored aronia melanocarpa wine is prepared from, by weight, 90-110 parts of fresh aronia melanocarpa fruits, 1-8 parts of Lengxiang roses and 0.2-0.8 part of pepsase; and the preparation method comprises the following steps of crushing raw materials, adding pepsase, fermenting twice, and ageing. The invention provides the flavored aronia melanocarpa wine, the aroma of the aronia melanocarpa wine is enriched, the nutritional value of the aronia melanocarpa wine is improved, the taste of the aronia melanocarpa wine is improved, and meanwhile, the series of the aronia melanocarpa wine is increased.

Owner:NINGXIA UNIVERSITY +1

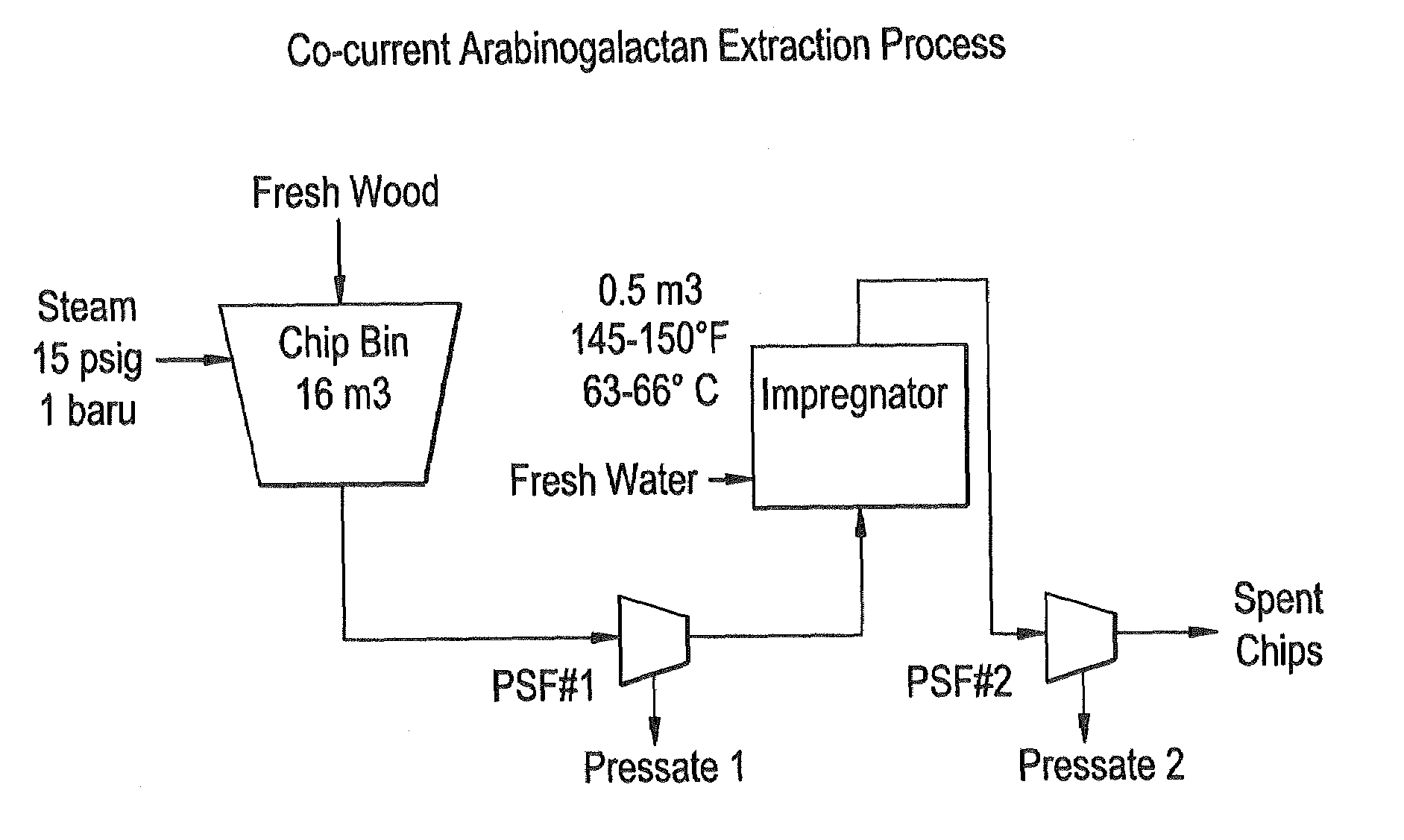

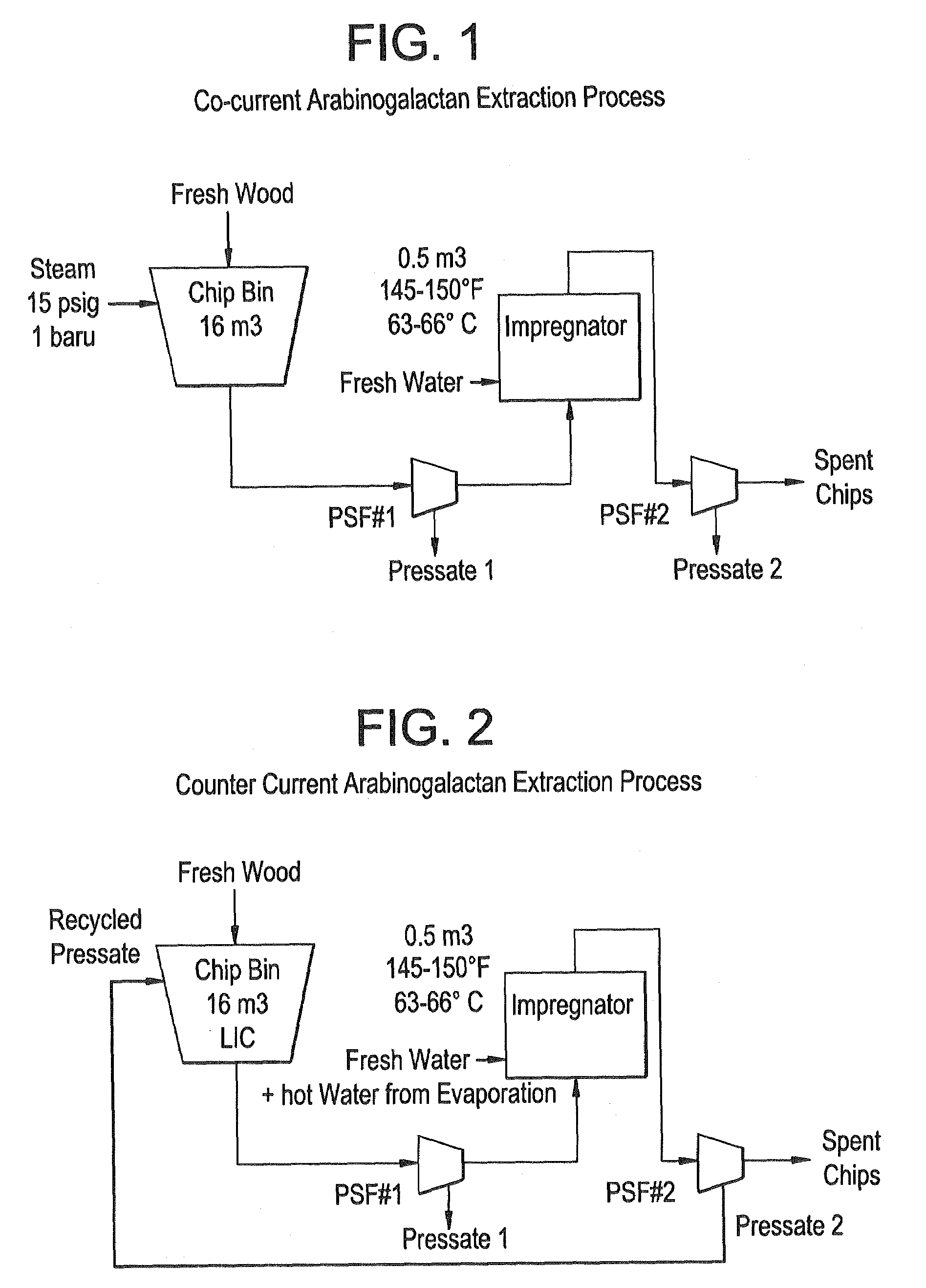

Method for recovering arabinogalactan (LAG) from fibrous natural plant materials

InactiveUS20100056772A1Efficiently and economically recoveringReduce water consumptionSugar derivativesSugar derivatives preparationEnrichment methodsEngineering

A method is provided for recovering arabinogalactan from fibrous natural plant material, such as wood from larch trees, said method being a continuous two-step extraction with enrichment method (i.e. counter current extraction) in which preferably water is employed as a solvent. In the counter current process of the invention the fresh solvent initially contacts plant material from which the greater part of the arabinogalactan has been leached and, subsequently, the resulting solution containing the lowest concentration of arabinogalactan contacts the freshest plant material

Owner:LONZA AG

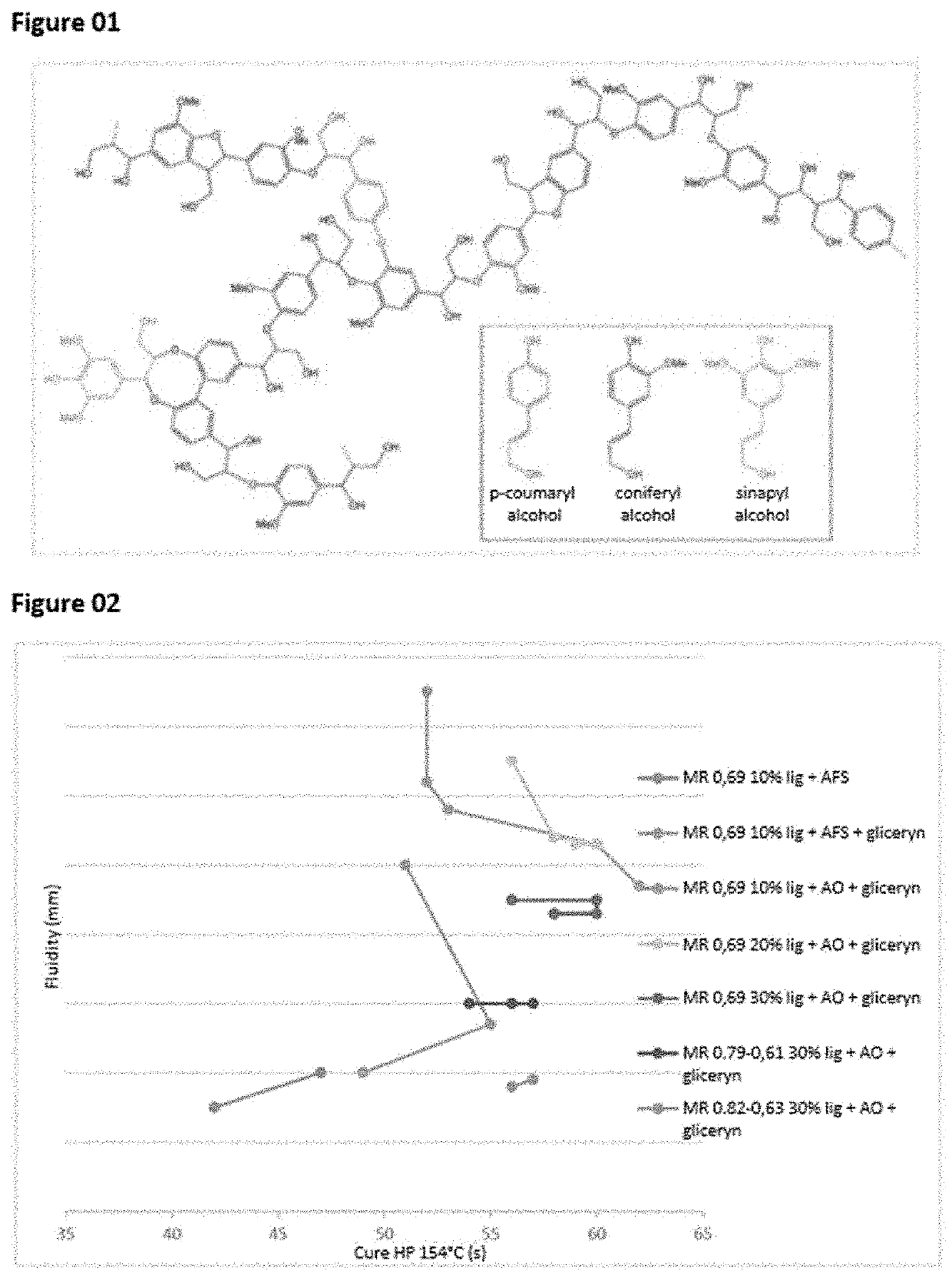

Novolac phenolic resins, process of synthesis of said phenolic resins and use thereof

PendingUS20220064356A1Quality improvementReduction of free phenolPolymer sciencePhenol formaldehyde resin

Owner:SUZANO SA

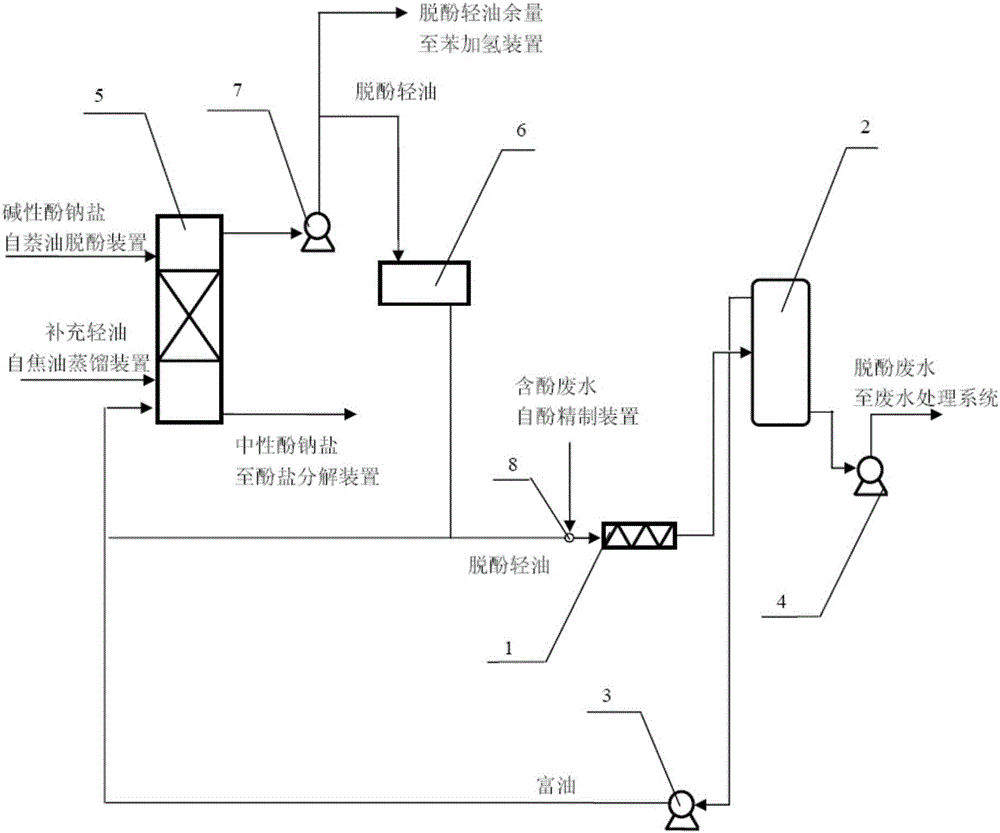

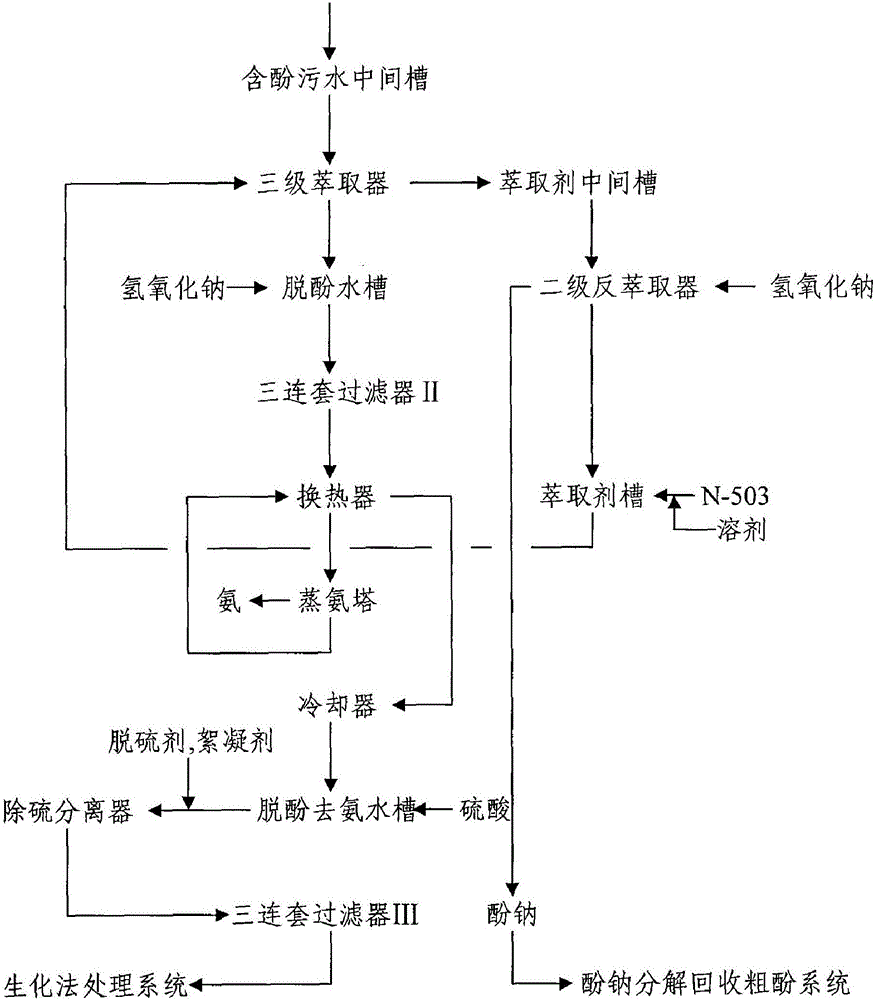

Method and apparatus for dephenolizing phenol-containing waste water generated by phenol refining

ActiveCN106315891ADecrease in the concentration of phenolsStrong extractable phenolic propertiesWater contaminantsMultistage water/sewage treatmentWater treatment systemSodium Phenolate

The invention provides a method and an apparatus for dephenolizing phenol-containing waste water generated by phenol refining. The method comprises a dephenolizing process for extraction of waste water and a dephenolizing process for stripping of rich oil. Light Oil for dephenolizing in the prior light oil washing process is used as an extractant, the extractant is used for extracting the phenol-containing waste water in order to remove phenol, after extraction, the rich oil returns to a light oil washing tower for carrying out stripping, a reaction is carried out between free alkali in sodium phenolate and phenol in the rich oil for recovery of sodium phenolate, and after dephenolization, the waste water is sent to a gas purifying and waste water treatment system. The method has the advantages of compact and concise process, low cost of equipment investment without accessory consumption, high cyclic utilization rate of the extractant for dephenolization of waste water, high oil removing rate during dephenolization of the waste water, increased of quality of sodium phenolate from the fraction dephenolizing apparatus, reduced sulfuric acid consumption of a phenate decomposition apparatus, and the like.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Preparation method of phenolic resin for producing epoxy resin

The invention discloses a method for preparing a phenolic resin. The method for preparing a phenolic resin of the present invention comprises: 1. The mass percentage is 55% to 65% of the total amount of phenol, 20% to 30% formaldehyde, and 20% of the weight of phenol %~50% of aromatic hydrocarbons and 0.2%~0.5% of oxalic acid are put into the reactor according to the ratio, and heated slowly to make it rise to the reflux temperature of 85°C-100°C; maintain it for 1.5-2.0 hours; 2. Cool to 80°C Below, add 0.4% to 0.6% of the total amount of hydrochloric acid with a mass concentration of 37%, reheat to the reflux temperature of 85°C-100°C, and maintain for 2.0-4.0 hours; 3. Cool to below 70°C, add the total amount of feed 0.2%~0.6% of the alkali solution with a mass concentration of 30% is neutralized until pH = 6.7-7.0; 4. Heating and reflux for water separation until the temperature exceeds 110°C, and the water separation ends; 5. Removal of aromatic hydrocarbons and phenol under reduced pressure , to the temperature ≥ 150 ° C, vacuum ≤ -0.9MPa, you can get the desired phenolic resin.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

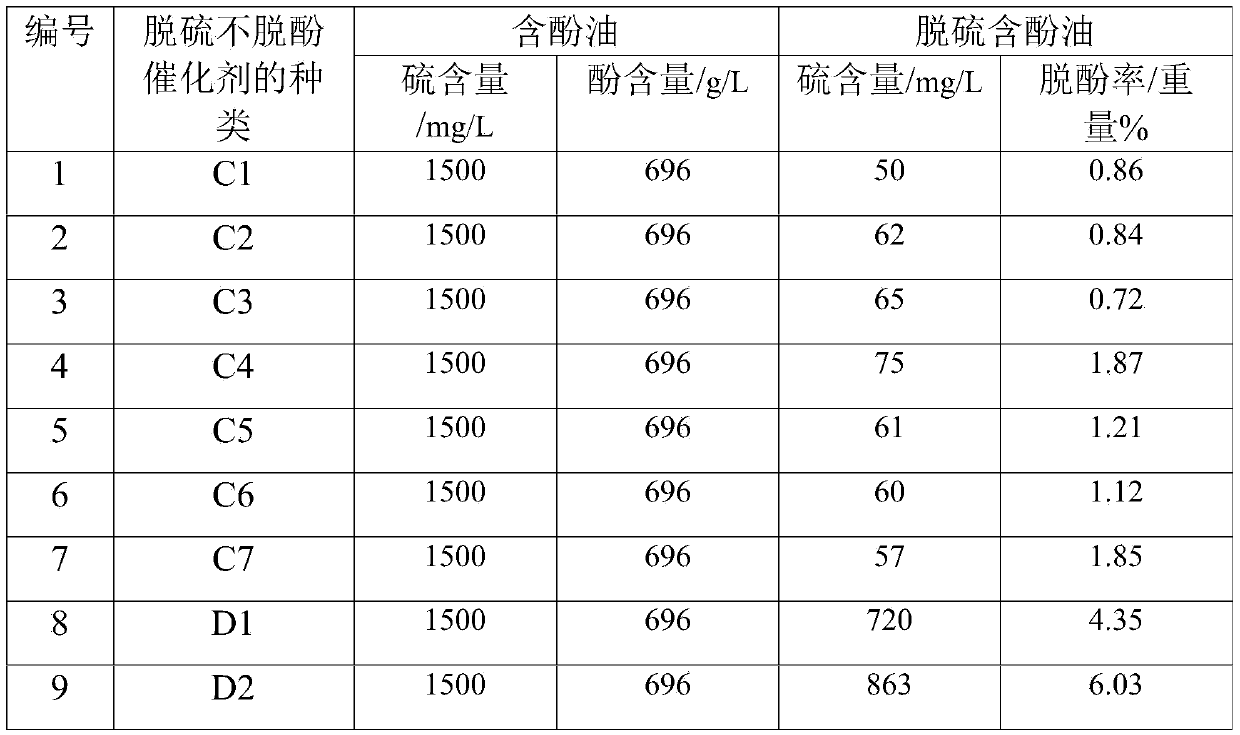

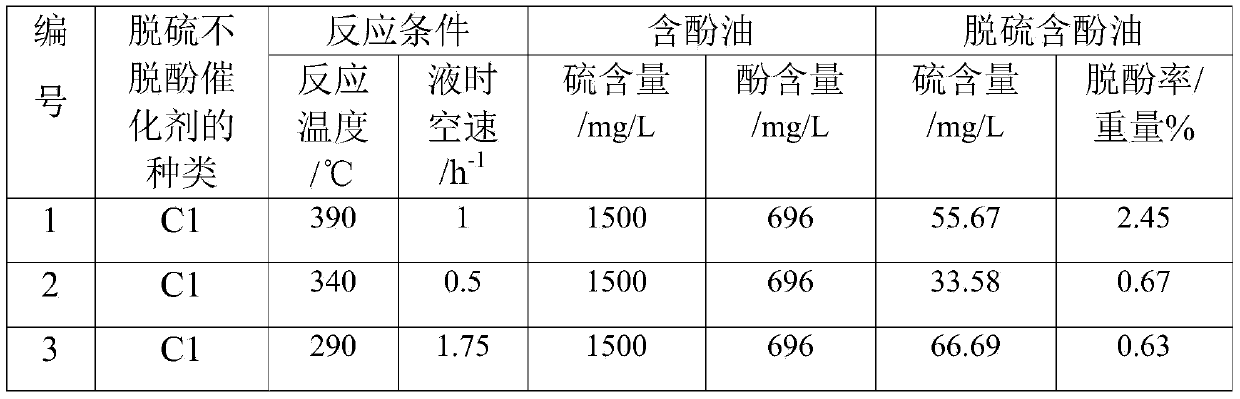

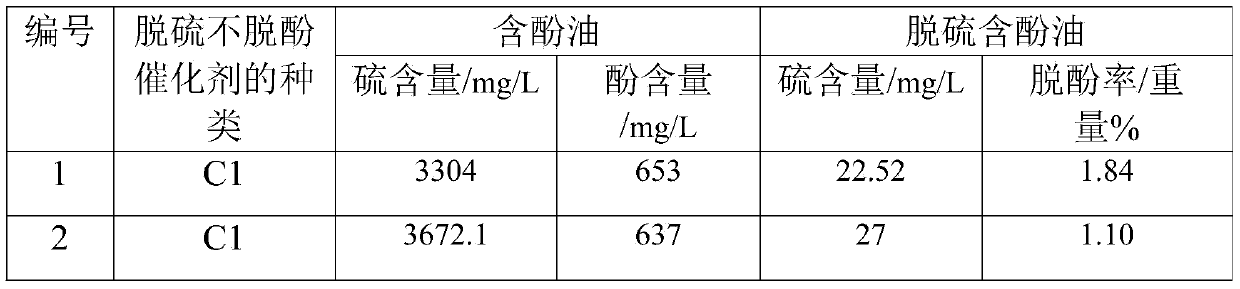

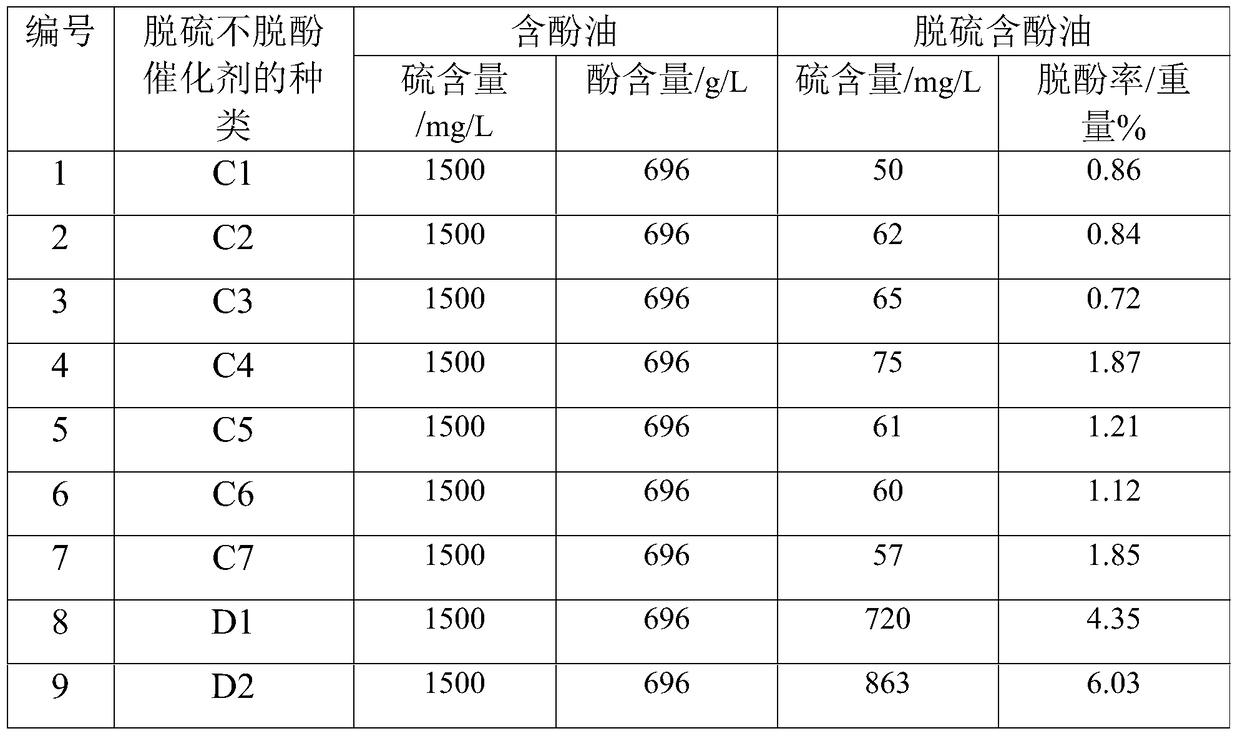

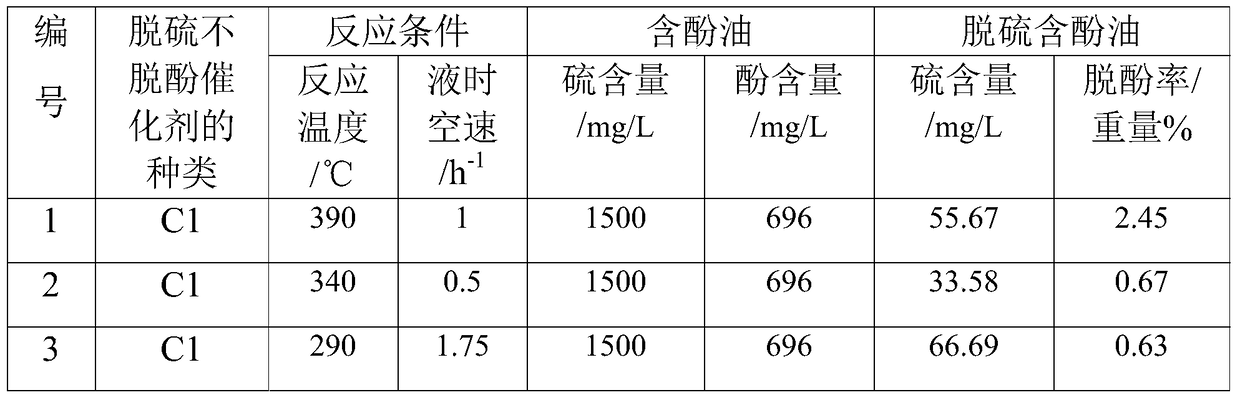

Desulfurization treatment method of phenol-containing oil and desulfurated phenolic-containing oil

ActiveCN106701158ALess economic valueReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrogen atmosphereSilicon oxide

The invention relates to the field of oil refining, and discloses a desulfurization treatment method of phenol-containing oil and desulfurated phenol-containing oil produced by the method. The method includes contacting the phenol-containing oil with a desulfurizing non-dephenolizing catalyst to perform treatment of desulfurizing without dephenolizing under a hydrogen condition. The desulfurizing non-dephenolizing catalyst comprises a carrier and an active metal component supported on the carrier. The carrier is one or at least two of zinc oxide, aluminum oxide and silicon oxide, and the active metal component is at least one of nickel, copper, palladium, platinum and ruthenium, wherein, based on the total weight of the desulfurizing non-dephenolizing catalyst, the content of the carrier is 80-98 wt%, and the content of the active metal component is 2-20 wt%. The hydrogen condition refers to that the reaction is carried out in a hydrogen atmosphere under normal pressure. The method in the invention can decrease the sulfur content to the utmost degree under a premise of decreasing the phenols content as little as possible, so as to enhance economic benefits to a greater degree.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Flavored dry red wine and preparation method thereof

The invention relates to the technical field of wine brewing, and particularly relates to flavored dry red wine and a preparation method thereof. The flavored dry red wine is prepared from the following raw materials in parts by weight: 90 to 110 parts of fresh cabernet sauvignon, 0.3 to 4 parts of cold fragrant rose, 0.3 to 0.7 part of fresh red raspberry and 0.1 to 0.5 part of pepsin. The preparation method comprises the following steps of: mixing all the raw materials, fermenting twice, and ageing. Through detection, the varieties and the contents of aromatic substances and ester substances in the flavored wine are remarkably improved, so that the defects that the contents of volatile aromatic substances and ester substances in pure wine are lower, the fruit wine fragrance is lighter, and the pleasant smell is not lasting are overcome to a great extent.

Owner:NINGXIA UNIVERSITY +1

Quality control technology for fresh-cut fruits and vegetables

InactiveCN109006983ANo residual toxicityEasy to operateFruits/vegetable preservation by freezing/coolingPolypropyleneCold storage

The present invention provides a quality control technology for fresh-cut fruits and vegetables by a saline-treated composite packaging material. The quality control technology comprises the followingsteps: fresh fruit and vegetable raw materials are selected; the selected fruit and vegetable raw materials are washed; the washed fruit and vegetable raw materials are put into a 100 ppm sodium hypochlorite solution to be soaked for 10 min; the soaked fruit and vegetable raw materials are rinsed; the rinsed fruit and vegetable raw materials are cut into needed sizes and shapes; the cut fruits and vegetables are put into 0.1 mol / l brine to be soaked for 20 min; the soaked fruits and vegetables are taken out; when the tissue surfaces of the fruits and vegetables are dry, the fruits and vegetables are loaded into a polypropylene (PP) packaging bag (at a thickness of 0.12 mm) to be sealed with a heat sealing machine; and the sealed fruits and vegetables are stored in a cold storage at 5 DEGC. The method can significantly inhibit the enzymatic browning of the fresh-cut fruits and vegetables, maintains original color and luster, prevents quality from decreasing, controls growth of microorganisms, thus prolongs a fresh-keeping period, and is suitable for the fruits and vegetables of fresh gingers, apples, potatoes, lotus roots, helianthus tuberosus, etc. The technology is good in the fresh-keeping effect, simple in operation, high in safety, low in cost and free of any toxic reagents, can efficiently extend shelf life, can extend the storage period of the fresh-cut fruits and vegetables to 20 days or more, and has broad market prospects.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

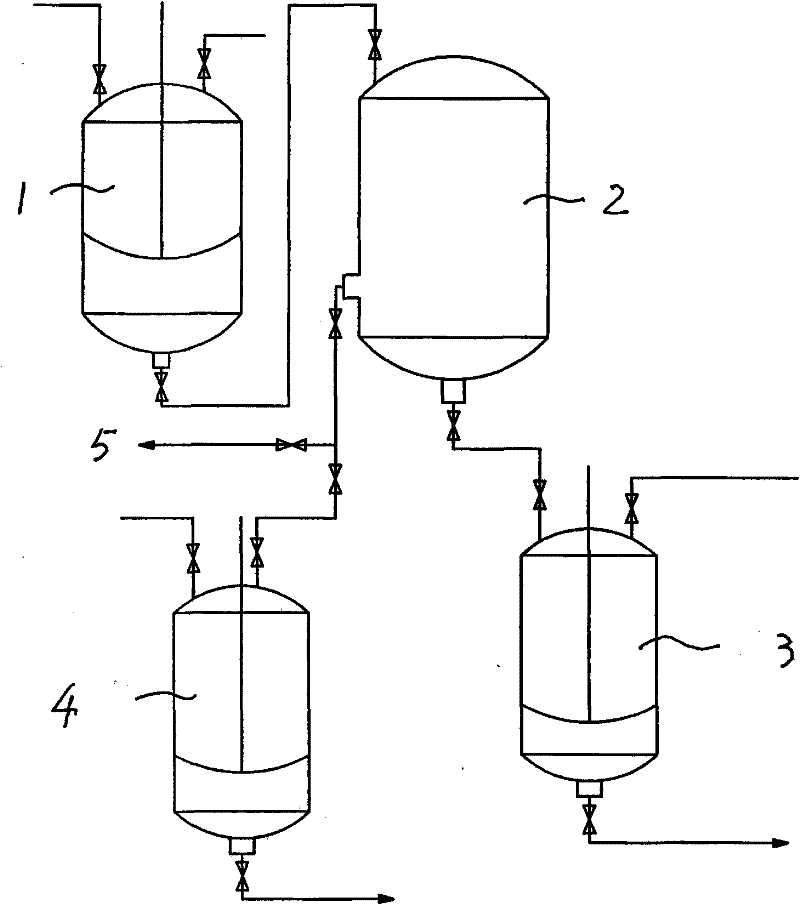

Comprehensive utilization method of phenolic resin wastewater

InactiveCN101906196BReduced phenolic contentShort production processMultistage water/sewage treatmentCarbonyl compound separation/purificationWastewaterWater soluble

The invention discloses a comprehensive utilization method of phenolic resin wastewater, belonging to the technical field of processing wastewater produced in the fine chemical engineering industry. The comprehensive utilization method comprises the steps of: adding the phenolic resin wastewater, an acid catalyst and formaldehyde in a condensation polymerization kettle according to the proportion, raising the temperature until the phenolic resin wastewater, the acid catalyst and the formaldehyde are boiled, preserving temperature for reaction; then reducing the temperature in the kettle, pumping materials in the condensation polymerization kettle into a settlement separation kettle by using a pump to reduce the temperature and settle and demix; flowing a lower layer resin material of a settlement formed by demixing into a resin synthesis kettle through a pipeline, adding the acid catalyst and the formaldehyde, raising temperature and boiling for reaction, vacuum dewatering to obtain thermoplastic phenolic resin; and injecting one part of wastewater with content of the free phenol formed after the settlement formed in the condensation polymerization kettle, which is reduced to be below 1 percent, into a water borne resin synthesis kettle to be used for reducing water soluble resin, absorbing the formaldehyde in a primary and a secondary absorption towers one part of which is injected with industrial formaldehyde, and forming the industrial formaldehyde. The invention realizes the purpose that the phenolic resin industrial wastewater achieves zero emission.

Owner:河北泽田化工有限公司

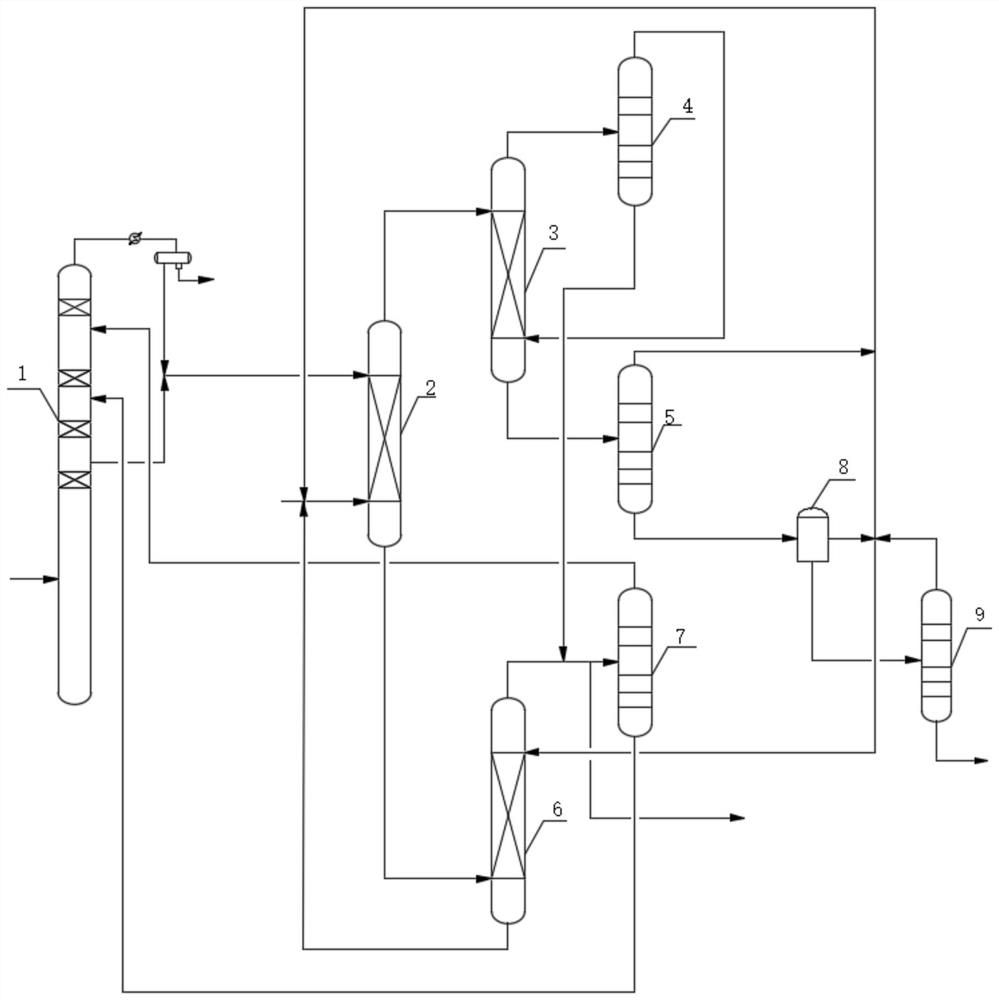

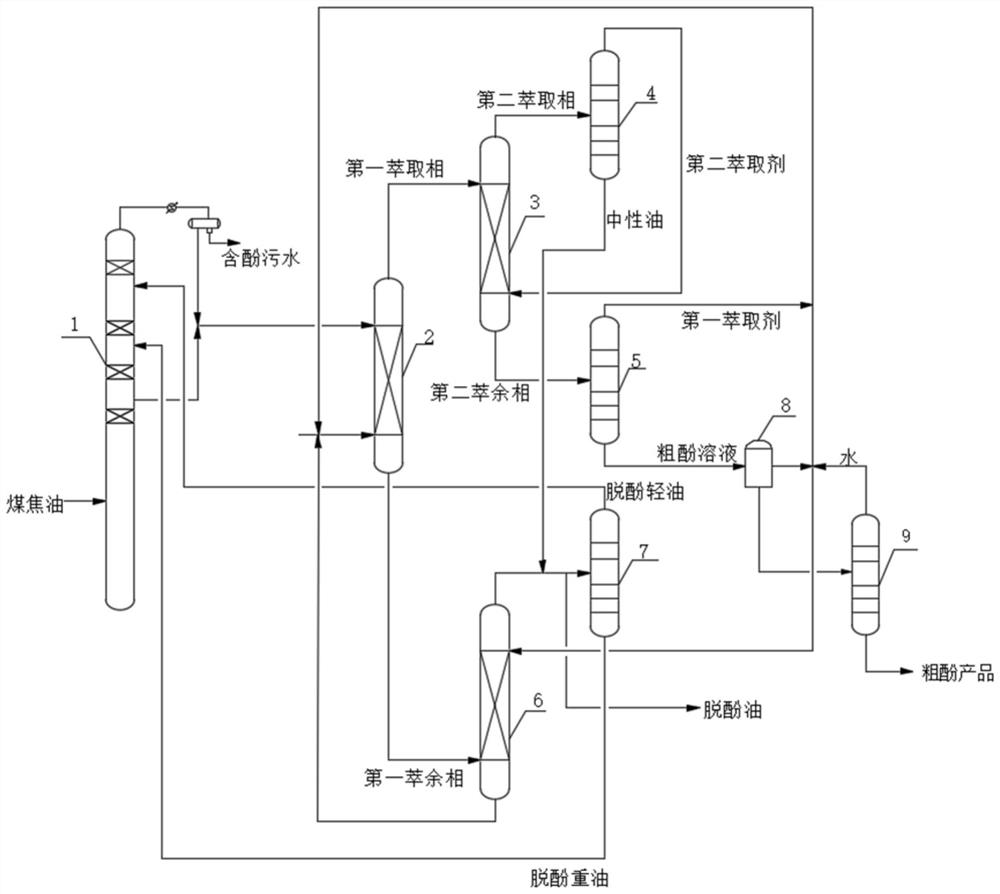

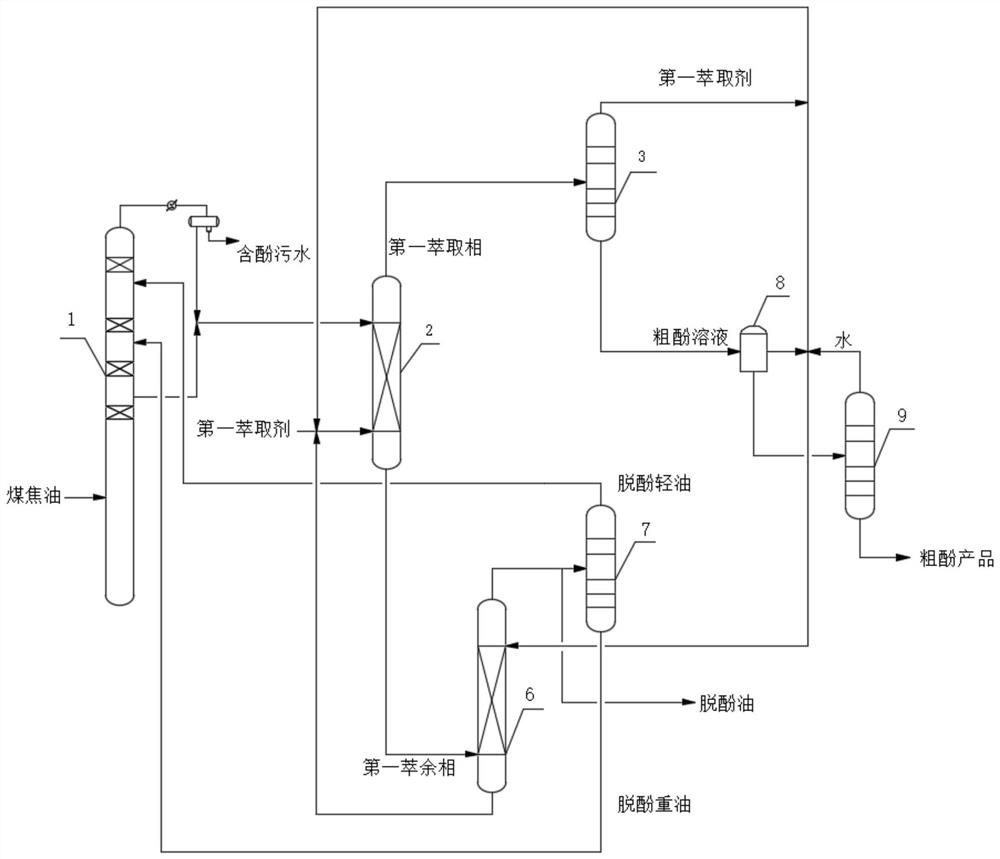

Coupling device and coupling process for extracting phenol from coal tar and treating phenol-containing water

ActiveCN113817490ASolve environmental problemsReduced phenolic contentTar working-up by distillationTar working-up by solvent extractionExtractive distillationProcess engineering

The invention provides a coupling device and a coupling process for extracting phenol from coal tar and treating phenol-containing water. The coupling device simultaneously solves the environmental protection problem in the process of extracting phenol from coal tar and distilling tar through the design combination of a plurality of fractionation sections and a two-stage extraction section and the assistance of a water washing section and a low-temperature separation section. According to the coupling technology, through the technology combining extractive distillation and liquid-liquid extraction, the quality of a crude phenol product is improved, the content of impurity neutral oil is reduced, through the operation of pre-separating a crude phenol solution at a low temperature, the energy consumption of a crude phenol distillation and dehydration section is greatly reduced, and the coupling technology has a good industrial application prospect.

Owner:胜帮科技股份有限公司

Treatment method of hydroxybenzene-containing wastewater

InactiveCN101037283BGuaranteed uptimeIndicators are stableTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTarget controlWastewater

The invention discloses a method of treating waste water including hydroxybenzene, including following steps: (1) synchronously adopting three segments target control method, a control method of mol ratio of hydroxybenzene to aldehyde and a timely separating method of resin and waste water, and processing a condensation polymerization of waste water in an acid condition with acid catalyst to produce resin with low molecular weight; (2) removing aldehyde of the waste water after the first treatment in an alkaline condition with alkaline catalyst and then processing an neutralization and deposition treatment; (3) adopting anaerobic and aerobic treatment to process a biochemical treatment of the waste water after the second treatment to meet emission requirements. The method meets the prescribed emission requirements of the hydroxybenzene-aldehyde resin waste water or waste water containing hydroxybenzen and has a simple art, a reliable operation, a low investment and a low operation fees and adequately utilizes the hydroxybenzene-aldehyde in the waste water.

Owner:海盐华强树脂有限公司

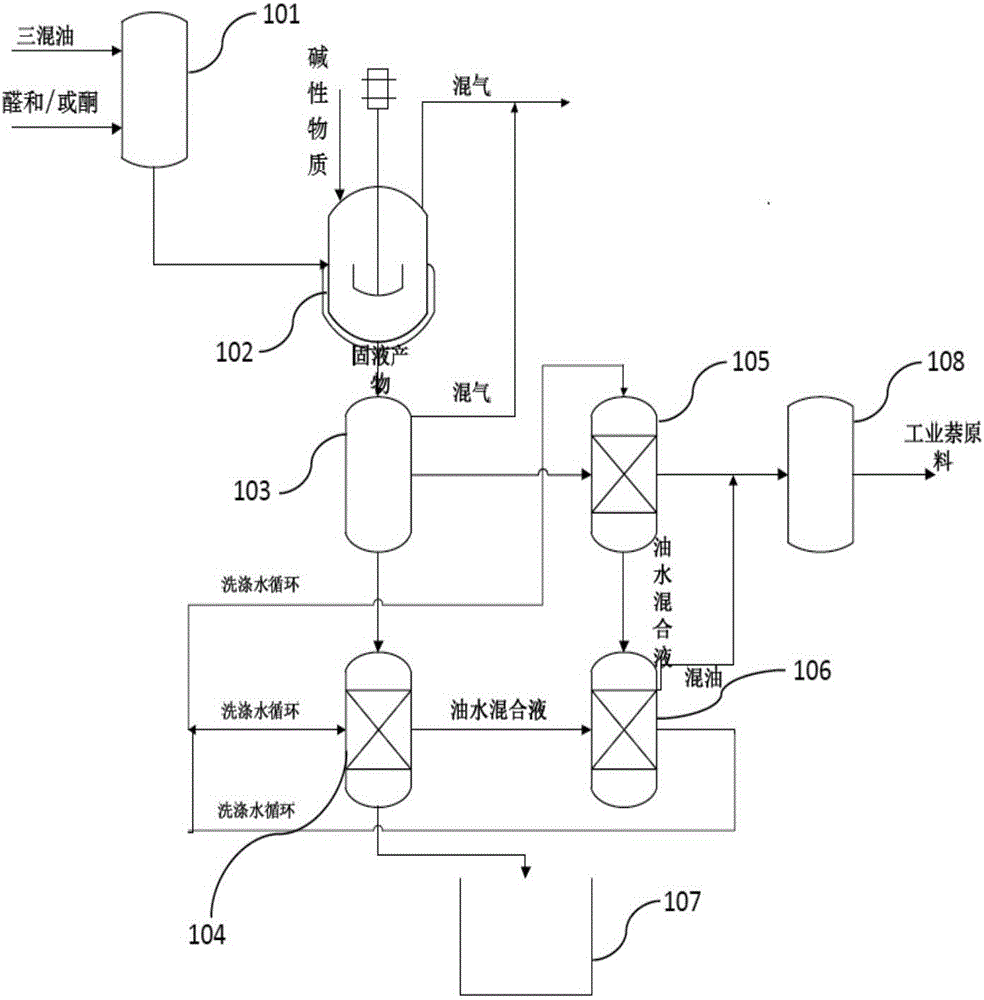

Three-oil mixture phenol removing method and device

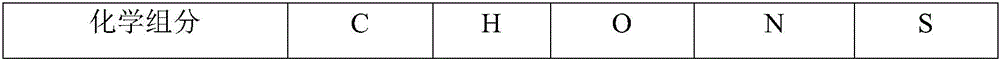

InactiveCN106635129ASolve intractableImprove protectionHydrocarbon oils refiningHydrocarbon oils treatmentKetoneNaphthalene

The invention relates to a three-oil mixture phenol removing method and device. The method comprises enabling three-oil mixtures and aldehydes and / or ketones to react in an alkaline environment to form phenolic resin; then performing solid-liquid separation on the reaction products to obtain a solid phase and a liquid phase, wherein the liquid phase is phenol-removed three-oil mixtures. The device comprises a reactor and a separating device, the discharging port of the reactor is connected with the feeding port of the separating device, and the separating device is a solid-liquid separating device; the reactor is used for enabling the three-oil mixtures and the aldehydes and / or the ketones to react in the alkaline environment to form the phenolic resin, wherein the ketones comprise a-H; the solid-liquid separating device receives and separates materials from the reactor to obtain the solid phenolic resin and liquid materials. According to the three-oil mixture phenol removing method, the phenol removal process does not require a large amount of water, the content of phenol in the reaction products is lower than that in existing separating technology, and the raw material quality of industrial naphthalene can be improved.

Owner:CCTEG CHINA COAL RES INST +1

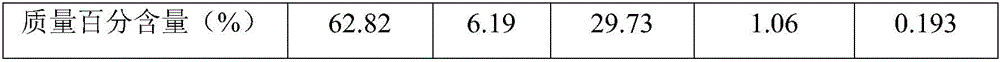

Phenol-containing wastewater treatment method

InactiveCN113149261AEfficient enrichmentReduced phenolic contentOrganic chemistryFatty/oily/floating substances removal devicesOil phaseSodium hydroxide

The invention relates to a phenol-containing wastewater treatment method, which adopts liquid membrane extraction to treat phenol-containing wastewater, and comprises the following steps: 1, measuring the phenol content in the phenol-containing wastewater, adding a liquid membrane extract according to the measured phenol content, and fully mixing the liquid membrane extract and the phenol-containing wastewater at a stirring speed of 60r / min, reacting phenol in the phenol-containing wastewater with sodium hydroxide in the liquid membrane extraction liquid for 10 min; 2, performing standing for 10 min after the reaction is completed, layering a water phase and an emulsion phase, and separating the water phase from the emulsion phase to obtain an emulsion containing sodium phenate; and 3, stirring the emulsion containing sodium phenate obtained in the step 2 at a stirring speed of 1500r / min for 3-10min for demulsification, performing standing for 20min after demulsification is completed, layering a water phase and an oil phase, separating the oil phase from the phase, and continuing to use the oil phase as a preparation raw material of the liquid membrane extraction liquid. According to the method, phenolic compounds in the wastewater can be effectively enriched into the emulsion, the extraction liquid can be repeatedly used, the extraction efficiency is high, the energy consumption is low, and resources can be effectively saved while wastewater treatment reaches the standard.

Owner:禹城京都新材料科技有限公司

Method of producing pure 1,1-bis-(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane

ActiveUS6972344B2Reduce the temperatureReduced phenolic contentOrganic chemistryOrganic compound preparationSolventPhenol

A method of producing 1,1-bis-(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane comprising: crystallizing a phenol adduct of 1,1-bis-(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane from a solution comprising 1,1-bis-(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane and phenol; washing the phenol adduct with a washing solution comprising phenol and water; decomposing by heating the washed phenol adduct in an aqueous solvent to remove phenol from the phenol adduct, thereby obtaining pure 1,1-bis-(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane.

Owner:HONSHU CHEM INDAL

A kind of preparation method of dl-p-hydroxydihydantoin

The invention discloses a preparation method of DL-p-hydroxytrihydantoin. Phenol, sulfuric acid with a mass concentration of 98% and water were added to the reactor, and a certain concentration of sulfuric acid aqueous solution was used to catalyze the para-activity of phenol, then the catalyst with a total molar weight of 1 / 3 was added after heating, and urea was added. Add a certain amount of water; slowly add the total molar amount of 1 / 3 glyoxylic acid aqueous solution, the dropwise addition is completed, add the remaining total molar amount of 2 / 3 catalyst, after stirring, the reaction temperature is increased, and the remaining total molar amount is added dropwise. The molar weight is 2 / 3 glyoxylic acid aqueous solution, the dropwise addition is completed and the insulation is completed, and after cooling, the insulation is centrifugal suction filtration to retain the solid; the surface of the solid material is washed with hot water, washed to neutral pH, and dried. The invention improves the product yield and purity, reduces the phenol content in the mother liquor, reduces the amount of waste water, relieves the pressure of environmental protection, effectively suppresses the generation of the largest single impurity, and improves the product yield and quality.

Owner:杭州新桂实业有限公司

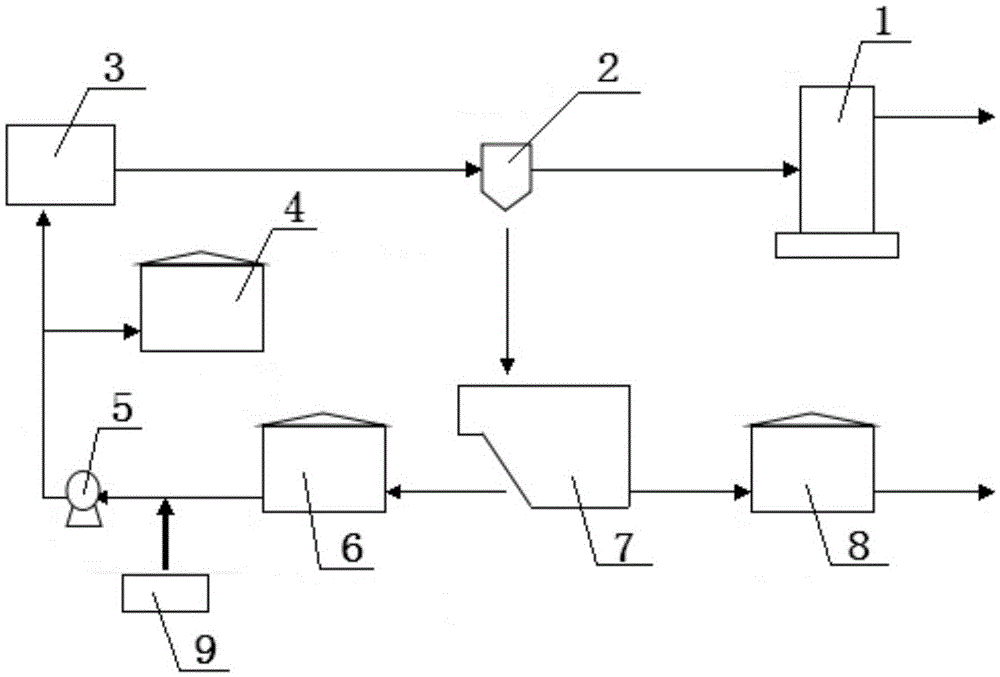

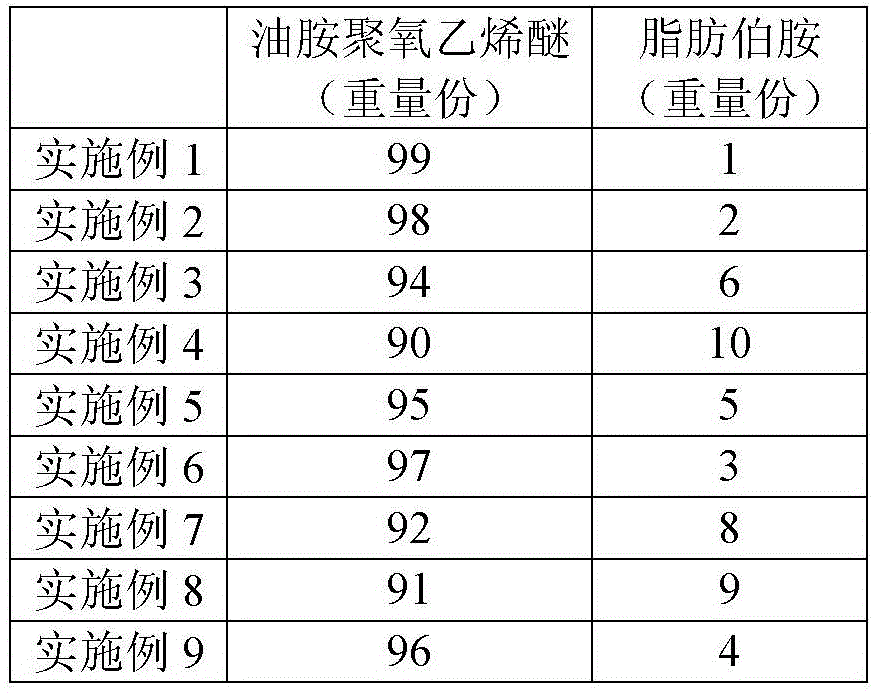

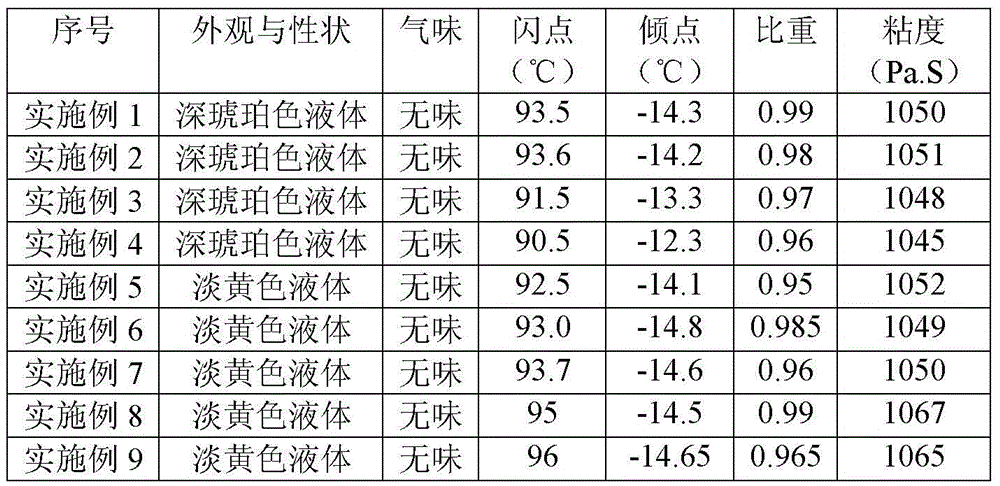

Purification additives used in coal chemical production and its application in coal chemical production

ActiveCN103801114BEfficient removalLow viscosityNon-miscible liquid separationChemical oxygen demandSlag

The invention discloses a purification assistant for coal chemical industry production and application of the purification assistant in the coal chemical industry production. The purification assistant for the coal chemical industry production comprises the following components in parts by weight: 90-99 parts of ethoxylated oleamine and 1-5 parts of fatty amine. The purification assistant has the beneficial effects that (1) the content of suspended solids in ammonium hydroxide and phenol are greatly reduced, therefore the separation effects of coal tar and coal cinder in the ammonium hydroxide and phenol are preferable, consequently, the loss of the coal tar is reduced and the yield of the coal tar is increased; (2) the water content in the coal tar is reduced; (3) a great number of sediments such as oil slag in each tank body and an evaporator tank heat-exchanging system are cleaned, the blockage phenomenon is avoided, the system cleaning frequency is reduced, and the service life of equipment is prolonged; and (4) the COD (chemical oxygen demand) and phenol content in gasification wastewater are reduced, and raw coke oven gas is cleaned at the same time. Therefore, the purification assistant provided by the invention is a high-efficiency product capable of reducing viscosity of coal tar and reducing water content of an oil product.

Owner:张征北

Desulfurization treatment method of phenolic oil and desulfurized phenolic oil

ActiveCN106701158BReduced phenolic contentLess economic valueMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystHydrogen atmosphere

The invention relates to the field of oil refining, and discloses a desulfurization treatment method of phenol-containing oil and desulfurated phenol-containing oil produced by the method. The method includes contacting the phenol-containing oil with a desulfurizing non-dephenolizing catalyst to perform treatment of desulfurizing without dephenolizing under a hydrogen condition. The desulfurizing non-dephenolizing catalyst comprises a carrier and an active metal component supported on the carrier. The carrier is one or at least two of zinc oxide, aluminum oxide and silicon oxide, and the active metal component is at least one of nickel, copper, palladium, platinum and ruthenium, wherein, based on the total weight of the desulfurizing non-dephenolizing catalyst, the content of the carrier is 80-98 wt%, and the content of the active metal component is 2-20 wt%. The hydrogen condition refers to that the reaction is carried out in a hydrogen atmosphere under normal pressure. The method in the invention can decrease the sulfur content to the utmost degree under a premise of decreasing the phenols content as little as possible, so as to enhance economic benefits to a greater degree.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

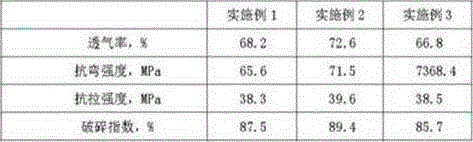

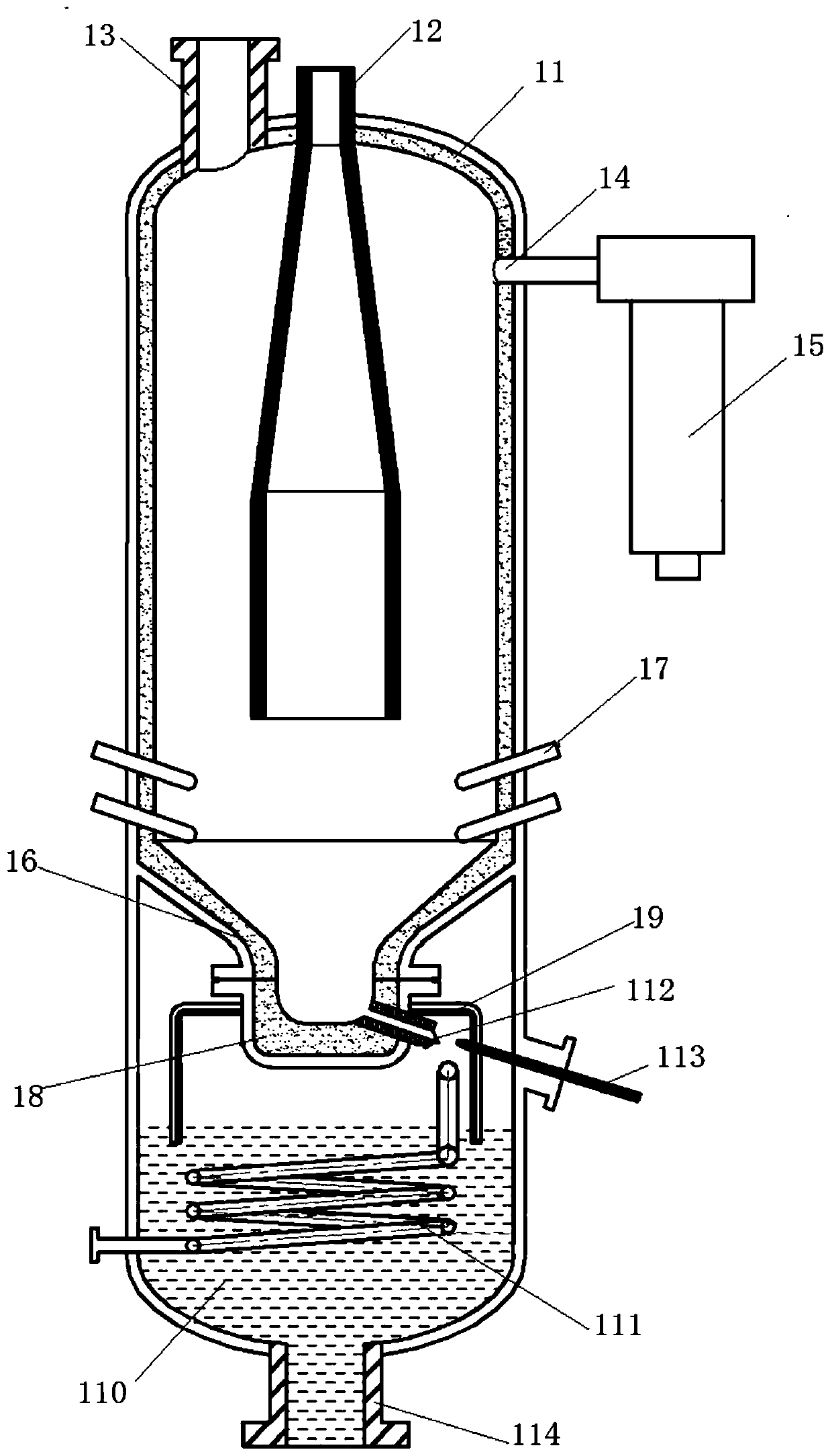

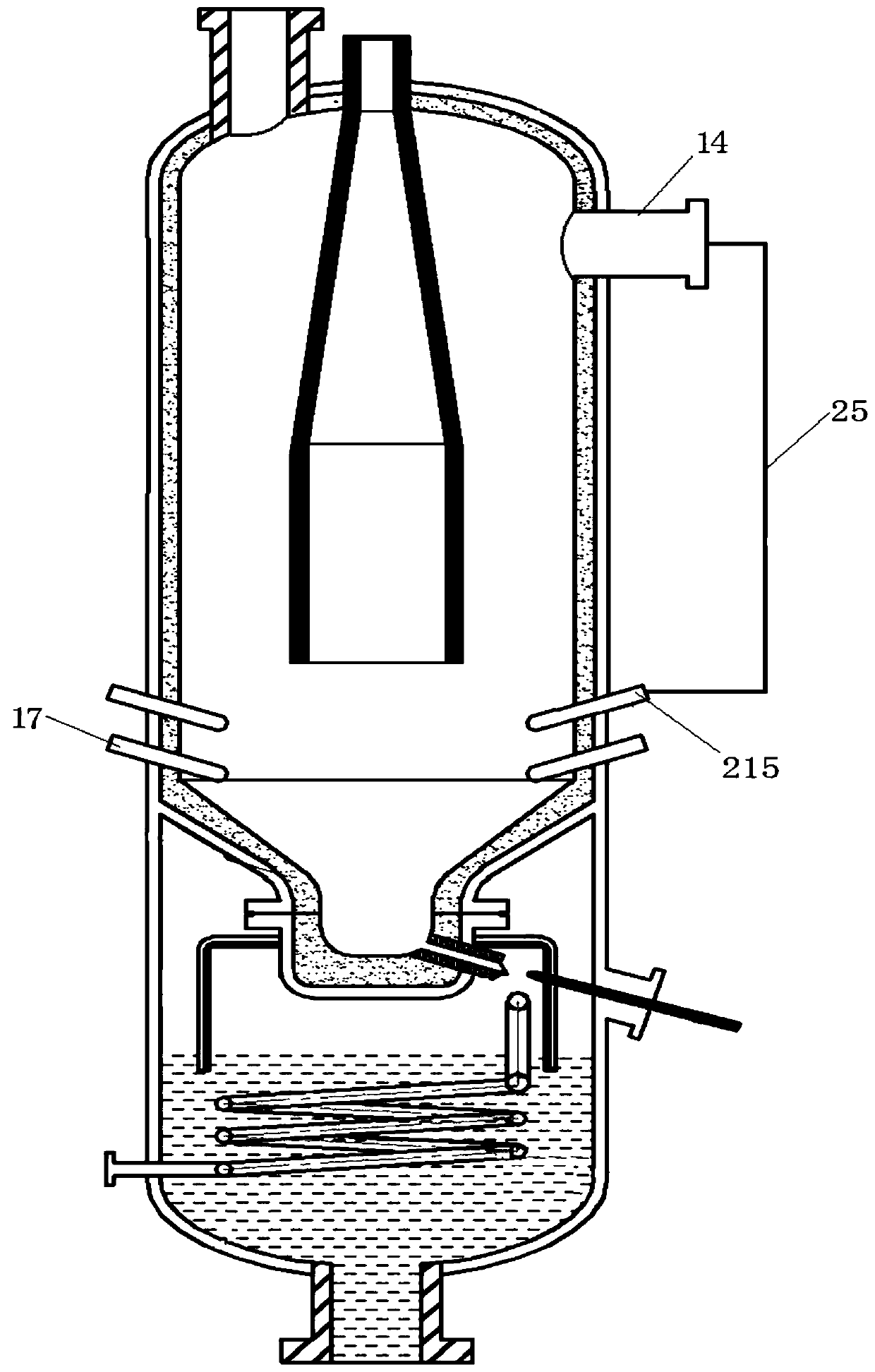

Phenolic resin coated core sand for car part casting and preparing method thereof

InactiveCN111195700AHigh strengthImprove high temperature resistanceFoundry mouldsFoundry coresCalcium silicateHexamethylenetetramine

The invention discloses a phenolic resin coated core sand for a car part casting and a preparing method thereof. The core sand is prepared by a raw material including, by weight part, 130 to 150 partsof silica sand, 20 to 30 parts of pulverized corundum, 20 to 24 parts of lead zinc ore tailings, 15 to 19 parts of amblygonite, 10 to 14 parts of water quenching nickel slag, 3 to 5 parts of phenolicresin, 0.5 to 0.7 part of urotropin, 1 to 2 parts of octadecanamide, 2 to 4 parts of aluminum hydroxy distearate, 0.2 to 0.4 part of carboxyl-terminated liquid polybutadiene rubber and the like. Theadded carboxyl-terminated liquid polybutadiene rubber and coal tar can react with free phenol, a product is intermediate state matter with certain chemical reactivity, the strength and high temperature resistance of the coated sand can be improved, the content of phenol in the core sand can be reduced, generation of smoke can be reduced, due to added porous calcium silicate, petroleum coke residue, amblygonite and the like, the mechanical property of the core sand can be improved, the melting point of the coated sand can be increased, a scattering agent configured by added methylphenol and thelike can improve the scattering property and the like of the core sand, and the property of the core sand can be improved.

Owner:LIFENG AUTO SPARES YUNXIAN

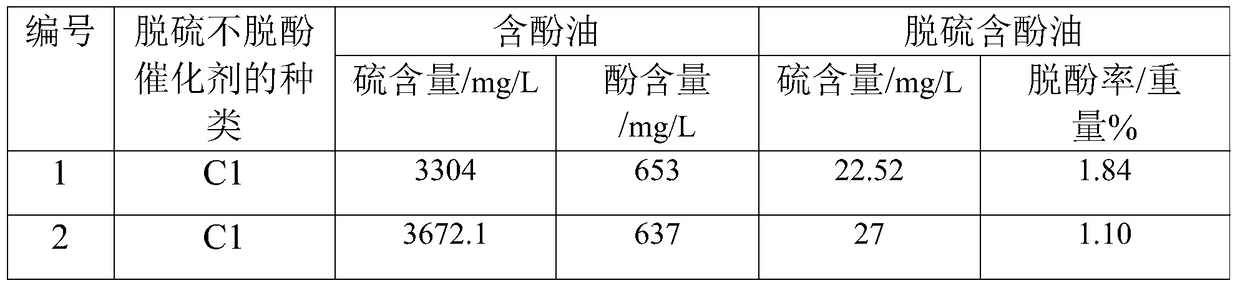

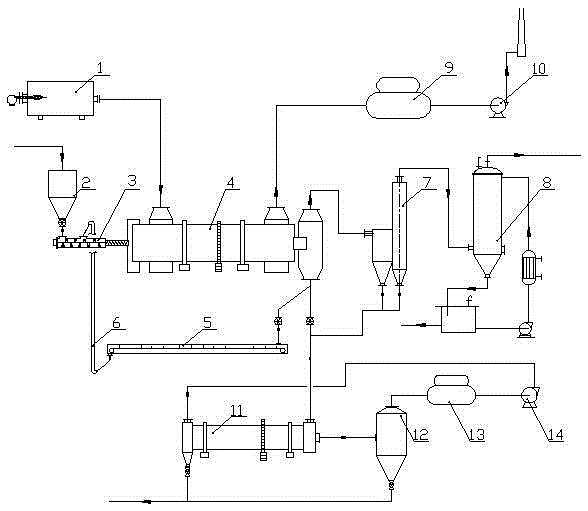

A membrane dedusting device and a coal pyrolysis process using the membrane dedusting device

ActiveCN104524908BImprove qualityAvoid condensationCombination devicesSpecial form destructive distillationGas heaterWastewater

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Phenolic resin coated core sand for automobile part and preparation method thereof

InactiveCN106141072AHigh strengthImprove high temperature resistanceFoundry mouldsFoundry coresCalcium silicateChemical reaction

The invention discloses a phenolic resin coated core sand for an automobile part and a preparation method thereof. The phenolic resin coated core is prepared from the following raw materials in parts by weight: 130 to 150 parts of silica sand, 20 to 30 parts of emery, 20 to 24 parts of lead-zinc tailing ore, 15 to 19 parts of amblygonite, 10 to 14 parts of water-quenching nickel slag, 3 to 5 parts of phenolic resin, 0.5 to 0.7 part of urotropin, 1 to 2 parts of octadecanamide, 2 to 4 parts of aluminium hydroxy distearate, 0.2 to 0.4 part of carboxyl terminated liquid polybutadiene rubber, and the like. The phenolic resin coated core has the advantages that the added carboxyl terminated liquid polybutadiene rubber and coal tar can react with free phenol, the generated matter is an intermediate matter with certain chemical reaction activity, the strength and high temperature-resistant property of coated sand are improved, the content of phenol in core sand is reduced, and the generation of smoke is reduced; by adding porous calcium silicate, petroleum tar slag, amblygonite and the like, the mechanical property of sand core is improved, and the melting point of coated sand is increased; by adding a breakdown agent which is prepared by p-cresol and the like, the breakdown property of core sand is improved, and the property of sand core is improved.

Owner:江阴联华铸造有限公司

A fixed bed slag gasifier

ActiveCN107674712BReduce processingReduced phenolic contentGasification with fuel pre-distillationFixed-bed gasificationSlagSprayer

The invention relates to a fixed bed slag gasification furnace which comprises a furnace body. A special outlet pipe is arranged in the furnace body along the axial direction of the furnace body, thespecial outlet pipe comprises an upper small-diameter section, a middle extension section and a lower large-diameter section, the upper small-diameter section penetrates the top of the furnace body toform a high-temperature coal gas outlet, fire-resistant materials are arranged on the inner surface of the special outlet pipe, an annular cavity is formed between the side wall of the special outletpipe and the side wall of the furnace body, a feeding port communicated with the annular cavity is formed in the top of the furnace body, a low-temperature coal gas outlet communicated with the annular cavity is formed in the side wall of the furnace body, a funnel-shaped slag tank with uniform wall thickness is arranged at the bottom of the furnace body, a slag storage tank is firmly connected at the bottom of the slag tank, a plurality of gasifying agent sprayers are circumferentially and uniformly arranged on the side wall of the lower portion of the furnace body, and an included angle between each gasifying agent sprayer and a horizontal plane ranges from 0 degree to 90 degrees.

Owner:CCTEG CHINA COAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com