Purification additives used in coal chemical production and its application in coal chemical production

A coal chemical and additive technology, applied in the field of purification additives in coal chemical production, can solve the problems of increasing the heat consumption of the distillation system, reducing equipment production capacity, safety accidents, etc., to reduce the water content of oil products, reduce viscosity, increase yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

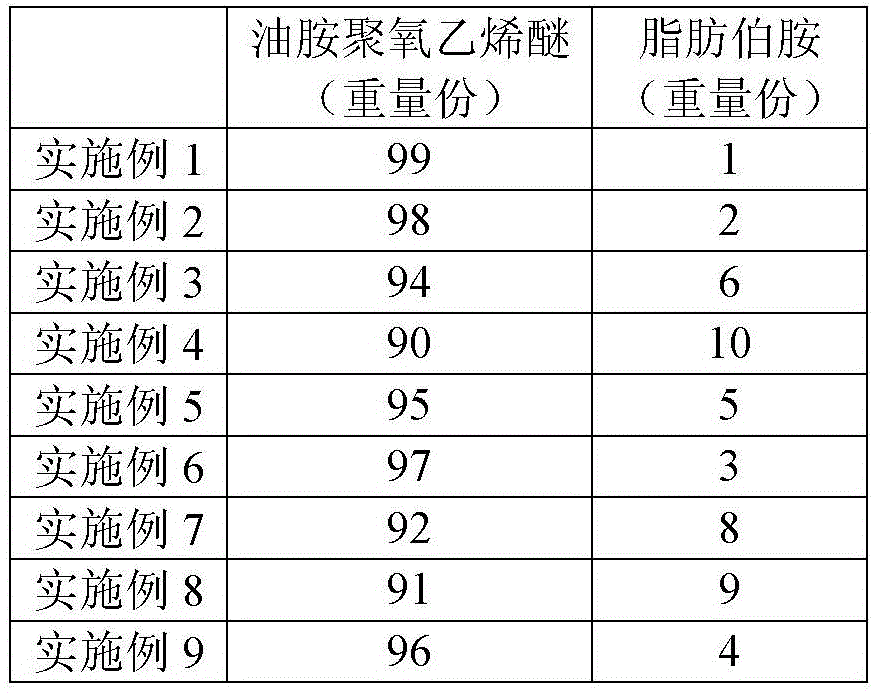

[0034] Mix oleylamine polyoxyethylene ether with fatty primary amine, in which oleylamine polyoxyethylene ether is oleylamine polyoxyethylene ether 5-20EO, see Table 1 for specific raw material parts.

[0035] Table 1

[0036]

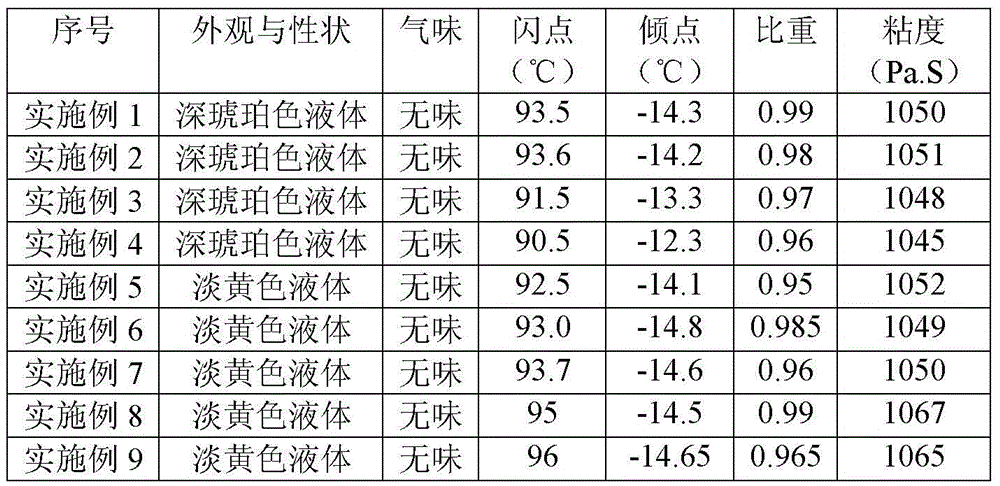

[0037] Performance tests were carried out on the purification aids prepared in Examples 1 to 9, wherein the specific gravity and viscosity were tested under standard atmospheric pressure and a temperature of 15.6° C. The specific test results are shown in Table 2.

[0038] Table 2

[0039]

[0040] The following test further demonstrates that the purification aid prepared by the present invention has a better separation and removal effect.

Embodiment 10

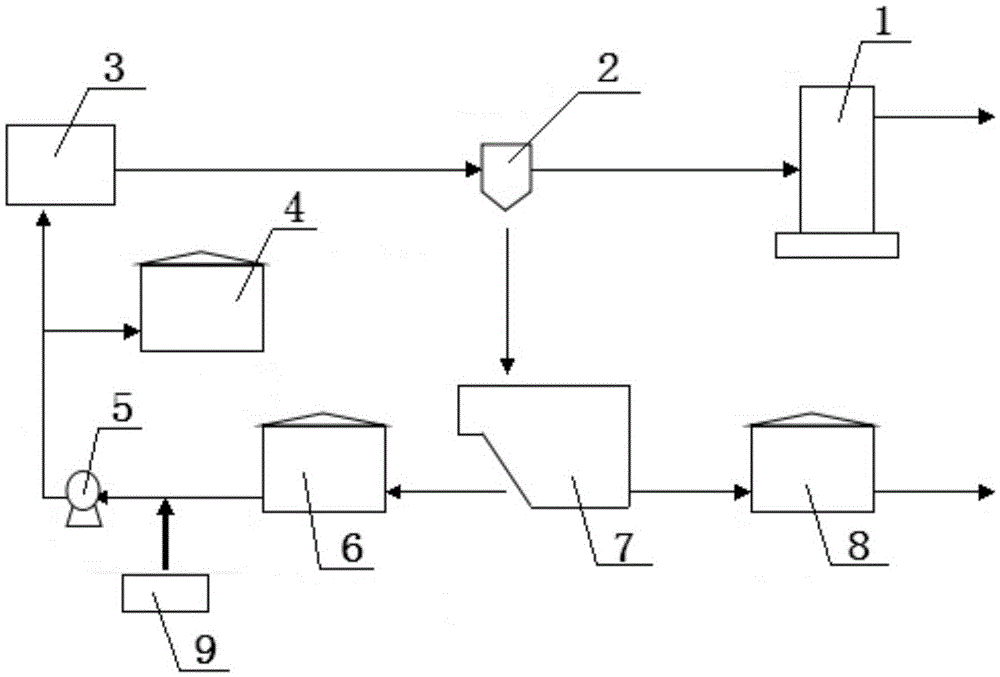

[0042] In the production process of the gas-making workshop of China Coal Longhua Harbin Coal Chemical Co., Ltd., the purification aid in Example 1 of the present invention was added to the recycling system to purify the phenolic water. The specific process is as follows: the crude gas from the gas plant comes out of the gas outlet and enters the phenol water recycling system of high temperature phenol water spraying through the circulating water pump. At the mouth, use a high-pressure metering pump to add the purification aid to the phenol water recovery circulation system in an increasing manner. The specific addition method is as follows:

[0043] First, add purification aids accounting for 3ppm of phenol water circulation in the recovery circulation system to the recycling system and keep for 15 days; secondly, add purification aids accounting for 5ppm of phenol water circulation in the recovery circulation system to the recovery circulation system and keep for 30 days Day...

Embodiment 11

[0046] The operating steps and method are the same as in Example 10, except that the cleaning aid prepared in Example 3 is used in Example 11, and the content of the added cleaning aid is different, as follows:

[0047] In the production process of the gas-making workshop of China Coal Longhua Harbin Coal Chemical Co., Ltd., the purification aid in Example 3 of the present invention was added to the recycling system to purify the phenolic water. The specific process is as follows: the crude gas from the gas plant comes out of the gas outlet and enters the phenol water recycling system of high temperature phenol water spraying through the circulating water pump. At the mouth, use a high-pressure metering pump to add the purification aid to the phenol water recovery circulation system in an increasing manner. The specific addition method is as follows:

[0048] S1, add to the recycling system a purification aid accounting for 1ppm of the phenolic water circulation in the recycli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com