A membrane dedusting device and a coal pyrolysis process using the membrane dedusting device

A dedusting device and pyrolysis technology, which is applied in the fields of dedusting device and pyrolysis process, membrane dedusting device and coal pyrolysis process, can solve the problem that there is no large-scale industrialized operation technology, the pyrolysis system is difficult to operate continuously, and the pyrolysis is hindered. Technology promotion and other issues to achieve the effects of less waste water discharge, high space utilization, and avoiding condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

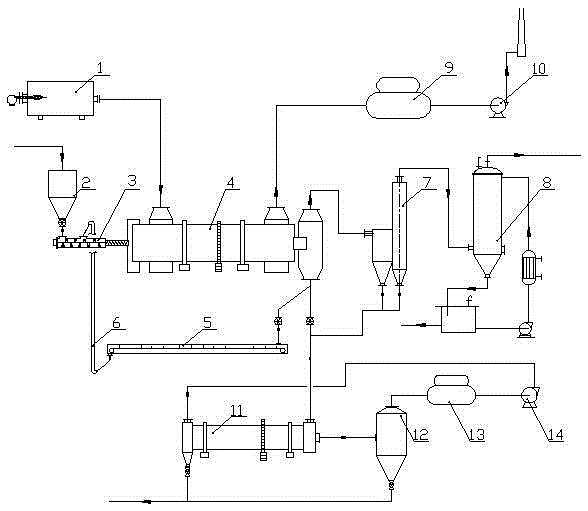

[0081] Example: such as figure 1 Shown, technique of the present invention is as follows:

[0082] Material flow: the dried low-rank coal is stored in the coal bunker 2, and the low-rank coal is sent to the interior of the multi-tube rotary retort 4 through the rotary valve and the mixer 3 according to a certain feed rate. In the multi-tube rotary retort, the coal goes through the tube side, the high-temperature flue gas goes through the shell side, the coal and the flue gas indirect heat exchange, the temperature rises and the carbonization reaction occurs, and semi-coke, gas and tar are produced. The high-temperature semi-coke is discharged from the tail of the multi-tube rotary retort 4, and part of it enters the interior of the cold coke machine 11, where it directly contacts with the circulating nitrogen to transfer heat. Part of the entrained semi-coke leaves the cold coke machine 11 and enters the semi-coke dust collector 12. This device can use inertial dust removal, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com