Coupling device and coupling process for extracting phenol from coal tar and treating phenol-containing water

A coupling device and coal tar technology are applied in the coupling process, coal tar extraction phenol and coupling device field of phenol-containing water treatment, which can solve the problems of poor quality of crude phenol products, high equipment cost and high processing cost, and reduce the phenol content. And the effect of processing cost, reducing energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] This embodiment provides a coupling device and coupling process for extracting phenol from coal tar and treating phenol-containing water, based on the coupling device provided in the specific implementation:

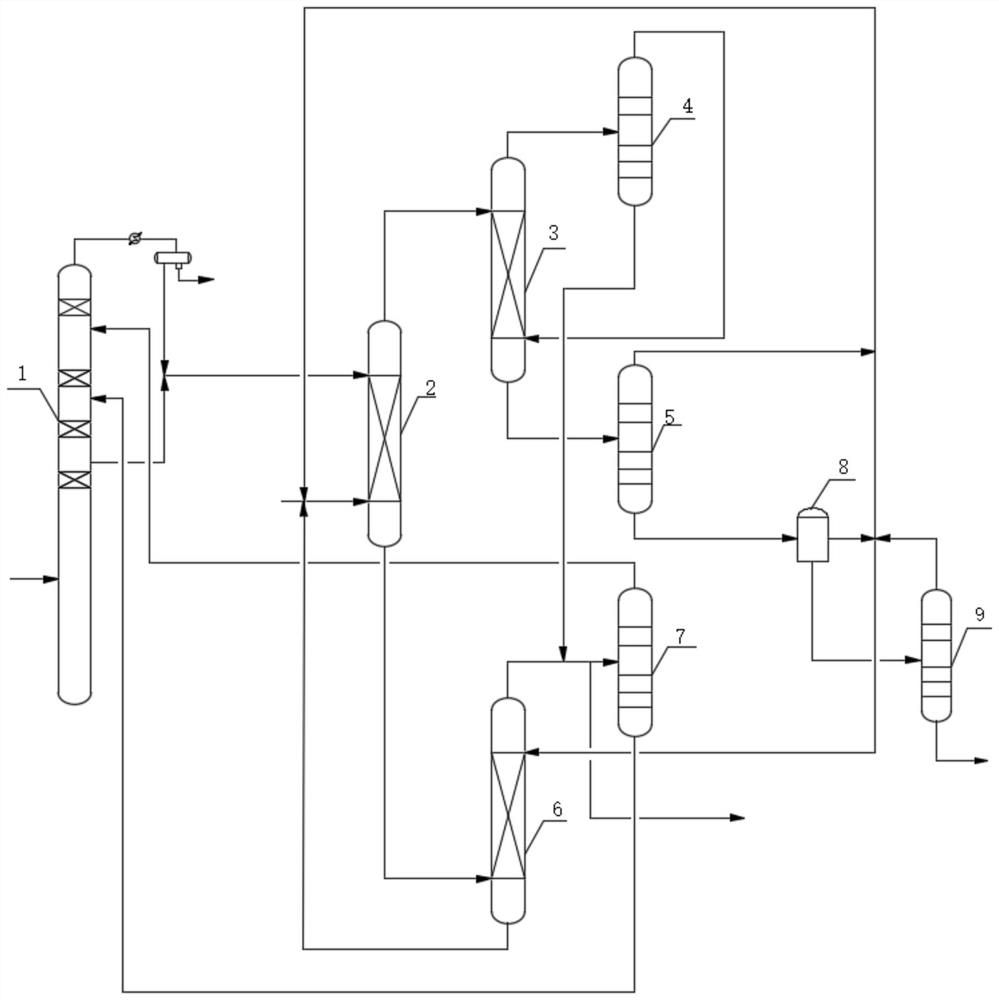

[0101] Among them, the packed rectification tower is provided with 4 packing sections. The schematic diagram of the connection structure of the coupling device provided in this embodiment is as follows: figure 1 shown.

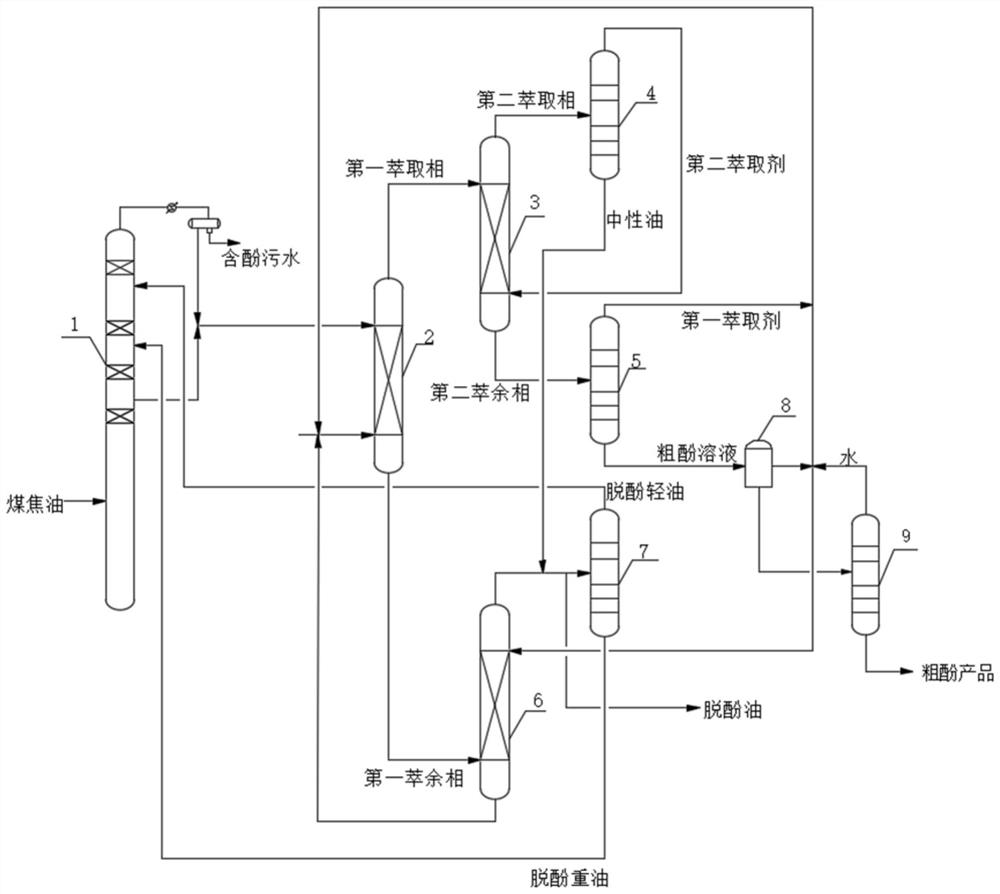

[0102] The coupling process that adopts above-mentioned coupling device to carry out comprises the following steps, and its technological process is as follows: figure 2 as shown,

[0103] (1) Carry out extraction and rectification of coal tar to obtain phenolic oil (taking 3 , crude phenol content is 36.7wt%); When carrying out described extractive rectification, used extractant obtains dephenolized light oil after the third rectification in step (3);

[0104] (2) Carry out primary extraction to the phenol-containing oil obtained in step (1) ...

Embodiment 2

[0114] This embodiment provides a coupling device and coupling process for extracting phenol from coal tar and treating phenol-containing water, based on the coupling device provided in the specific implementation:

[0115] Among them, the packed rectification tower is provided with 4 packing sections.

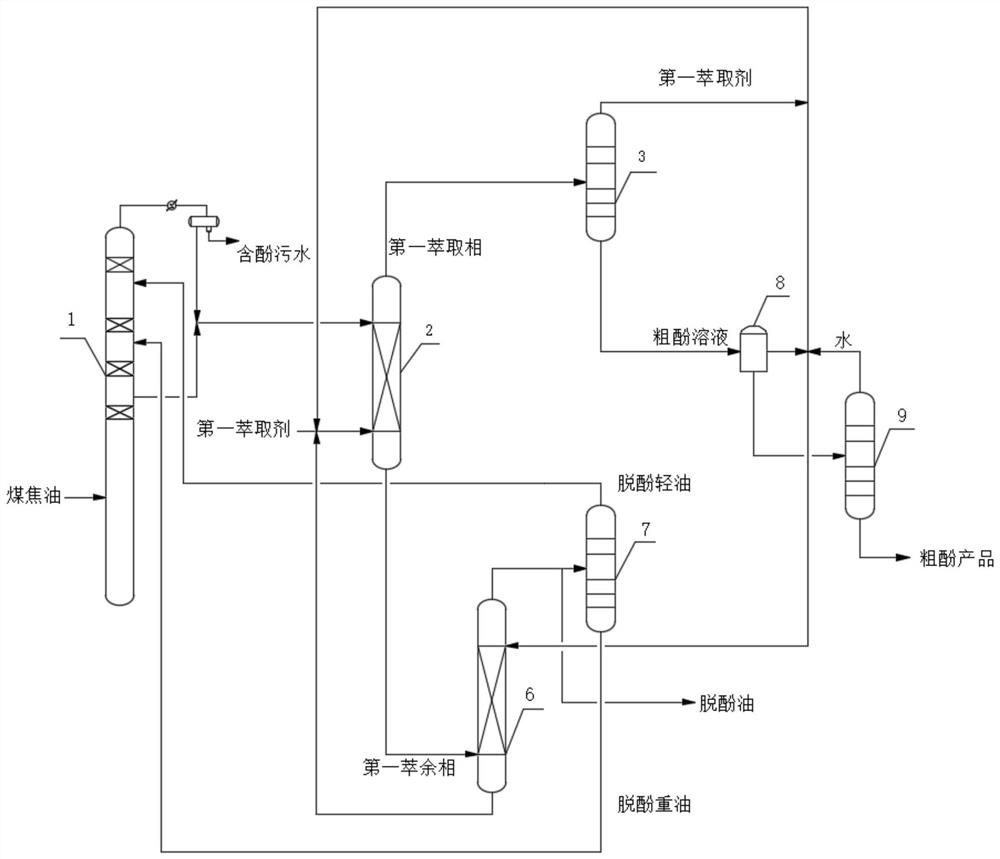

[0116] The coupling process that adopts above-mentioned coupling device to carry out comprises the following steps:

[0117] (1) extracting and rectifying coal tar to obtain phenol-containing oil; when carrying out said extracting and rectifying, the extractant used is obtained after the third rectifying in step (3) to obtain dephenolized light oil;

[0118] (2) Carry out primary extraction to the phenolic oil that step (1) obtains by adding methanol aqueous solution (the mass ratio of described methanol aqueous solution and described phenolic oil is 1:1), the primary extraction phase that obtains adopts ring Hexane carries out secondary extraction (the mass ratio of describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com