Three-oil mixture phenol removing method and device

A technology of three-mixing oil and separation device, which is applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of intractability, high consumption, environmental pollution, etc., to improve quality, reduce phenolic substance content, improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

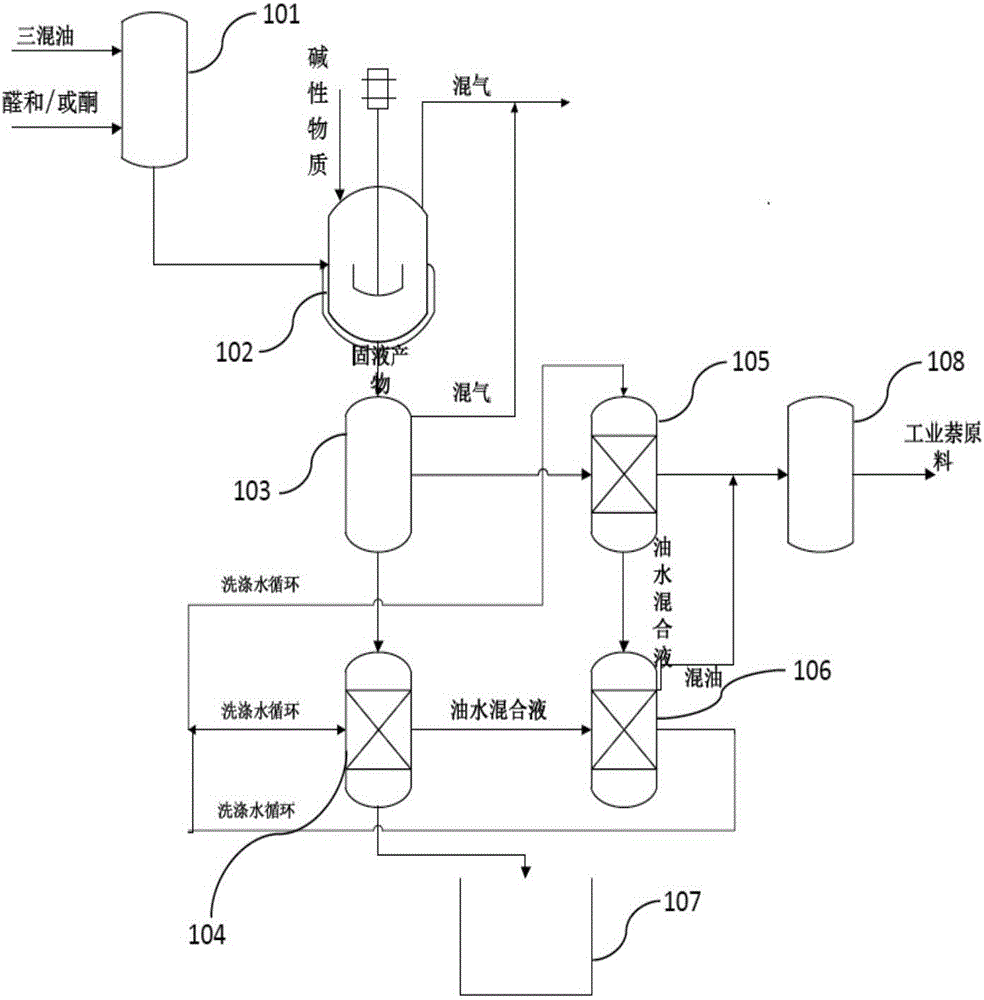

[0036] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the method for removing phenols and the device for removing phenols from triple-mixed oil proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Embodiments, structures, features and effects thereof are described in detail below. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures or characteristics of one or more embodiments may be combined in any suitable manner.

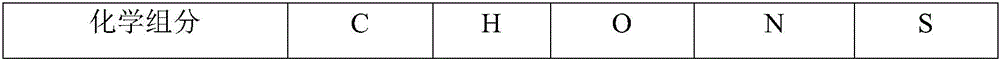

[0037] Reaction of three mixed oils with aldehydes and ketones in an alkaline environment to generate phenolic resins, wherein the ketones contain α-H; solid-liquid separation of the reacted product to obtain a solid phase and a liquid phase, wherein the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com