Oil dephenolizing extractant in brown coal tar, and preparation method and application thereof

A technology for removing phenolic extractants and lignite tar, which is applied in chemical instruments and methods, extraction water/sewage treatment, liquid solution solvent extraction, etc., can solve the problem of low economic value, achieve economic value improvement, wide source of raw materials, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

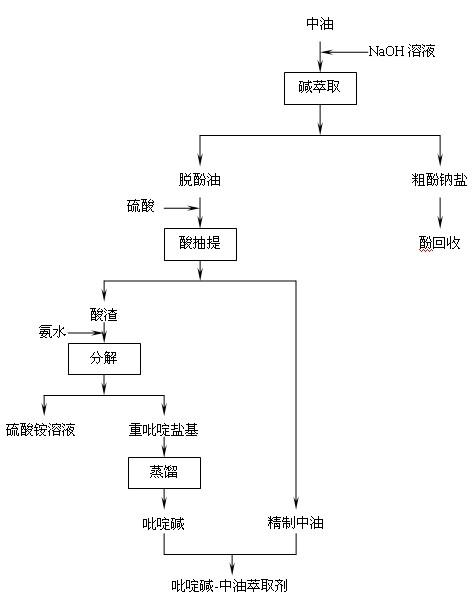

Method used

Image

Examples

Embodiment 1

[0041] 1, the preparation method of lignite tar oil dephenol extraction agent

[0042] (1) The NaOH solution with a mass percentage of 20% is used as the lignite tar medium oil alkali washing solution. After mixing 16L of NaOH solution and 20L of lignite tar medium oil at a volume ratio of 0.8 to 1, place it in a constant temperature air shaker for oscillating alkali washing. The speed of constant temperature air shaker is 160r / min, the temperature is 50°C, the shaking time is 5min, let it stand for stratification, take out the upper layer and wash it with medium oil;

[0043] (2) Use 92% sulfuric acid as the pickling solution for medium oil of lignite tar, mix 4L of sulfuric acid with 20L of medium oil after alkali washing according to the volume ratio of 1 to 5, then place it in a constant temperature air shaker for oscillating pickling, the constant temperature air shaker speed 160r / min, temperature 50°C, shaking time 5min, standing for stratification, the upper layer is re...

Embodiment 2

[0049] 1. Preparation of oil-removing phenolic extractant in lignite tar

[0050] (1) Use NaOH solution with a mass percentage of 25% as lignite tar medium oil alkali washing solution, mix 16L of NaOH solution and lignite tar medium oil 16L according to the volume ratio of 1 to 1, and then place it in a constant temperature air shaker for oscillating alkali washing. The speed of constant temperature air shaker is 160r / min, the temperature is 50°C, the shaking time is 5min, let it stand for stratification, take out the upper layer and wash it with medium oil;

[0051] (2) Use 92% sulfuric acid as the pickling solution for medium oil of lignite tar, mix 4L of sulfuric acid with 20L of medium oil after alkali washing according to the volume ratio of 1 to 5, then place it in a constant temperature air shaker for oscillating pickling, the constant temperature air shaker speed 160r / min, temperature 50°C, shaking time 5min, standing for stratification, the upper layer is refined medi...

Embodiment 3

[0058] 1. Preparation of oil-removing phenolic extractant in lignite tar

[0059] (1) The NaOH solution with a mass percentage of 20% is used as the lignite tar medium oil alkali washing solution. After mixing 16L of NaOH solution and 17.7L of lignite tar medium oil at a volume ratio of 0.9 to 1, place it in a constant temperature air shaker for oscillating alkali washing , the speed of the constant temperature air shaker is 160r / min, the temperature is 50°C, the shaking time is 5min, let it stand for stratification, take out the upper layer and wash it with medium oil;

[0060] (2) Use 92% sulfuric acid as the pickling solution for medium oil of lignite tar, mix 4L of sulfuric acid with 20L of medium oil after alkali washing according to the volume ratio of 1 to 5, then place it in a constant temperature air shaker for oscillating pickling, the constant temperature air shaker speed 160r / min, temperature 50°C, shaking time 5min, standing for stratification, the upper layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com