Comprehensive utilization method of phenolic resin wastewater

A phenolic resin and waste water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as inability to realize zero discharge of waste water, unfavorable popularization and use, and cumbersome operation , to achieve the effect of simple operation and easy control, saving manpower and power, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

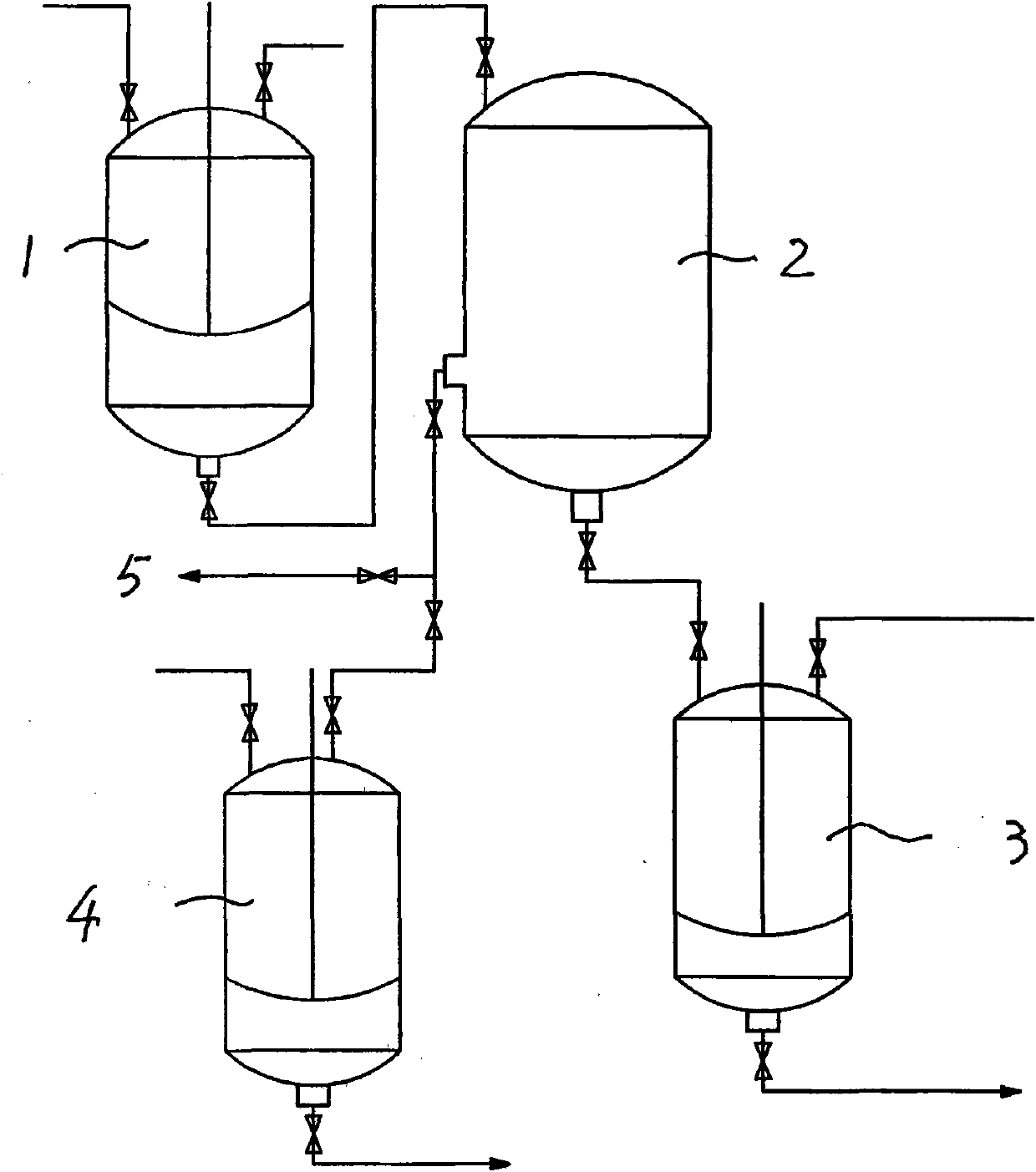

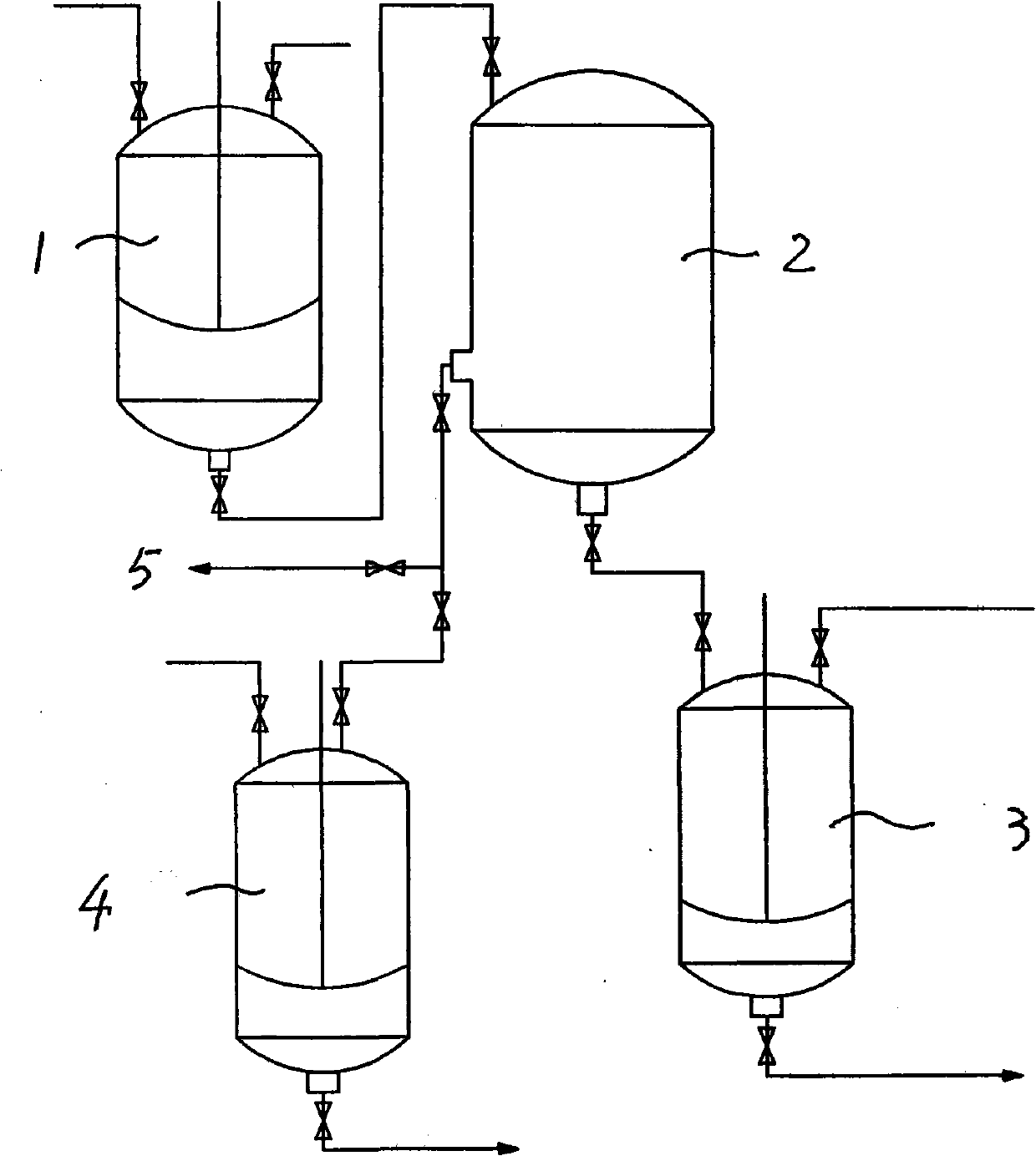

[0029] (1) Polycondensation treatment:

[0030] A. The 10000kg process wastewater produced by the production of phenolic resin is injected into the polycondensation reactor 1 and stirred;

[0031] B. According to the free phenol content in the inspection and analysis waste water, calculate the amount of formaldehyde added by formula formaldehyde quality=waste water quality×waste water phenol content%×0.256÷formaldehyde content, the free phenol content is 5%, and the formaldehyde addition is 346kg;

[0032] C. Pour 346kg of formaldehyde into the polycondensation reactor 1, and at the same time add an acidic catalyst composed of industrial grade hydrochloric acid to adjust its pH to 1-2, turn on the steam to raise the temperature to 100°C to boil and reflux, keep the temperature for 5 hours, and then cool down to 55°C, put the material in the polycondensation reactor into the settling separation tank 2 to settle and cool for 10 hours to obtain 1600kg of precipitated small molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com