Method and apparatus for dephenolizing phenol-containing waste water generated by phenol refining

A technology for phenol wastewater and dephenolization, which is applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problem of high cost of dephenolization technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

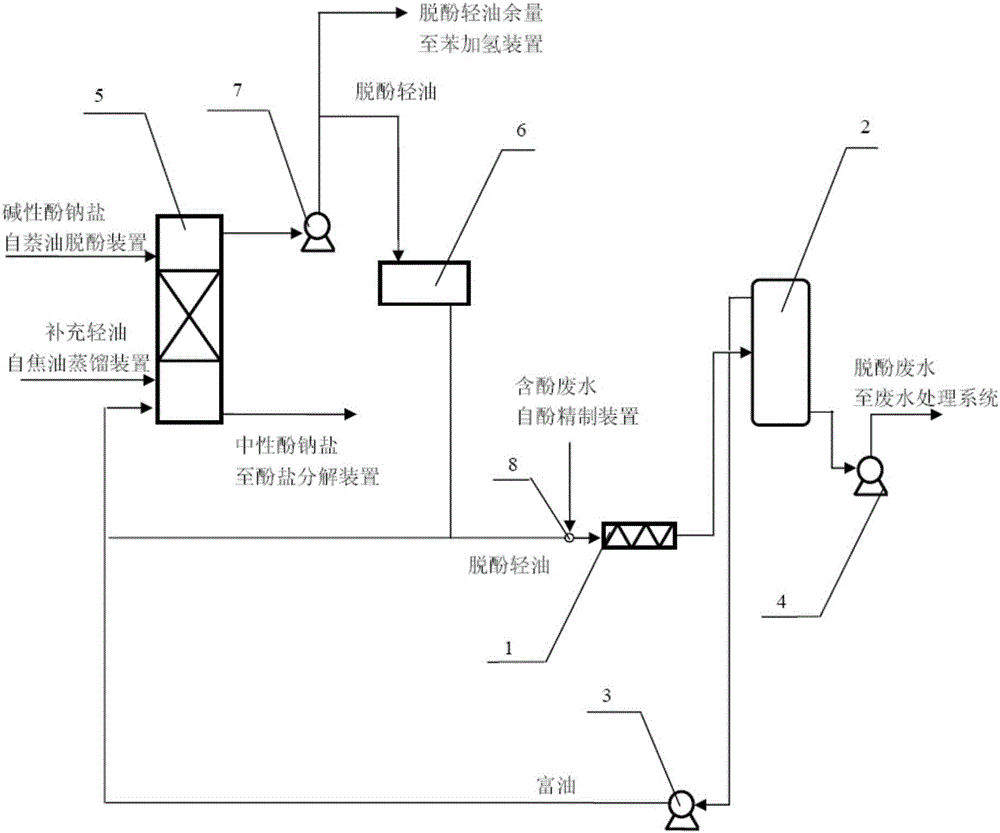

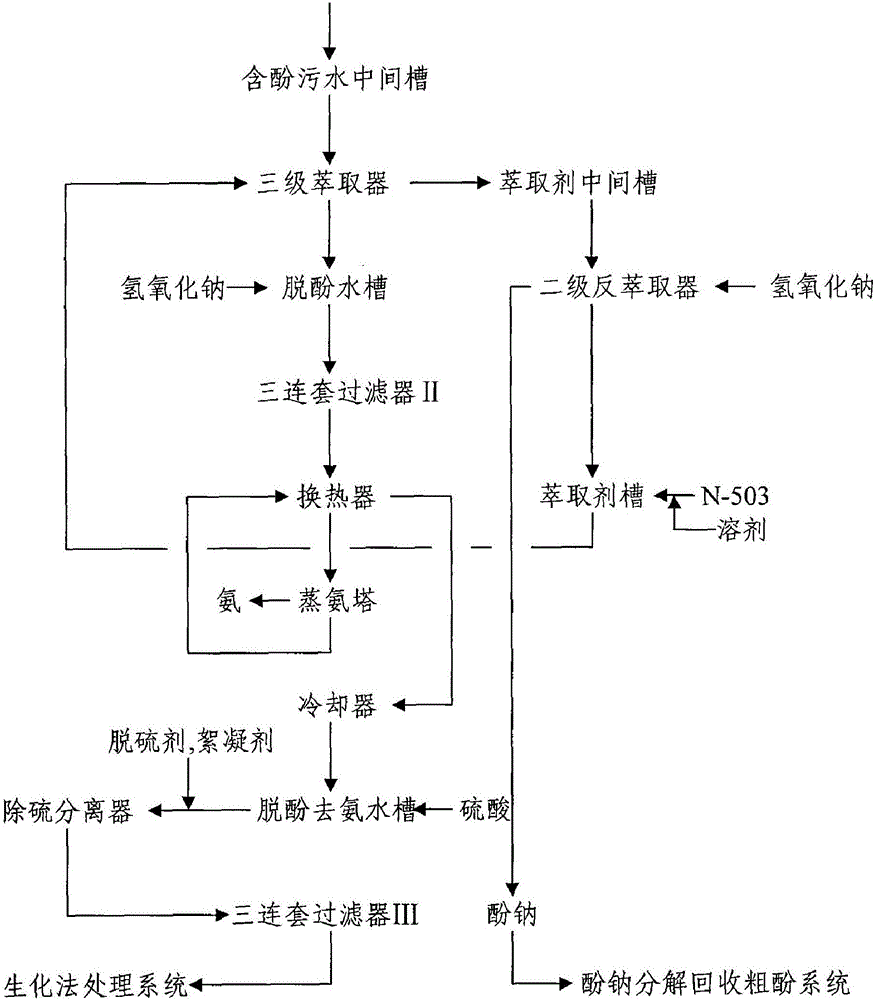

[0042] As shown in the accompanying drawing, a process flow chart of a method for dephenolizing phenol-containing wastewater from phenol purification, the process of the method for dephenolizing phenol-containing wastewater from phenol purification, one of which is extraction and dephenolization of phenol-refined phenol-containing wastewater, and the other is, Rich oil stripping to remove phenols. The process of extracting and dephenolizing the phenol-containing waste water from the refining of phenol is realized by static mixer 1, oil-water separator 2, oil-rich pump 3, and waste water pump 4; , Light oil circulation pump 7 equipment realization.

[0043] A method for removing phenols from phenol-containing waste water produced by phenol refining, comprising the steps of:

[0044] (1) The process of extracting and dephenolizing the phenol-containing waste water from the phenol-refined phenol-containing wastewater is realized in that the phenol-refined phenol-containing waste w...

Embodiment 2

[0047] The method for dephenolizing the phenol-containing wastewater produced by phenol refining provided by the present invention comprises a static mixer 1, the static mixer 1 is connected with the oil-water separator 2 through a pipeline, and the outlet of the dephenol-containing wastewater is set at the bottom of the oil-water separator 2, An oil-rich outlet is set on the top of the oil-water separator 2, and the oil-rich outlet is connected to the light oil washing tower 5 through a pipeline. The top of the clean tower 5 is connected with the cooler 6 through the light oil circulation pump 7, and the cooler 6 is connected with the static mixer 1 again, and the neutral phenol sodium salt outlet is set at the bottom of the light oil wash tower 5; The outlet is connected with the wastewater pump 4 through a pipeline.

[0048] A method for removing phenols from phenol-containing waste water produced by phenol refining, comprising the steps of:

[0049] (1) The process of ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com