Phenolic resin coated core sand for automobile part and preparation method thereof

A technology of phenolic resin and auto parts, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of poor high temperature resistance of coated sand, endangering workers' health, and high curing temperature, so as to increase mechanical properties and reduce smoke. Gas, the effect of increasing the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A phenolic resin-coated core sand for automotive parts casting, which is prepared from the following raw materials in parts by weight (kg): silica sand 130, corundum sand 20, lead-zinc ore tailings 20, phosphate phosphate 15, water-quenched nickel slag 10 , phenolic resin 3, urotropine 0.5, stearic acid amide 1, hydroxyaluminum distearate 2, carboxyl-terminated liquid polybutadiene rubber 0.2, porous calcium silicate 8, petroleum coke residue 5, propylene glycol alginate 2. Coal tar 0.2, p-cresol 0.4, ethylene glycol 3, sodium nitrate 2, potassium chloride 0.4, water 20.

[0015] A preparation method of phenolic resin coated core sand for automobile parts casting, comprising the following steps:

[0016] (1) Dissolve p-cresol in ethylene glycol for later use; add sodium nitrate into water and stir, after the sodium nitrate is dissolved, add p-cresol alcohol solution and potassium chloride, after completely dissolving, the disintegrating agent is obtained ;

[0017] (2...

Embodiment 2

[0020] A phenolic resin-coated core sand for automotive parts casting, which is prepared from the following raw materials in parts by weight (kg): silica sand 140, corundum sand 25, lead-zinc ore tailings 22, phosphate-aluminite 17, water-quenched nickel slag 12 , phenolic resin 4, urotropine 0.6, stearic acid amide 1.5, hydroxyaluminum distearate 3, carboxyl-terminated liquid polybutadiene rubber 0.3, porous calcium silicate 9, petroleum coke residue 6, propylene glycol alginate 2.5, coal tar 0.25, p-cresol 0.5, ethylene glycol 4, sodium nitrate 2.5, potassium chloride 0.55, water 25.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A phenolic resin-coated core sand for automotive parts casting, which is prepared from the following raw materials in parts by weight (kg): silica sand 150, corundum sand 30, lead-zinc ore tailings 24, phosphate phosphate 19, water-quenched nickel slag 14 , phenolic resin 5, urotropine 0.7, stearic acid amide 2, hydroxyaluminum distearate 4, carboxyl-terminated liquid polybutadiene rubber 0.4, porous calcium silicate 10, petroleum coke residue 7, propylene glycol alginate 3. Coal tar 0.3, p-cresol 0.6, ethylene glycol 5, sodium nitrate 3, potassium chloride 0.7, water 30.

[0024] The preparation method is the same as in Example 1.

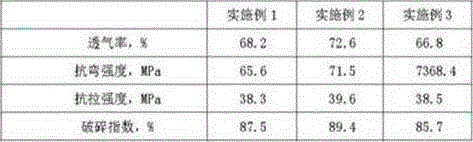

[0025] The performance detection result of the phenolic resin coated core sand that above-mentioned embodiment 1-3 makes is shown in the table below:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com