Desulfurization treatment method of phenolic oil and desulfurized phenolic oil

A treatment method and technology for phenolic oil, applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of not reaching and retaining phenolic compounds at the same time, and achieve the effect of saving production costs and reducing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

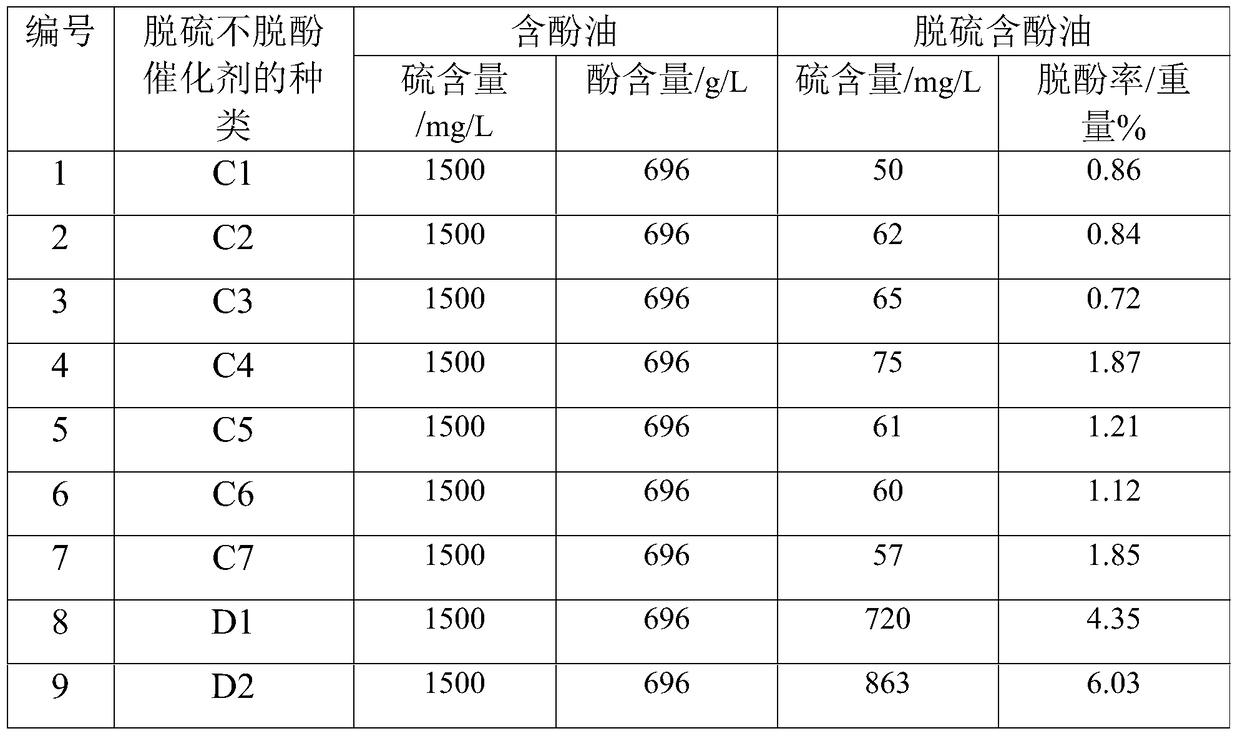

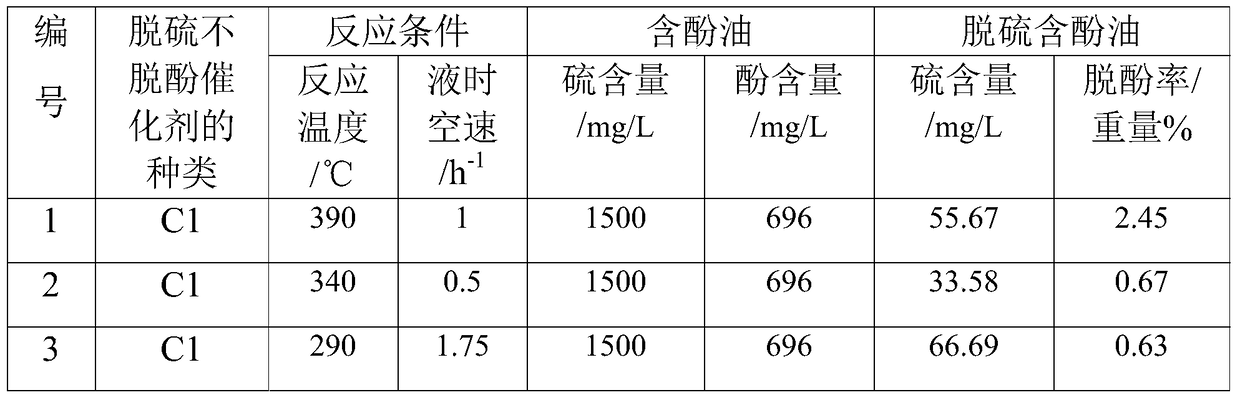

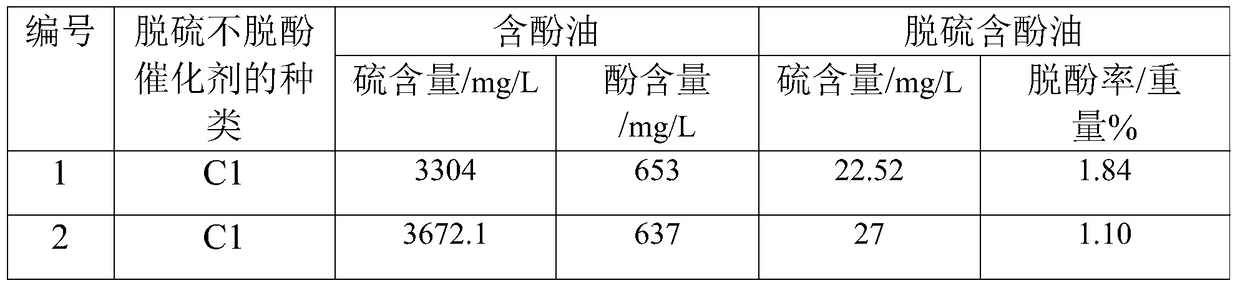

Examples

preparation example Construction

[0033] The method of the present invention has no special limitation on the preparation method of the carrier. In the process of preparing the carrier, various additives that need to be added conventionally, such as scallop powder, acidic binder, etc., can be added, and the amount of the additive is not particularly limited. Those skilled in the art can determine the amount of additives added according to actual needs.

[0034] The method of the present invention is not particularly limited to the concentration of the solution containing the active metal component elements, as long as the content of the active metal component of the desulfurization and non-removing phenol catalyst prepared by using the solution containing the active metal component elements It only needs to meet the aforementioned scope of the present invention. The method of the present invention has no special limitation on the type of the solution containing the active metal component elements, for example,...

preparation example 1

[0048] This preparation example is used to prepare the desulfurization and non-removal phenol catalyst of the present invention, and the specific method is as follows:

[0049] After mixing 450g of zinc oxide, 50g of aluminum oxide, and 15g of scallop powder evenly, add 3% by weight of dilute nitric acid to make the dry-mixed sample present a paste, and use a screw extruder to extrude the paste sample into strips, and then dry it in a blast dryer Dry overnight at 120°C, place in a muffle furnace and bake at 400°C for 6 hours to obtain ZnO-Al 2 o 3 carrier. Then, prepare the supported catalyst for desulfurization without dephenolization by equal volume impregnation method: take 5g of nickel nitrate and dissolve it in 7ml of deionized water, add 20g of the aforementioned ZnO-Al 2 o 3 The carrier was stirred for 30 minutes and soaked overnight at room temperature (25°C). The solid product was dried at 120° C. for 6 hours to obtain a catalyst precursor for desulfurization with...

preparation example 2

[0052] This preparation example is used to prepare the desulfurization and non-removal phenol catalyst of the present invention, and the specific method is as follows:

[0053] After mixing 500g of alumina and 15g of turnip powder evenly, add 3% by weight of dilute nitric acid to make the dry-mixed sample present as a paste, use a screw extruder to extrude the paste sample into strips, and then place it in a blast dryer at 120°C Dry overnight, place in a muffle furnace and bake at 400°C for 6 hours to obtain Al 2 o 3 carrier. Then, prepare the supported catalyst for desulfurization without dephenolization by equal-volume impregnation: take 5g of nickel nitrate and dissolve it in 7ml of deionized water, add 20g of the aforementioned Al 2 o 3 The carrier was stirred for 30 minutes and soaked overnight at room temperature. The solid product was dried at 120° C. for 6 hours to obtain a catalyst precursor for desulfurization without dephenolization. Desulfurization without dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com