Fixed bed slag gasification furnace

A technology of slag gasification and fixed bed, which is applied in fixed bed gasification, gasification process, gasification device details, etc., can solve the problems of increasing the amount of cooling scrubbing gas, increasing the difficulty of extraction, and increasing the amount of phenol-containing wastewater. Reach the effect of reducing the processing capacity, maximizing the economic benefits and reducing the amount of oil residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

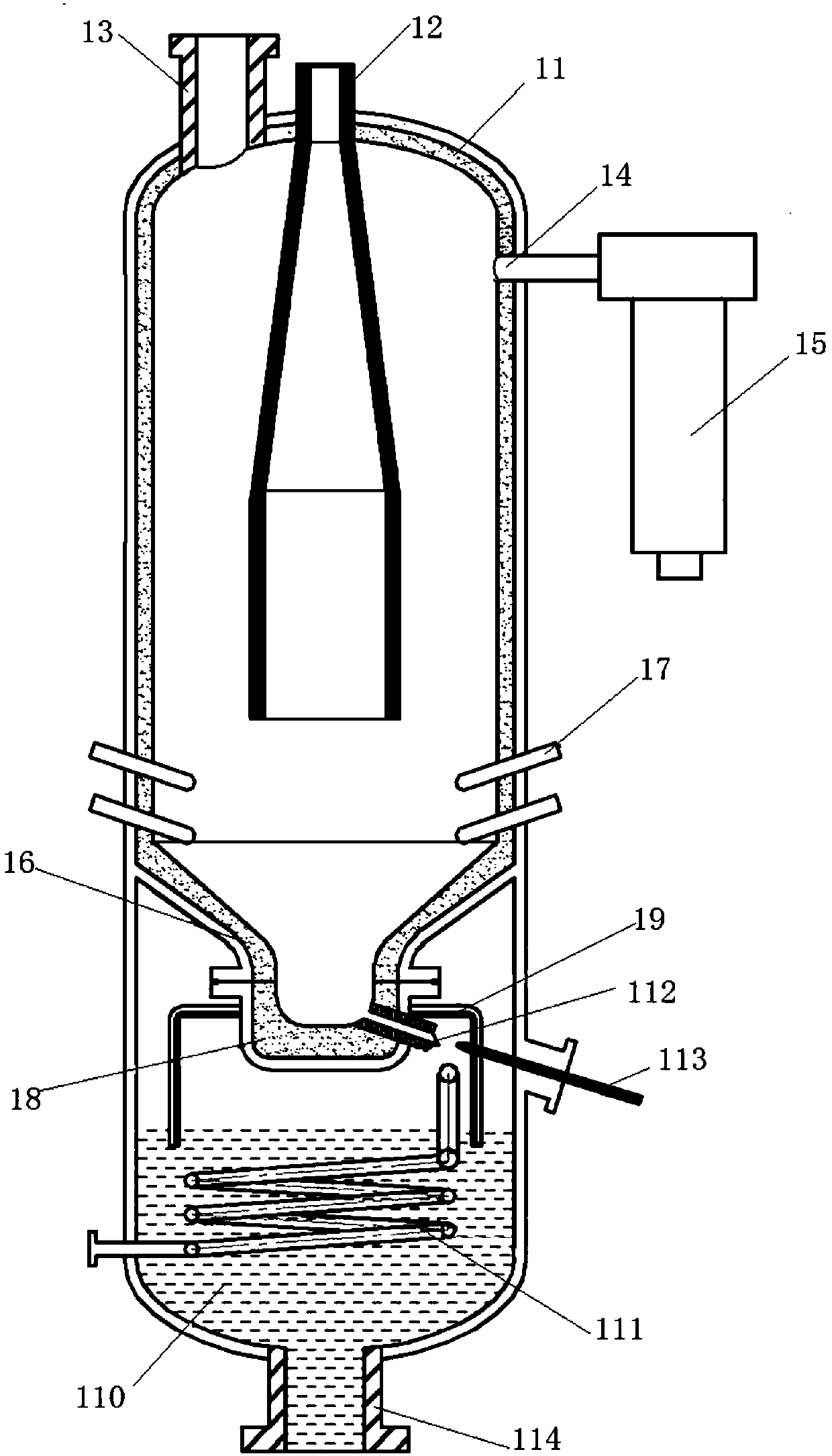

[0020] Such as figure 1 As shown, the present embodiment includes a furnace body 11, in which a different outlet pipe 12 arranged along the axial direction of the furnace body 11 is arranged, and the different outlet pipe 12 includes an upper small-diameter section, a middle expansion section and a lower large-diameter section , wherein the upper small-diameter section passes through the top of the furnace body 11 to form a high-temperature gas outlet. The inner surface of the outlet pipe 12 is provided with a refractory material, and an annular cavity is formed between the side wall of the outlet pipe 12 and the side wall of the furnace body 11, and a feeding inlet 13 communicating with the annular cavity is provided on the top of the furnace body 11 , the side wall of the furnace body 11 is provided with a low-temperature gas outlet 14 communicating with the annular cavity, and the low-temperature gas outlet 14 is connected with a spray scrubber 15 for removing tar and pheno...

Embodiment 2

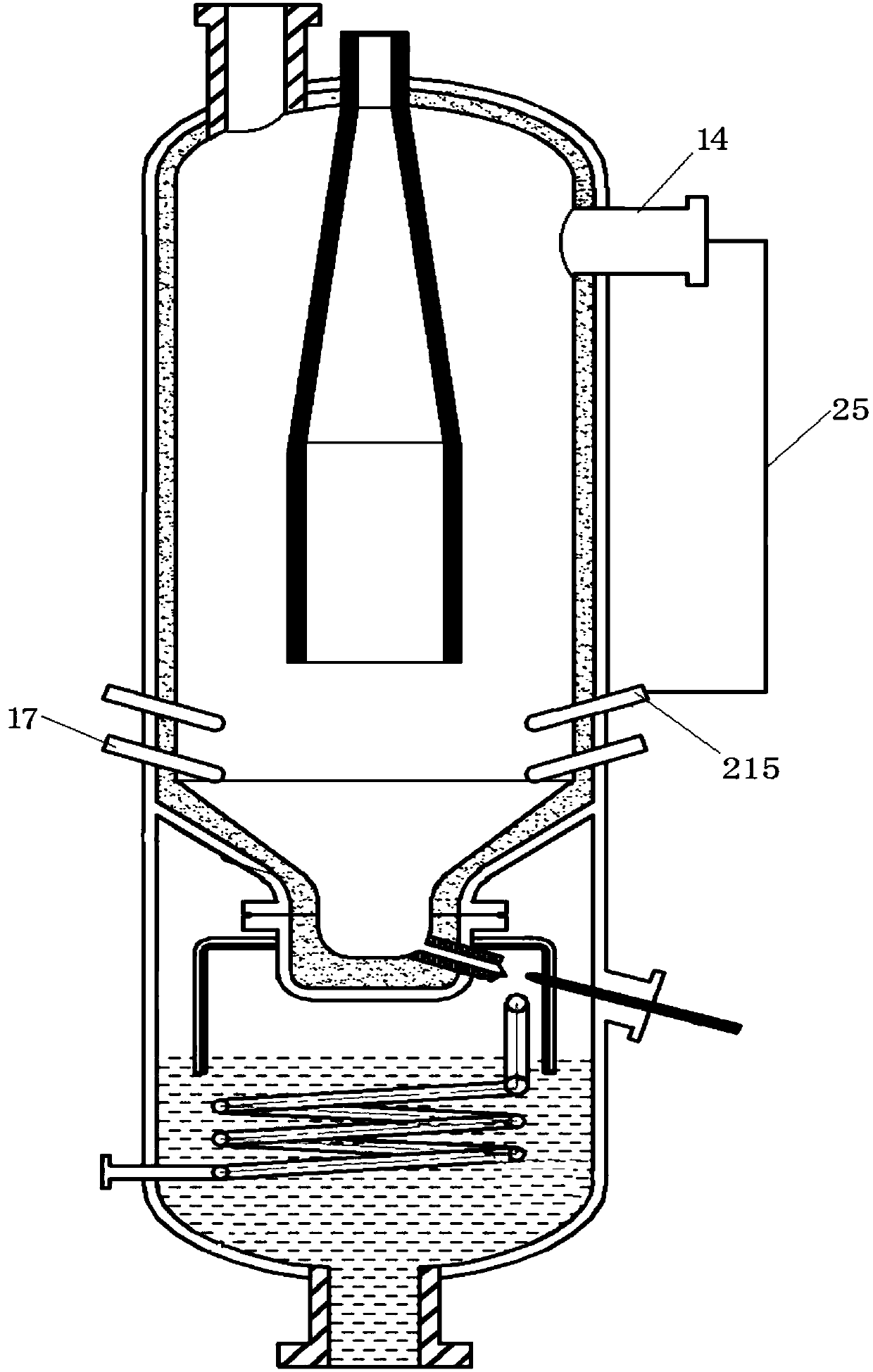

[0036] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the low-temperature gas outlet 14 is connected to one end of the low-temperature gas circulation pipeline 25, and the other end of the low-temperature gas circulation pipeline 25 is connected to the low-temperature gas nozzle 215, and the low-temperature gas nozzle 215 is arranged above the gasification agent nozzle 17, and the nozzle of the low-temperature gas nozzle 17 faces the molten slag pool 16. Part of the high-temperature gas produced by the reaction exchanges heat with the gasification raw material in the inter-annulus gap, and after passing through the dry distillation and drying sections, the low-temperature gas and tar and other dry distillation products after heat exchange pass through the low-temperature gas outlet 14, the low-temperature gas circulation pipeline 25 and the low-temperature The gas nozzle 215 leads into the high-temperature slag area, and the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com