Patents

Literature

53results about How to "Fully enriched" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

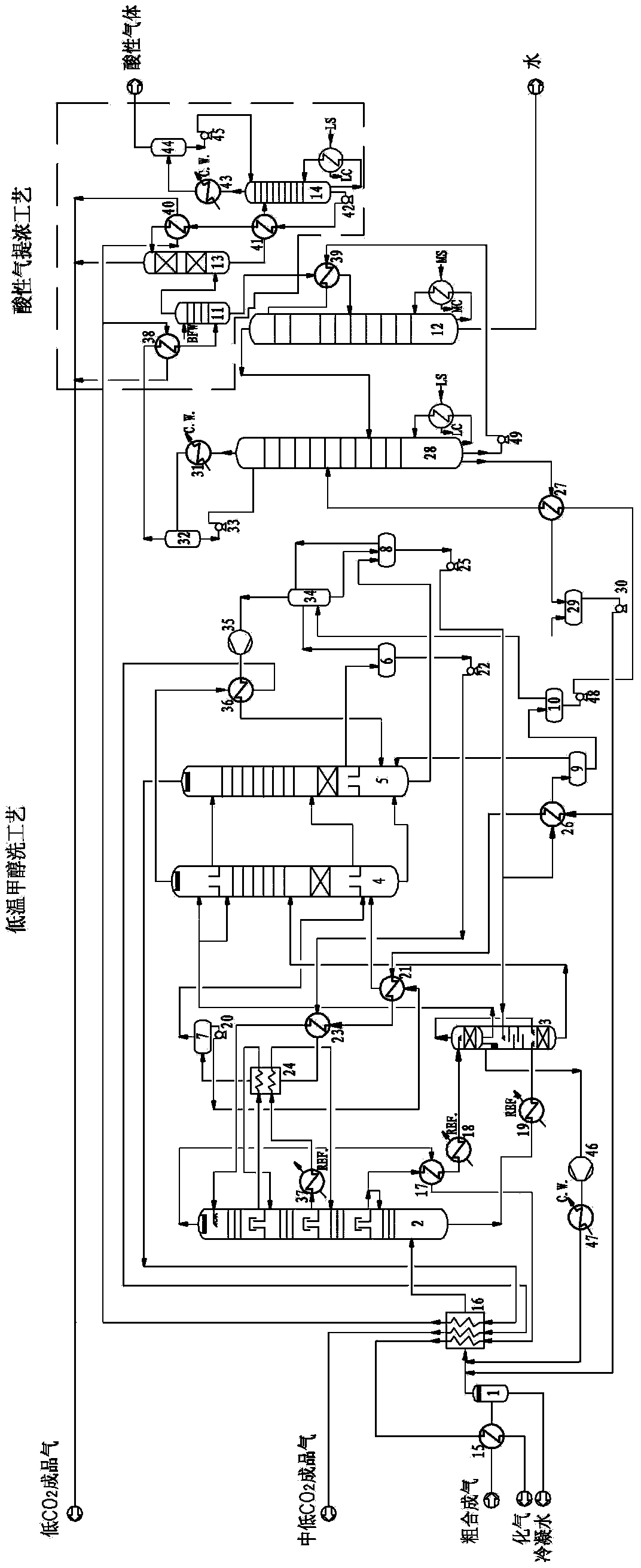

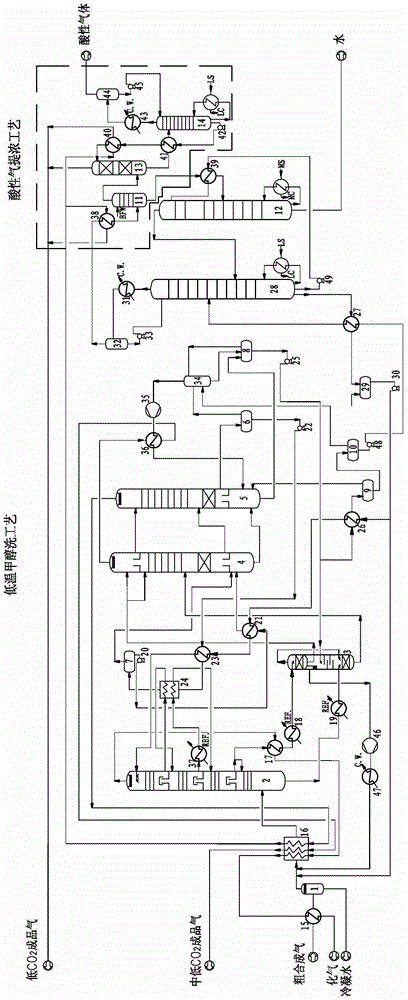

CO2 full capture and H2S enrichment process

The invention discloses a CO2 full capture and H2S enrichment process. According to the process, a low-temperature methanol washing process and an acid gas extraction concentration process are effectively combined, and a nitrogen gas extraction system and an H2S enrichment tower are canceled, so that no nitrogen gas consumption is in a running process and the running cost of the process is reduced; finished low-pressure CO2 gas in the low-temperature methanol washing process is fully utilized to cool acid gas, so that the solubility of an MDEA (methyldiethanolamine) solution is improved, at least 5% of MDEA solution circulation volume is reduced, and the energy consumption is lowered; a tail gas washing and discharging system is not configured, no tail gas is generated in the running process, and more than 99.5% of CO2 gas in coarse synthesis gas can be recovered and turned into finished high-concentration CO2 gas, so that the full capture of the CO2 gas is achieved, the volume concentration of the H2S gas in the H2S-rich acid gas is more than 70%, and the full enrichment of the H2S gas is achieved.

Owner:SINOPEC NINGBO ENG +2

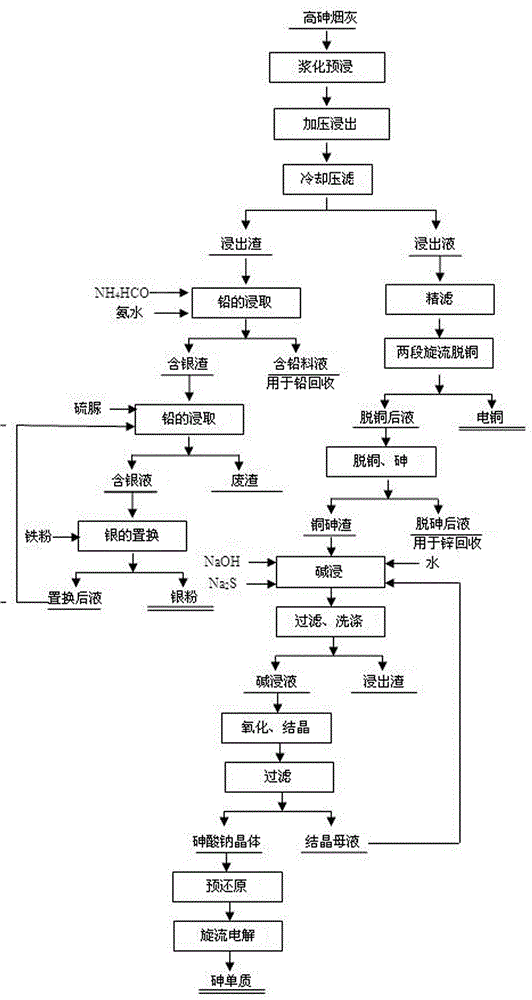

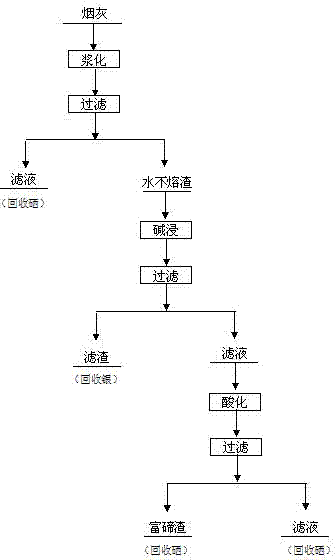

Comprehensive recycling method for high-arsenic soot

The invention discloses a comprehensive recycling method for high-arsenic soot. The method specifically comprises the following steps that two-stage leaching is conducted on the high-arsenic soot; two-stage leaching liquid enters a cyclone electrolytic system for extracting copper, and a copper product is obtained through two-stage deep decoppering; then arsenic removal is conducted, and copper-arsenic slag and a zinc sulfate solution are obtained; the copper-arsenic slag is subjected to alkaline leaching, oxidization-crystallization, prereduction and the cyclone electrolytic technology, and simple substance arsenic is produced; lead and silver in high-pressure leaching residuals are subjected to lead conversion through ammonium bicarbonate and ammonium hydroxide, the lead is made to enter feed liquid, and a lead-containing solution is obtained after solid-liquid separation to recycle the lead; and the leaching residuals are leached through thiourea, a silver-containing solution is obtained, and silver powder is obtained through replacement. According to the comprehensive recycling method, various valuable metals in the high-arsenic soot are recycled through different techniques; and meanwhile, the techniques are combined organically, basically no waste slag or waste water or waste gas or other matter is generated from the whole system, the recycling degree is high, the techniques are advanced, the recycling rate is high, the recycling cost is low, and the comprehensive recycling method has quite remarkable environment protection significance.

Owner:浙江科菲科技股份有限公司

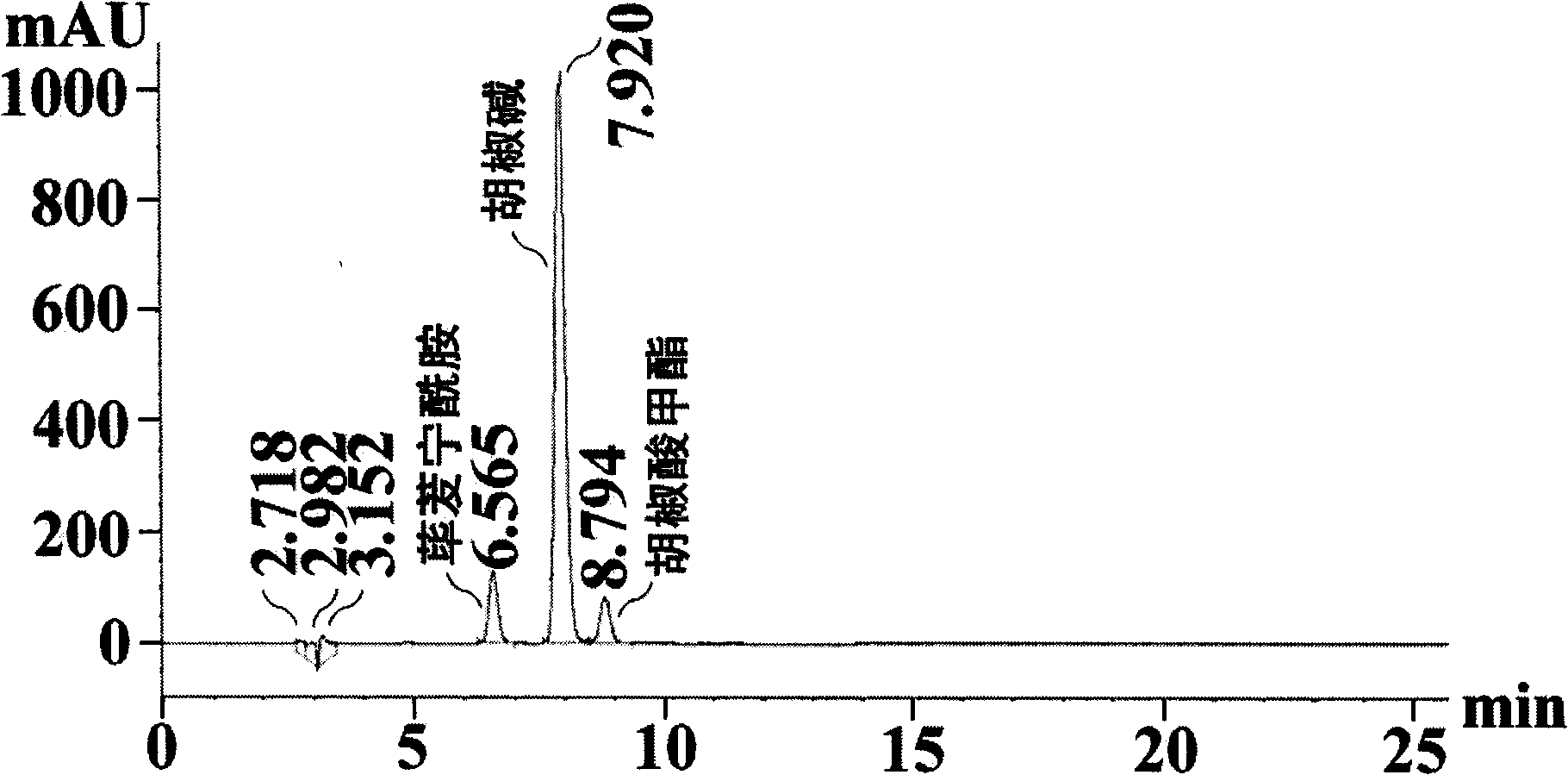

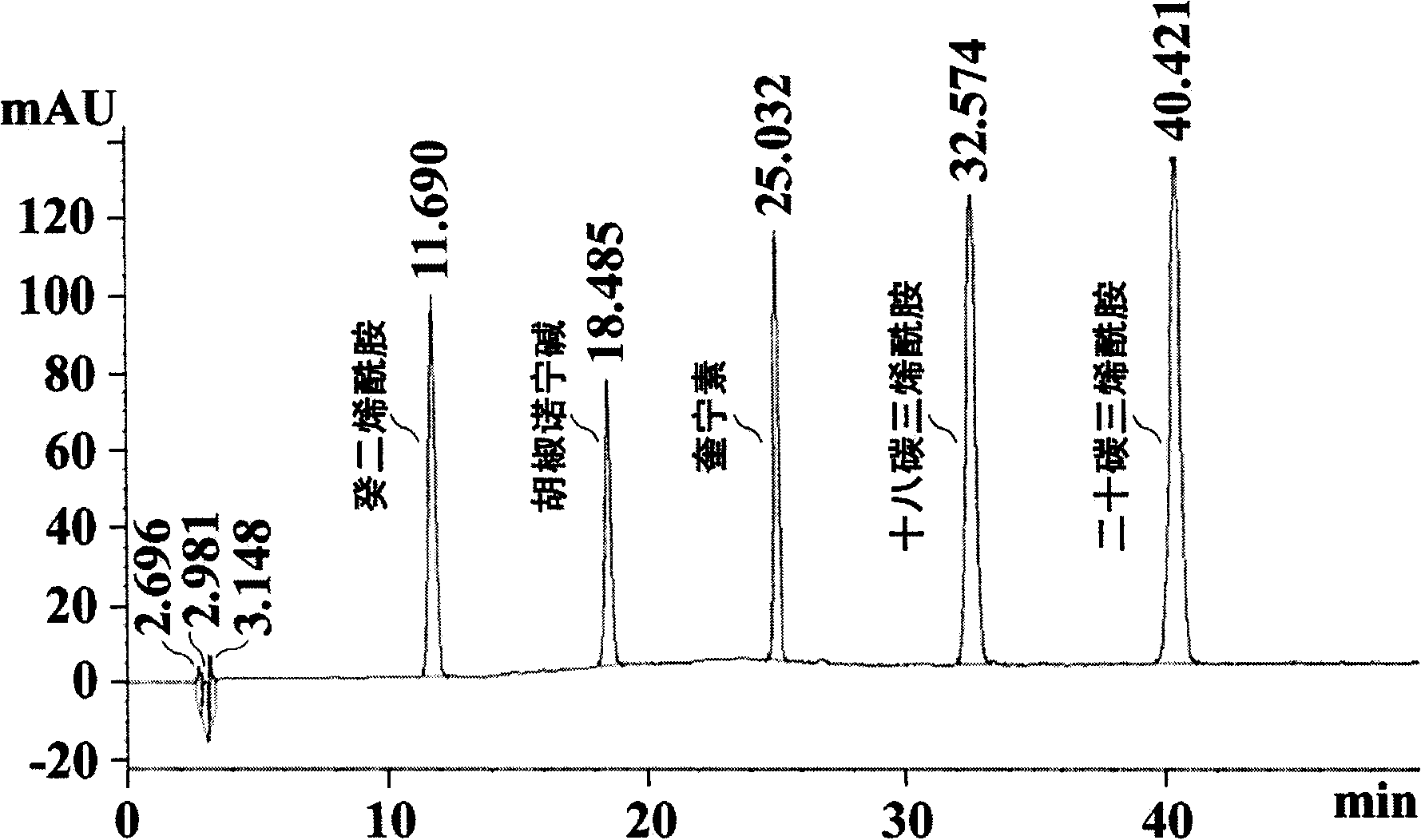

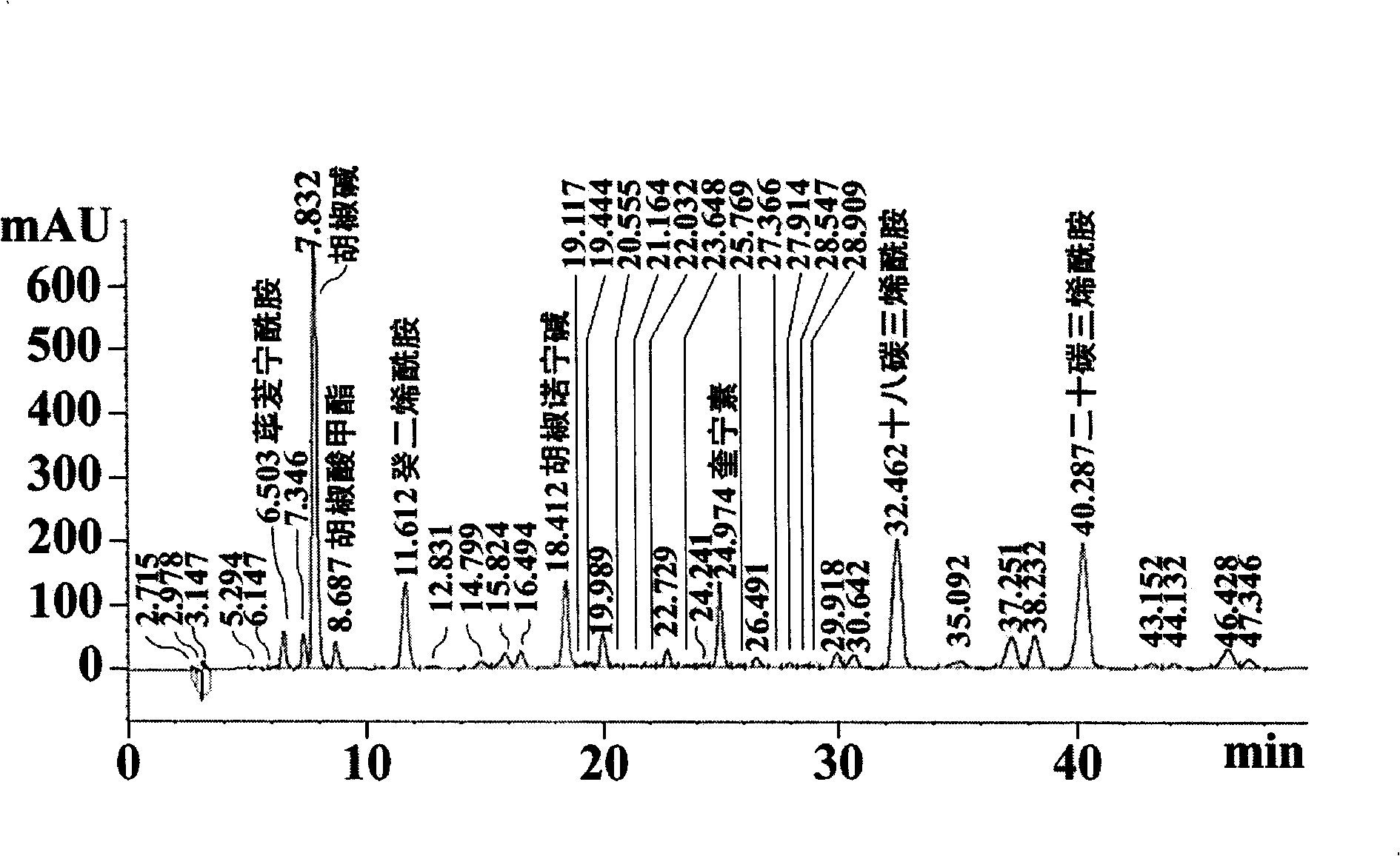

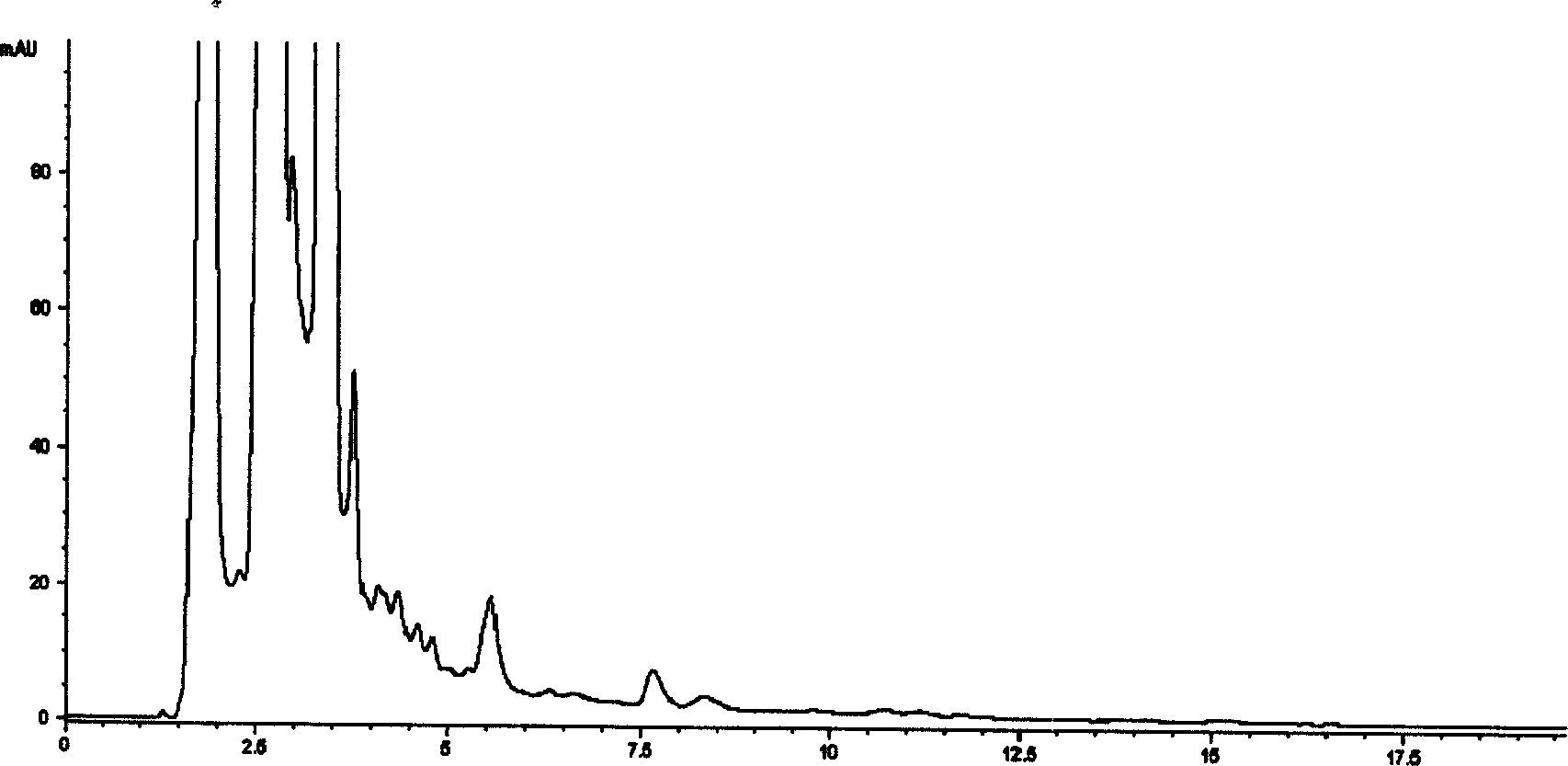

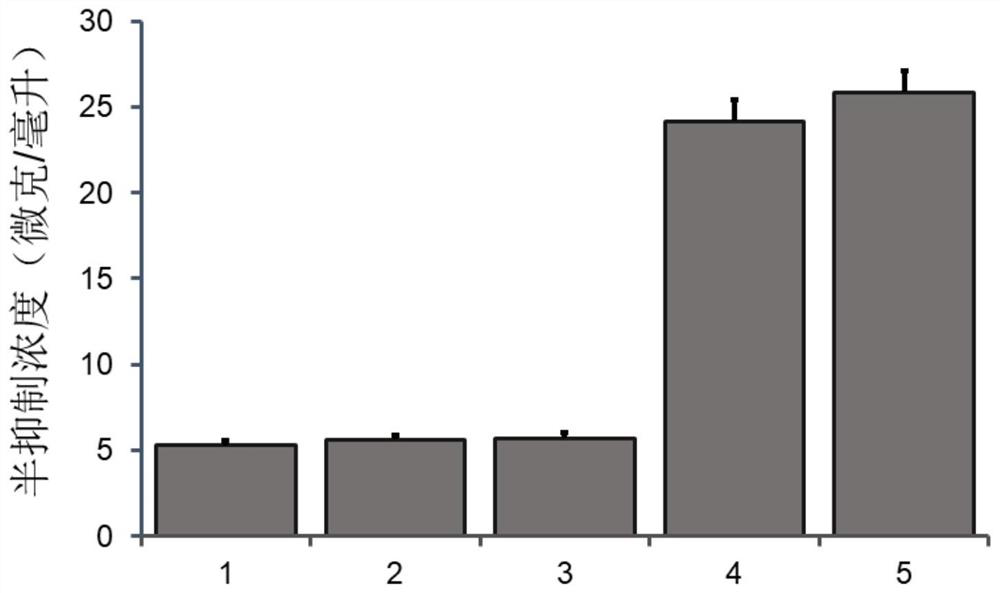

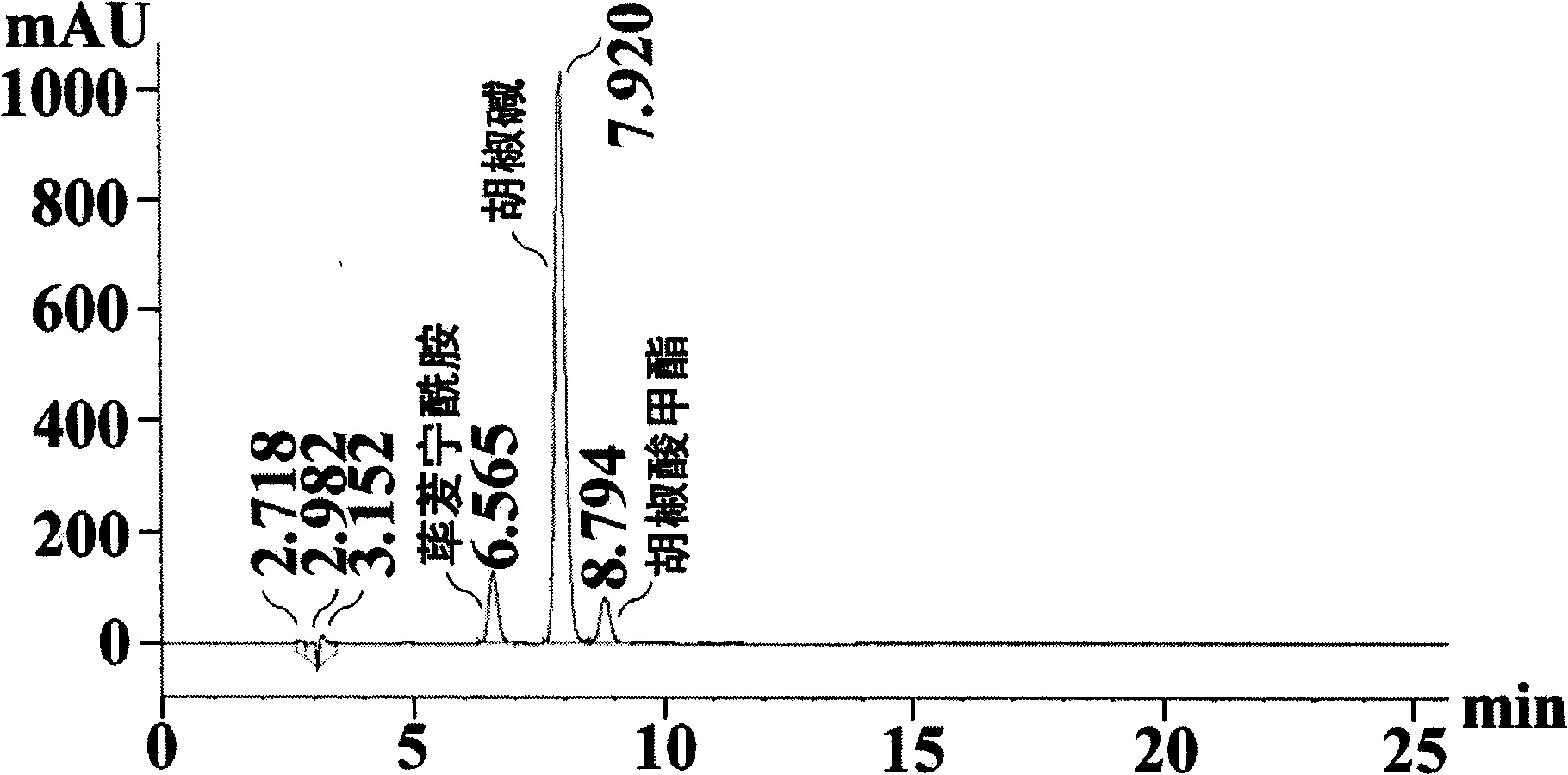

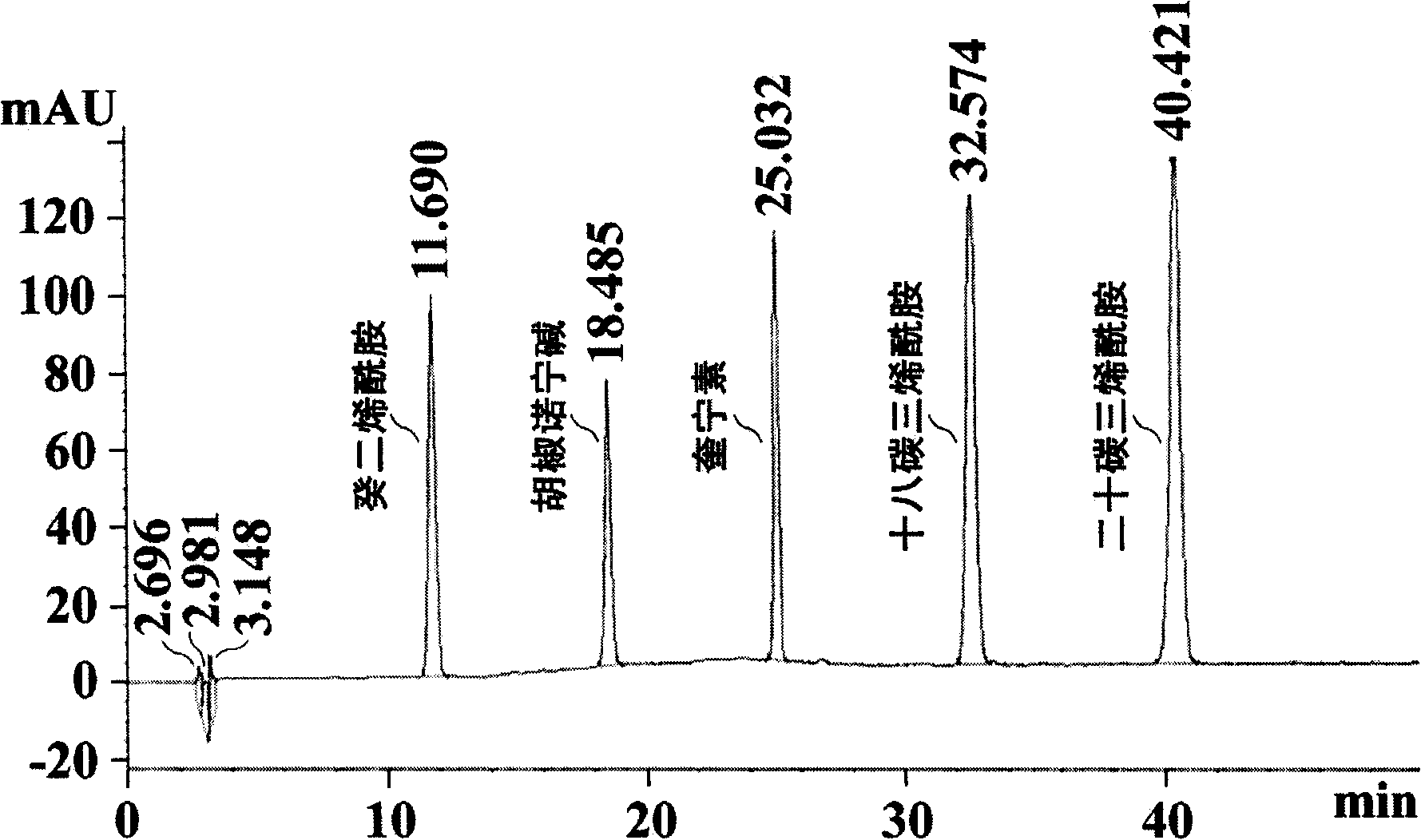

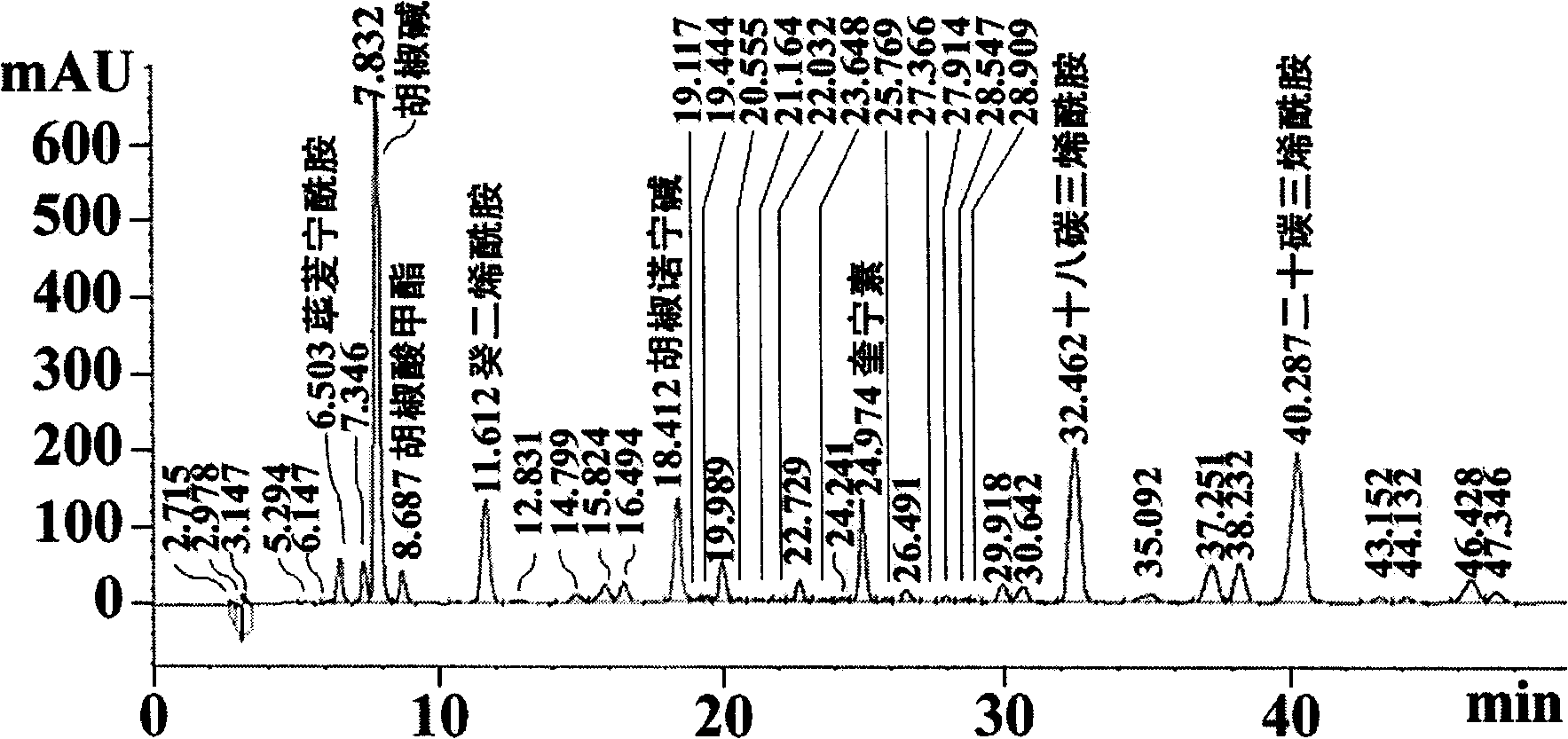

Long pepper extract, preparation method thereof, medicament composition and uses thereof

ActiveCN101352487AAvoid residueAvoid toxicityPowder deliveryAntipyreticLong pepper extractEritadenine

The invention relates to a long pepper extract, a preparation method and a medicine combination thereof. The long pepper extract mainly contains methyl piperate and seven piperlongumine compounds, namely, peperlomguminine, piperine, decadiene amide, pepper nonine alkali, quinia, octadecyl triene amide and eicosatriene amide; by weight percentage, the total weight of the eight compounds accounts for 29.07-87.80 % of the total weight of the long pepper extract, wherein, peperlomguminine accounts for 0.95-3.43 % of the total weight of the long pepper extract, piperine accounts for 14.52-42.78 %, methyl piperate 0.82-3.11%, decadiene amide 1.36-4.27%, pepper nonine alkali 2.96-8.03%, quinia 1.04-3.26%, octadecyl triene amide 3.17-10.94% and eicosatriene amide 4.25-12.42%. The invention also provides the preparation method of the long pepper extract, the medicine combination and the application thereof.

Owner:北京云威科技有限公司

Biological selenium-rich fertilizer and whole course dynamic gradient method for selenium-rich purple wheat

ActiveCN102795908AAvoid toxic effectsSolve the safety problems caused by inorganic selenium residuesFertilising methodsFertilizer mixturesWheat productCrop cultivation

The invention relates to a method for producing a selenium-rich purple wheat by using a biological selenium-rich fertilizer and a whole course dynamic gradient selenium-rich method, which belongs to the crops cultivation technical field. The method is characterized in that the biological selenium-rich fertilizer is produced, and is used to prepare a selenium-rich fertilizer mother liquor, and then the selenium-rich fertilizer mother liquor is diluted to a selenium-containing fertilizer liquid with different selenium concentrations, and is affected on soil, purple wheat seeds and whole purple wheat at different growth periods. The wheat seeds enable full enrichment on the selenium element, according to the growth characteristics of the purple wheat, the selenium-containing fertilizer liquid with different gradients is used for fitting with the purple wheat growth rules during the whole growth process of the purple wheat, thereby the exogenous inorganic selenium can be conversed to plant endogenous organic selenium with high efficiency. By detecting, the selenium content of the purple wheat product provided in the invention is 0.18-0.28mg / kg, wherein the organic selenium content is 0.16-0.25mg / kg, compared with the purple wheat product which is sprayed by a single selenium-containing fertilizer liquid c in the whole process, the selenium content multiple can reach 5-7 times.

Owner:JIANGSU ACAD OF AGRI SCI

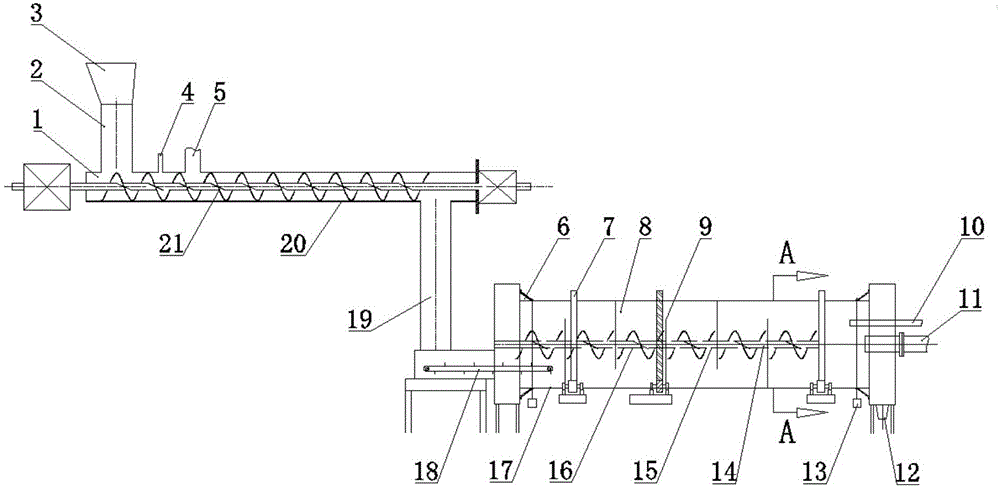

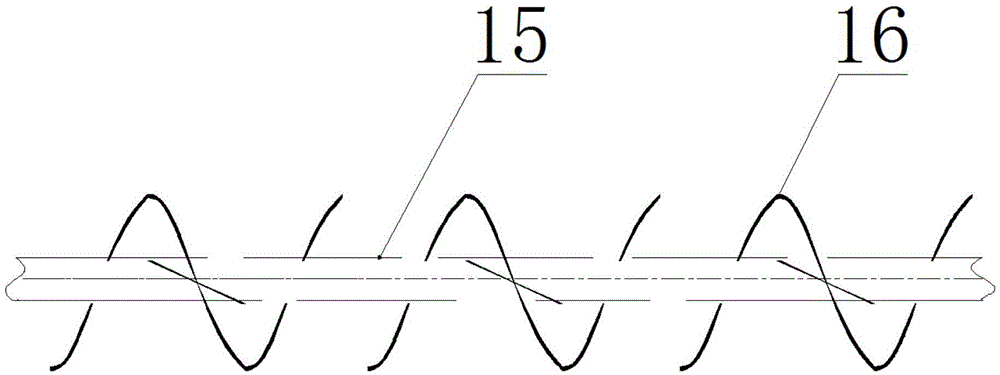

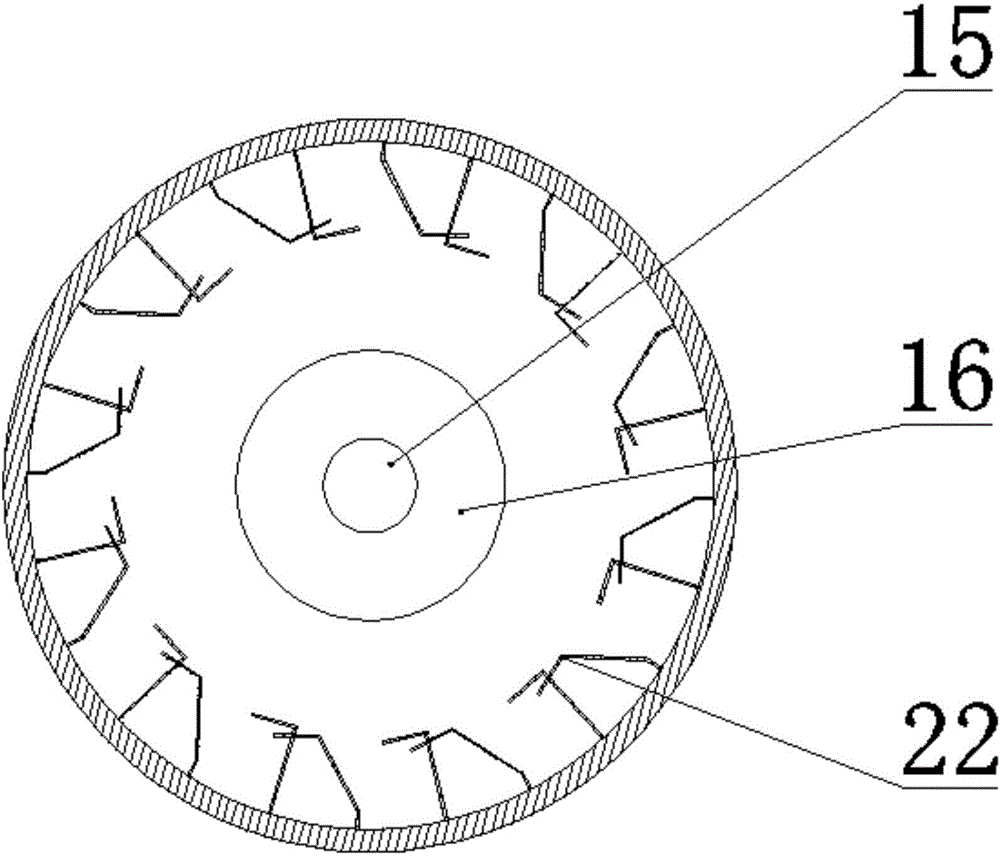

Continuous two-stage biomass nitrogen-rich pyrolytic reaction device

ActiveCN104099118ARealize continuous nitrogen-enriched pyrolysisReasonable control of pyrolysis reaction parametersProductsReagentsSupercapacitorNitrogen

The invention discloses a continuous two-stage biomass nitrogen-rich pyrolytic reaction device. The continuous two-stage biomass nitrogen-rich pyrolytic reaction device comprises an auger pre-pyrolysis reactor and a rotary type turbulence pyrolytic reactor, wherein the auger pre-pyrolysis reactor comprises a pre-pyrolysis reaction cylinder, an auger and a feed pipe, and biomass enters the pre-pyrolysis reaction cylinder through a feed pipe, utilizes the pumped-in powdery exogenous nitrogen to achieve pre-pyrolysis under the pushing action of the auger and can be output through a discharge opening at the other end of the pre-pyrolysis reaction cylinder; the rotary type turbulence pyrolytic reactor comprises a pyrolytic reaction cylinder and a turbulence rotor capable of rotating relative to the pyrolytic reaction cylinder, as well as a gaseous exogenous nitrogen lead-in pipe and a high-temperature oxygen-free heat-carrying gas lead-in pipe, and under the atmosphere of the gaseous exogenous nitrogen and the high-temperature oxygen-free heat-carrying gas, counterrotation of the turbulence rotor and the pyrolytic reaction cylinder is utilized to enable full pyrolytic reaction between pre-pyrolysis biomass raw materials and nitrogenous gas so as to realize two-stage pyrolysis to produce multi-phase products. According to the invention, two-stage introduction of the exogenous nitrogen is utilized to manufacture nitrogen-rich oil and nitrogen-rich coke which can be respectively used for synthesizing high-quality chemicals and preparing high-performance super capacitors.

Owner:HUAZHONG UNIV OF SCI & TECH +1

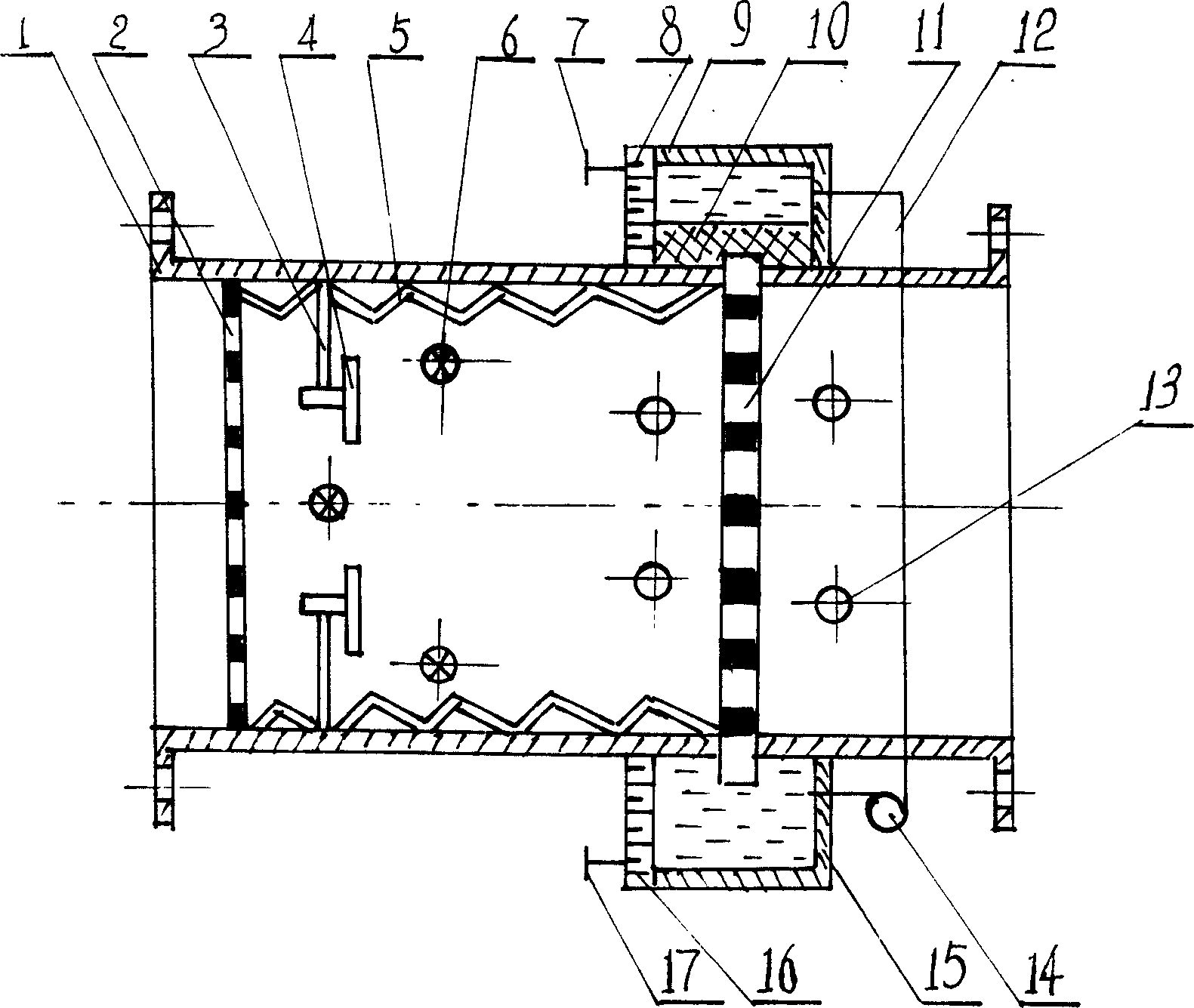

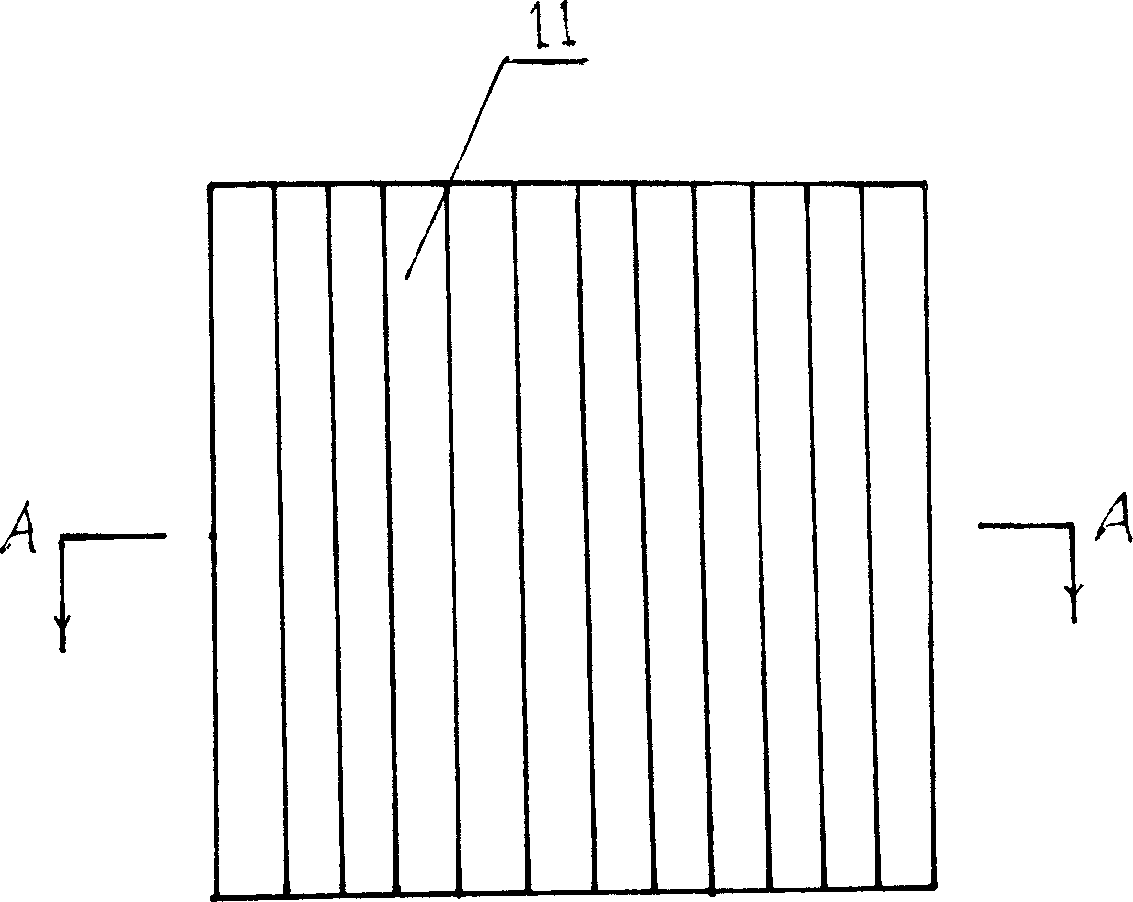

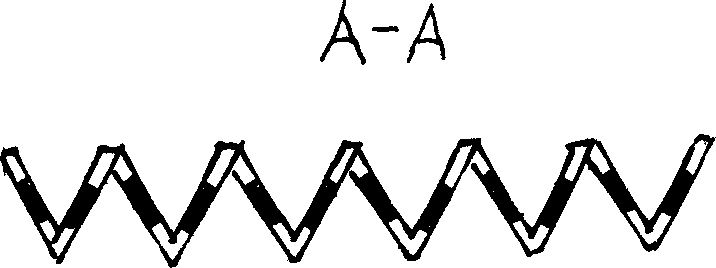

Supersonic synergic nano light catalytic air-sterilizing-purifying apparatus

InactiveCN1850283AImprove performanceImprove dust removal efficiencyDeodrantsRadiationAir cleaningPhotocatalysis

The present invention relates to an ultrasonic synergistic nano photocatalytic air sterilization and purification equipment. It includes the following several portions: shell body, upper water tank, lower water tank, water inlet valve, water outlet valve, miniature water pump, filtering screen, ultrasonic air energy transducer, filter, photocatalysis three-dimensional screen, ultrasonic reflecting plate and sterilization UV-light. Said invention also provides the connection mode of all the above-mentioned portions and the working principle of said air sterilization and purification equipment.

Owner:SHAANXI NORMAL UNIV

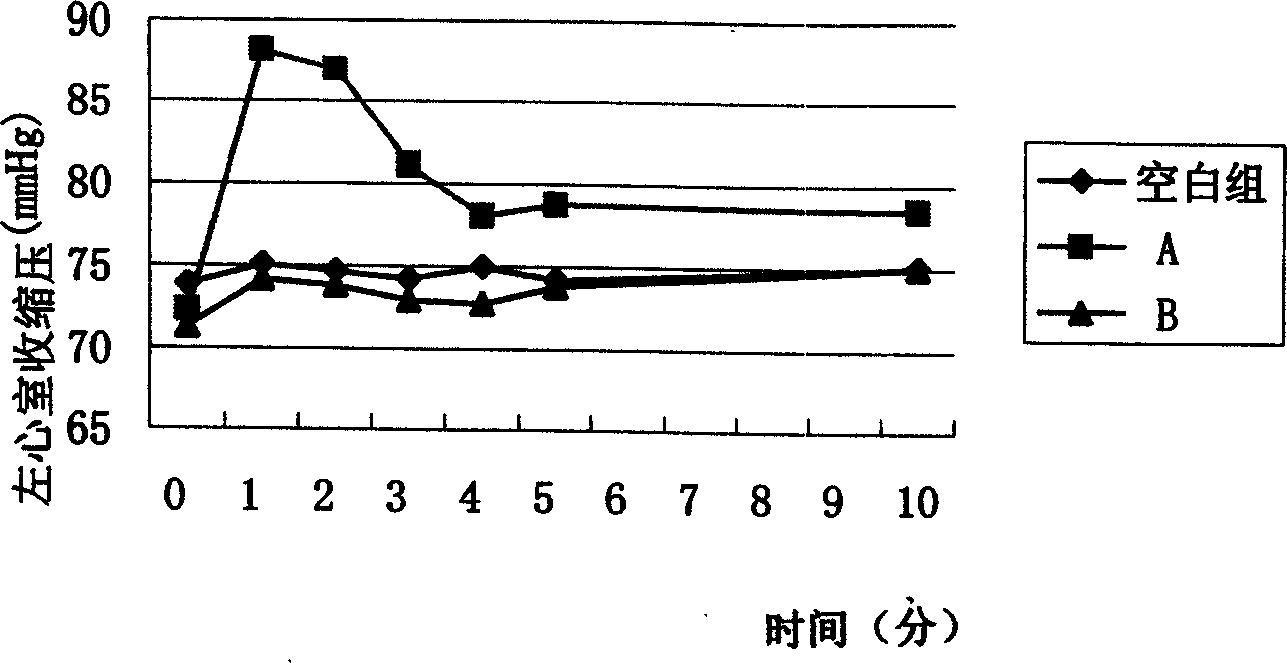

Effective extract of Chinese silkuine bark with cardotonic function and its preparing process and uasge

The invention discloses the effective extract of Chinese silkuine bark with cardotonic function and its preparing process and use thereof, where the preparation process includes, (1) abstraction of Chinese silkuine bark by using 40%-80% alcohol or 40%-100% methyl alcohol as extracting agent, purifying through macroscopic adsorption resin column, eluting with 2-10 times of resin bed volume ethanol, collecting the eluent, concentrating, and drying.

Owner:TIANJIN TASLY PHARMA CO LTD

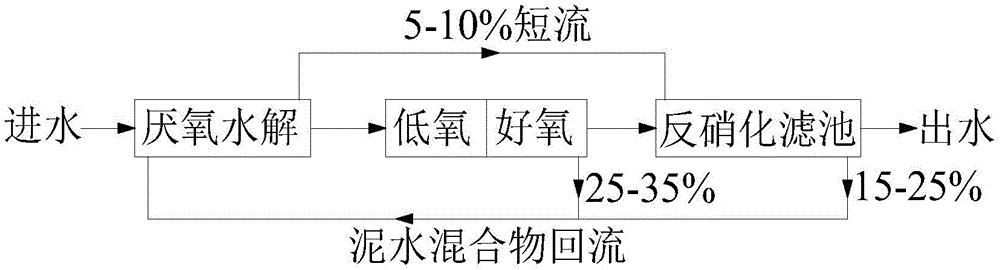

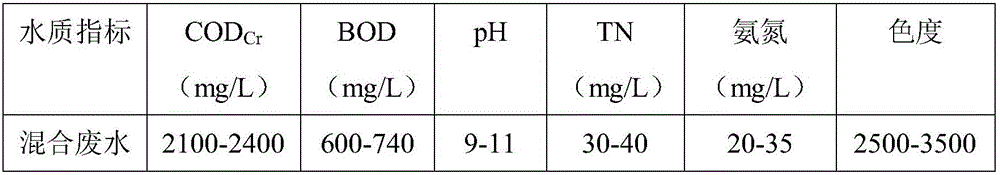

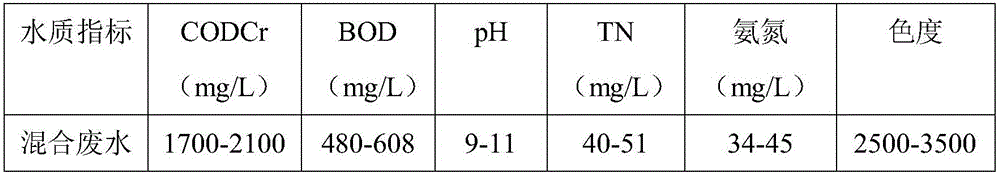

Denitrification technology for printing and dyeing wastewater

ActiveCN106186320AGuaranteed supplementRealize multi-effect denitrificationWater treatment parameter controlSpecific water treatment objectivesFiltrationSludge

The invention discloses a denitrification technology for printing and dyeing wastewater. The technology comprises steps as follows: step 1, a denitrification system for the printing and dyeing wastewater is established and comprises an anaerobic hydrolysis tank, a low-oxygen tank, an aerobic tank and a denitrification filter which communicate with one another sequentially; step 2, the to-be-degraded printing and dyeing wastewater enters the anaerobic hydrolysis tank from a water inlet of the anaerobic hydrolysis tank, 5%-10% of sewage after hydrolysis directly enters the denitrification filter, and residual sewage flows into the low-oxygen tank; step 3, the sewage flows into the aerobic tank for denitrification treatment via the low-oxygen tank, residual sludge produced by the aerobic tank and a nitrification liquid flow back to the anaerobic hydrolysis tank in the ratio being 25%-35%, and the residual nitrification liquid flows into the denitrification filter; step 4, a sludge and water mixture obtained through backwashing by the denitrification filter also flows back to the anaerobic hydrolysis tank in the ratio being 15%-25%, and residual sewage is discharged out of the system after denitrification filtration. The technology has the advantages of good treatment effect, low sludge yield, small occupied area of the system and low operation cost.

Owner:HOHAI UNIV

Method for extracting selenium and tellurium from pyrometallurgy smelting soot

The invention relates to a method for extracting selenium and tellurium from pyrometallurgy smelting soot, and relates to a method for extracting selenium and tellurium from pyrometallurgy smelting soot collected by a dust collection system in the pyrometallurgy treatment process of copper anode slime. The method is characterized by comprising the following steps: (1) adding water to the pyrometallurgy smelting soot for slurrying and dissolution, filtering to obtain a seleninic acid solution, and extracting crude selenium through direct reduction; (2) adding a sodium hydroxide solution to filter residues to leach selenium and tellurium, and filtering again; (3) adding sulfuric acid to a filtrate, regulating the pH value to obtain a selenium-containing filtrate to extract crude selenium through reduction, and extracting tellurium by using tellurium-rich filter residues as a raw material. According to the method provided by the invention, the direct recovery rates of extracting selenium and tellurium from the soot are 95% and 80% respectively, and the crude selenium contains more than 93% selenium, and the tellurium-rich residues contain more than 50% of tellurium after reduction. In addition, the soot from which selenium and tellurium are recovered is fully enriched in precious metal elements, the grade reaches about 15%, and the soot can be mixed with the copper anode slime to be dried and then treated by pyrometallurgy.

Owner:JINCHUAN GROUP LIMITED

A method of producing cordyceps militaris-ganoderma spore powder soft capsule by a supercritical technique

InactiveCN104586902AFully enrichedHigh in active ingredientsOrganic active ingredientsNervous disorderHigh concentrationTriterpene

A method of producing cordyceps militaris-ganoderma spore powder soft capsule by a supercritical technique is disclosed. Cordyceps militaris spore powder and ganoderma spore powder are preferably adopted as main medicines. Effective components which comprise cordyceps polysaccharides and ganoderma lucidum polysaccharides are extracted from the main medicines, essence oil containing high-concentration cordyceps militaris oil and triterpene components are extracted by utilizing a supercritical fluid extraction technique, and coenzyme Q, natural vitamin E, and other components which are antioxidant, anti-radiation and antifatigue are adopted in auxiliary to prepare the soft capsule that is good in appearance, good in effects and easy to absorb. Coordination functions of multiple components, multiple channels and multiple target points in the components are given full play, and a strong immune group is formed and exerts together. The soft capsule has a function of boosting human body immunity, an anti-radiation function, an antifatigue function, and a function of assisting cancer prevention and treatment.

Owner:JIANGSU XUE FU BIOLOGICAL ENG

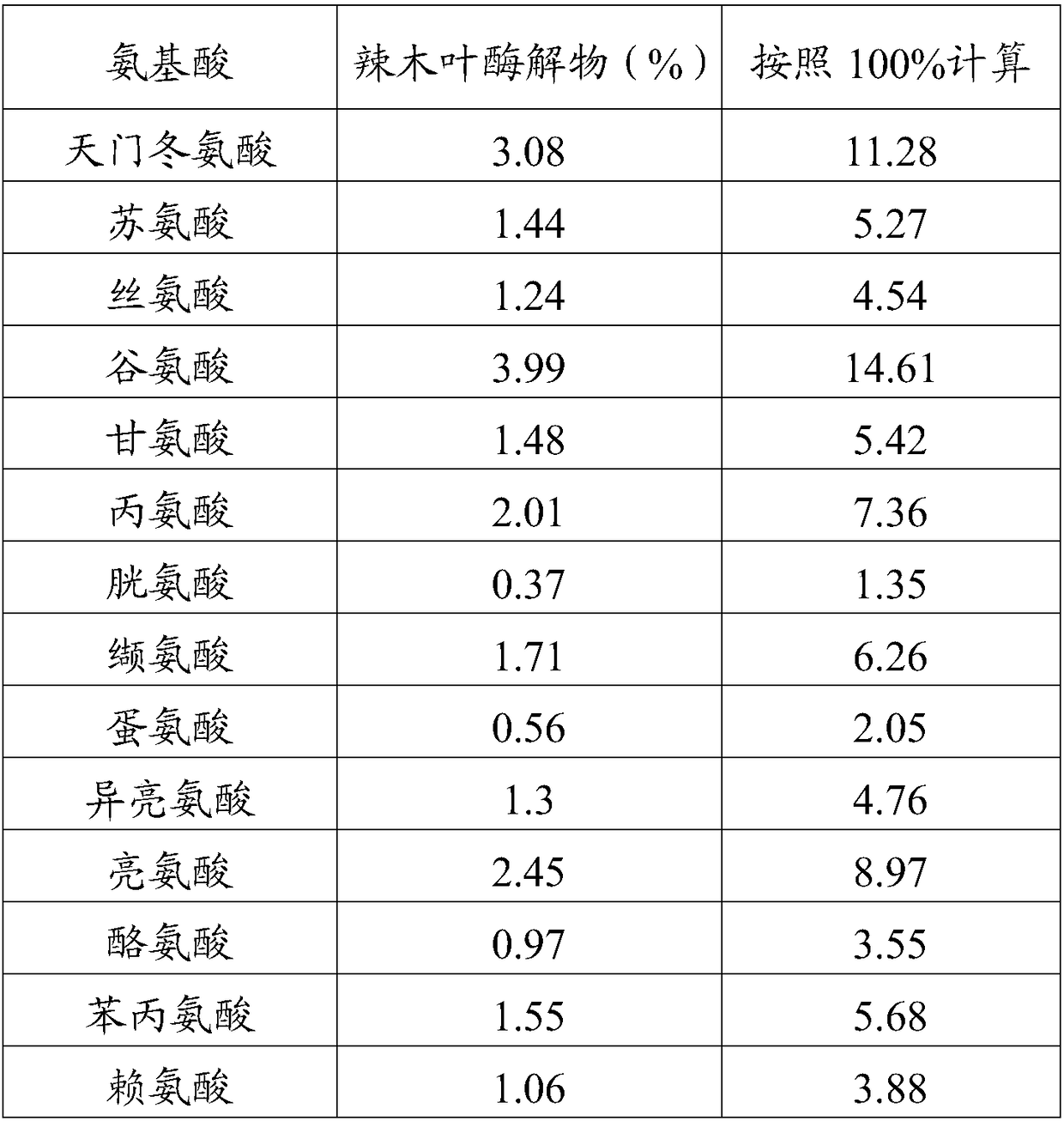

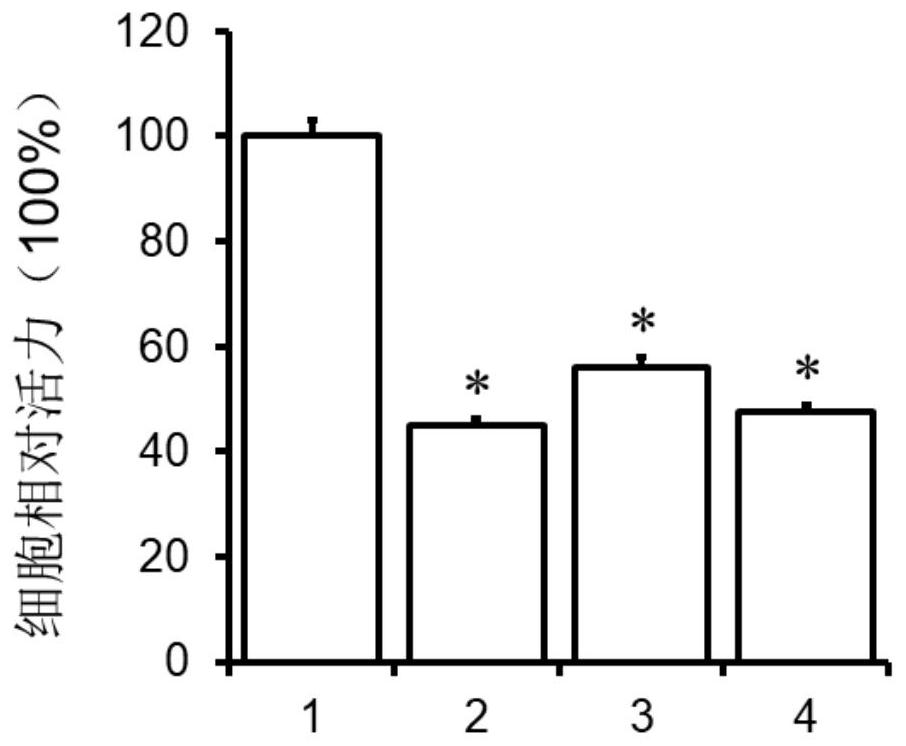

Horseradish tree zymolyte as well as preparation method and application thereof

ActiveCN108486202AReduce lossesReduced post-processingAntinoxious agentsFermentationBioavailabilityCell wall

The invention discloses horseradish tree zymolyte as well as a preparation method and application thereof and relates to the technical field of biological extraction. According to the horseradish treezymolyte disclosed by the invention, a horseradish tree raw material is resolved by carbohydrase at first, horseradish tree cell walls are broken, and other matters in the cells are released; then protease is used for degrading plant protein in the horseradish tree cells into small-molecular polypeptide; zymolyte obtained by degradation can be directly applied to drying after enzyme deactivationand filtering to obtain horseradish tree zymolyte; thus, a preparation technology is simple and convenient, and production cost is low. The prepared horseradish tree zymolyte can extract protein and polysaccharide in the horseradish trees to the maximum extent, can fully gather biological active small molecules, is easy to digest and absorb in the human body and has high bioavailability and a goodanti-fatigue effect.

Owner:成都金希生态农业开发股份有限公司

Feed for improving chicken immunity and preparation method thereof

InactiveCN106852413APromote digestion and absorptionRelease fullyFood processingAnimal feeding stuffCapsicum extractAnimal science

Relating to the field of feed processing, the invention discloses a feed for improving chicken immunity and a preparation method thereof. The feed for improving chicken immunity comprises the following raw materials: corn flour, rice bran, soybean meal, peanut cake, fish meal, bone meal, salt, vitamin and a pepper extract. The preparation method of the feed includes: firstly conducting enzymolysis treatment on crude pepper powder to make the pepper extract, then making the pepper extract and other raw materials into granulated feed. According to the invention, active substances in the crude pepper powder involved in the feed can be efficiently released after enzymolysis, and can be easily digested, absorbed, utilized and enriched by chickens, therefore the feed can effectively improve chicken immunity and enhance the disease resistance.

Owner:广西浩昌敏再生资源利用有限公司

CO2 full capture and H2S enrichment process

ActiveCN103418210BImprove solubilityReduce circulationProductsCarbon compoundsSolubilityHigh concentration

Owner:SINOPEC NINGBO ENG +2

Technology for extracting and purifying naphthalene from coal tar

InactiveCN102731244AFully enrichedImprove fullyDistillation purification/separationCrystallisation purification/separationDistillationProcess engineering

The invention relates to a deep processing technology for coal tar, and specifically relates to a technology for extracting and purifying naphthalene from the coal tar. The technology solves the technical problems of utilizing efficiency of the coal tar and purifying and deep processing of the naphthalene, so the technology for extracting and purifying the naphthalene from the coal tar is provided. The technology comprises an alkali washing step, dephenolizing the naphthalene distillation oil through the alkali washing step, and a dehydrating step, heating the material to a temperature between 210-215 DEG C and inputting the material into a primary distillation tower, preliminarily separating the raw material in the primary distillation tower, letting phenol oil to overflow from the top of the primary distillation tower and to enter a condenser for cooling followed by entering an oil-water separator for separating of the water, obtaining the phenol oil and inputting the phenol oil to the primary distillation tower again, letting the naphthalene oil and wash oil fraction distillated from the primary distillation tower to flow to a storage tank at the bottom of the primary distillation tower, and inputting a portion of the oil to a tube heating furnace of the primary distillation tower for heating and returning back to the bottom of the primary distillation tower after the oil is heated; inputting the rest of the oil into a rectifying tower, circulatingly heating the oil in the rectifying tower and a tube heating furnace of the rectifying tower to keep the oil at a temperature of 215-220 DEG C, letting gas naphthalene to overflow from the top of the rectifying tower and to pass through a heat exchanger and a condenser to become a liquid state naphthalene oil, and filling the oil into a collecting groove and sending the oil to a crystallization technology section for processing.

Owner:段伦虎

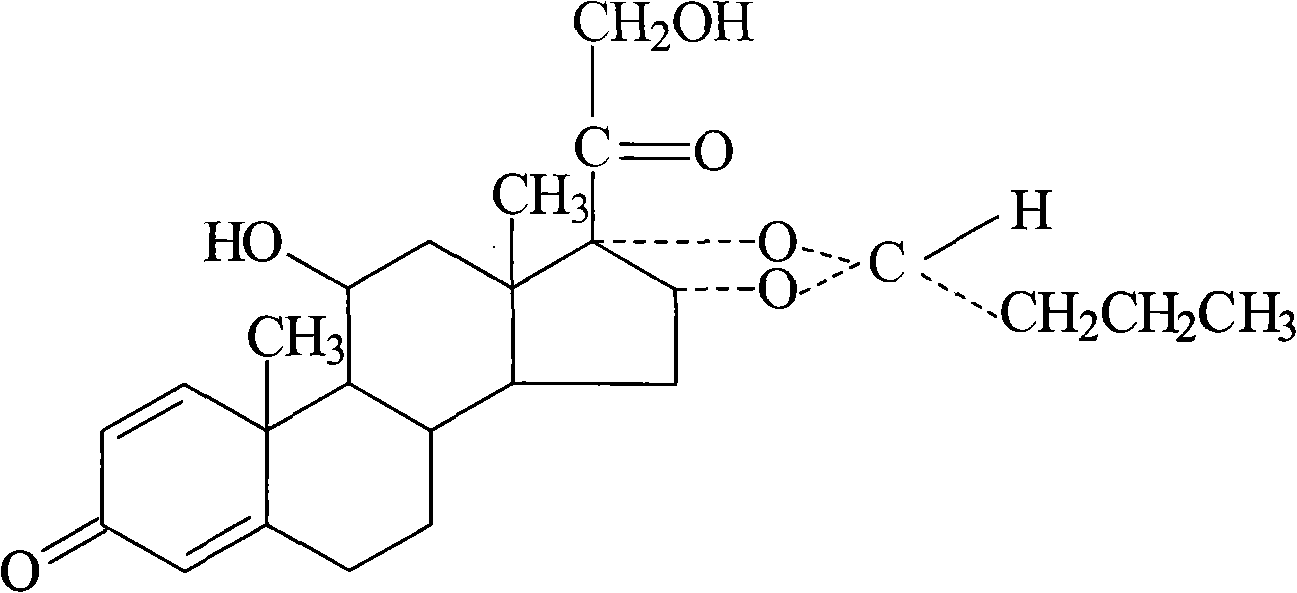

Budesonide R capsule type inhalation dust cloud agent and preparation method thereof

InactiveCN101401811AEasy to prepareFully enrichedPowder deliveryOrganic active ingredientsMedicineUltra fine

The invention discloses a budesonide R capsulated powder inhalation and a method for preparing the same. The budesonide R capsulated powder inhalation comprises a capsule shell and capsule contents which consist of 0.1 to 10 percent of budesonide R ultra-fine powder and 90 to 99.9 percent of carrier, wherein the average particle diameter of the budesonide R ultra-fine powder is between 1 and 5 mu m, and the particle diameter of the carrier is less than 160 mu m.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

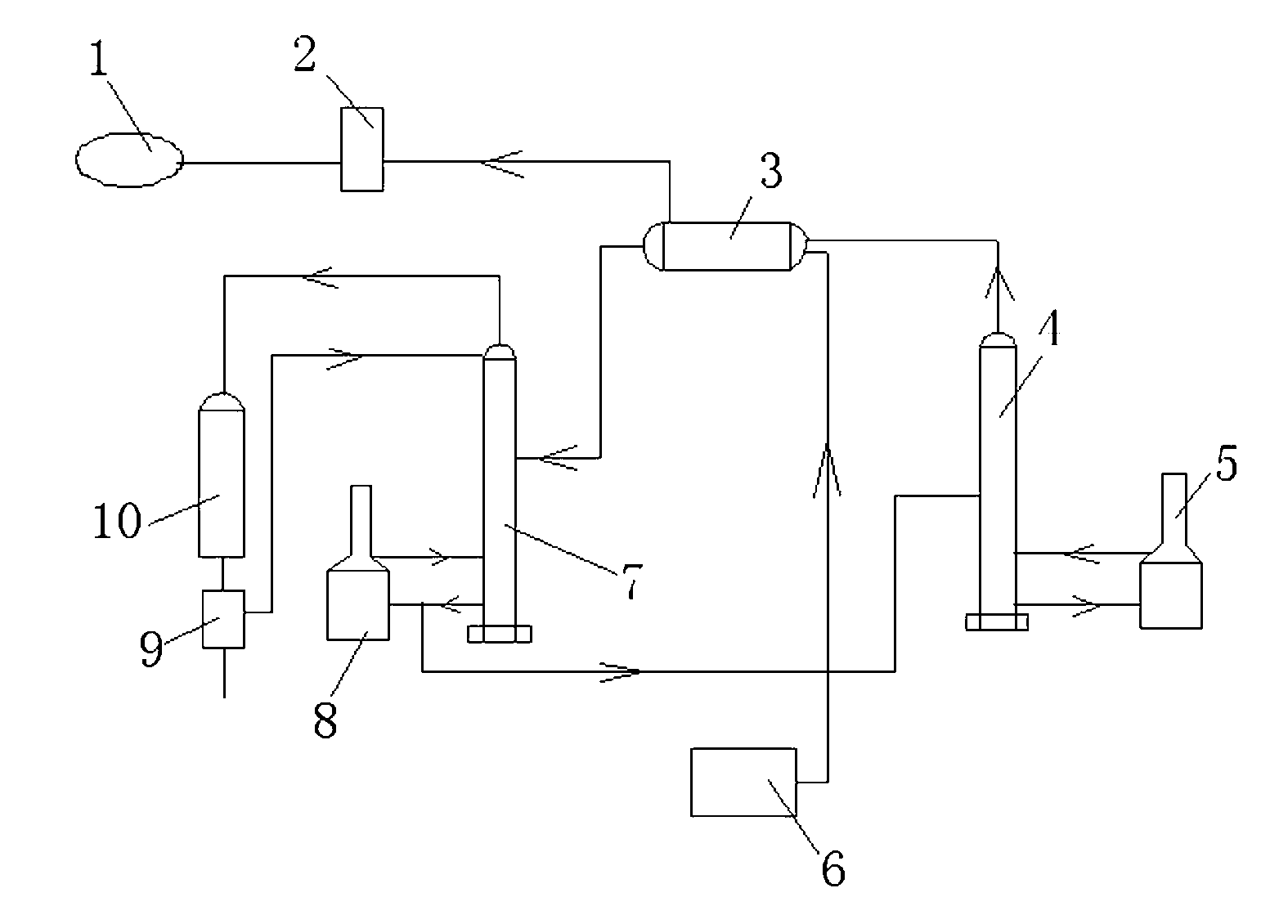

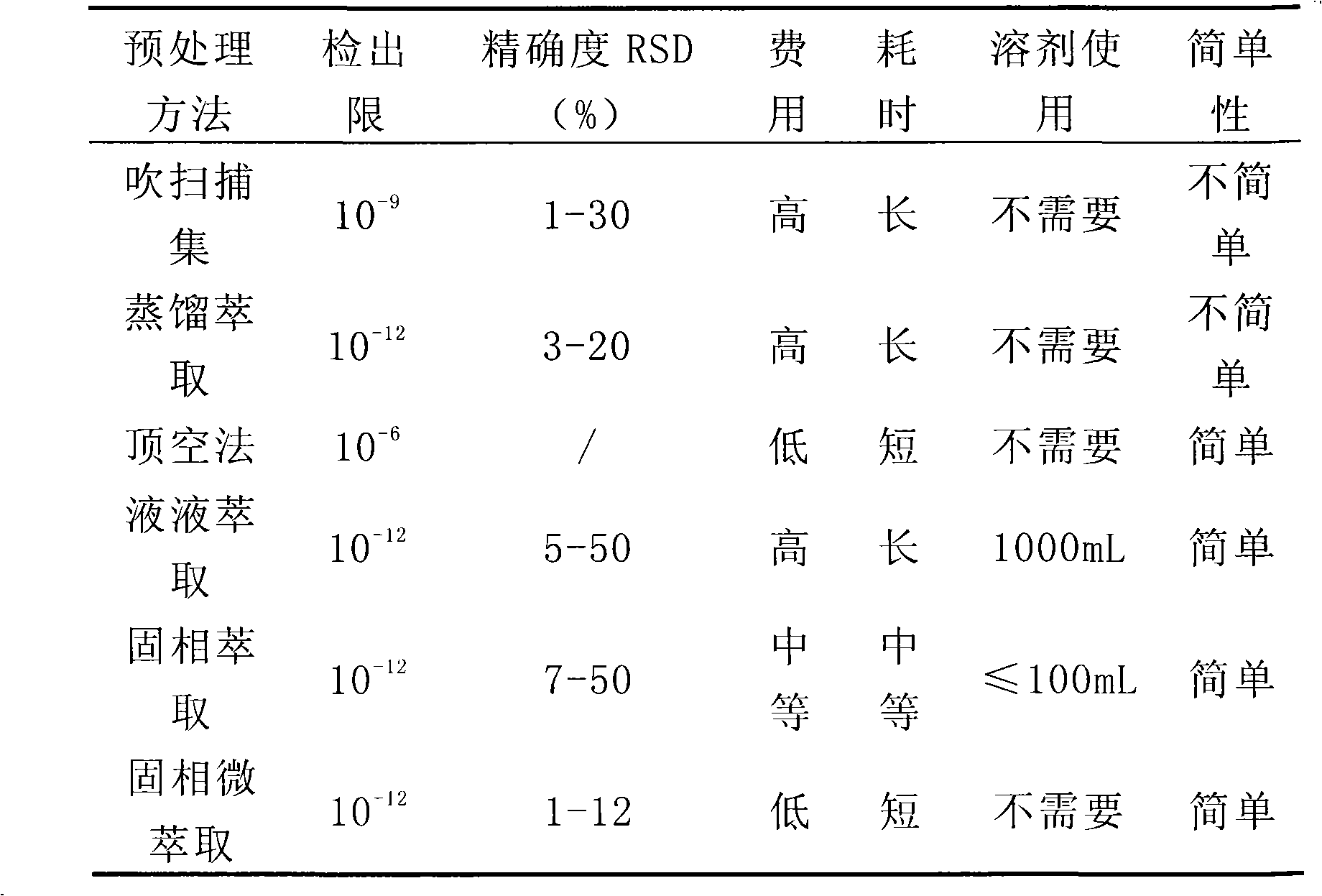

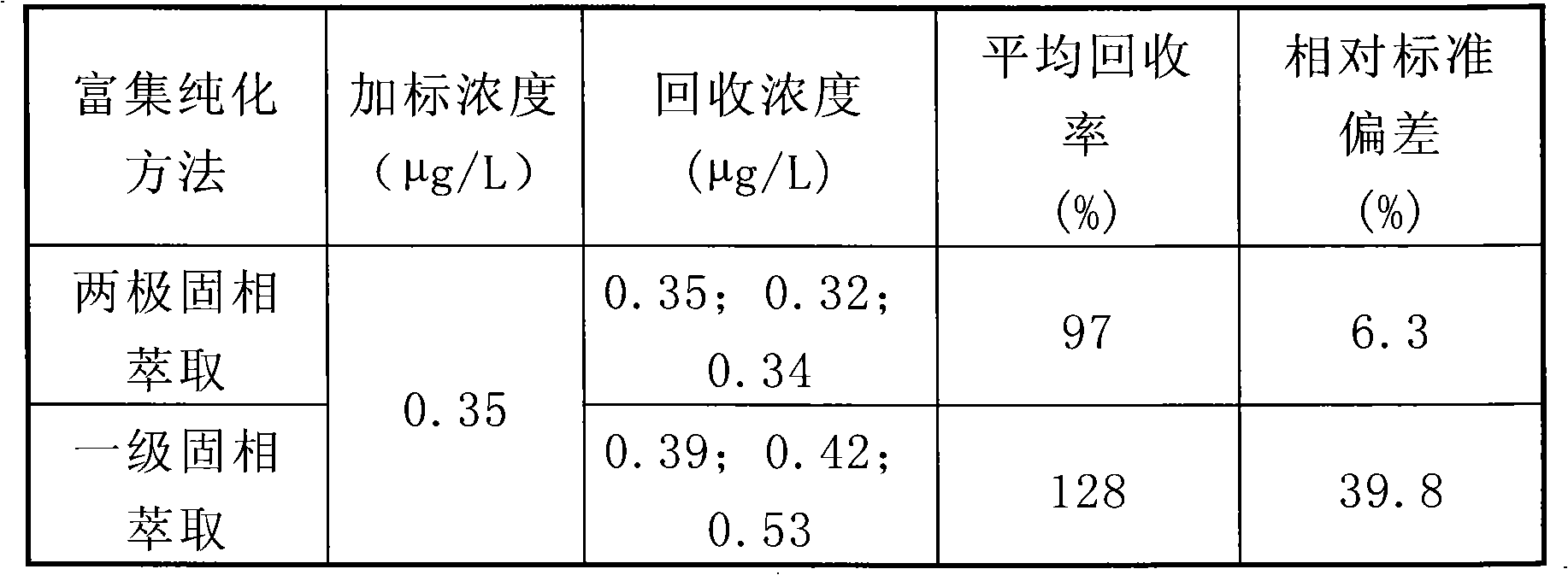

Method for enriching and purifying organic contaminant in water

InactiveCN101264951AFully enrichedFully purifiedWater/sewage treatment by extractionWater sourceUrban water

The invention discloses a method for enriching and purifying organic pollutants in water, which comprises the following steps of: (1) performing reversed phase solid extraction of a water sample, and removing polar impurities to obtain an eluate containing organic pollutants and non-polar impurities; and (2) performing positive phase solid extraction of the eluate obtained in step (1), and removing non-polar impurities to obtain an eluate containing organic pollutants. The inventive method enriches and purifies organic pollutants in water by using 'reversed phase-positive phase' two-phase solid extraction technique. The inventive method has high accuracy and high recovery rate; and can be used for enriching and purifying organic pollutants in urban water resource water and drinking water.

Owner:济南市供排水监测中心

Peony petal extract as well as preparation method and application thereof

ActiveCN112791127AAvoid dissociationEfficient removalCosmetic preparationsToilet preparationsSolventChemistry

The invention discloses a peony petal extract as well as a preparation method and the application thereof. The preparation method of the peony petal extract provided by the invention comprises the following steps: (1) drying and crushing peony petals, adding an organic acid-organic solvent-water mixed solvent for ultrasonic extraction, and collecting and combining extracting solutions to obtain a crude extracting solution; (2) concentrating the crude extract obtained in the step (1) under reduced pressure until no organic solvent smell exists, adding an aqueous alkali solution, adjusting the pH value of the solution to 11.0-13.0, filtering to remove insoluble substances, extracting the filtered solution with ethyl acetate, and removing the ethyl acetate extract to obtain an aqueous alkali extract; and (3) acidifying the alkaline water extract obtained in the step (2) with acid water, extracting with ethyl acetate to obtain an ethyl acetate extract, removing the solvent, and drying to obtain the target extract.

Owner:瑞莱茵(北京)生物科技有限责任公司 +1

Long pepper extract, preparation method thereof, medicament composition and uses thereof

ActiveCN101352487BAvoid residueAvoid toxicityPowder deliveryAntipyreticLong pepper extractEritadenine

The invention relates to a long pepper extract, a preparation method and a medicine combination thereof. The long pepper extract mainly contains methyl piperate and seven piperlongumine compounds, namely, peperlomguminine, piperine, decadiene amide, pepper nonine alkali, quinia, octadecyl triene amide and eicosatriene amide; by weight percentage, the total weight of the eight compounds accounts for 29.07-87.80 % of the total weight of the long pepper extract, wherein, peperlomguminine accounts for 0.95-3.43 % of the total weight of the long pepper extract, piperine accounts for 14.52-42.78 %,methyl piperate 0.82-3.11%, decadiene amide 1.36-4.27%, pepper nonine alkali 2.96-8.03%, quinia 1.04-3.26%, octadecyl triene amide 3.17-10.94% and eicosatriene amide 4.25-12.42%. The invention also provides the preparation method of the long pepper extract, the medicine combination and the application thereof.

Owner:北京云威科技有限公司

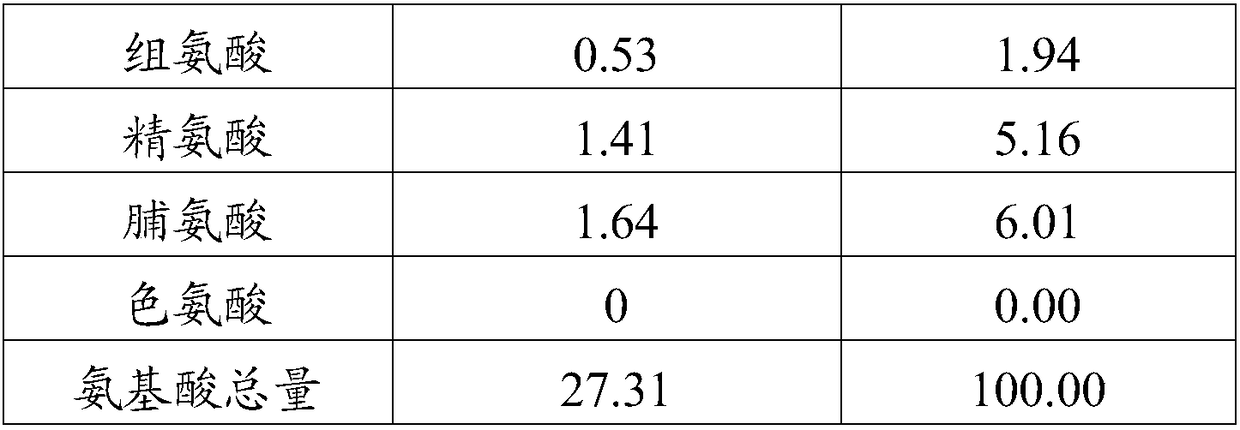

Treatment method for bone grain production wastewater

InactiveCN108840499AEasy to separateSimple processTreatment involving filtrationMultistage water/sewage treatmentFlocculationSorbent

The invention provides a treatment method for bone grain production wastewater. The wastewater is filtered by the procedures such as flocculation, adsorption, solid-liquid separation, reverse osmosisfiltration, concentrating, homogenizing and drying. In the treatment method, a low-price natural organic polymeric flocculant is coordinated with a combined adsorbent for use, so that oil and proteinin the wastewater are sufficiently enriched, and an integral wastewater treatment process is simplified; by means of a reverse osmosis technology, required concentrated and dried wastewater is reducedby 50 percent, energy consumption of subsequent procedures is reduced, and the treatment cost of the wastewater is reduced.

Owner:吴忠市王国旗生物科技有限公司

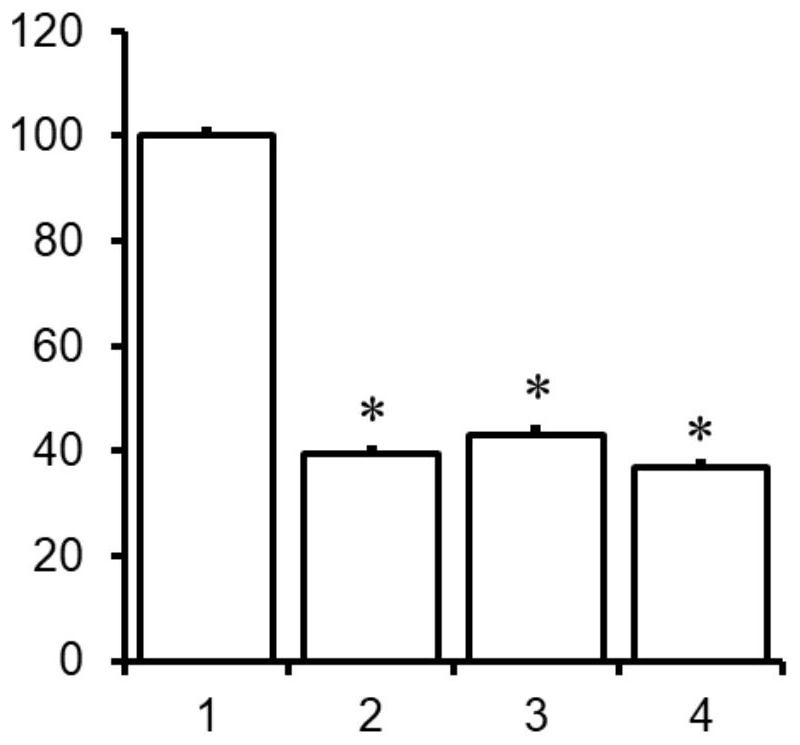

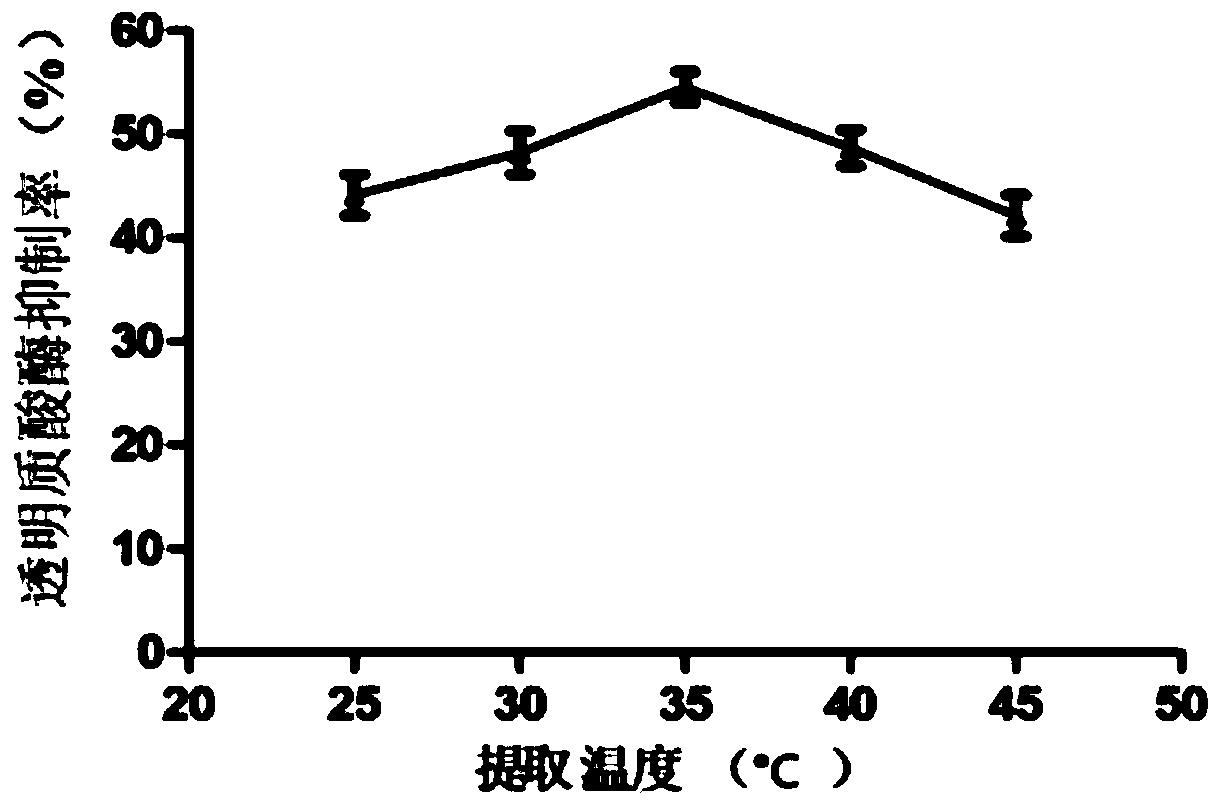

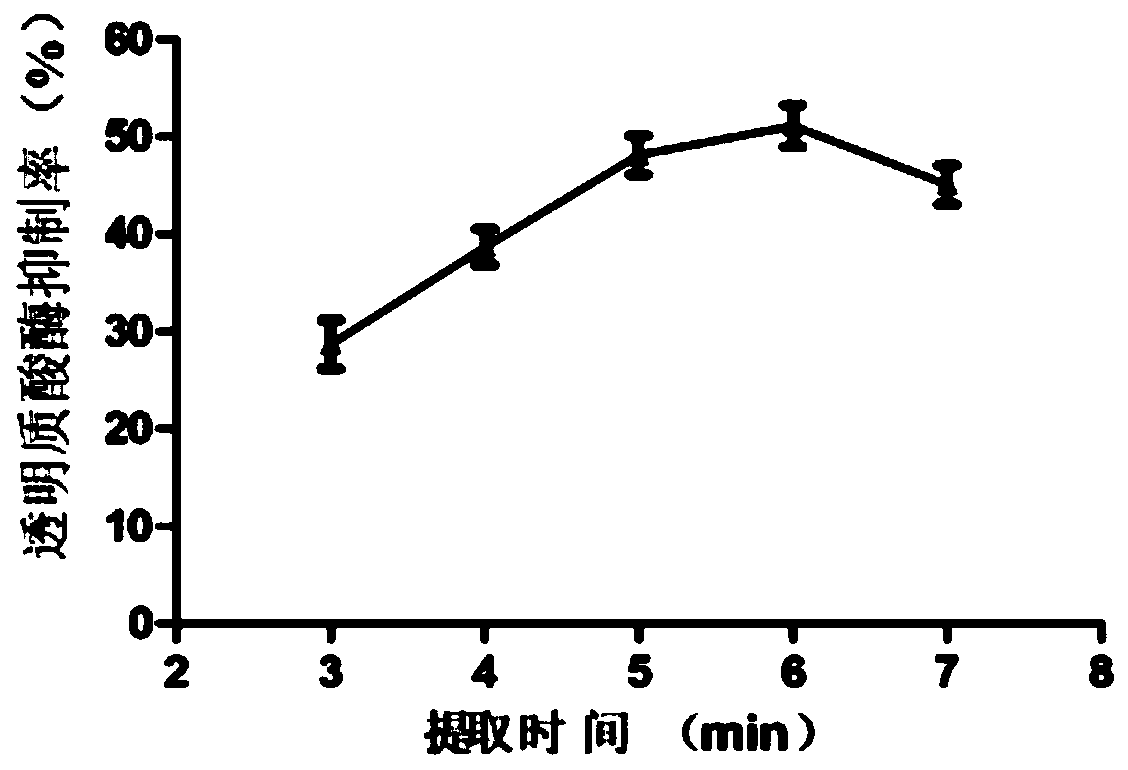

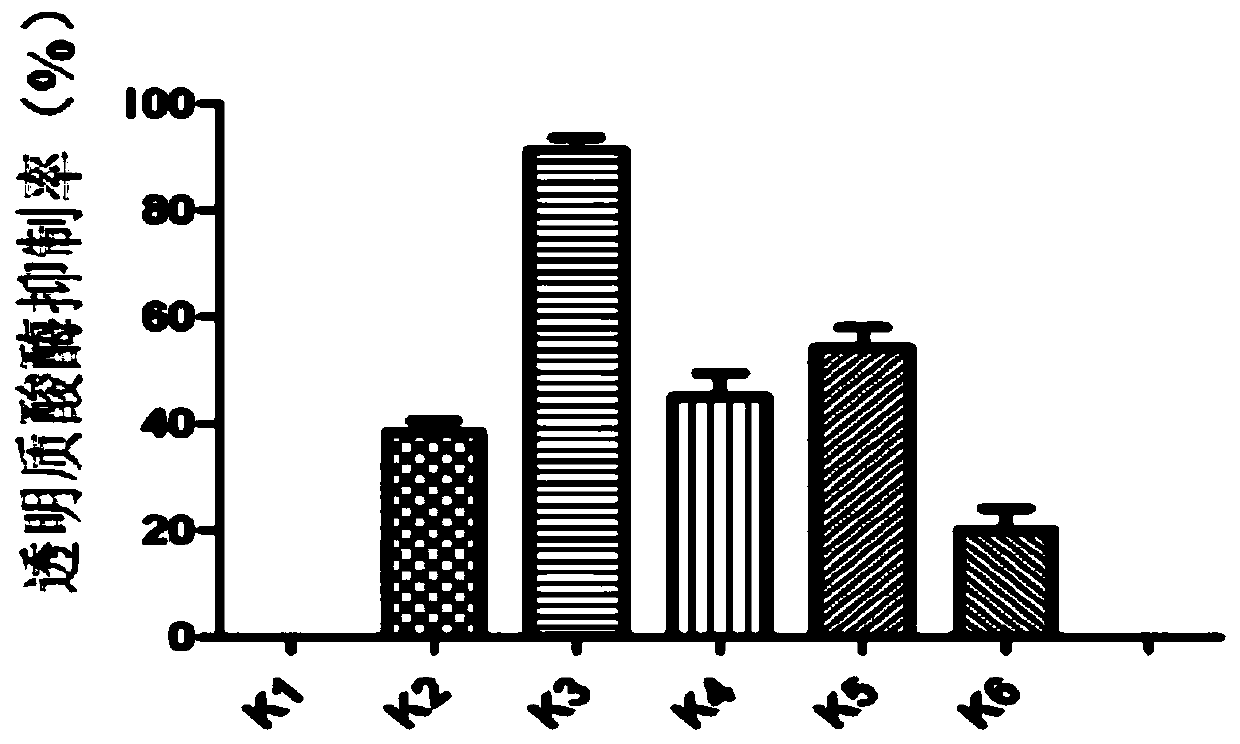

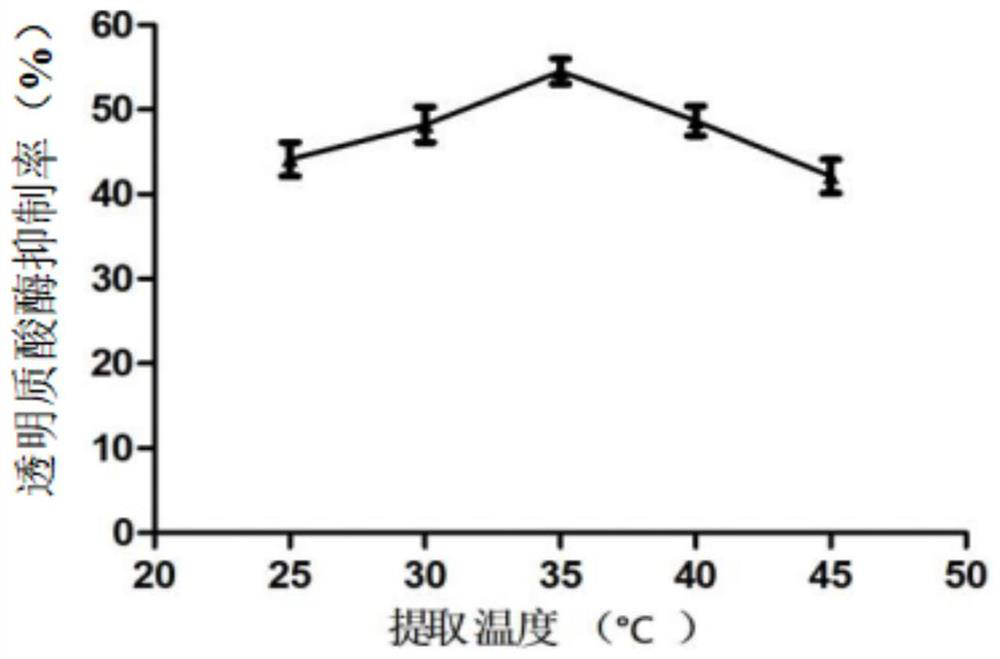

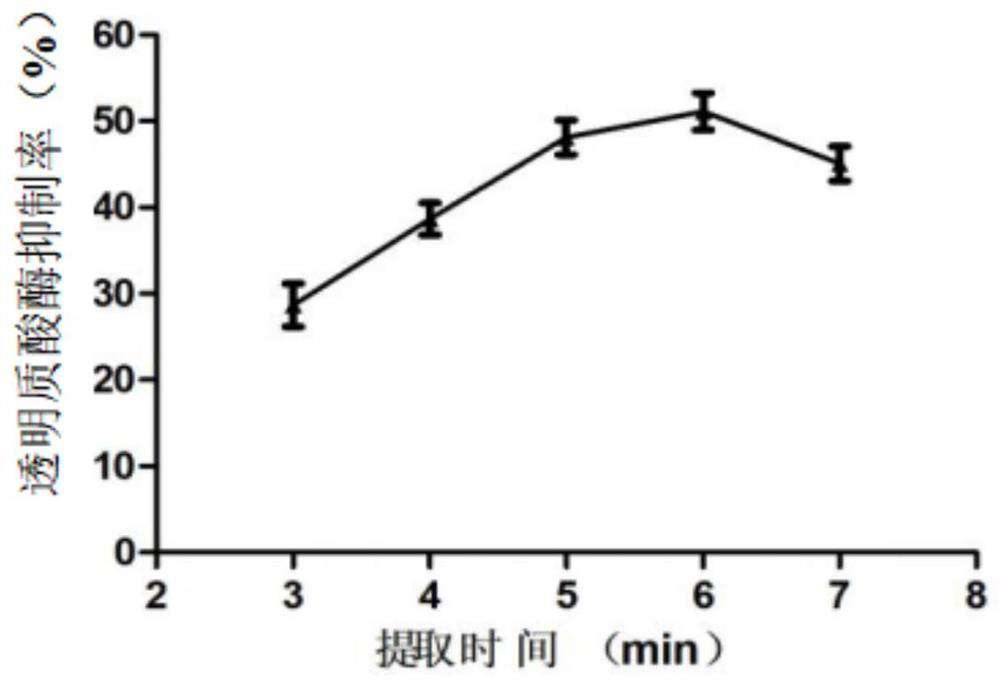

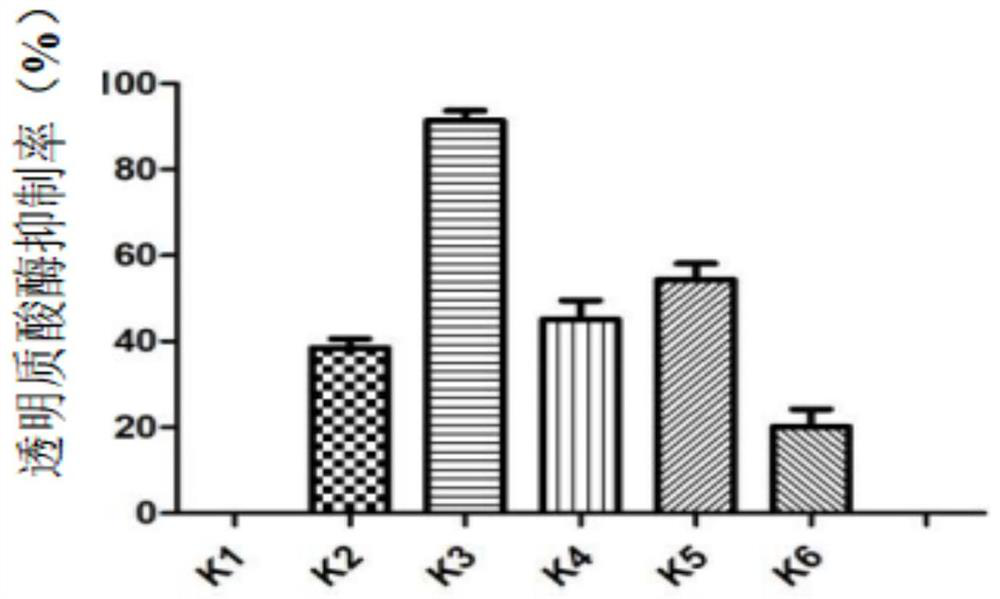

Method for separating and purifying anti-allergic components in perilla leaves

ActiveCN110755476AReduce the impactReduce extraction timeImmunological disordersPlant ingredientsAllergic antiHyaluronidase

The invention discloses a method for separating and purifying anti-allergic components in perilla leaves. The method comprises the steps that first, fresh perilla leaves are subjected to normal temperature shade dryness, crushing and sieving, solvent soaking and enhanced mass transfer method for extraction to obtain crude perilla anti-allergy components; then thin layer chromatography is used fordetermining an elution solvent, silica gel column chromatography and dextran gel column chromatography are used for purifying perilla anti-allergic crude extract components to obtain a high anti-allergic activity perilla extract with the hyaluronidase inhibition rate being as high as 89.76%. The method for separating and purifying the anti-allergic components in perilla leaves has the advantages of simple operation, less use time, high yield, significant activity and good reproducibility of results, and is suitable for the separation and purification of most plant active substances.

Owner:ZHONGBEI UNIV

Biological selenium-rich fertilizer and whole course dynamic gradient method for selenium-rich purple wheat

ActiveCN102795908BAvoid toxic effectsSolve the safety problems caused by inorganic selenium residuesFertilising methodsFertilizer mixturesWheat productCrop cultivation

The invention relates to a method for producing a selenium-rich purple wheat by using a biological selenium-rich fertilizer and a whole course dynamic gradient selenium-rich method, which belongs to the crops cultivation technical field. The method is characterized in that the biological selenium-rich fertilizer is produced, and is used to prepare a selenium-rich fertilizer mother liquor, and then the selenium-rich fertilizer mother liquor is diluted to a selenium-containing fertilizer liquid with different selenium concentrations, and is affected on soil, purple wheat seeds and whole purple wheat at different growth periods. The wheat seeds enable full enrichment on the selenium element, according to the growth characteristics of the purple wheat, the selenium-containing fertilizer liquid with different gradients is used for fitting with the purple wheat growth rules during the whole growth process of the purple wheat, thereby the exogenous inorganic selenium can be conversed to plant endogenous organic selenium with high efficiency. By detecting, the selenium content of the purple wheat product provided in the invention is 0.18-0.28mg / kg, wherein the organic selenium content is 0.16-0.25mg / kg, compared with the purple wheat product which is sprayed by a single selenium-containing fertilizer liquid c in the whole process, the selenium content multiple can reach 5-7 times.

Owner:JIANGSU ACAD OF AGRI SCI

A health drink containing tribulus terrestris and preparation method thereof

The invention provides a health drink containing Tribulus terrestris and a preparation method thereof, which is composed of the following components by weight ratio: 10-20 parts of Tribulus terrestris juice, 10-20 parts of reconstituted granules of Tribulus terrestris pomace, konjac 2-10 parts of fine powder, 50-100 parts of water, has the characteristics of simple preparation, sufficient extraction of active ingredients, good taste, no chemical additives, etc., and is a pure natural functional drink.

Owner:GUIZHOU SHENQI PHARMA RES INST

A method for extracting phosphorus from sewage sludge

ActiveCN112678790BSolve technical problems with low recovery ratesGood for pickling and leachingPhosphorus compoundsSolid componentSludge

Owner:CHONGQING TECH & BUSINESS UNIV

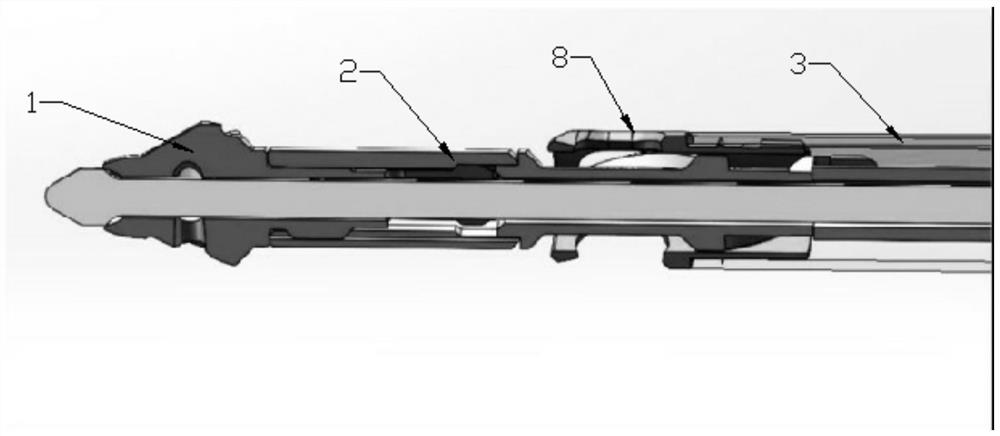

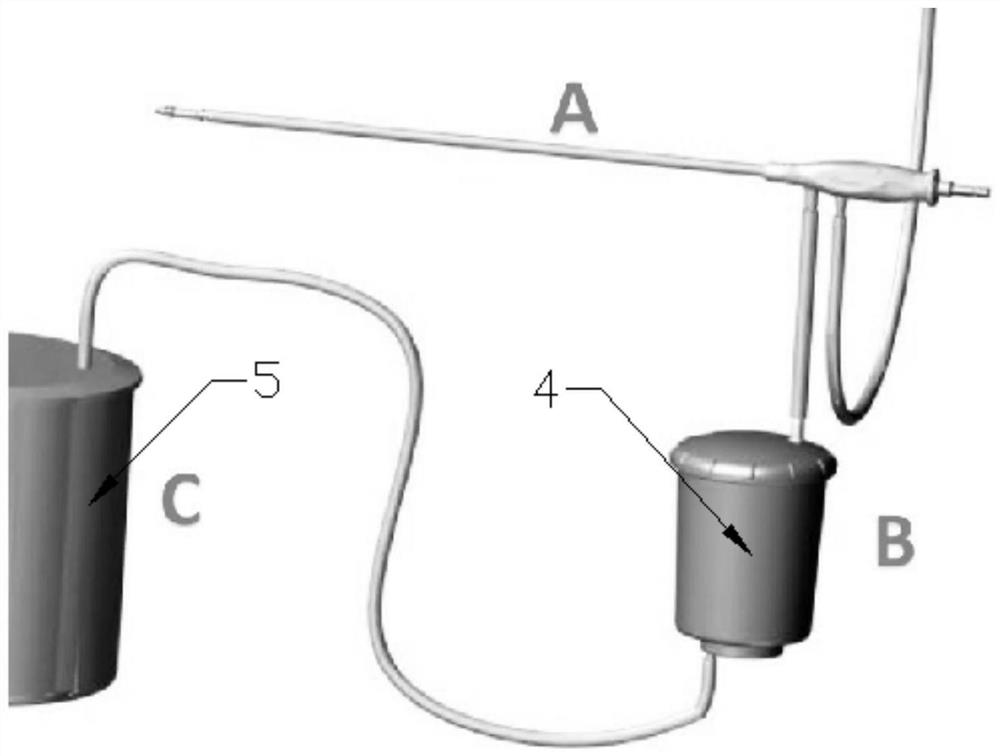

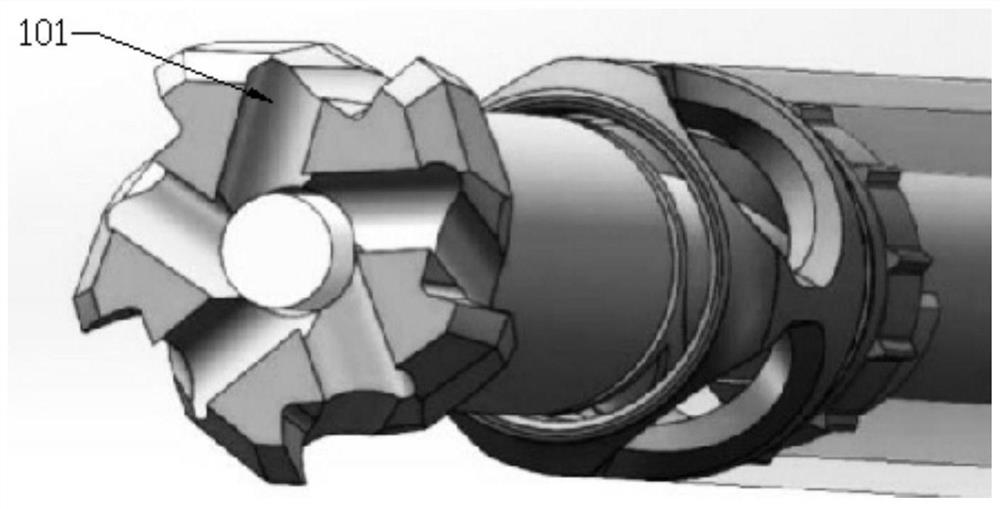

High-activity bone construction method based on bone marrow suction enrichment system

PendingCN114259276AFully enrichedNo problem of inaccurate bone harvestingBone implantSurgeryBone decalcificationBone tissue engineering

The invention belongs to the technical field of bone tissue engineering, and particularly relates to a high-activity bone construction method based on a bone marrow suction enrichment system, which comprises the following steps: soaking an allogeneic bone decalcification scaffold in a prepared peptide solution, and flushing after soaking to obtain a self-assembled polypeptide modified allogeneic bone decalcification scaffold; putting the prepared enrichment material into an inner tank body of a material mixing and stirring tank of a bone marrow suction enrichment system, and enriching according to preset time; and after the enrichment is completed, discharging the waste liquid in the material mixing and stirring tank to obtain the constructed high-activity bone repair material. The problems that in the prior art, the bone taking mode is not accurate, and bone forming materials are prone to losing can be solved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

A method for separation and purification of antiallergic components in perilla leaves

ActiveCN110755476BReduce extraction timeLow extraction temperatureImmunological disordersPlant ingredientsAllergyElution

Owner:ZHONGBEI UNIV

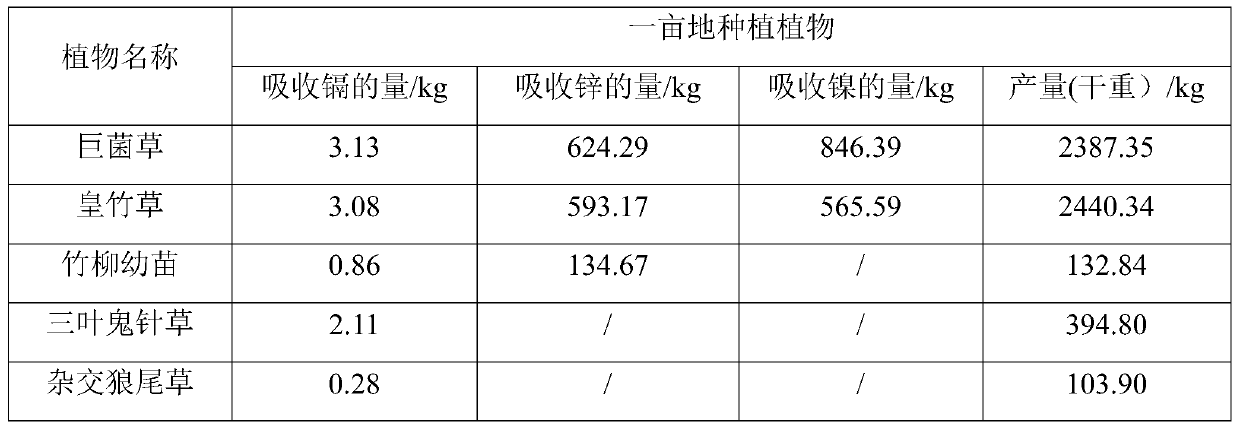

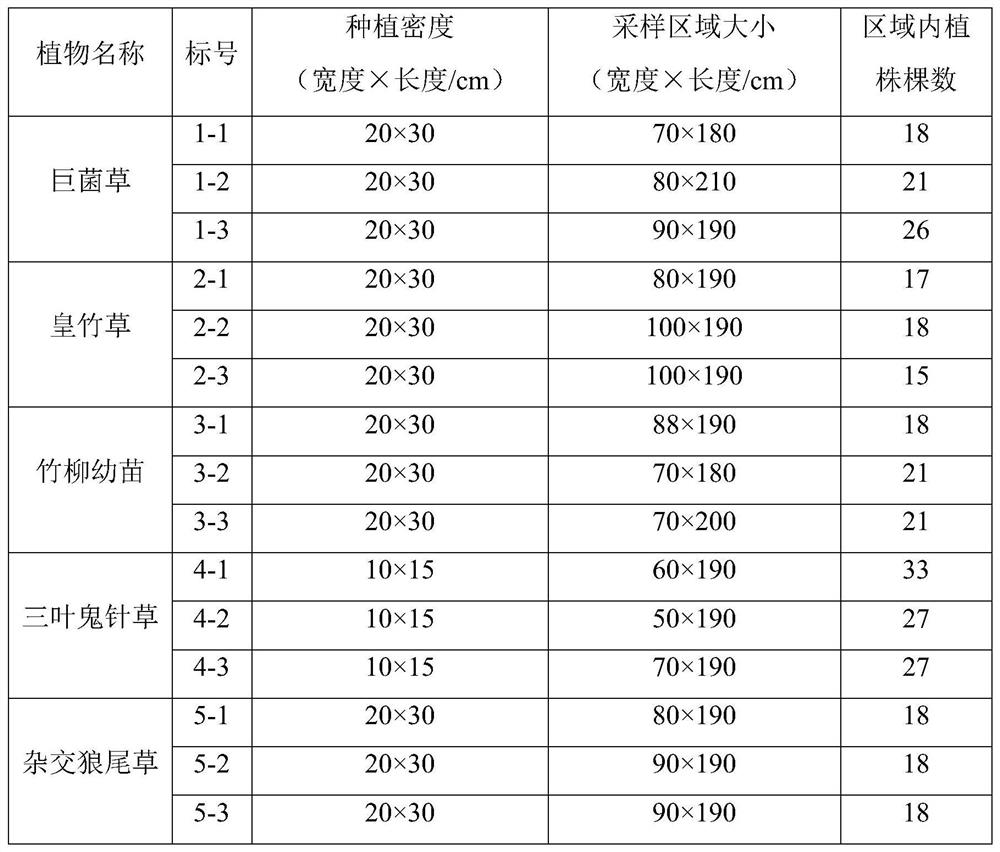

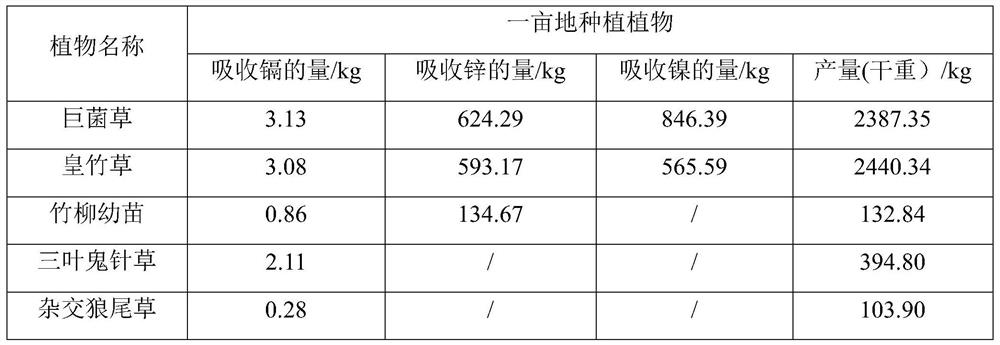

Garden landscape construction method for moderate-light heavy metal contaminated soil

ActiveCN111468527AGood tolerance or enrichment ability of heavy metal elementsGood viewingContaminated soil reclamationGarden designContaminated soils

The invention belongs to the technical field of soil pollution treatment and garden construction, and particularly relates to a garden landscape construction method for moderate-light heavy metal contaminated soil. The method comprises the following steps: 1, soil sealing and isolating; 2, soil detection; 3, plant variety screening; and 4, planting plants: planting the heavy metal enriching or tolerant plants screened in the step 3. According to the method, the polluted soil is used as engineering terrain modeling and planting soil in garden design; corresponding isolation measures are taken and heavy metal enrichment plants are planted for a long time to reduce the content of heavy metals in the soil; the garden planning can be performed for more than ten years to dozens of years, or evenhundreds of years, so that the plants have sufficient time to purify the soil. The method can fully utilize the contaminated soil, and the contaminated soil can be purified by the plants in the long-term growth process of the plants on the premise that no extra site is occupied.

Owner:WANYUAN ECOLOGY GRP

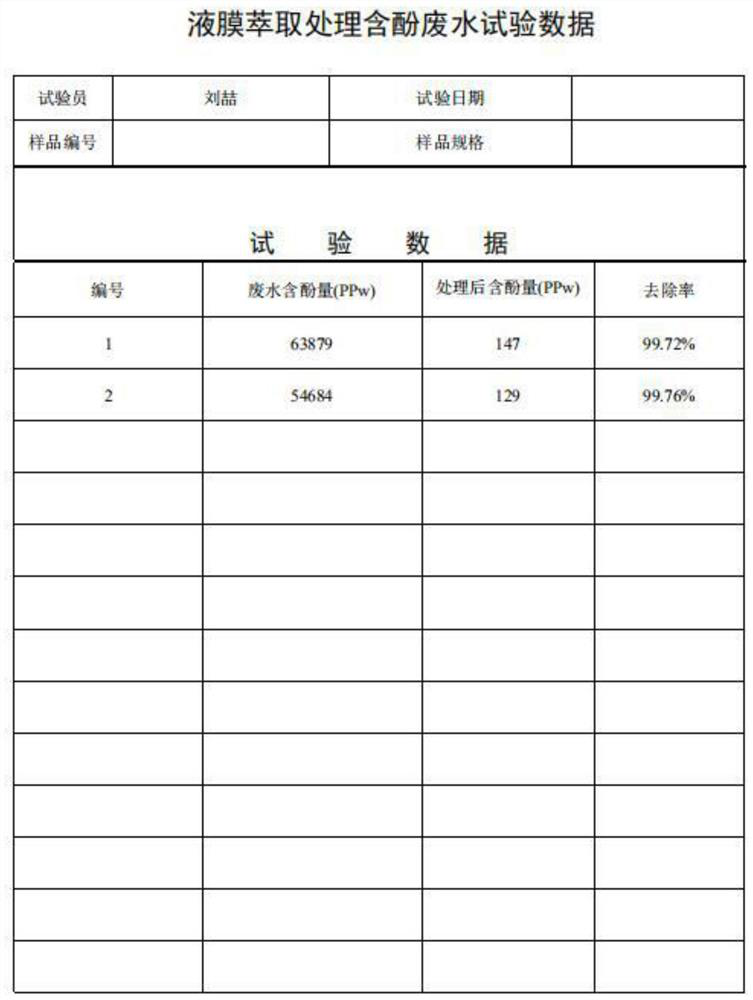

Phenol-containing wastewater treatment method

InactiveCN113149261AEfficient enrichmentReduced phenolic contentOrganic chemistryFatty/oily/floating substances removal devicesOil phaseSodium hydroxide

The invention relates to a phenol-containing wastewater treatment method, which adopts liquid membrane extraction to treat phenol-containing wastewater, and comprises the following steps: 1, measuring the phenol content in the phenol-containing wastewater, adding a liquid membrane extract according to the measured phenol content, and fully mixing the liquid membrane extract and the phenol-containing wastewater at a stirring speed of 60r / min, reacting phenol in the phenol-containing wastewater with sodium hydroxide in the liquid membrane extraction liquid for 10 min; 2, performing standing for 10 min after the reaction is completed, layering a water phase and an emulsion phase, and separating the water phase from the emulsion phase to obtain an emulsion containing sodium phenate; and 3, stirring the emulsion containing sodium phenate obtained in the step 2 at a stirring speed of 1500r / min for 3-10min for demulsification, performing standing for 20min after demulsification is completed, layering a water phase and an oil phase, separating the oil phase from the phase, and continuing to use the oil phase as a preparation raw material of the liquid membrane extraction liquid. According to the method, phenolic compounds in the wastewater can be effectively enriched into the emulsion, the extraction liquid can be repeatedly used, the extraction efficiency is high, the energy consumption is low, and resources can be effectively saved while wastewater treatment reaches the standard.

Owner:禹城京都新材料科技有限公司

A kind of landscaping construction method of medium and light heavy metal polluted soil

ActiveCN111468527BReduce heavy metal contentTake advantage ofContaminated soil reclamationSoil sciencePollution soil

The invention belongs to the technical field of soil pollution control and garden architecture, and in particular relates to a method for constructing garden landscapes in soils polluted by moderate to light heavy metals. The method includes the following steps: step 1, soil sealing and isolation; step 2, soil testing; step 3, plant variety screening; step 4, plant planting: planting the heavy metal-enriched or tolerant plants screened in step 3. In the present invention, polluted soil is used as engineering topography and planting soil in garden design, and corresponding isolation measures and long-term planting of heavy metal-enriched plants are used to reduce the heavy metal content in the soil. Since garden planning has always existed for more than ten years to several Ten years, or even hundreds of years, allows plants to have sufficient time to purify the soil. This method can not only make full use of the polluted soil, but also allow the plants to purify the polluted soil without occupying additional space. The soil is purified during the long-term growth of the plants.

Owner:WANYUAN ECOLOGY GRP

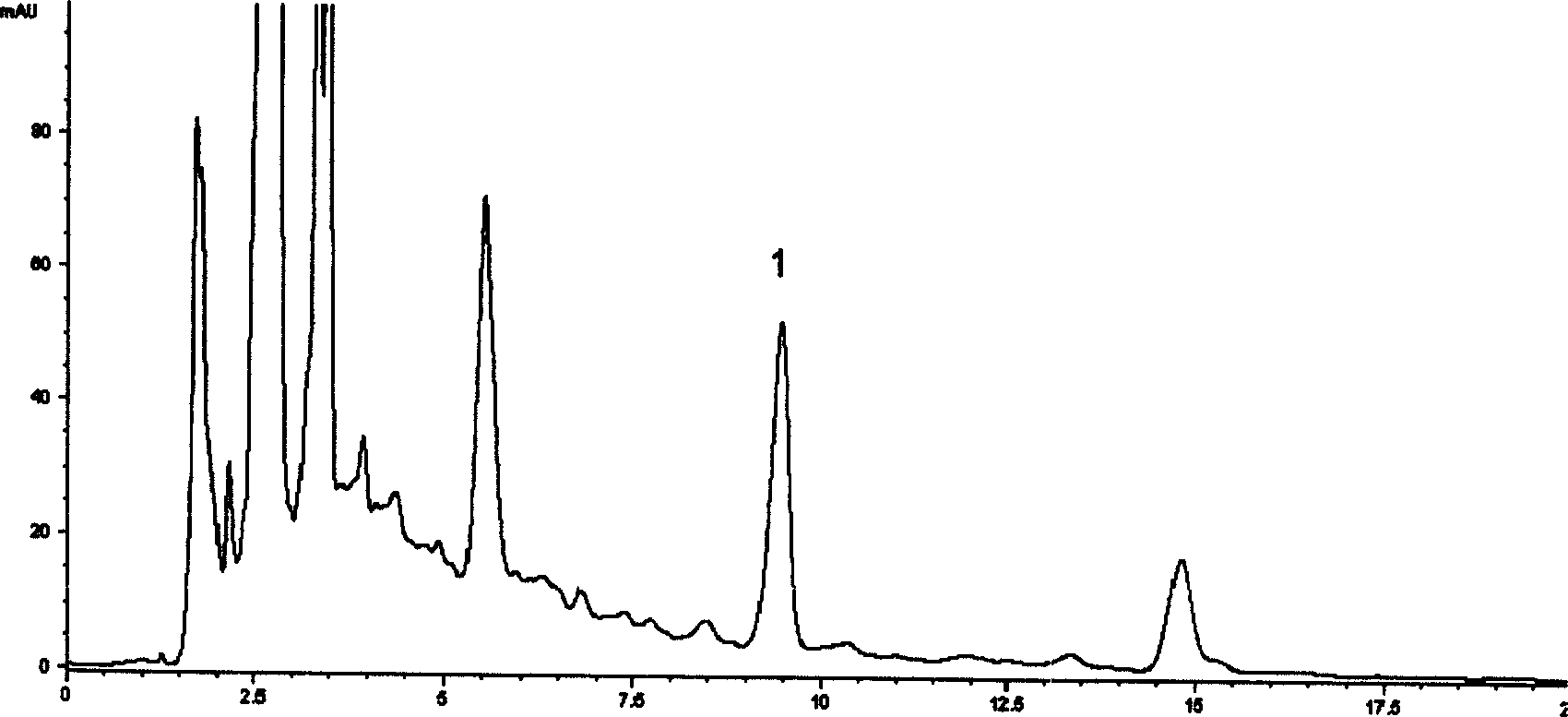

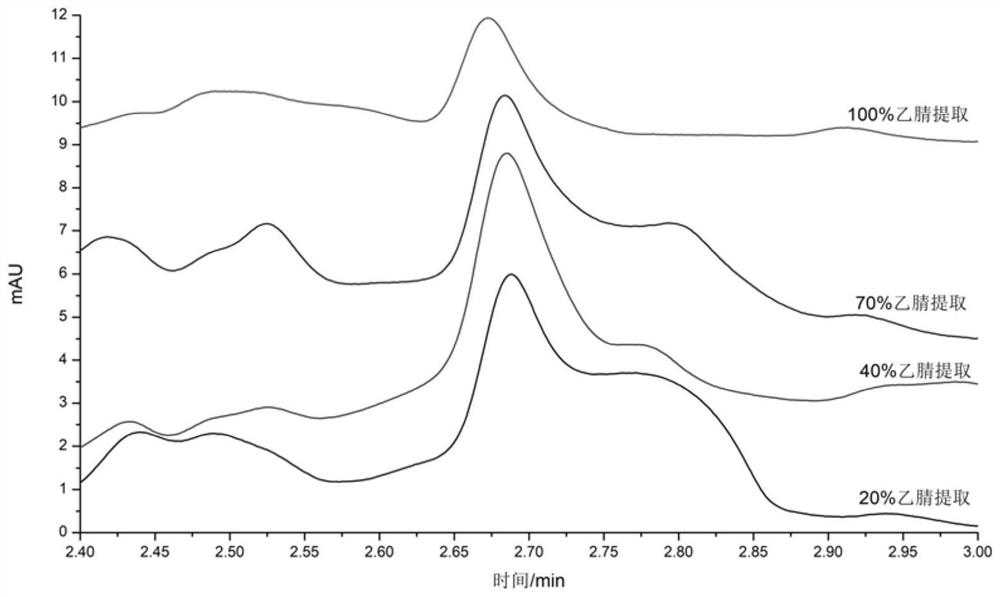

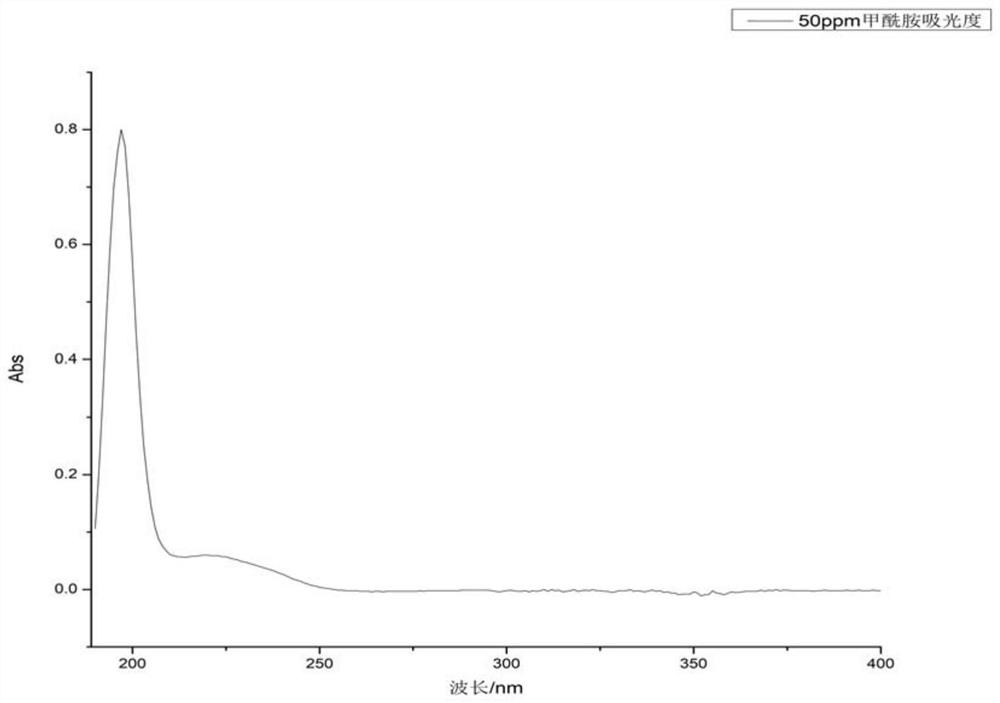

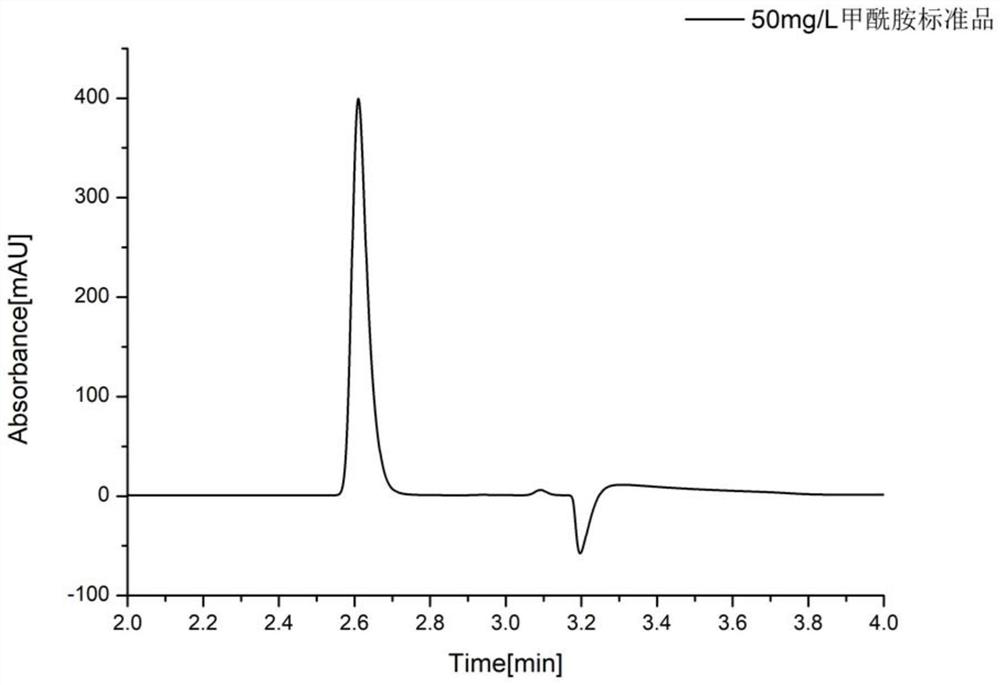

Method for detecting content of formamide in product

The invention provides a method for detecting the content of formamide in a product. The method comprises the following steps: crushing the product, extracting in a nitrile solution, filtering, and detecting the content of the formamide in the product by adopting a high performance liquid chromatography. According to the method, the nitrile solution is used as the extraction solvent to extract the formamide in the product, and water and acetonitrile are used as mobile phases when the high performance liquid chromatography is used for detection, so that the loss of the formamide in the extraction process and the detection process can be reduced, and the method has the advantages of high extraction efficiency, high detection precision and high sensitivity.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for extracting phosphorus element from sewage sludge

ActiveCN112678790ASolve technical problems with low recovery ratesGood for pickling and leachingPhosphorus compoundsSludgeDivalent metal ions

The invention relates to the field of sewage sludge recycling, in particular to a method for extracting phosphorus from sewage sludge. The method sequentially comprises the following steps of: S1, a dehydration step: obtaining a mud-water mixture with the water content of 75-95%; S2, an aluminum salt treatment step: adding an aluminum salt into the mud-water mixture to obtain a reaction system; S3, a hydrothermal reaction step: carrying out hydrothermal reaction on the reaction system, and then carrying out solid-liquid separation to obtain a solid component; S4, an acid pickling step: performing dilute acid pickling on the solid component and collecting leachate; and S5, a phosphorus element recovery step: adding divalent metal ions into the leachate to obtain a phosphorus-containing solid substance. With the method provided by the technical schemes of the invention, the technical problem that the recovery rate of the phosphorus element is not high can be solved; the recovery rate of the phosphorus element can reach 90% or above through the extraction method; the method has a wide application prospect; the problem that phosphorus resources face an exhaustion crisis in the world can be solved; and the method caters to the current advocated sustainable development strategy.

Owner:CHONGQING TECH & BUSINESS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com