Technology for extracting and purifying naphthalene from coal tar

A technology of coal tar and process, applied in the direction of crystallization purification/separation, distillation purification/separation, etc., to achieve the effect of increasing added value, stable product quality, and less equipment usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

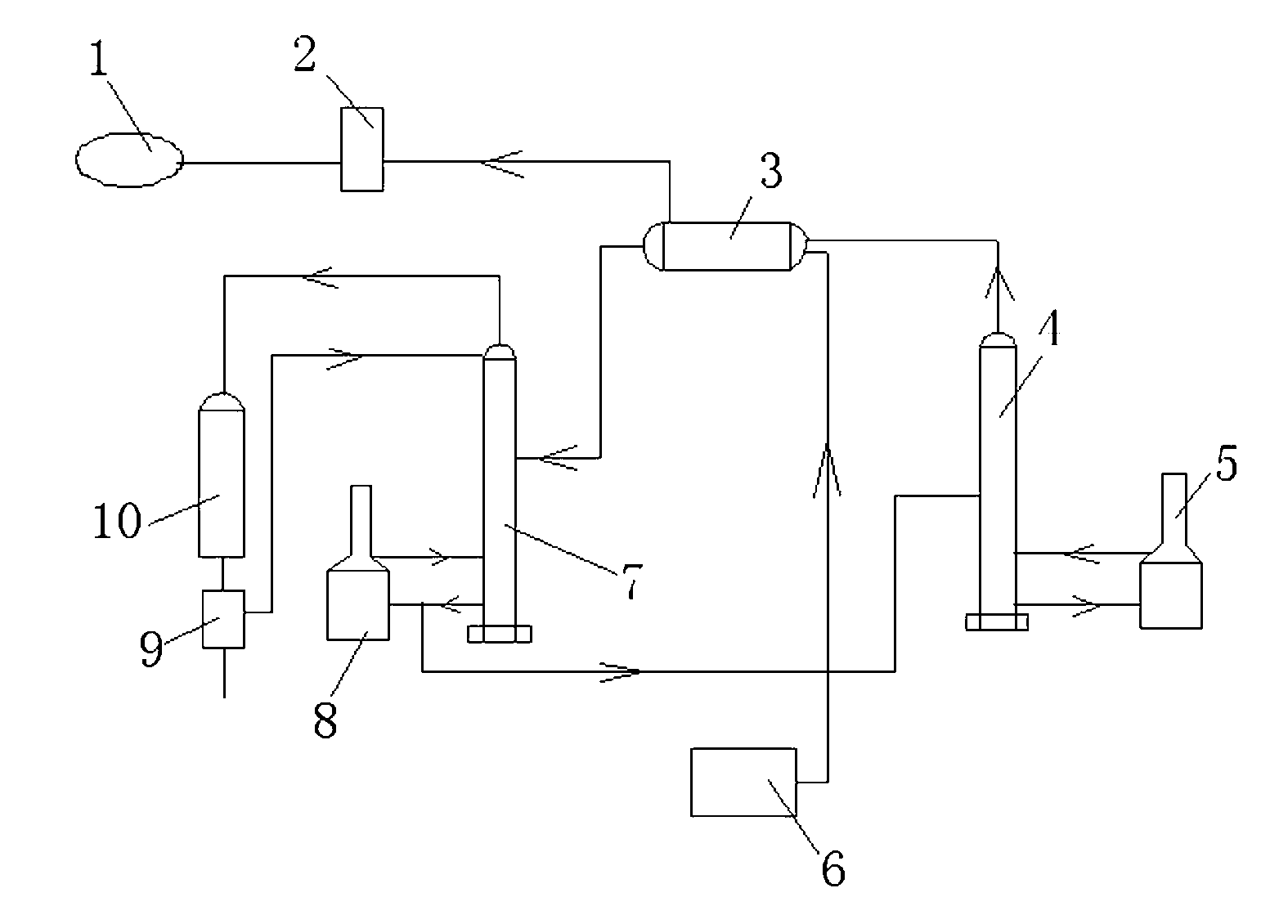

[0009] Example 1, Such as figure 1 Shown, a kind of technology that extracts and purifies naphthalene from coal tar, the step comprises alkali washing, and naphthalene distillate part is 10-15% sodium hydroxide solution alkali eluting phenol by concentration, after alkali washing, temperature is 80- The raw material at 90°C is left to stand for dehydration, pumped out from the raw material tank 1 by the raw material pump, and put into the naphthalene heat exchanger 3, where it exchanges heat with the naphthalene vapor at 210-220°C from the top of the rectifying tower 4 , make the temperature rise to 210-215, then enter the initial distillation tower 7, the raw material is preliminarily separated in the initial distillation tower 7, the phenol oil contained in the raw material overflows from the initial distillation tower 7, enters the condenser 10 to cool, and then enters the oil-water Separator 9, separated water to obtain phenol oil and put it into the initial distillation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com