Method for enriching and purifying organic contaminant in water

A technology of organic pollutants and purification methods, which is applied in the field of enrichment and purification of organic pollutants in water, can solve the problems of low accuracy and precision, monitoring influence, etc., and achieve the effect of high accuracy and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

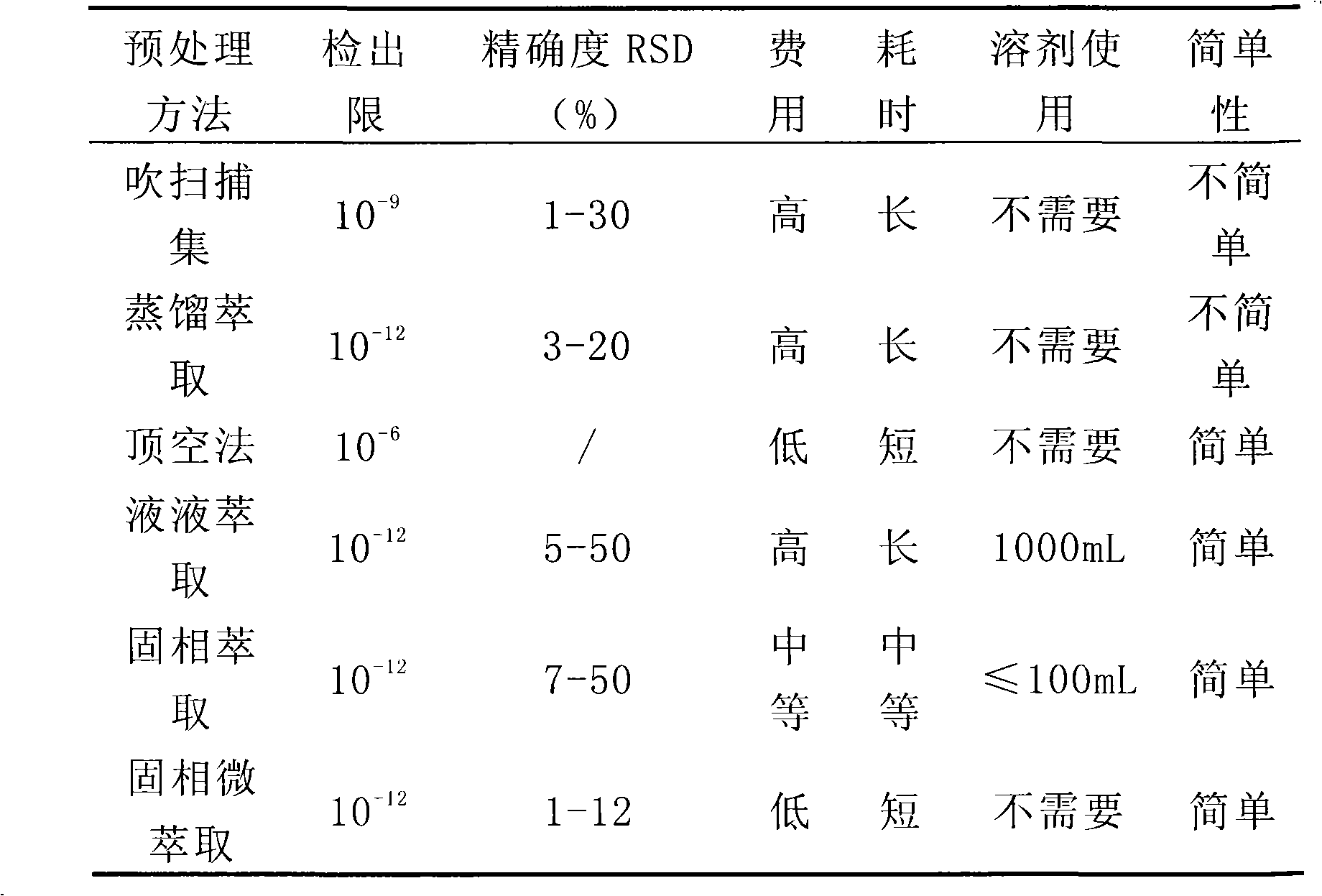

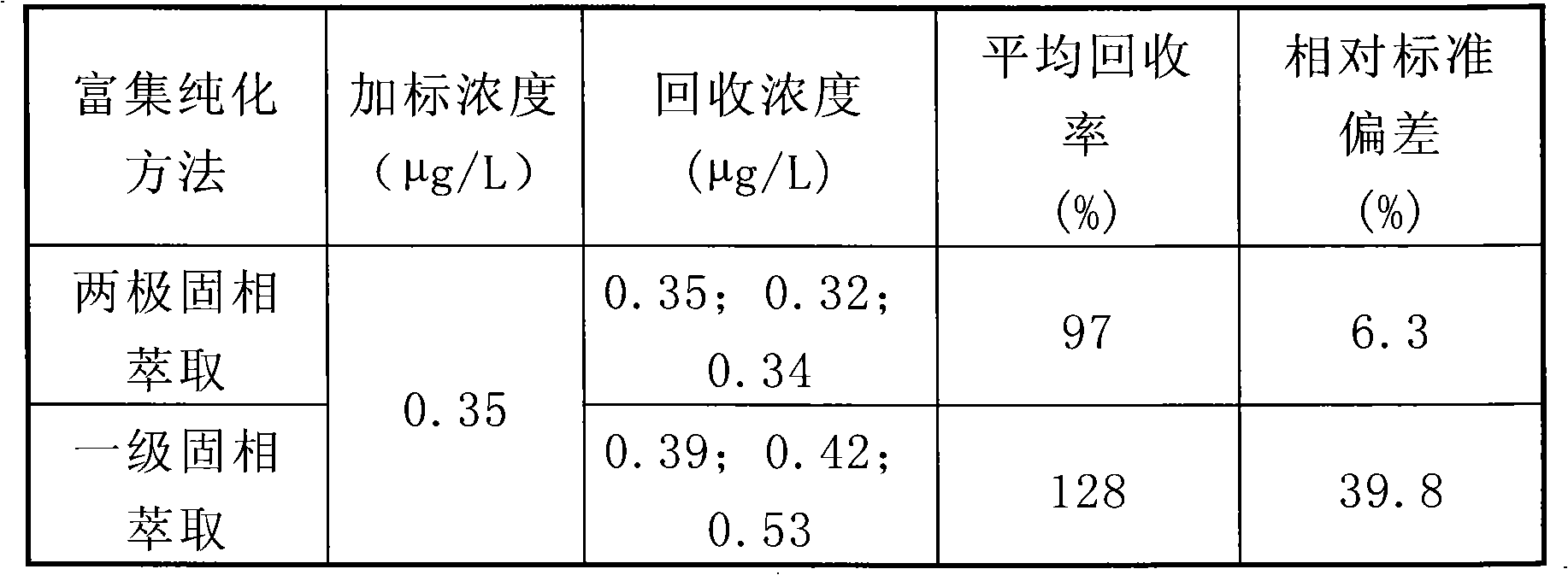

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] This specific embodiment comprises the following steps carried out in sequence:

[0019] (1) Reverse-phase column preparation: first wash and activate the reverse-phase column with 10 mL of methanol, and then add 15 mL of ultrapure water to condition the activated reverse-phase column.

[0020] (2) Reverse-phase column enrichment: pass the water sample through the reverse-phase column at a filtration rate of 4mL / min. After the filtration is completed, wash the reverse-phase column with 12mL of methanol-water mixture (φmethanol=20%), and dry pump for 5min After that, it was eluted with 2ml of methanol.

[0021] (3) Normal-phase column preparation: wash and activate the column bed with 10 mL of methanol, and then condition the activated normal-phase column with 10 mL of methanol-water mixture (φmethanol=20%).

[0022] (4) Normal-phase column purification: Dilute the methanol eluent from reverse-phase solid-phase extraction into a methanol-water mixture (φmethanol=20%), p...

specific Embodiment 2

[0023] This specific embodiment comprises the following steps carried out in sequence:

[0024] (1) Reversed-phase column preparation: first wash and activate the reverse-phase column with 10 mL of methanol, then add 20 mL of ultrapure water to condition the activated reverse-phase column.

[0025] (2) Reverse-phase column enrichment: pass the water sample through the reverse-phase column at a filtration rate of 4.5mL / min. After the filtration is completed, wash the reverse-phase column with 11 mL of methanol-water mixture (φmethanol=20%), and dry extract After 8 min, it was eluted with 2 ml methanol.

[0026] (3) Normal-phase column preparation: wash and activate the column bed with 10 mL of methanol, and condition the activated normal-phase column with 12 mL of methanol-water mixture (φmethanol=20%).

[0027] (4) Normal-phase column purification: Dilute the methanol eluent from reverse-phase solid-phase extraction into a methanol-water mixture (φmethanol=20%), pass through ...

specific Embodiment 3

[0028] This specific embodiment comprises the following steps carried out in sequence:

[0029] (1)C 18 Reversed-phase column preparation: wash with 10mL methanol and activate C 18 Reversed-phase column, add 19mL ultrapure water to activate the C 18 Reverse-phase column conditioning.

[0030] (2)C 18 Reverse-phase column enrichment: pass the water sample through C at a filtration rate of 4.5mL / min 18 Reversed-phase column, after filtration, wash C with 14 mL of methanol-water mixture (φmethanol=20%) 18 Reversed-phase column, after 10 minutes of dry pumping, eluted with 2ml of methanol.

[0031] (3) Silica gel normal-phase column preparation: wash and activate the column bed with 10 mL of methanol, and then condition the activated normal-phase column with 15 mL of methanol-water mixture (φmethanol=20%).

[0032] (4) Silica gel normal-phase column purification: Dilute the methanol eluent from reverse-phase solid-phase extraction into a methanol-water mixture (φmethanol=20%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com