Method for separating and purifying anti-allergic components in perilla leaves

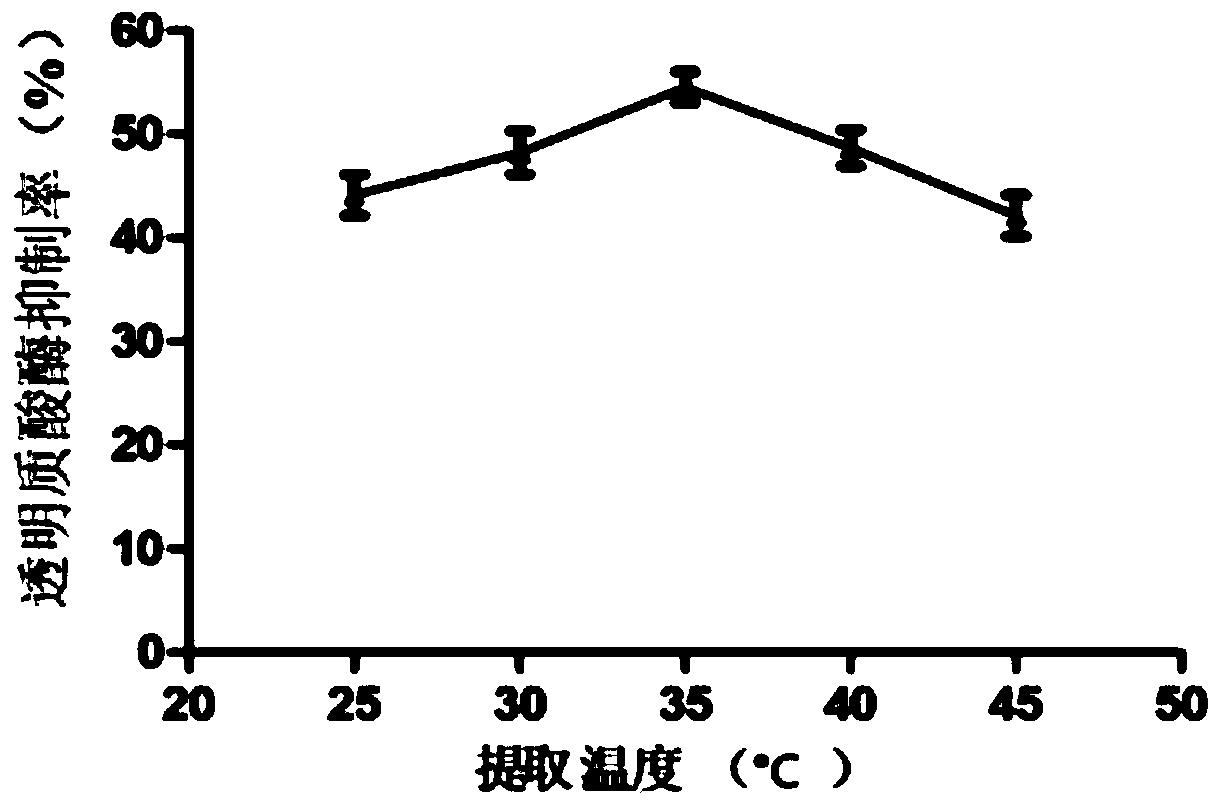

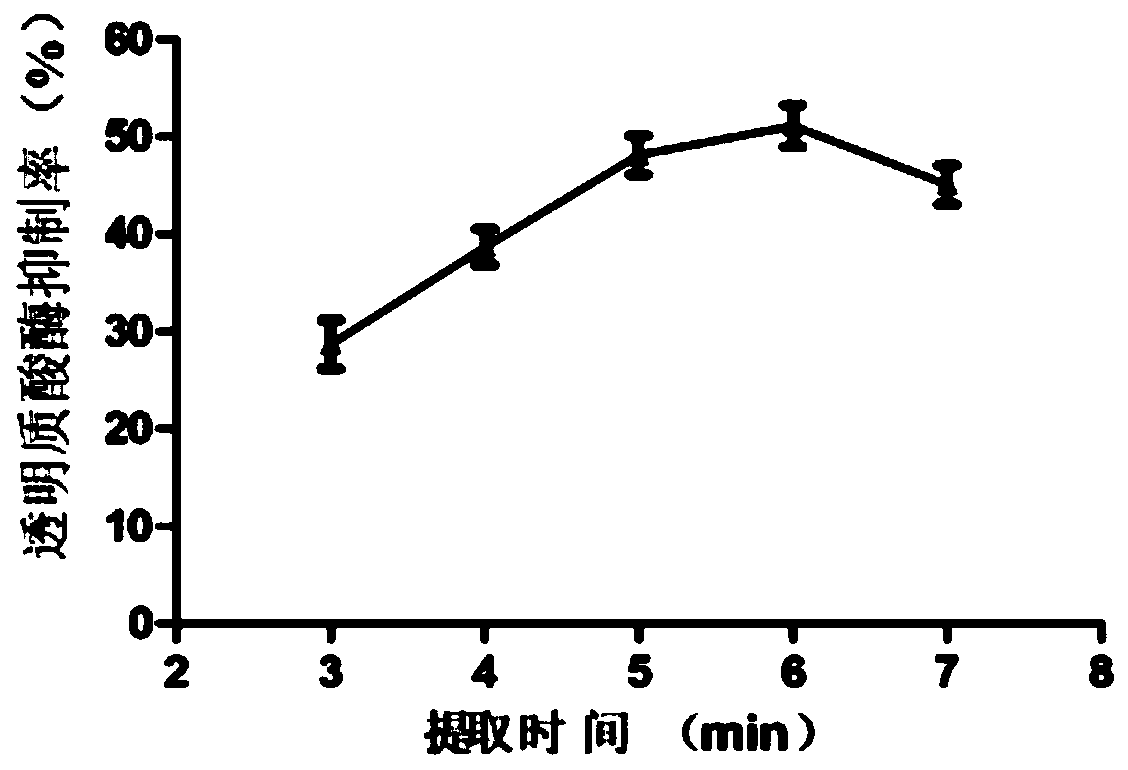

A separation, purification and anti-allergic technology, applied in medical preparations containing active ingredients, allergic diseases, plant/algae/fungus/moss components, etc., can solve various complications, human troubles, life-threatening problems, etc. Achieve the effects of short extraction time, simple and feasible method, and low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take by weighing 10.0g perilla leaf powder in a plastic beaker, according to the solid-liquid ratio of 1:15 (kg / L), add 150mL of ethanol with a volume concentration of 70% therein, after stirring evenly, place the beaker in a high-speed dispersion On the instrument, set the speed of the instrument at 11000r / min, the temperature at 30°C, disperse for 1min, disperse 5 times, pour out the upper layer solution, collect, then add 150mL of 70% ethanol to the beaker, repeat the above dispersion process, and combine the obtained upper layer The solution was subjected to suction filtration, and the obtained clear solution was dried at 50°C to obtain a crude extract;

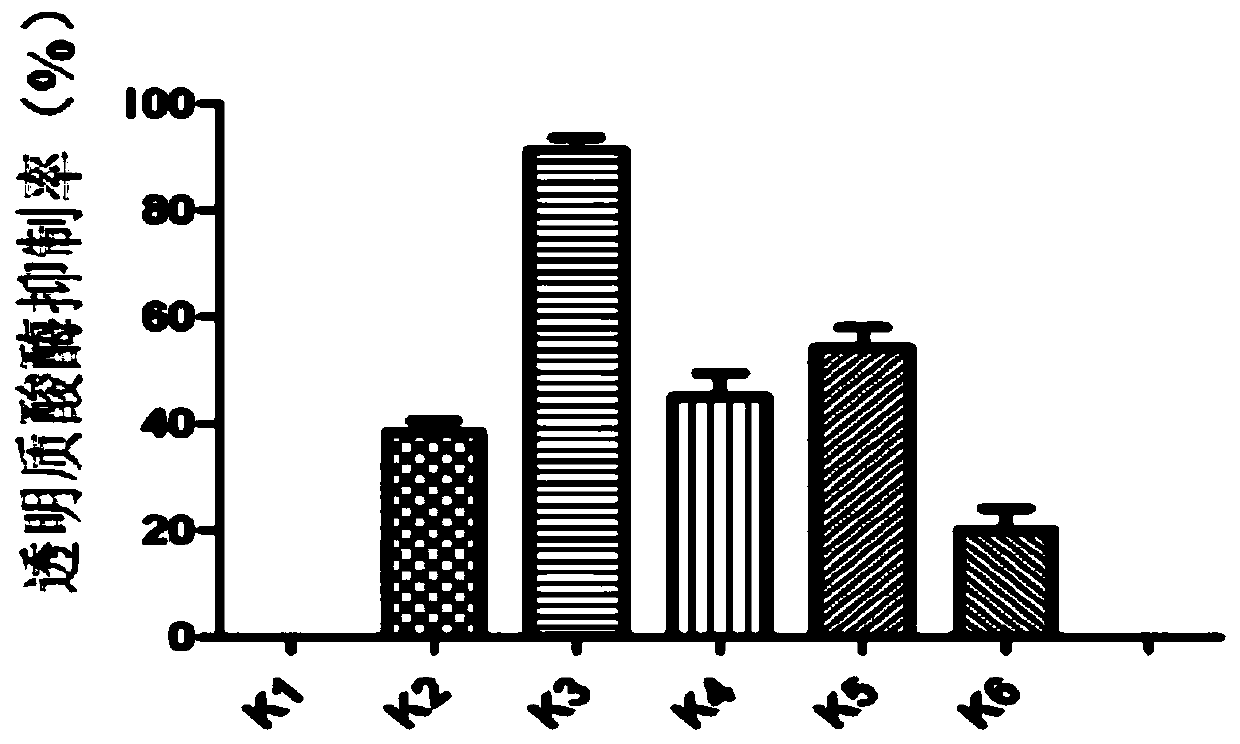

[0035] Mix the crude extract with silica gel (200-300 mesh) at a mass ratio of 1:1, place in a mortar, grind evenly, and obtain a sample for later use; weigh an appropriate amount of silica gel and add petroleum ether and mix well, for later use; take a Put a small amount of cotton at the bottom of the chromatograp...

Embodiment 2

[0037] Take by weighing 10.0g perilla leaf powder in a plastic beaker, add 150mL of ethanol with a volume concentration of 70% according to a solid-liquid ratio of 1:20 (kg / L), stir evenly, put the beaker into a high-speed disperser Above, set the speed of the instrument at 11000r / min, the temperature at 35°C, disperse for 1min, disperse 6 times, pour out the upper solution, collect it, then add 150mL of 70% ethanol to the beaker, repeat the above dispersion process, combine the upper solution and Suction filtration was carried out, and the obtained clear solution was dried at 50°C to obtain a crude extract;

[0038] Mix the crude extract with silica gel (200-300 mesh) at a mass ratio of 1:1, place in a mortar, grind evenly, and obtain a sample for later use; weigh an appropriate amount of silica gel and add petroleum ether and mix well, for later use; take a Put a small amount of cotton at the bottom of the chromatography column, slowly put the silica gel mixed with petroleum...

Embodiment 3

[0040]Take by weighing 10.0g perilla leaf powder in a plastic beaker, according to the solid-liquid ratio of 1:25 (kg / L), add 150mL of ethanol with a volume concentration of 70% therein, stir evenly, put the beaker into a high-speed disperser Above, set the speed of the instrument at 11000r / min, the temperature at 40°C, disperse for 1min, disperse 7 times, pour out the upper layer solution, collect it, then add 150mL of 70% ethanol to the beaker, repeat the above dispersion process, combine the upper layer solution and carry out Suction filtration, drying the obtained clear solution at 50°C to obtain a crude extract;

[0041] Mix the crude extract with silica gel (200-300 mesh) at a mass ratio of 1:1, place in a mortar, grind evenly, and set aside; weigh an appropriate amount of silica gel and add petroleum ether, mix well, set aside; take a chromatographic Plug a small amount of cotton at the bottom of the column, slowly put the silica gel mixed with petroleum ether into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com