Supersonic synergic nano light catalytic air-sterilizing-purifying apparatus

An air sterilization and purification device technology, applied in the direction of irradiation, deodorization, disinfection, etc., to achieve the effect of improving purification efficiency, improving dust removal efficiency, and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

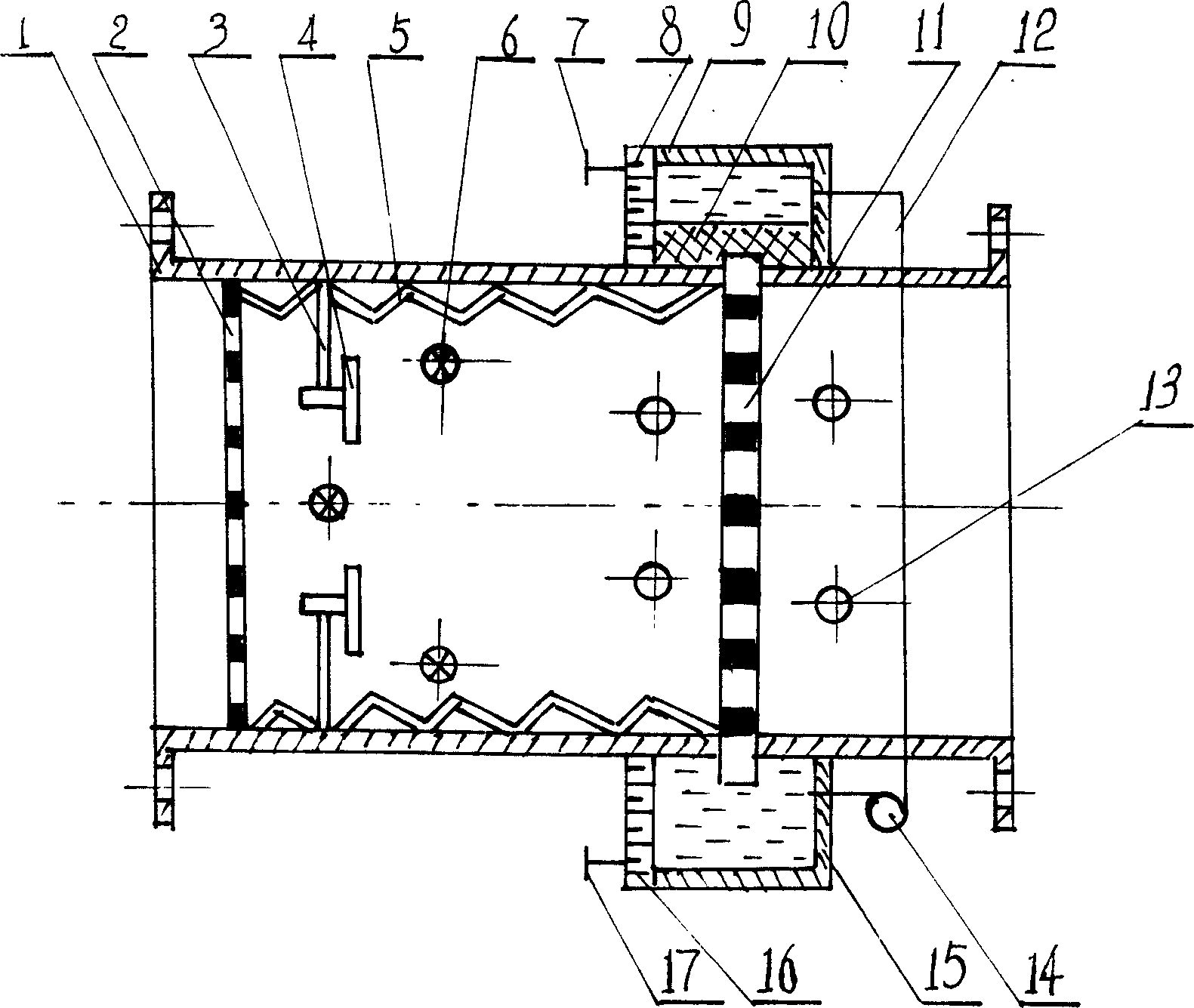

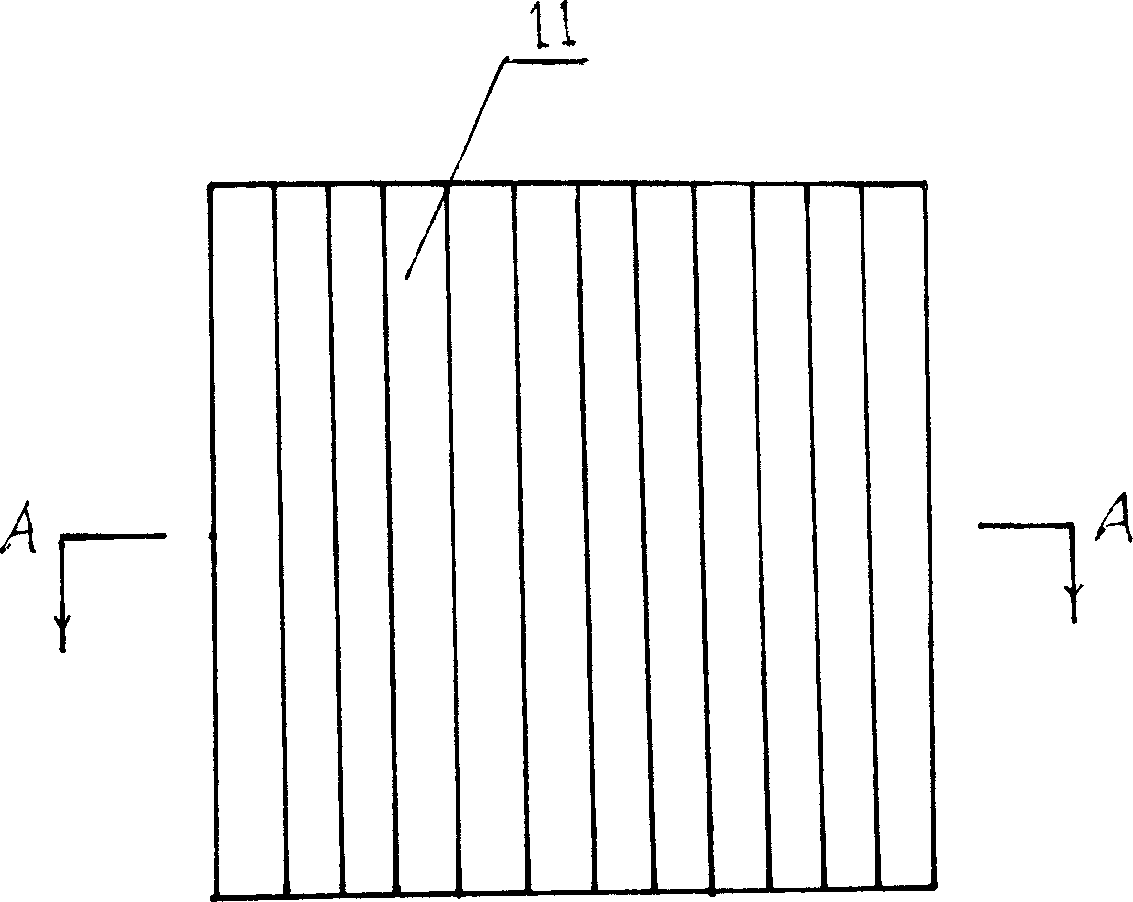

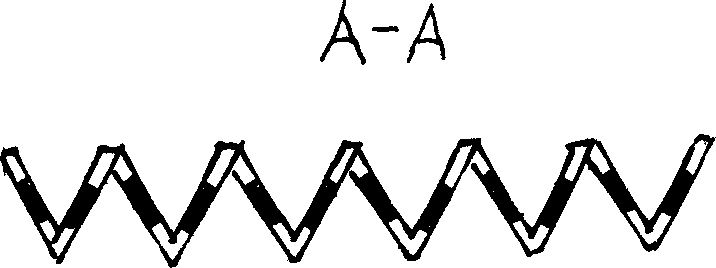

[0018] exist figure 1 , 2 , 3, the ultrasonic synergistic nano-photocatalytic air sterilization and purification device of the present embodiment consists of a housing 1, a coarse filter screen 2, a transducer bracket 3, an ultrasonic air transducer 4, an acoustic reflection plate 5, a sterilizing ultraviolet lamp 6, Water inlet valve 7, upper water storage tank water level gauge 8, upper water storage tank 9, sponge filter 10, photocatalytic three-dimensional net 11, upper water pipe 12, photocatalytic ultraviolet lamp 13, micro water pump 14, lower water storage tank 15, lower water storage tank The water level scale 16 and the drain valve 17 are connected to form.

[0019] The cross section of the housing 1 in this embodiment is a rectangular frame structure, and the upper surface outside the housing 1 is fixedly connected with an upper water storage tank 9 with a threaded fastening connector, and the lower surface is fixedly connected with a lower water storage tank with ...

Embodiment 2

[0021] In this embodiment, four transducer brackets 3 are fixedly connected to the downstream housing 1 in the airflow direction of the coarse filter screen 2 in the housing 1 with threaded fastening connectors, and the transducer brackets 3 are connected with threaded fastening An ultrasonic air transducer 4 is installed in each fixed connection of the components. The working frequency of the ultrasonic air transducer 4 is 20-25KHz and the power is 20W. A germicidal ultraviolet lamp is installed downstream of each ultrasonic air transducer 4, the power of the germicidal ultraviolet lamp is 20W, and the wavelength of the emitted ultraviolet light is 254nm. The photocatalytic three-dimensional net 11 is loaded with nano-TiO with a porosity greater than or equal to 95% and a thickness of 5 mm. 2 The nickel foam of photocatalyst, photocatalytic three-dimensional net 11 is planar structure, and the airflow direction upstream of photocatalytic three-dimensional net 11 and the downs...

Embodiment 3

[0023] In this embodiment, a transducer bracket 3 is fixedly connected to the housing 1 downstream of the coarse filter screen 2 in the direction of air flow in the housing 1 with a threaded fastening connector, and the transducer bracket 3 is connected with a threaded fastening An ultrasonic air transducer 4 is installed in each fixed connection of the parts, the working frequency of the ultrasonic air transducer 4 is 20-25KHz, and the power is 100W. Two germicidal ultraviolet lamps are installed downstream of the ultrasonic air transducer 4, the power of the germicidal ultraviolet lamp is 30W, and the wavelength of the emitted ultraviolet light is 254nm. The photocatalytic three-dimensional net 11 is loaded with nano-TiO with a porosity greater than or equal to 95% and a thickness of 10 mm. 2 The nickel foam of the photocatalyst, the photocatalytic three-dimensional network 11 is a planar structure, and the upstream and downstream of the photocatalytic three-dimensional netw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com