High-activity bone construction method based on bone marrow suction enrichment system

A highly active and enriched technology, applied in bone implants, medical science, joint implants, etc., can solve the problems of easy damage to peripheral blood vessels and nerves, easy loss of osteogenic materials, and inaccurate bone extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is further described in detail through specific implementation methods:

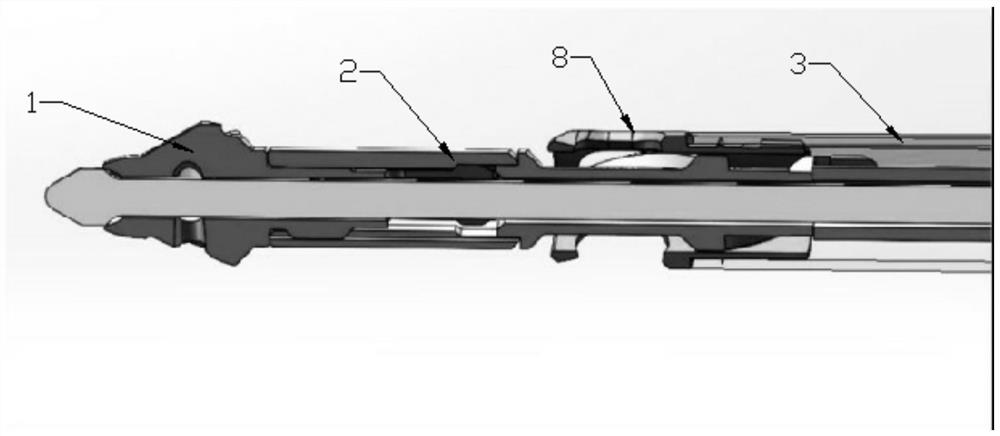

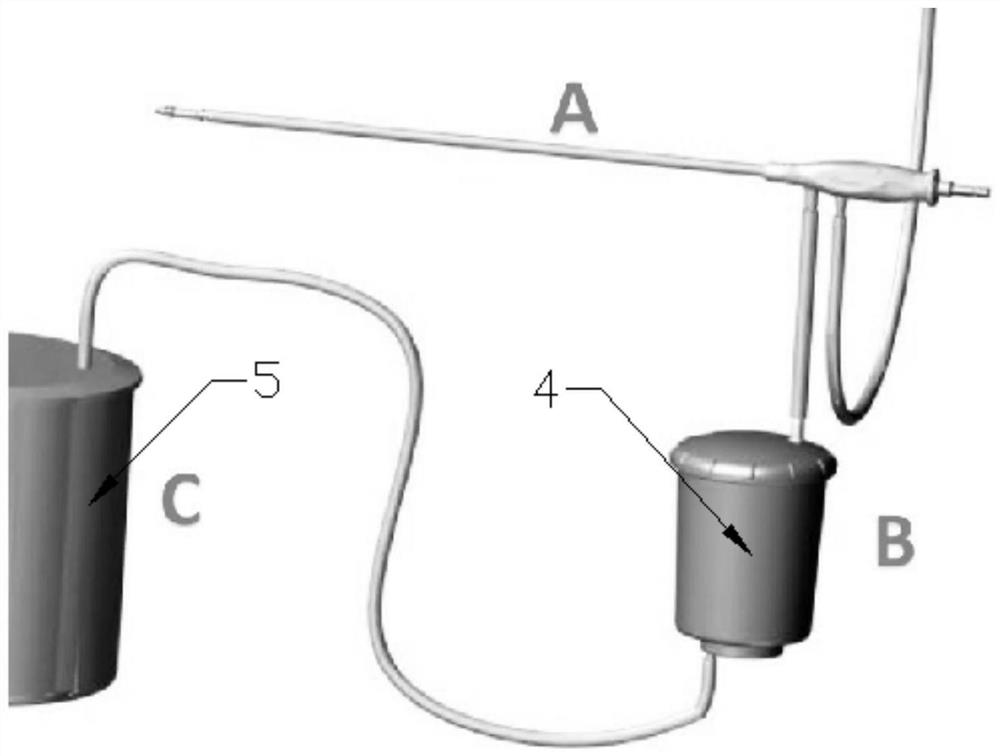

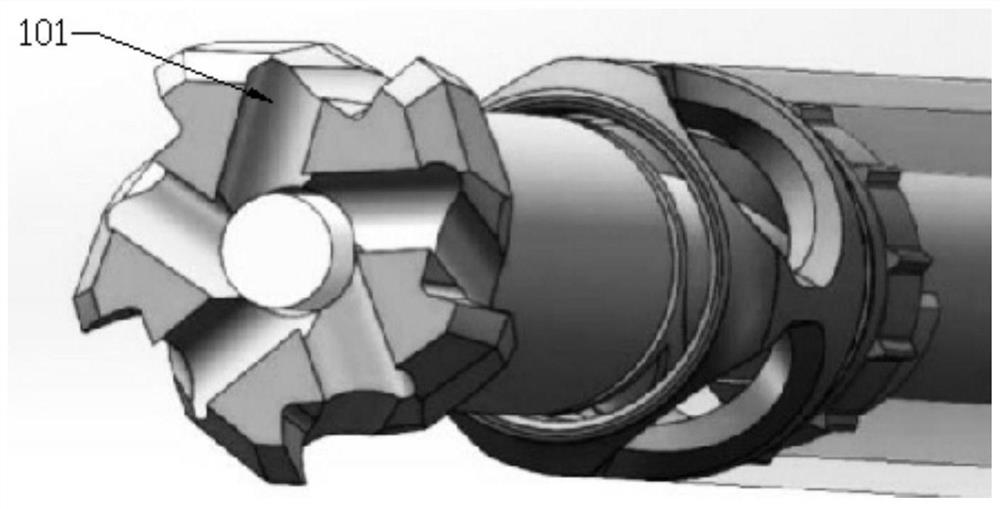

[0040] The marks in the accompanying drawings include: reaming drill bit 1, drainage hole 101, drill pipe 2, drill pipe seal 201, collection pipe 3, water outlet 301, water inlet 302, mixing tank 4, inner tank body 401, outer tank Body 402, mixing and stirring device 403, turbulence device 404, waste liquid collection tank 5, speed regulating motor 6, lock clamp cover 7, casing 8.

[0041] The embodiment is basically as figure 1 , figure 2 with image 3Shown: a bone marrow aspiration enrichment system, including a reaming drill bit 1, a drill pipe 2, a collection tube 3, a mixing tank 4 and a waste liquid collection tank 5, the reaming drill bit 1 and the drill pipe 2 are detachably connected , in the present embodiment, disassembly and connection are carried out by means of screw connection, the reaming drill bit 1 and the drill rod 2 are hollow, the reaming drill bit 1 is conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com