Horseradish tree zymolyte as well as preparation method and application thereof

A technology of moringa enzyme and enzymatic hydrolyzate, which is applied in the field of preparation of moringa enzymatic hydrolyzate and moringa enzymatic hydrolyzate, can solve the problems of lagging development of moringa oleifera, poor efficacy, low absorption efficiency of moringa oleifera leaves, etc., and achieve Low production cost, high oral bioavailability, and reduced post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of Moringa oleifera hydrolyzate, comprises the following steps:

[0028] a. Mix 100 parts by weight of Moringa raw material with 800 to 1200 parts by weight of water, add 1 to 8 parts of carbohydrase to the mixture, and perform constant temperature enzymolysis at 30 to 65°C for 0.5 to 12 hours to obtain carbohydrate hydrolyzate;

[0029] b. Adjust the pH value of the sugar hydrolyzate to 8-9, add 1-8 parts by weight of alkaline protease to the sugar hydrolyzate, and perform constant temperature enzymolysis at 30-65°C for 0.5-12 hours to obtain primary proteolyzate;

[0030] c. Add 1-8 parts by weight of neutral protease to the primary proteolyzate obtained in step b, and perform constant temperature enzymolysis at 30-65° C. for 0.5-12 hours to obtain a final proteolyzate;

[0031] d. Inactivate the enzyme in the final protein hydrolyzate described in step c, and obtain Moringa oleifera hydrolyzate after filtering and ...

Embodiment 1

[0052] Preparation of Moringa oleifera leaf enzymatic hydrolyzate from Yunnan dried Moringa oleifera leaves

[0053] Crush 100 grams of clean Moringa oleifera leaves from Yunnan, add 1000 ml of deionized water at a constant temperature of 55°C, adjust the pH value to 5, add 2 grams of carbohydrase, and react for 3 hours; then adjust the pH value with sodium hydroxide solution at the same temperature To 8, add 2 grams of alkaline protease to react for 2 hours under constant temperature stirring; then add 2 grams of neutral protease to react for 2 hours under the same temperature conditions; raise the temperature of the obtained enzymatic hydrolyzate to 90 ° C, keep the temperature for half an hour, so that the enzyme loses Live, filter. The filtrate was concentrated under reduced pressure at a vacuum degree of 0.08 Mpa and a temperature of 50° C., and finally freeze-dried to obtain solid Moringa leaf enzymatic hydrolyzate dry powder with a yield of 62.1%.

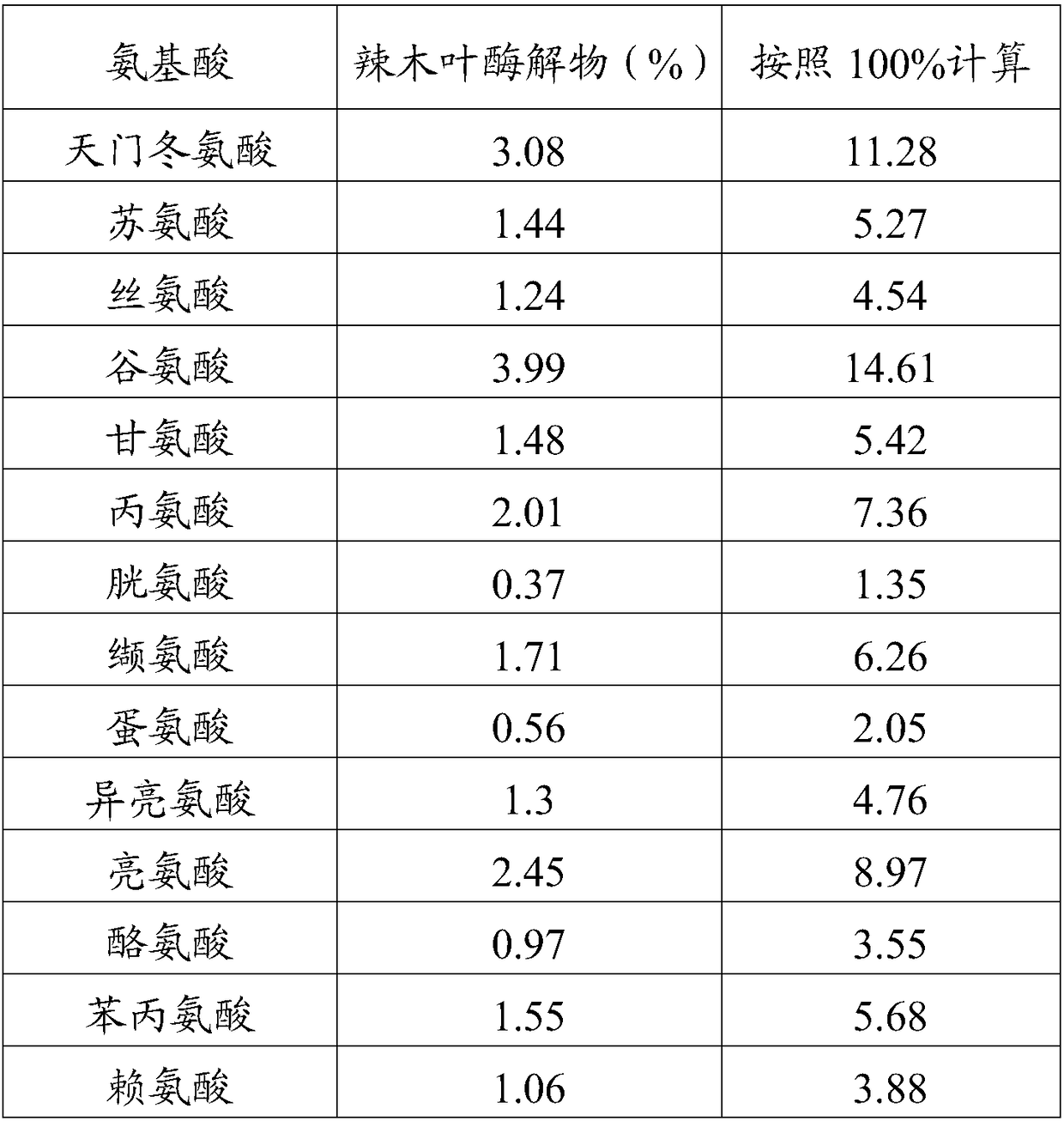

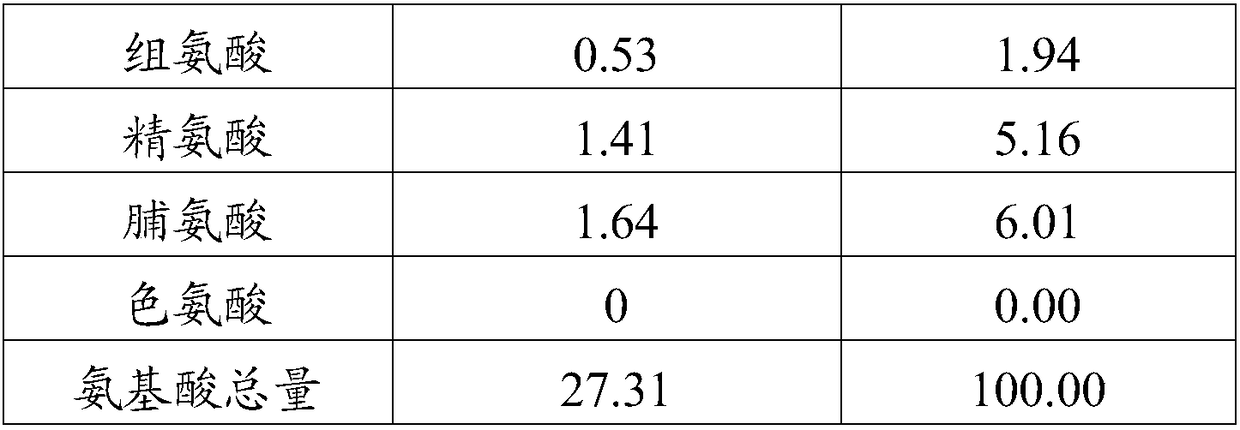

[0054] According to...

Embodiment 2

[0059] Preparation of dry powder of Moringa oleifera leaf enzyme hydrolyzate from Sichuan moringa oleifera leaves

[0060] Add 100 grams of clean dried and crushed leaves of Moringa oleifera from Sichuan, add 800 ml of deionized water at a constant temperature of 35°C, adjust the pH value to 5, add 7 grams of carbohydrase, and react for 4 hours; then adjust the pH value to 8 at the same temperature , add 8 grams of alkaline protease and react for 5 hours under constant temperature stirring; then add 8 grams of neutral protease and react for 5 hours under the same temperature conditions; then raise the temperature to 80°C, react at constant temperature for 40 minutes to inactivate the enzyme, and filter. The filtrate was concentrated under reduced pressure at a vacuum degree of 0.10 MPa and a temperature of 40° C., and finally freeze-dried to obtain solid Moringa oleifera leaf enzymatic hydrolyzate dry powder with a yield of 48.5%.

[0061] According to the measurement, in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com