Denitrification technology for printing and dyeing wastewater

A printing and dyeing wastewater and denitrification technology, applied in the field of denitrification process, can solve the problems of biological denitrification performance decline, activity reduction, etc., and achieve the effect of low sludge production, reduced sludge output and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

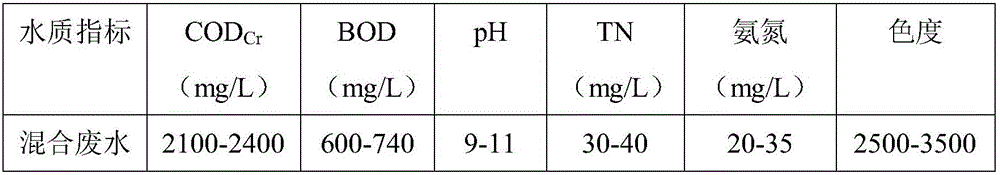

[0021] The raw water in Example 1 is taken from the wastewater of a certain printing and dyeing factory. The wastewater includes pretreatment wastewater and dyeing wastewater. The pretreatment wastewater is mainly composed of wastewater produced by desizing, scouring and rinsing processes. The dyeing wastewater is mainly composed of wastewater produced by dyeing and printing processes. . The printing and dyeing wastewater to be treated is the mixed wastewater of two streams of wastewater, and the water quality of the mixed wastewater is shown in Table 1.

[0022] Table 1 Water quality indicators of wastewater, dyeing wastewater mixed wastewater

[0023]

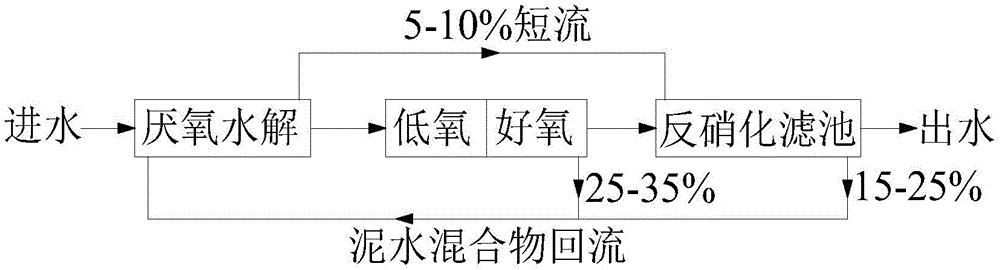

[0024] The above-mentioned waste water to be treated enters the denitrification system constructed by the process of the present invention, and the waste water to be treated passes through the anaerobic hydrolysis tank, the hypoxic tank, the aerobic tank, and the denitrification filter in sequence; according to the charact...

Embodiment 2

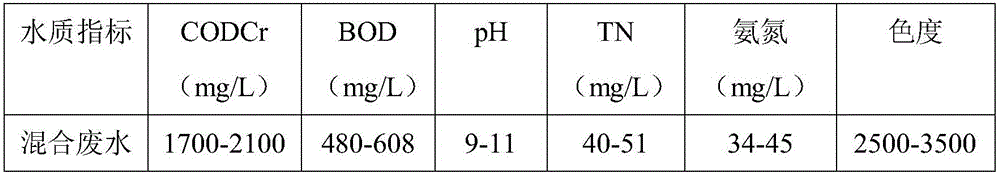

[0027] In Example 2, the raw water is taken from the wastewater of a printing and dyeing factory. The wastewater includes pretreatment wastewater and dyeing wastewater. The pretreatment wastewater is mainly composed of wastewater produced by desizing, scouring and rinsing processes, and the dyeing wastewater is mainly produced by dyeing and printing processes. . The printing and dyeing wastewater to be treated is the mixed wastewater of the two streams, and the water quality of the mixed wastewater is shown in Table 2.

[0028] Table 2 Water quality indicators of wastewater, dyeing wastewater mixed wastewater

[0029]

[0030] The above-mentioned waste water to be treated enters the denitrification system constructed by the process of the present invention, and the waste water to be treated passes through the anaerobic hydrolysis tank, the hypoxic tank, the aerobic tank, and the denitrification filter in sequence; according to the characteristics of water quality, it is fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com