Method for extracting selenium from nickel-molybdenum ore smelting smoke dust in alkali system

A technology for nickel-molybdenum ore and soot is applied in the field of hydrometallurgical extraction of selenium, which can solve the problems of easy leakage of toxic gas, low selenium recovery rate, low production cost, etc., and achieve the effects of easy floating, improved recovery rate, and reduced emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

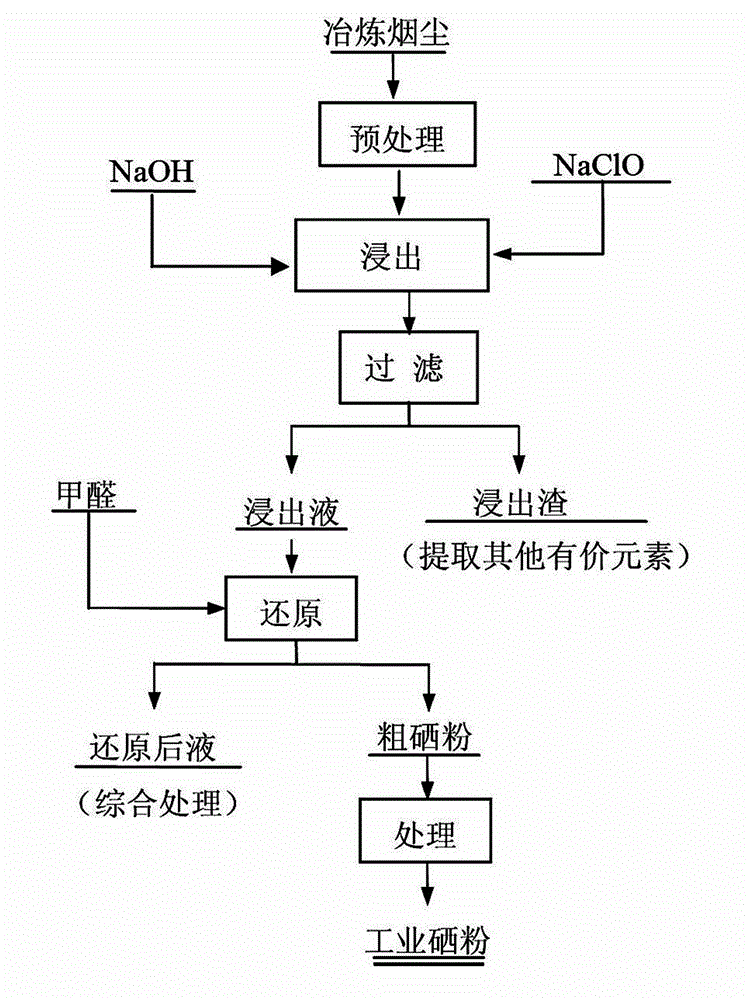

[0029] such as figure 1 The shown method for extracting selenium in nickel-molybdenum ore smelting smoke in an alkaline system comprises the following steps:

[0030] (1) Pretreatment of nickel-molybdenum ore smelting fume: First, the raw materials are crushed, ball-milled and screened to obtain -100 mesh nickel-molybdenum ore smelting fume (particle size less than 0.15mm in the range of 100-300 mesh).

[0031] (2) Oxidative leaching of selenium in an alkaline system: in an alkaline system, the nickel-molybdenum ore smelting dust obtained after the pretreatment in step (1) is subjected to oxidative leaching, and the oxidative leaching is carried out in a leaching system of an aqueous sodium hydroxide solution , the oxidant is sodium hypochlorite. The specific operation steps of oxidative leaching are as follows: first, prepare 100ml with a concentration of 2.0mol·L -120 g of nickel-molybdenum ore smelting dust obtained after the pretreatment in step (1) was added to the reac...

Embodiment 2

[0034] such as figure 1 The shown method for extracting selenium in nickel-molybdenum ore smelting smoke in an alkaline system comprises the following steps:

[0035] (1) Pretreatment of nickel-molybdenum ore smelting fume: First, the raw materials are crushed, ball-milled and screened to obtain -150 mesh nickel-molybdenum ore smelting fume (the particle size is less than 0.15mm in the range of 100-300 mesh).

[0036] (2) Oxidative leaching of selenium in an alkaline system: in an alkaline system, the nickel-molybdenum ore smelting dust obtained after the pretreatment in step (1) is subjected to oxidative leaching, and the oxidative leaching is carried out in a leaching system of an aqueous sodium hydroxide solution , the oxidant is sodium hypochlorite. The specific operation steps of oxidative leaching are as follows: first, prepare 120ml with a concentration of 2.5mol·L -1 20 g of nickel-molybdenum ore smelting dust obtained after the pretreatment in step (1) was added to ...

Embodiment 3

[0039] such as figure 1 The shown method for extracting selenium in nickel-molybdenum ore smelting smoke in an alkaline system comprises the following steps:

[0040] (1) Pretreatment of nickel-molybdenum ore smelting fume: First, the raw materials are crushed, ball-milled and screened to obtain -150 mesh nickel-molybdenum ore smelting fume (the particle size is less than 0.15mm in the range of 100-300 mesh).

[0041] (2) Oxidative leaching of selenium in an alkaline system: in an alkaline system, the nickel-molybdenum ore smelting dust obtained after the pretreatment in step (1) is subjected to oxidative leaching, and the oxidative leaching is carried out in a leaching system of an aqueous sodium hydroxide solution , the oxidant is sodium hypochlorite. The specific operation steps of oxidative leaching are as follows: First, prepare 80ml with a concentration of 3.0mol·L -1 20 g of nickel-molybdenum ore smelting dust obtained after the pretreatment in step (1) was added to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com