Preparation method of plant selenium enrichment enhancer

A fortifier and selenium-enriched technology, which is applied in the field of preparation of plant selenium-enriched fortifiers, can solve problems such as harming human health, poisonous crops, and inorganic selenium residues, and achieve the effects of increased production, low production costs, and high conversion rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

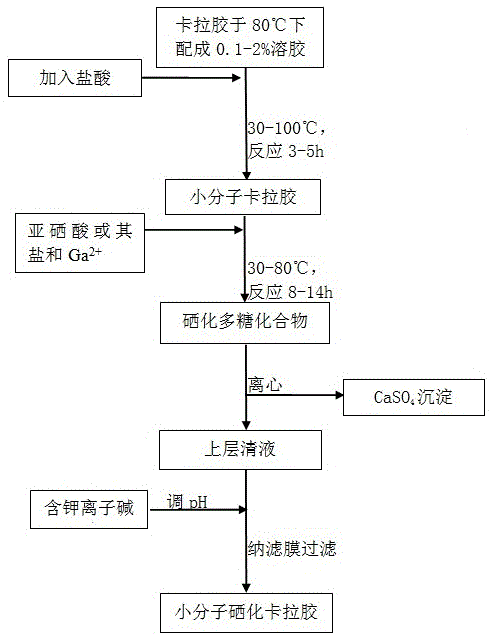

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Preparation of selenium-enriched enhancer for wheat and rice plants

[0030] (1) Degradation of carrageenan: 1.2kg of carrageenan is formulated into a 1.6% sol at 80°C, and 1271ml of 6mol / L hydrochloric acid is added under stirring to make the molar concentration of hydrochloric acid in the solution about 0.1mol / L. Reaction at low temperature for 3h to obtain small molecule carrageenan with a molecular weight of 300-1000;

[0031] (2) Selenization reaction: Add 0.5kg sodium selenite and 1.0kg calcium nitrate to the carrageenan solution, heat to 70°C, and react at constant temperature for 8 hours to generate small molecule selenized carrageenan;

[0032] (3) Centrifuge to remove CaSO 4 : Centrifuge the above reaction solution to remove CaSO 4 ;

[0033] (4) Neutralize the acidic solution: adjust the pH to 7 with KOH, and stir to promote the reaction;

[0034] (5) Nanofiltration membrane filtration: Filtrate with a nanofiltration membrane with a molecula...

Embodiment 2

[0036] Embodiment 2: the preparation of vegetable plant selenium-enriched fortifier

[0037] (1) Degradation of carrageenan: 1.0kg of carrageenan is made into 1% sol at 80°C, and 3896ml of 8mol / L hydrochloric acid is added under stirring to make the molar concentration of hydrochloric acid in the solution about 0.3mol / L. Reaction at low temperature for 4h to obtain small molecule carrageenan with a molecular weight of 300-1000;

[0038] (2) Selenization reaction: Add 0.73kg of selenous acid and 1.33kg of calcium chloride to the carrageenan solution, heat to 65°C, and react at constant temperature for 10 hours to generate selenized polysaccharide compounds;

[0039] (3) Centrifuge to remove CaSO 4 : Centrifuge the above reaction solution to remove CaSO 4 ;

[0040] (4) Neutralize the acidic solution: adjust the pH to 8 with KOH, and stir to promote the reaction;

[0041] (5) Nanofiltration membrane filtration: Filtrate with a nanofiltration membrane with a molecular weight ...

Embodiment 3

[0043] Embodiment 3: Preparation of tea plant selenium enrichment enhancer

[0044] (1) Degradation of carrageenan: 1.5kg of carrageenan is formulated into a 1.8% sol at 80°C, and 4900ml of 9mol / L hydrochloric acid is added under stirring to make the molar concentration of hydrochloric acid in the solution about 0.5mol / L. Reaction at low temperature for 4.5h to obtain small molecule carrageenan with a molecular weight of 300-1000;

[0045](2) Selenization reaction: add 0.63kg sodium selenite and 1.25kg calcium nitrate to the carrageenan solution, heat to 55°C, and react at constant temperature for 12 hours to generate small molecule selenized carrageenan;

[0046] (3) Centrifuge to remove CaSO 4 : Centrifuge the above reaction solution to remove CaSO 4 ;

[0047] (4) Neutralize the acidic solution: adjust the pH to 6 with KOH, and stir to promote the reaction;

[0048] (5) Nanofiltration membrane filtration: Filtrate with a nanofiltration membrane with a molecular weight c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com