Patents

Literature

258 results about "Sustainable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sustainable production and consumption can be defined as production and use of products and services in a manner that is socially beneficial, economically viable and environmentally benign over their whole life cycle.

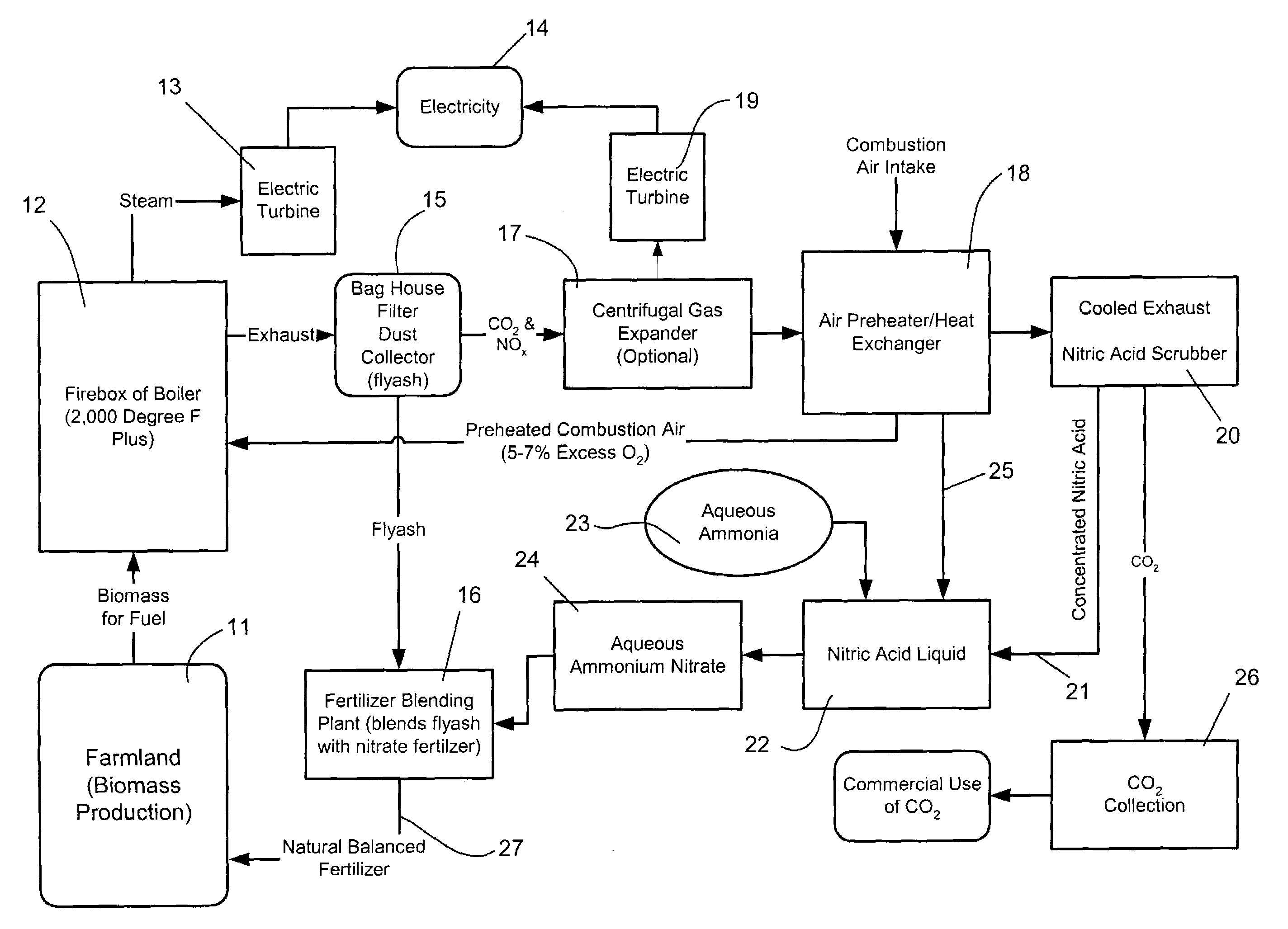

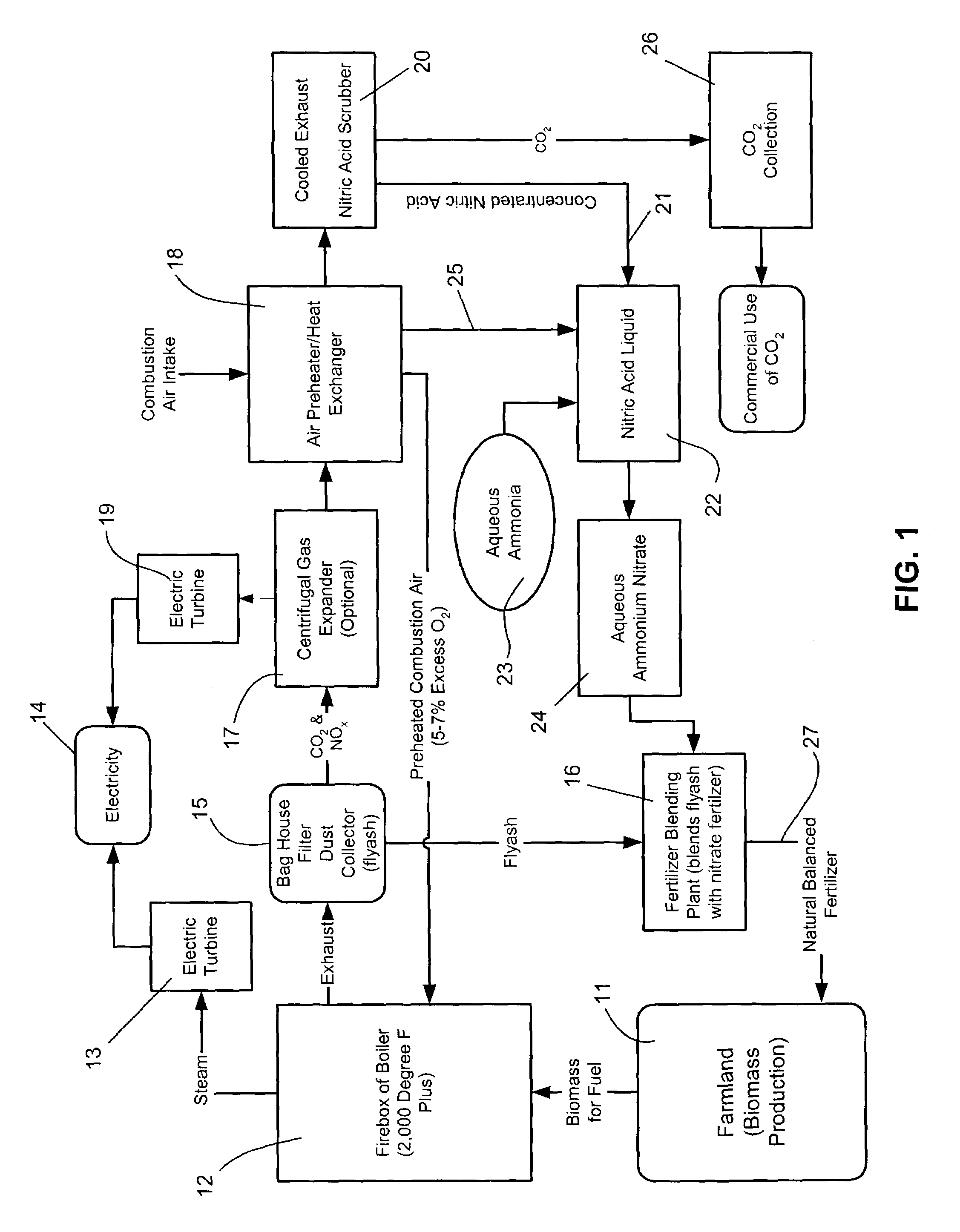

Process and apparatus for generating power, producing fertilizer, and sequestering, carbon dioxide using renewable biomass

ActiveUS7055325B2Improve economyImprove environmental impactCalcareous fertilisersSteam useCombustion chamberElectric power

A process and apparatus are described for generating electrical energy using grains or other renewable biomass as the fuel, and for producing fertilizer to grow subsequent crops. In the process, a biomass material is incinerated in a firebox of a boiler to power a first turbine to create electricity. An excess air flow is introduced into the firebox to increase NOx production. The oxidation area of the boiler is operated at a temperature exceeding about 2,000° F., and the flue gases are maintained in the high temperature environment for an increased residence time to increase NOx production. The flyash from the incinerated biomass is filtered from the flue gases exhausted from the boiler. The NOx is removed from the filtered flue gases and used to produce a nitrogen fertilizer. The nitrogen fertilizer is blended with the flyash to form a balanced fertilizer product which allows sustainable production of the biomass material.

Owner:WOLKEN MYRON B

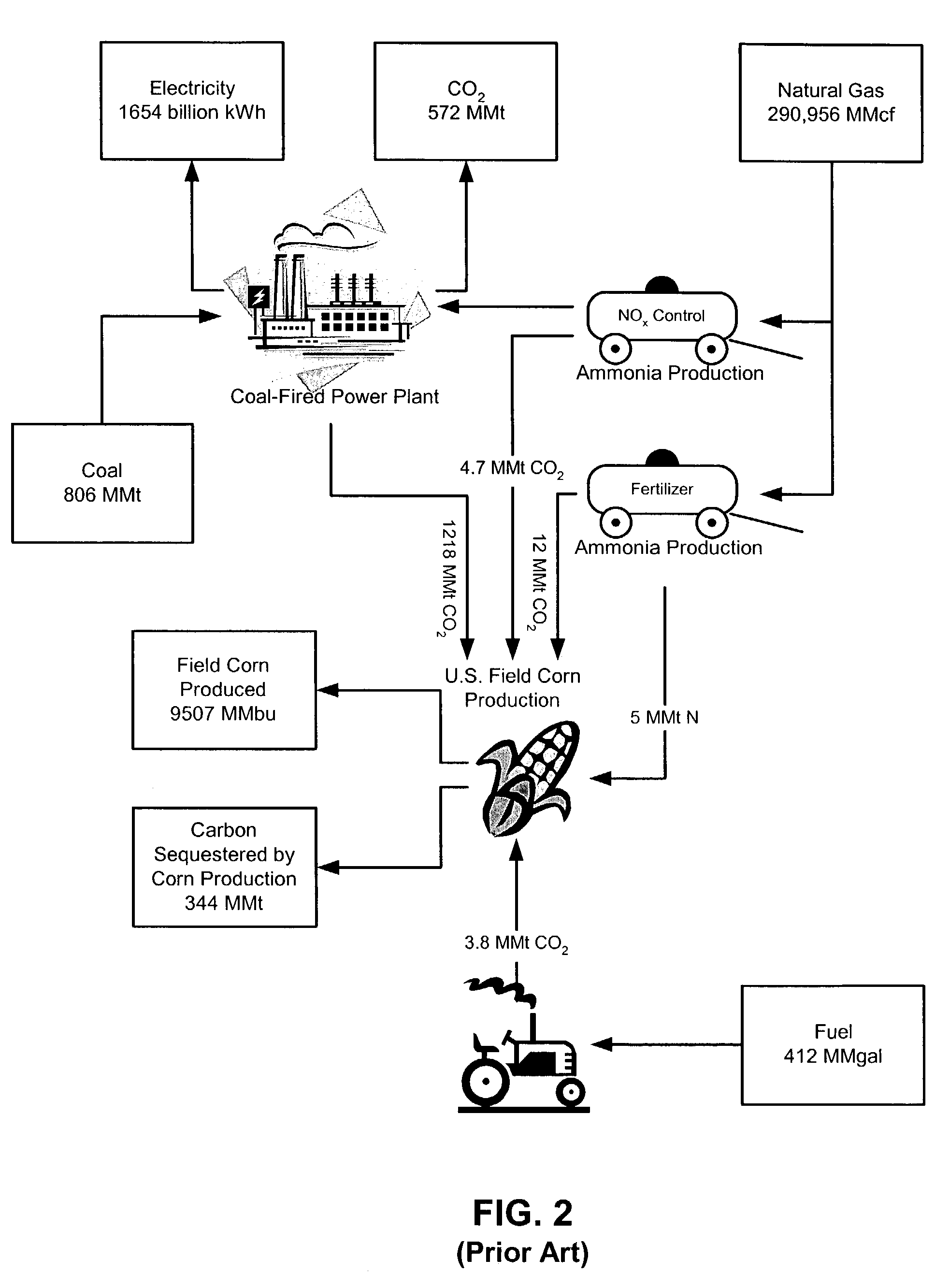

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

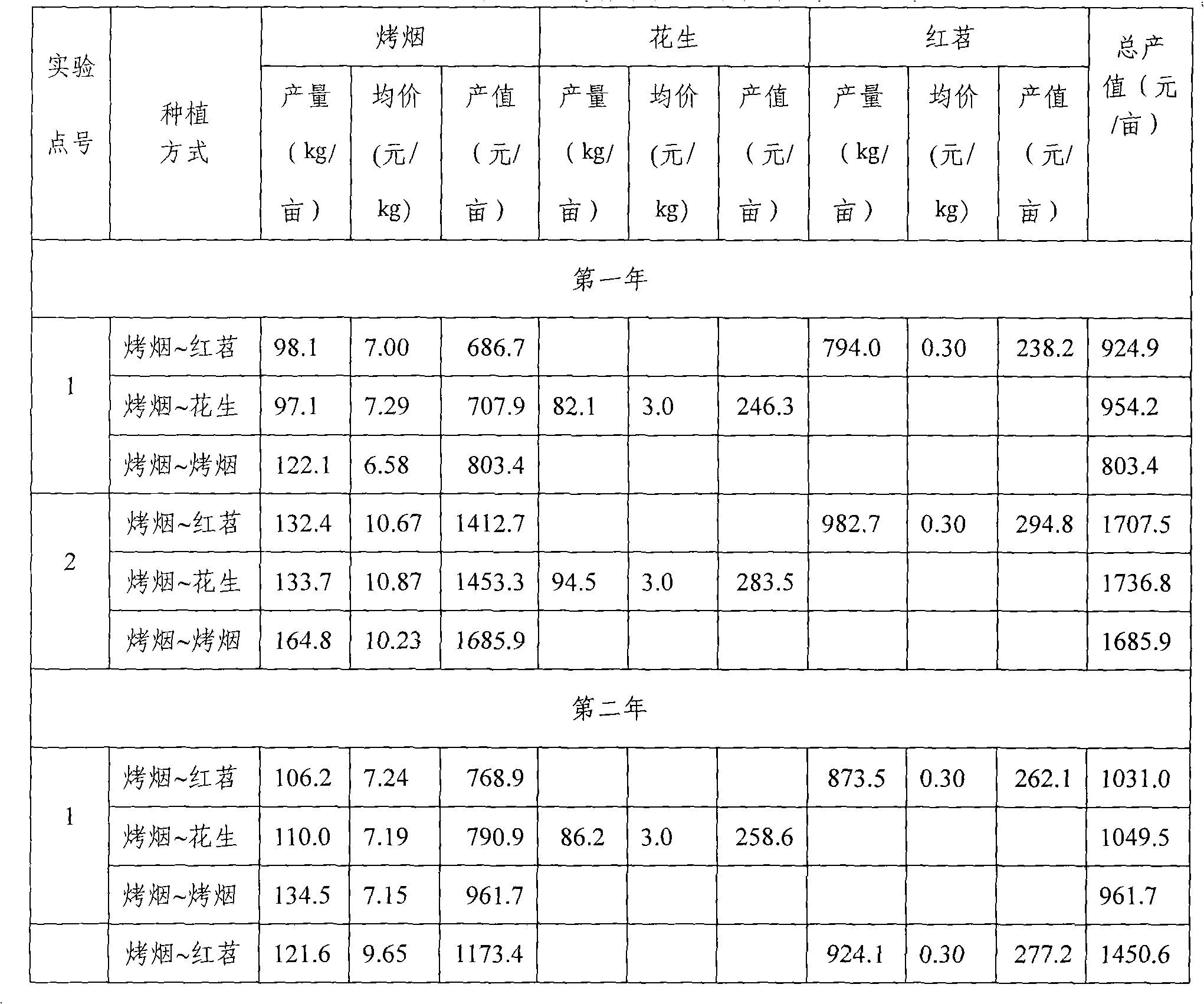

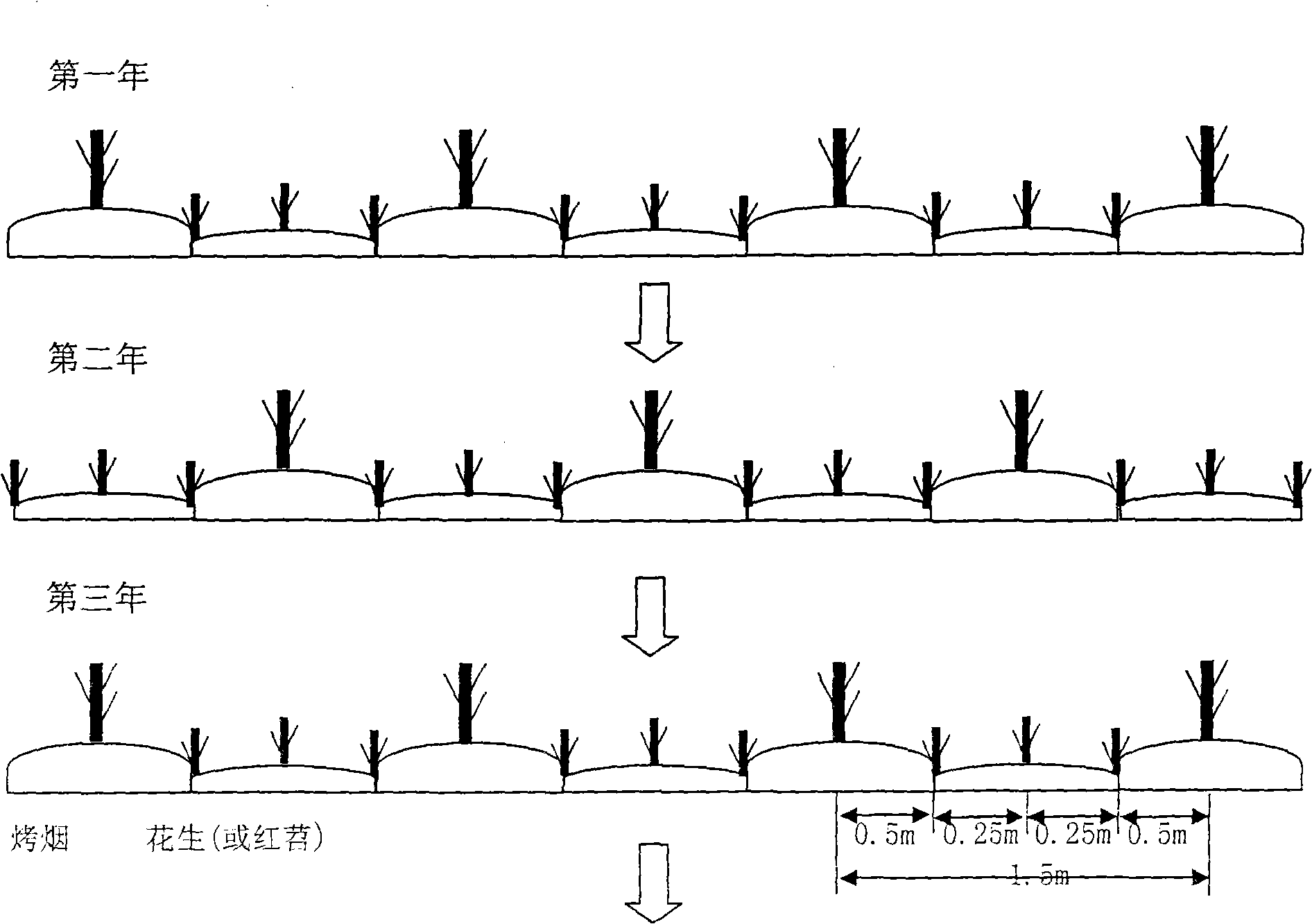

Planting method for conquering the continuous cropping obstacle of cured tobacco

InactiveCN101305670AAlleviate continuous cropping obstaclesGuaranteed sustainable productionFertilising methodsHorticultureContinuous croppingDisease

The invention relates to a planting method for overcoming the continuous cropping problems of flue-cured tobacco. The quality of the flue-cured tobacco is improved by alternately intercropping the flue-cured tobacco and peanuts or sweet potatoes so as to improve the ratio of the medium and high rank tobacco, and both the output value per unit of land and the income of the tobacco grower are increased; and meanwhile, the flue-cured tobacco planting is integrated with the generalized agriculture production, therefore, the continuous cropping problems (such as growth inhibition, disease and insect pest epidemiology and product quality reduction, etc.) of the flue-cured tobacco are remarkably lightened, the flue-cured tobacco can be basically planted for a long term and in successive years, the problem of serious tobacco field resources in the southwest region is solved, and the sustainable production of the flue-cured tobacco is guaranteed.

Owner:SOUTHWEST UNIVERSITY

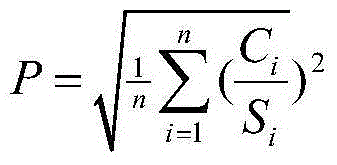

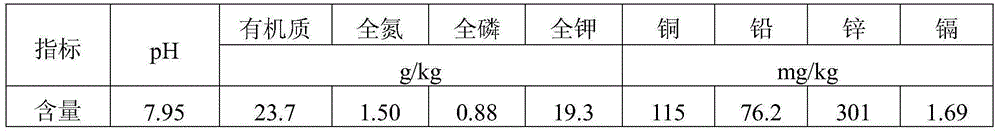

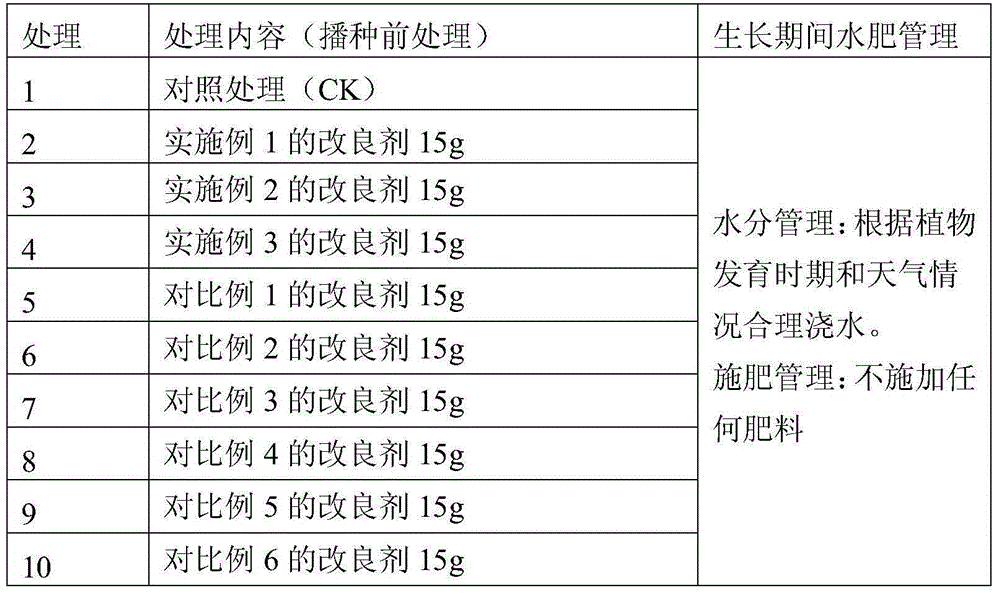

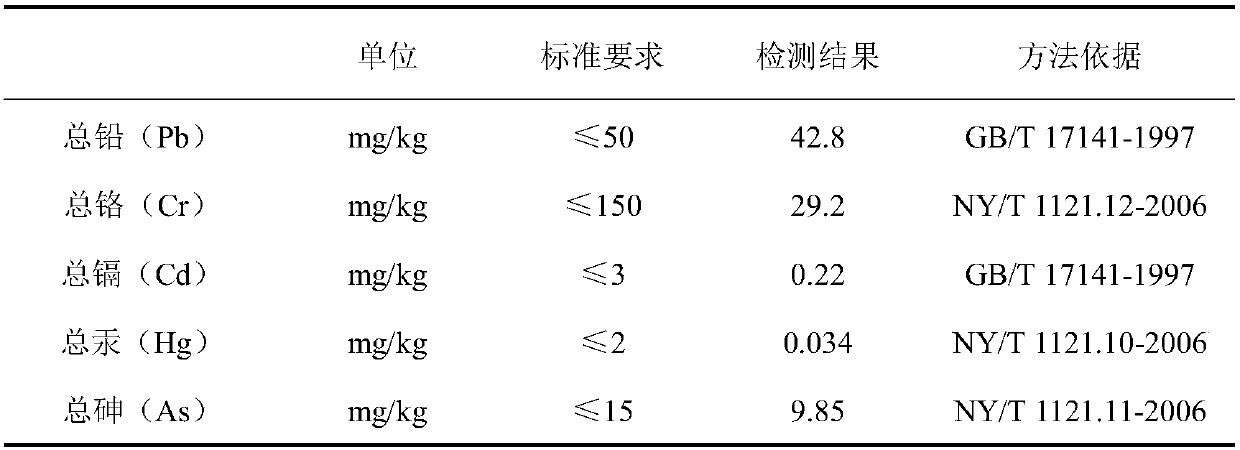

Farmland heavy metal contaminated soil compound modifying agent and preparation method and application method thereof

ActiveCN105061114ALow costSimple recipeFertilising methodsFertilizer mixturesSustainable productionDiammonium phosphate

The invention relates to a farmland heavy metal contaminated soil compound modifying agent and a preparation method and an application method thereof. The farmland heavy metal contaminated soil compound modifying agent comprises, by weight, 20-40% of activated decomposed coal, 15-25% of charcoal, 10-25% of sepiolite, 10-20% of calcium magnesium phosphate fertilizer and 10-20% of diammonium phosphate, wherein the activated decomposed coal is obtained by activating ammonium bicarbonate and ultrasonic waves, and the sepiolite is obtained by pyrolysis at the temperature of 600-800 DEG C. The farmland heavy metal contaminated soil compound modifying agent is low in cost and simple in formula and mainly used for passivating heavy metal of Cd, Cu, Pb and Zn in soil, the soil polluted by the heavy metal can be effectively repaired, the sustainable production capacity of the soil can be ensured, and the sustainable soil utilization is achieved.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Lake mandarin fish scale culturing method

InactiveCN101720682AEstimated productivityEstimating Production PotentialClimate change adaptationPisciculture and aquariaSustainable productionDistribution characteristic

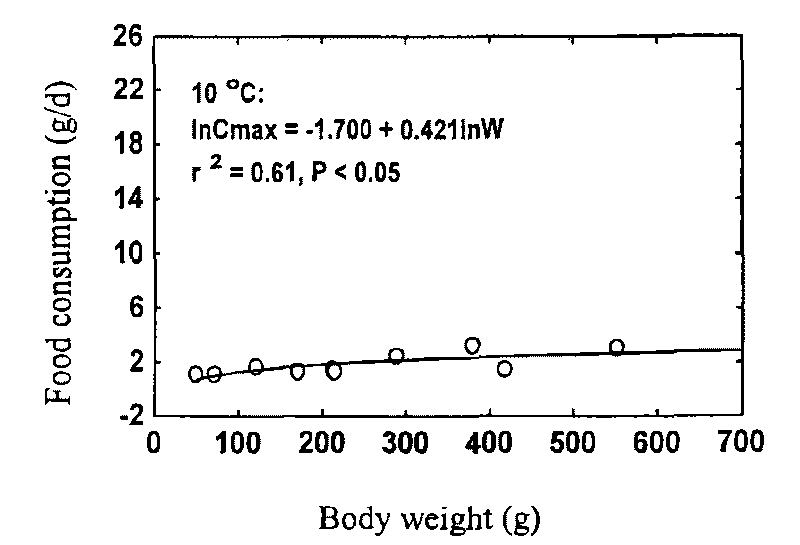

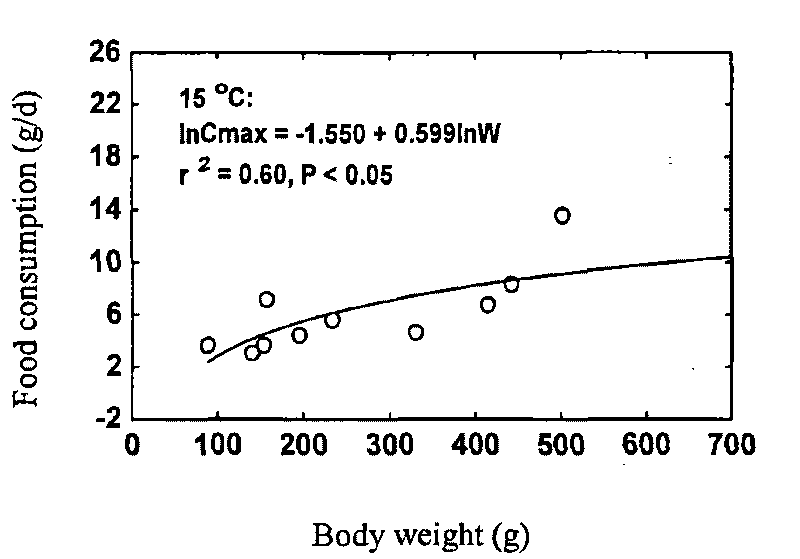

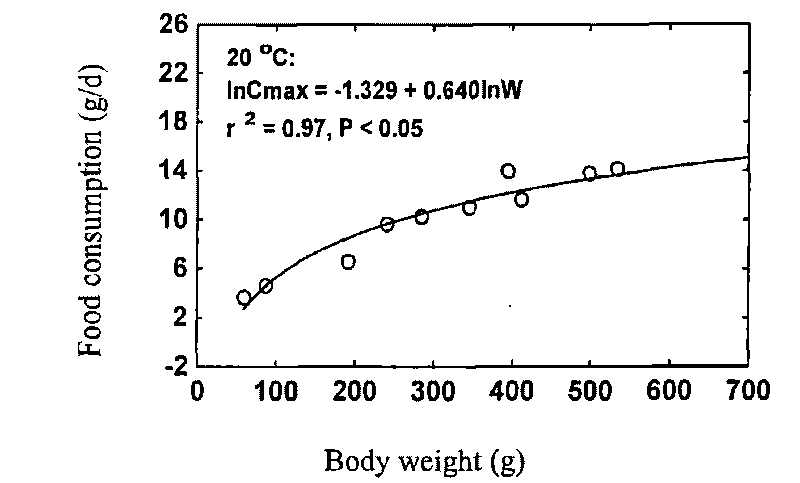

The invention discloses a lake mandarin fish scale culturing method, comprising feeding efficiency, defecation rate, excretion rate, standard metabolism, SDA, activity metabolism and fish physical ability value and growth sub-model. The growing conditions and the bait consumption rate of the piscivorous fish after stocking can be predicted by the model; water body is taken as the research site, the time and space distribution characteristics, the biomass, the structure of the main population, the population growth trends of the growth period, the bait base and tropic niche width and competition overlapping of the advantageous small-sized fish in the shallow water reeds lakes are systematically researched, thus establishing the quantitatively acquiring method of the small-sized fish in theshallow water reeds lakes, completing the productivity analysis and measurement of the advantageous population of the small-sized fish in the shallow water reeds lakes, and estimating the sustainableproduction capacity of the lake bait fish.

Owner:INST OF AQUATIC LIFE ACAD SINICA

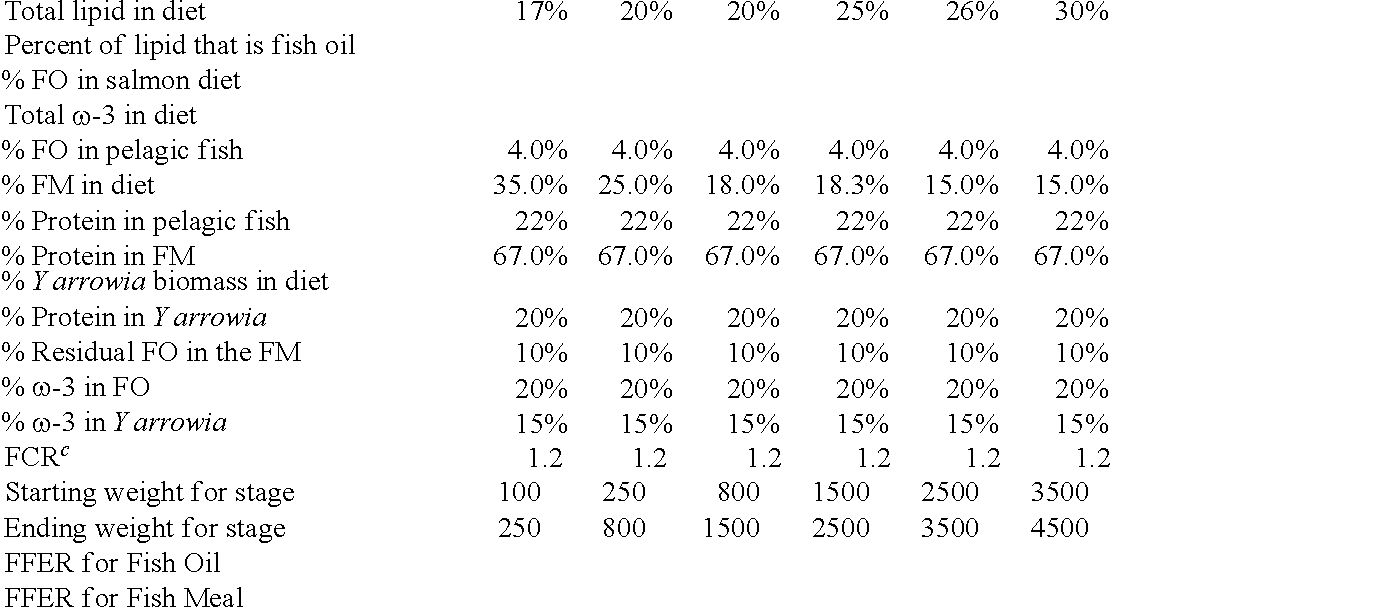

Sustainable aquaculture feeding strategy

InactiveUS20120204802A1Vitamin food ingredientsClimate change adaptationDocosahexaenoic acidBusiness efficiency

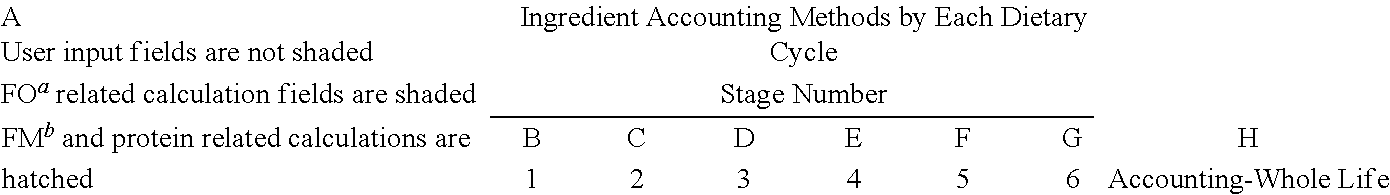

A method of sustainably producing an aquaculture meat product by feeding a fish over its dietary cycles a sustainably produced aquaculture feed composition is disclosed. This method comprises: a) formulating an aquaculture feed composition by replacing all or part of fish oil in the composition with an alternate source(s) of eicosapentaenoic acid (“EPA”) and, optionally, docosahexaenoic acid (“DHA”), wherein the EPA:DHA ratio is at least 2:1 in the aquaculture feed composition; and, b) adjusting the aquaculture feed composition over the life cycle of the fish to produce an aquaculture meat product; wherein the Feeder Fish Efficiency Ratio for fish oil is equal to or less than two and the aquaculture meat product has a EPA:DHA ratio equal to or greater than 1.4:1.

Owner:EI DU PONT DE NEMOURS & CO

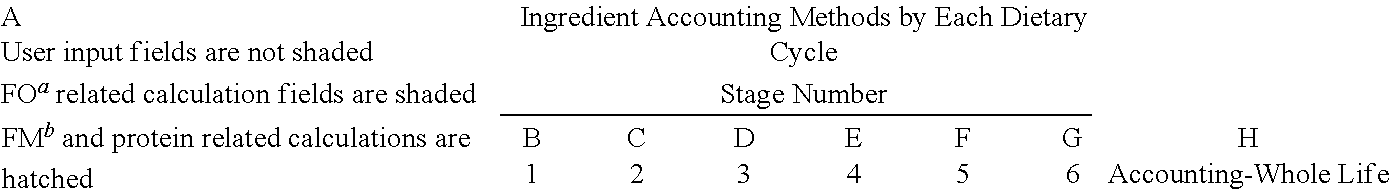

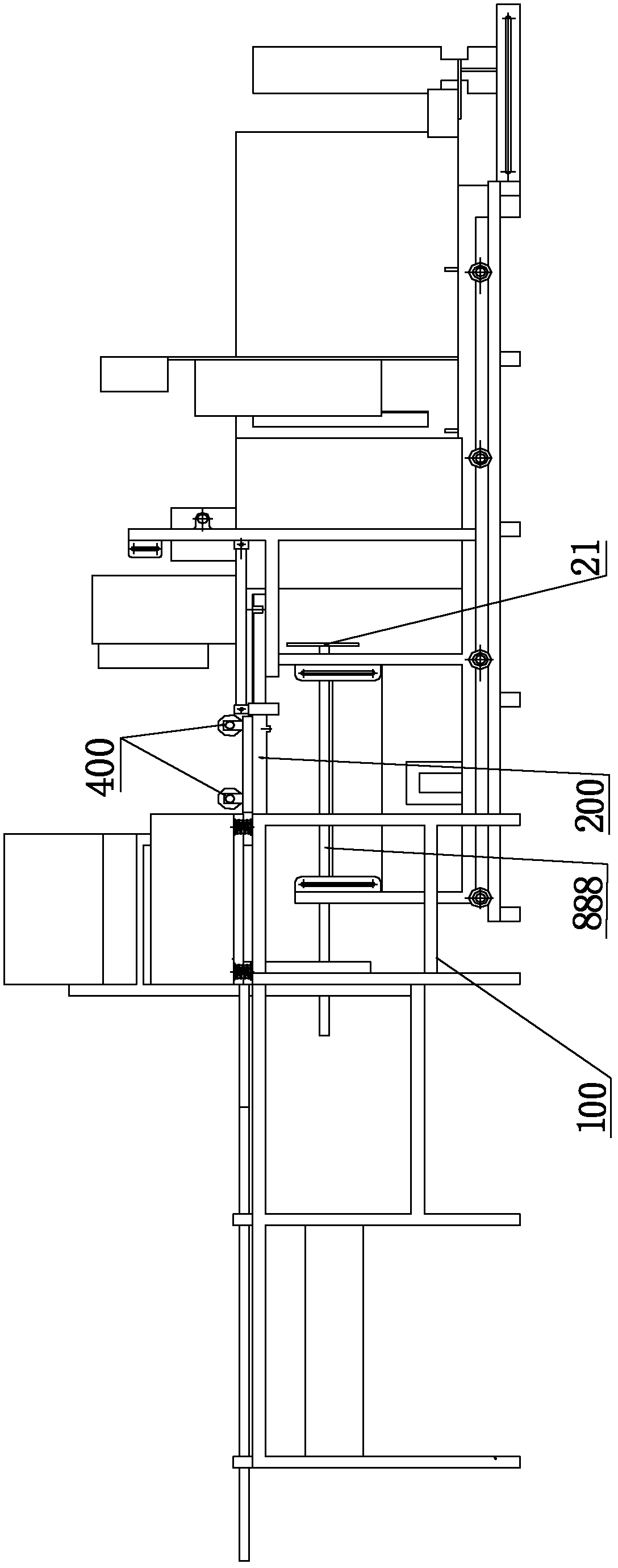

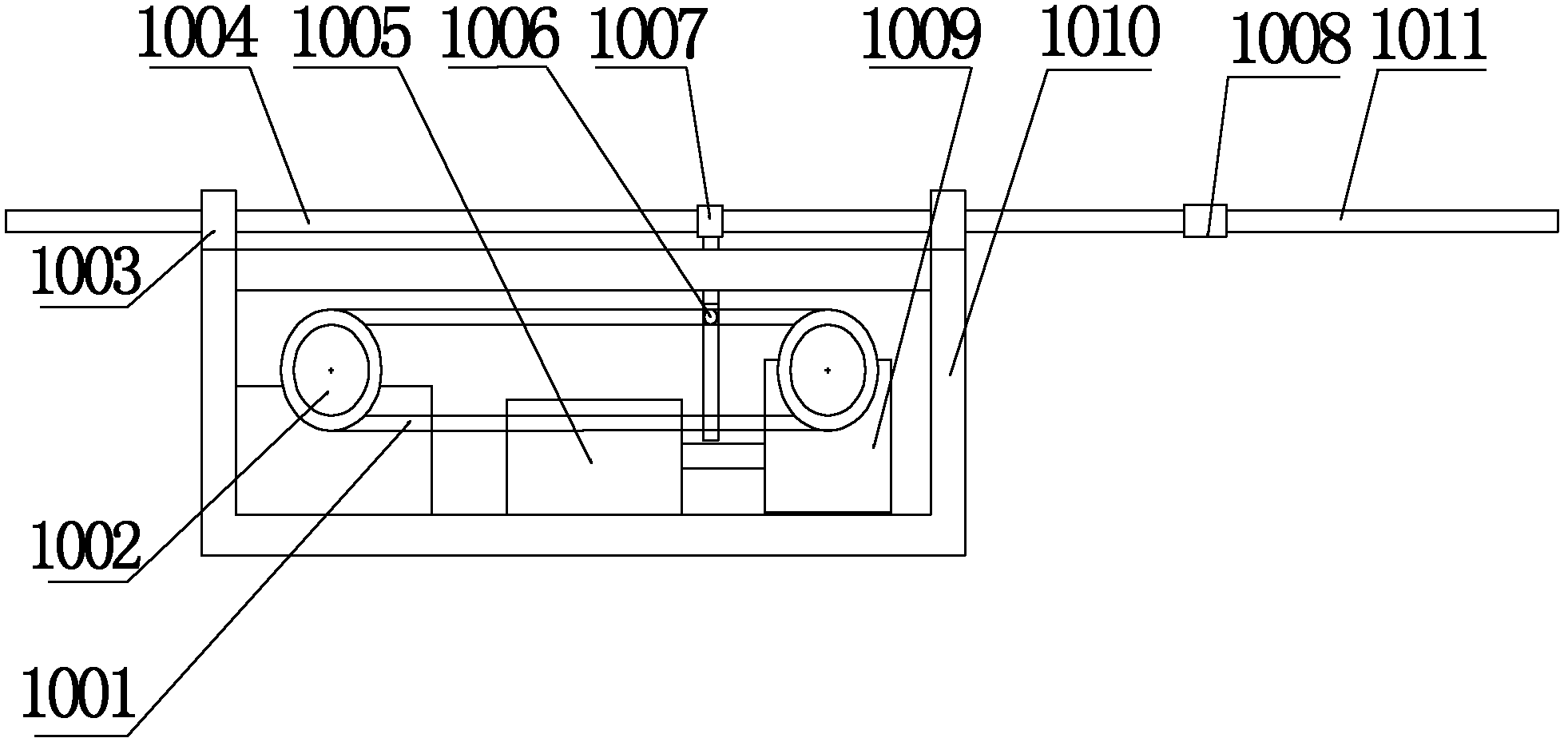

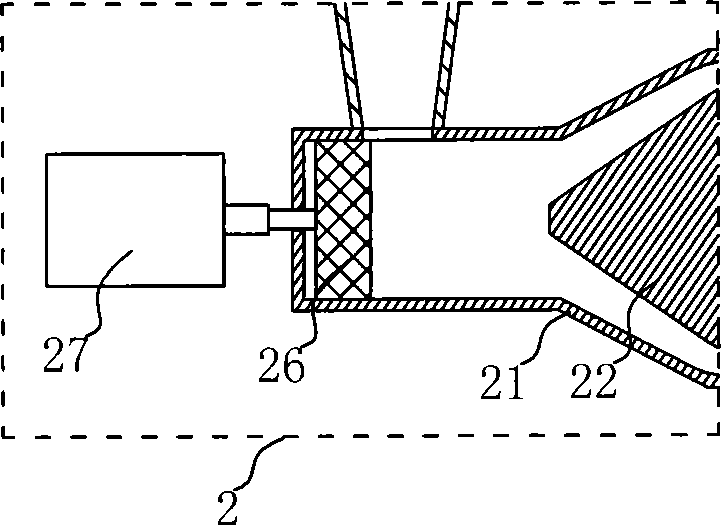

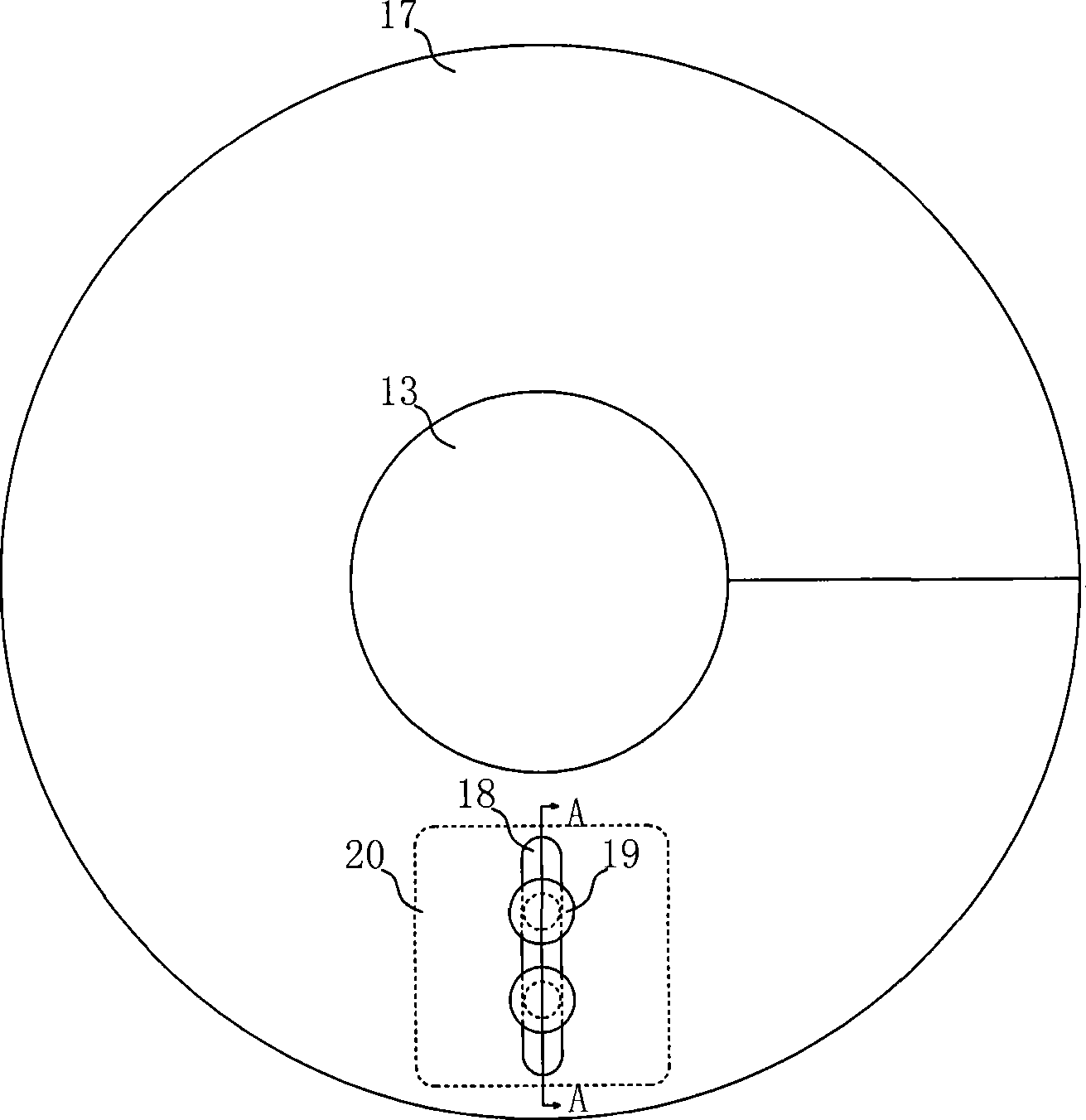

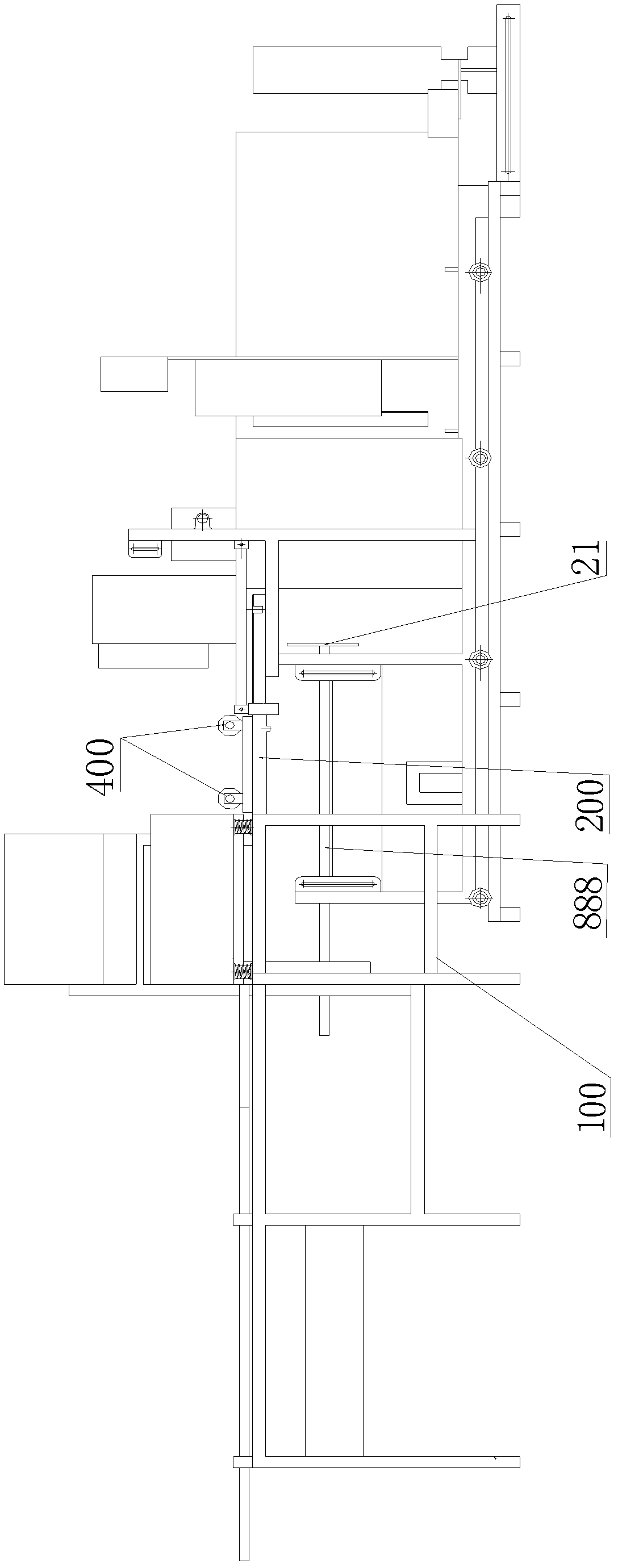

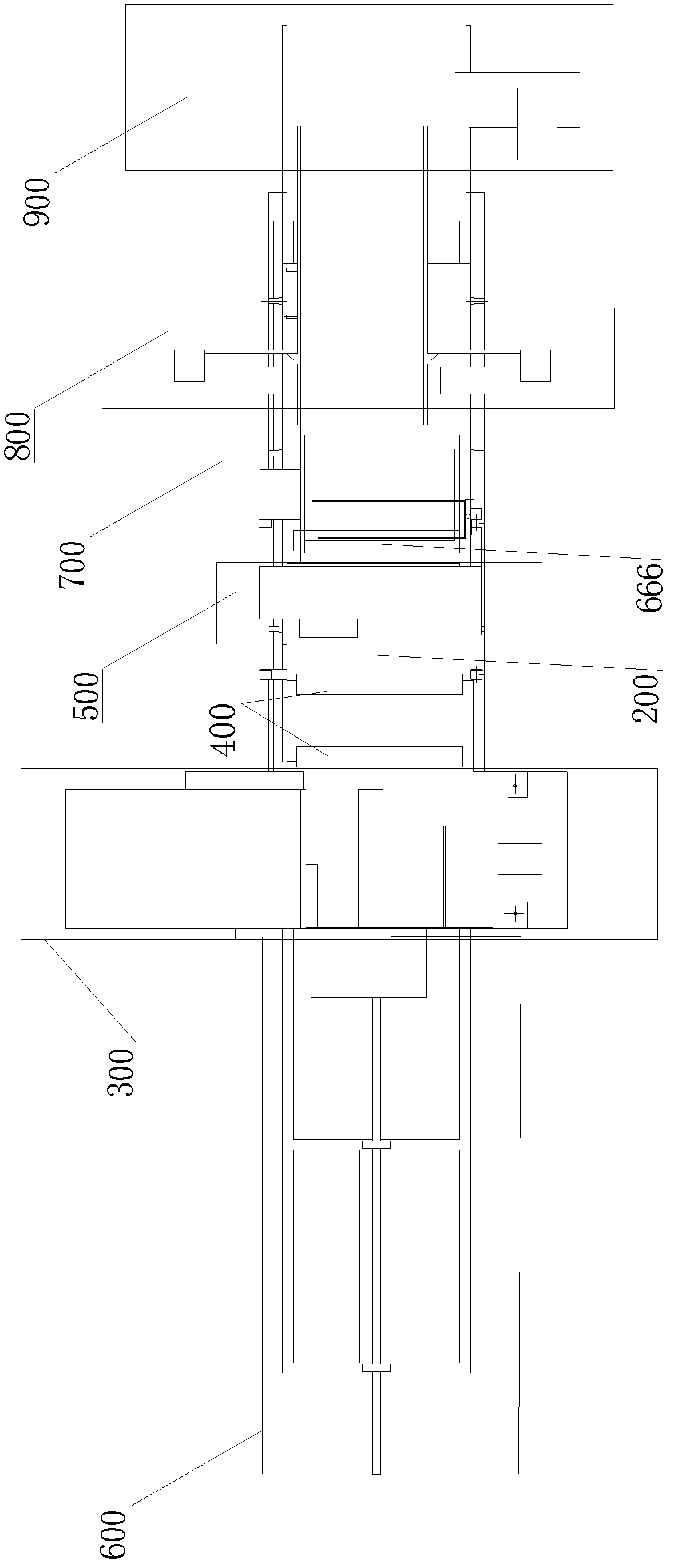

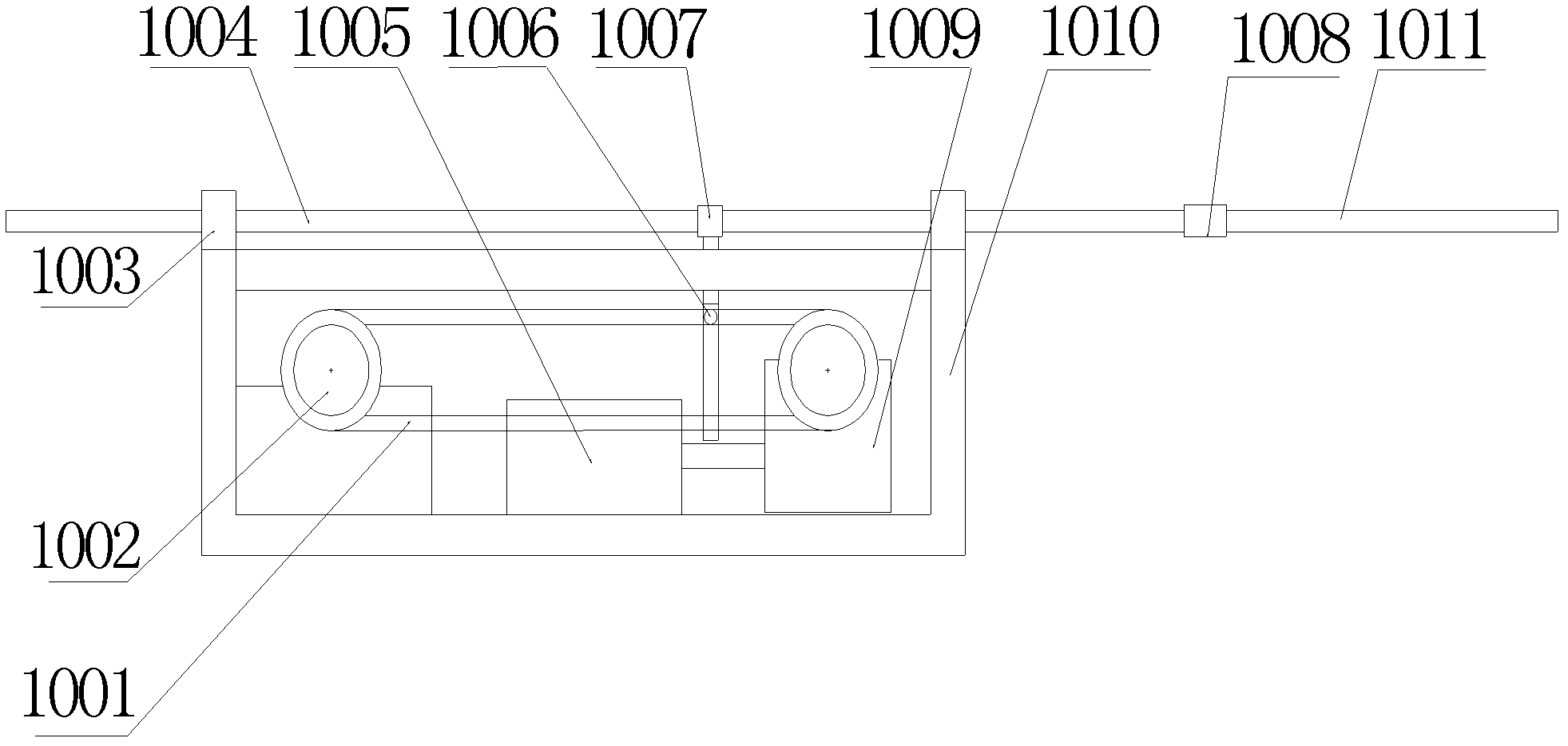

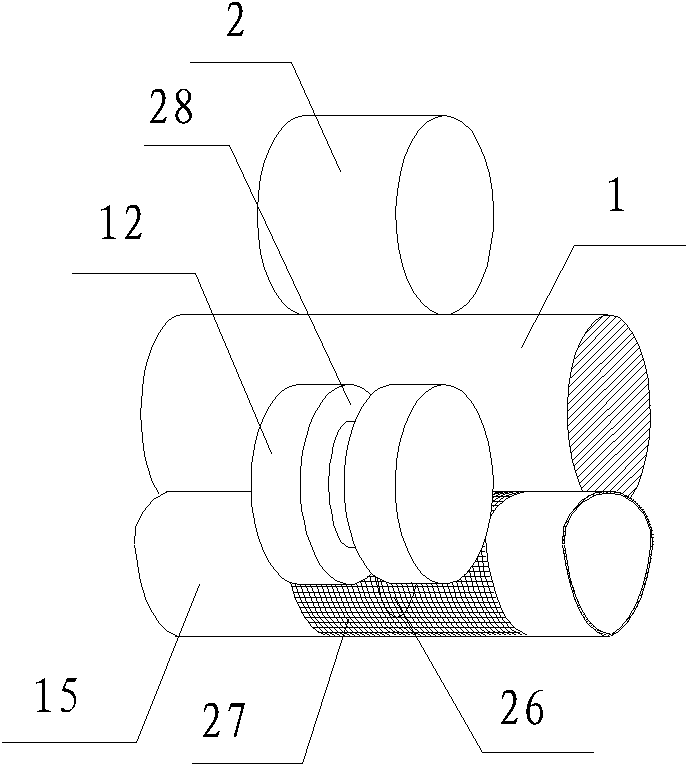

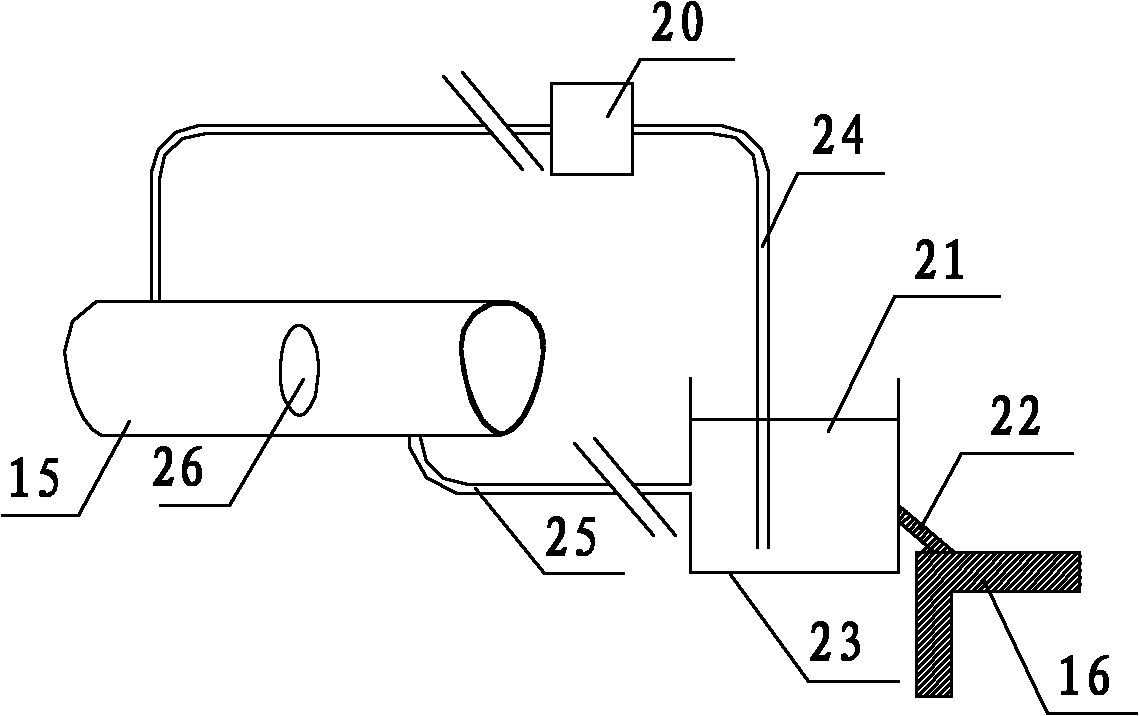

Firework assembling machine

The invention discloses a firework assembling machine. The firework assembling machine comprises a blanking discharge barrel system, a conveying roller group and a moving inserting fuse system which are sequentially arranged along a worktable surface of a main machine frame, wherein a pushing device working corresponding to the blanking discharge barrel system is arranged at the back of the worktable surface, and a forming system working corresponding to the moving inserting fuse system is arranged in front of the worktable surface. The scheme changes horizontal feeding processing through firework barrels one by one in the prior art into longitudinal feeding processing through a plurality of firework barrels in rows, so that processing flow path is shortened, production efficiency is greatly improved, operation is stable, adverse factors like tube body rolling and error accumulation are avoided, work load for maintenance and adjustment in operation is greatly reduced, and the firework assembling machine can perform production continuously without being limited any more. The firework assembling machine solves technical problems and lays good foundation for full automation and mechanized process of fireworks production.

Owner:浏阳市百合机械制造有限公司

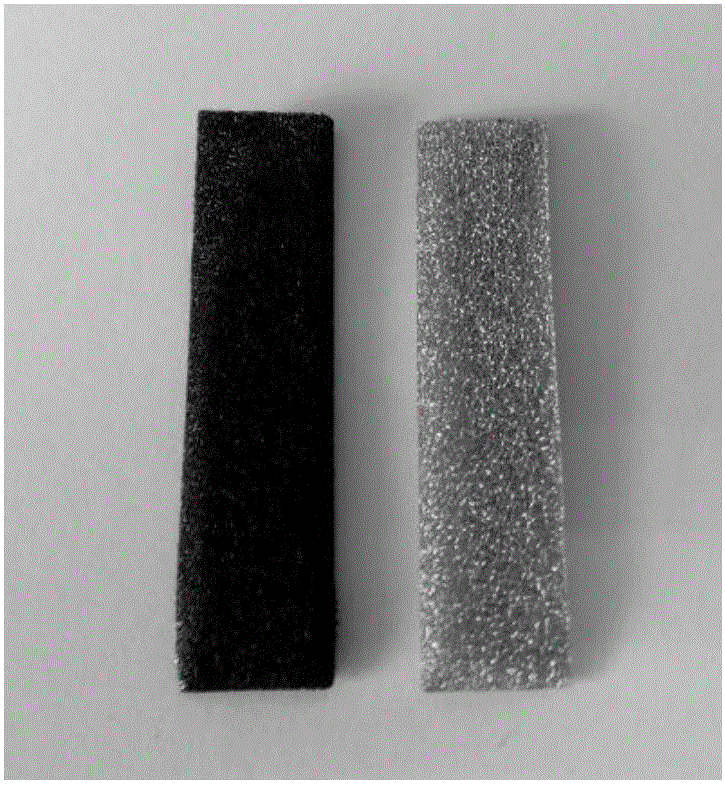

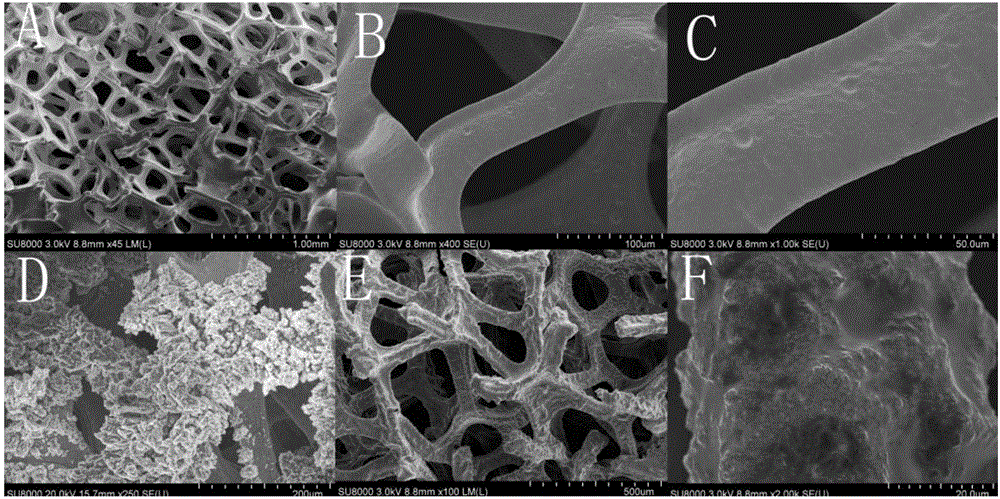

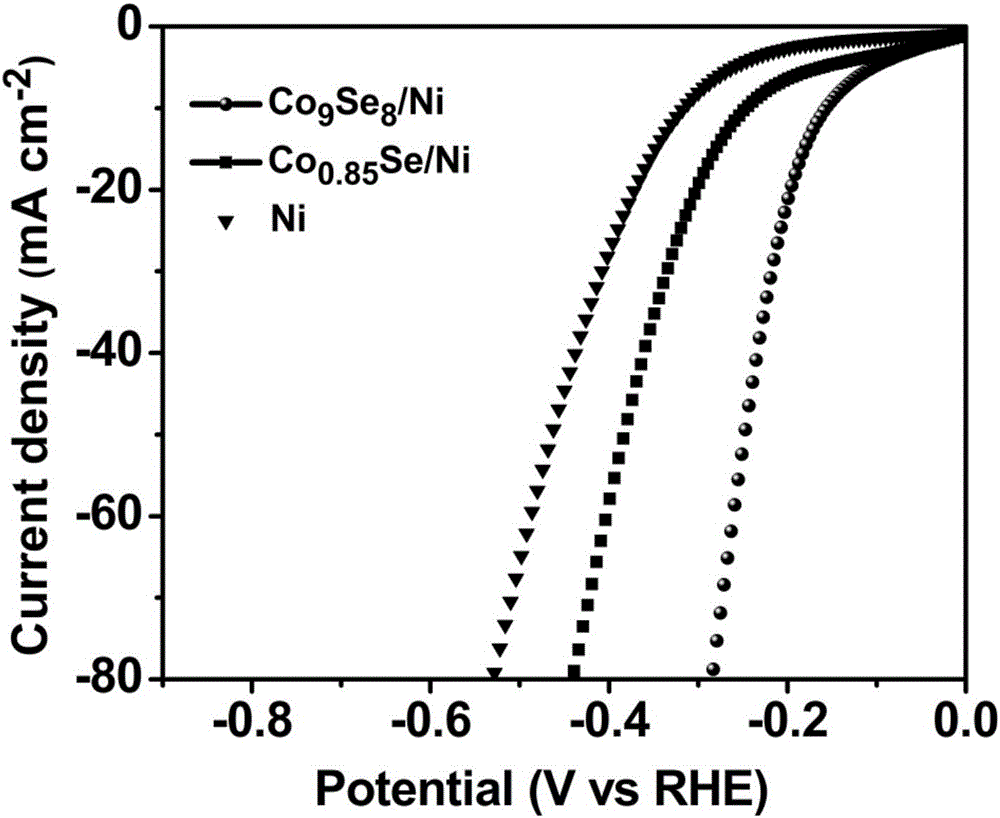

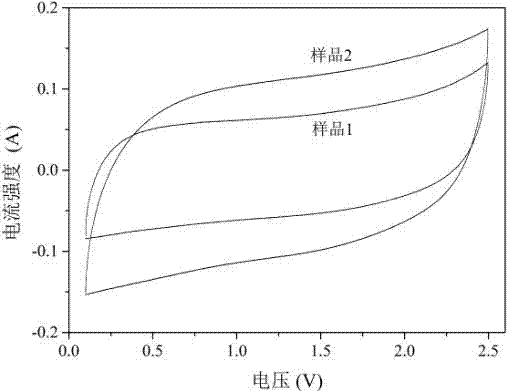

Low overpotential electrocatalyst for producing hydrogen by efficient water splitting and preparation method of electrocatalyst

ActiveCN106492846AImprove hydrogen production efficiencyReduce consumptionPhysical/chemical process catalystsHydrogen productionSodium Selenite PentahydratePotassium

The invention provides a low overpotential electrocatalyst for producing hydrogen by efficient water splitting and a preparation method of the electrocatalyst, and belongs to the technical field of catalyst preparation. The low overpotential electrocatalyst is prepared by in-situ growth of Co9Se8 on foamed nickel. The low overpotential electrocatalyst is prepared by one of cobalt nitrate hexahydrate, cobalt chloride, cobalt acetate or cobalt sulfate and one of sodium selenite pentahydrate, potassium selenite or seleninic acid in an organic amine environment in which the foamed nickel serves as a catalyst. The foamed nickel can serve as both a carrier and the catalyst of a synthetic reaction. The overpotential of the electrocatalyst is only -284mV when the electric current density is 80 mA / cm<-2> and is increased by more than 46.5% relative to that of pure foamed nickel with the overpotential of -530 mV when the electric current density is 80 mA / cm<-2>, and the electrocatalyst is a relatively low overpotential electrocatalyst in non noble metal electrocatalysts. The electrocatalyst is one of advanced technical means for the sustainable production of hydrogen energy, has good industrial application prospects and can be used to relieve an increasingly intense global energy supply pattern at present.

Owner:JILIN UNIV

Salt-resistant soil-improving slow release fertilizer and preparation method thereof

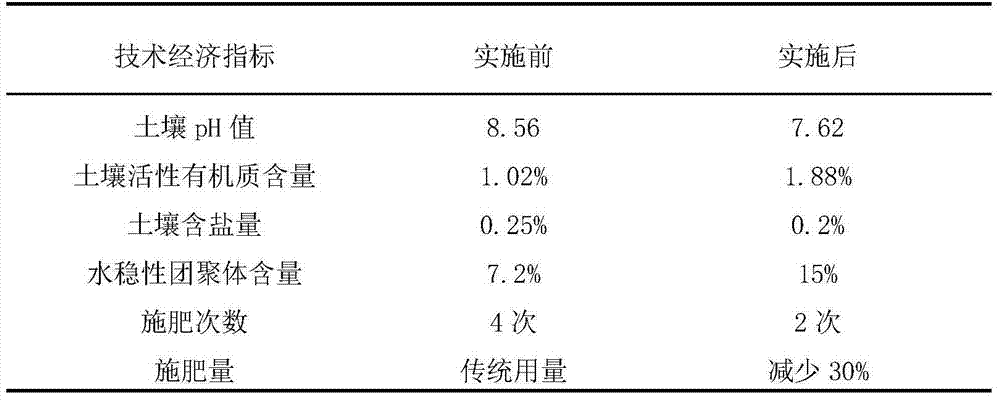

The invention relates to a salt-resistant soil-improving slow release fertilizer and a preparation method thereof. The salt-resistant soil-improving slow release fertilizer is prepared from the following raw material components: furfural residues, humic acid, montmorillonite, zeolite powder, polyvinyl alcohol, a nitrogen fertilizer, a phosphorus fertilizer and a potassium fertilizer. The method comprises the following steps: mixing humic acid, montmorillonite and zeolite powder, spreading the mixture onto the surface of the nitrogen fertilizer in a revolving drum, spraying a polyvinyl alcohol aqueous solution, and drying to obtain a coated nitrogen fertilizer; mixing the obtained coated nitrogen fertilizer with the furfural residues, the phosphorus fertilizer and the potassium fertilizer to obtain the salt-resistant soil-improving slow release fertilizer. By adopting the salt-resistant soil-improving fertilizer, the fertilizer utilization ratio can be increased, and secondary salt damage of fertilization to soil is reduced; on the other hand, by adopting a coating material, the soil fertility can be improved remarkably, the residual free salt content of saline-alkali soil is adsorbed, and the sustainable production capability is improved; the salt-resistant soil-improving slow release fertilizer is low in cost, and easy to prepare.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

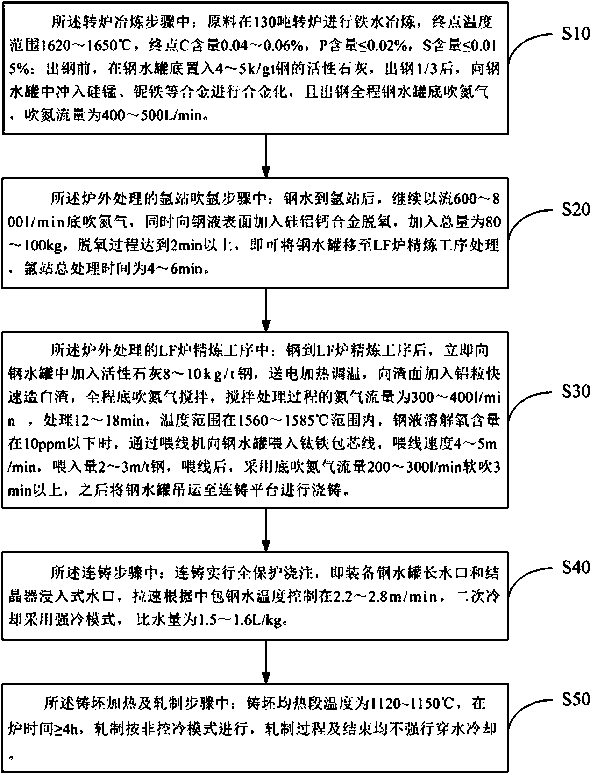

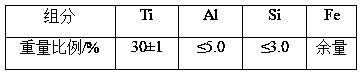

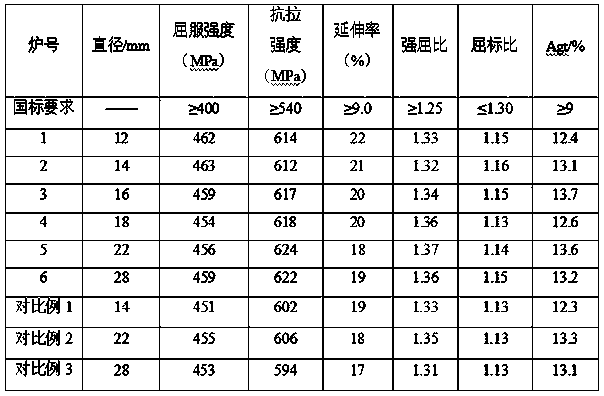

Niobium-titanium microalloying HRB400-scale screw-thread steel and manufacturing method thereof

The invention discloses a kind of niobium-titanium microalloying HRB400-scale screw-thread steel and a manufacturing method thereof. The screw-thread steel comprises C, Si, Mn, P, S, Nb, Ti, N and the balance Fe and impurities. The manufacturing method of the niobium-titanium microalloying HRB400-scale screw-thread steel comprises the following steps of smelting in a revolving furnace, treatment outside the furnace, continuous casting, casting blank heating and rolling. During smelting in the revolving furnace, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment. During treatment outside the furnace, argon is blown in an argon station, and refining is conducted in an LF furnace. In the process of refining in the LF furnace, a ferrotitanium core-spun yarn is fed for titanium microalloying treatment. According to the technical scheme, before tapping, alloy such as silicomanganese and ferroniobium is added for niobium microalloying treatment, the ferrotitanium core-spun yarn is fed in the process of refining in the LF furnace for titanium microalloying treatment, after titanium is fused into molten steel, proper niobium-titanium microalloying treatment is conducted, the yield of the niobium-titanium alloy is increased, and stable, sustainable and low-cost production of the screw-thread steel is achieved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

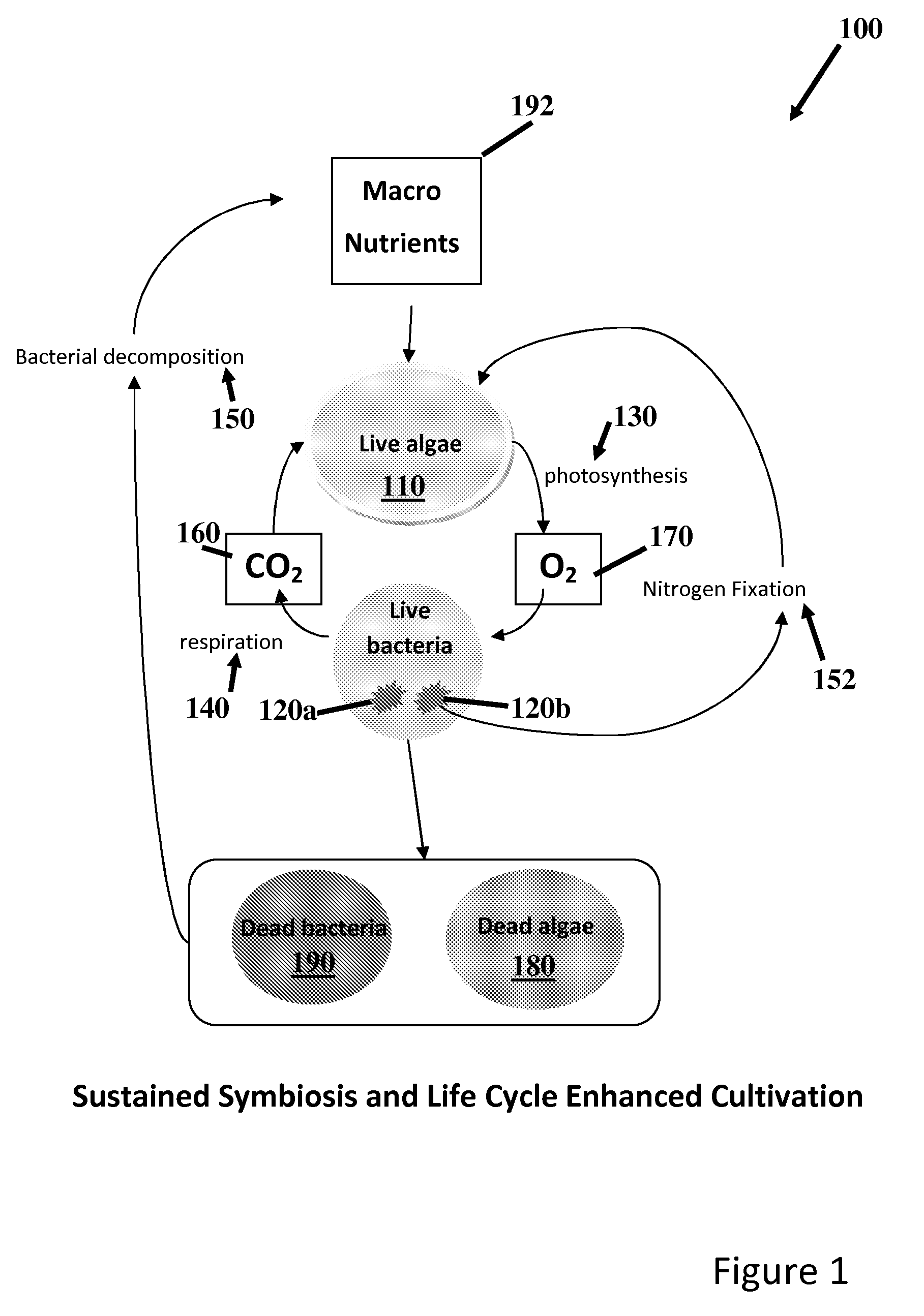

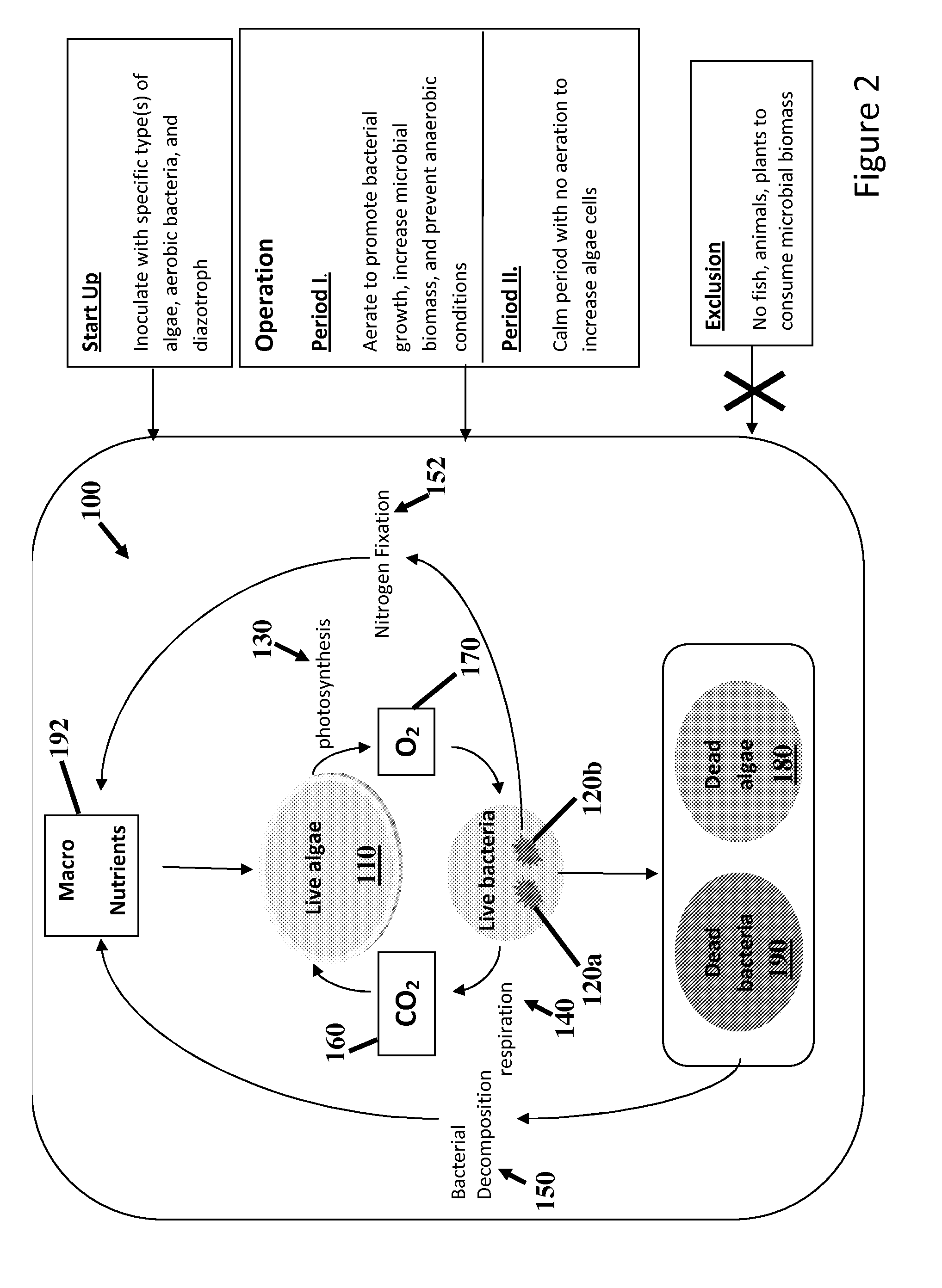

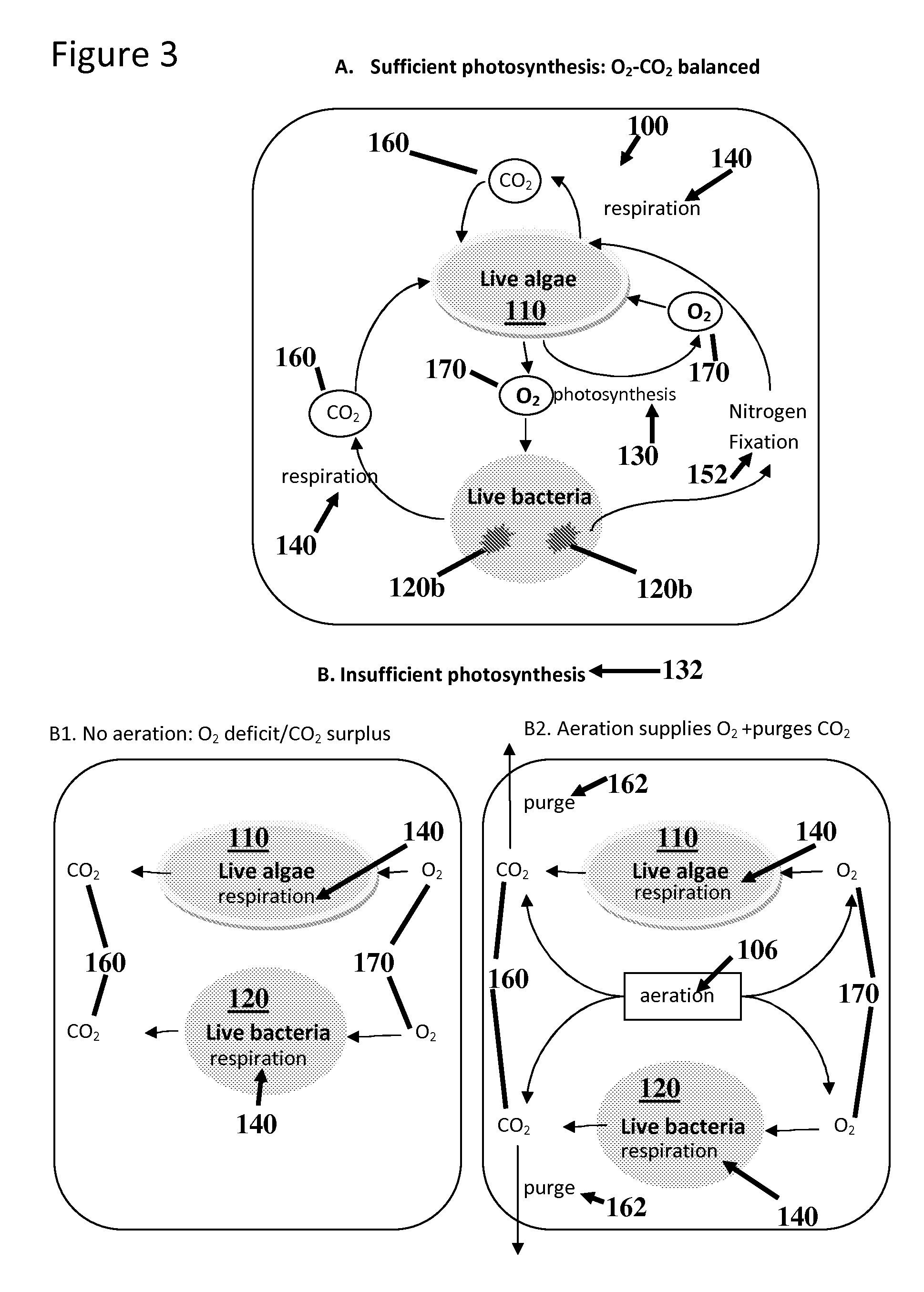

Method of enhanced sustainable production of algal bio-products, comprising use of symbiotic diazotroph-attenuated stress co-cultivation

InactiveUS20110045564A1Enhanced sustainable productionControl growthBacteriaUnicellular algaeLipid formationAlgal growth

Provided are compositions and methods for sustainable cultivation of algae for biomass, biofuel and bioproduct production, preferably with minimal addition of exogenous nutrients, comprising co-cultivating at least one algal species with at least one aerobic bacterial species and at least one diazotroph (or, in certain embodiments, cultivation of at least one algal species with at least one diazotroph) under continuous sustainable symbiotic conditions, wherein a significant proportion of the macronutrients derive from endogenous decomposed algal and bacterial cells. Certain aspects provide continuous symbiotic diazotroph-attenuated nitrogen stress co-cultivation, wherein a continuous, balanced attenuated nitrogen-stress response provides for adequate sustained algal growth, while yet preserving advantages of algal nitrogen stress responses for algal bioproduct production. Preferred aspects provide for enhanced algal production of at least one of: lipids; triacylglycerols (TAGs); percentage of lips as TAGs; and percentage of saturated and mono-saturated fatty acids relative to polyunsaturated fatty acids (PUFAs) in TAGs.

Owner:DHAMWICHUKORN SRISUDA

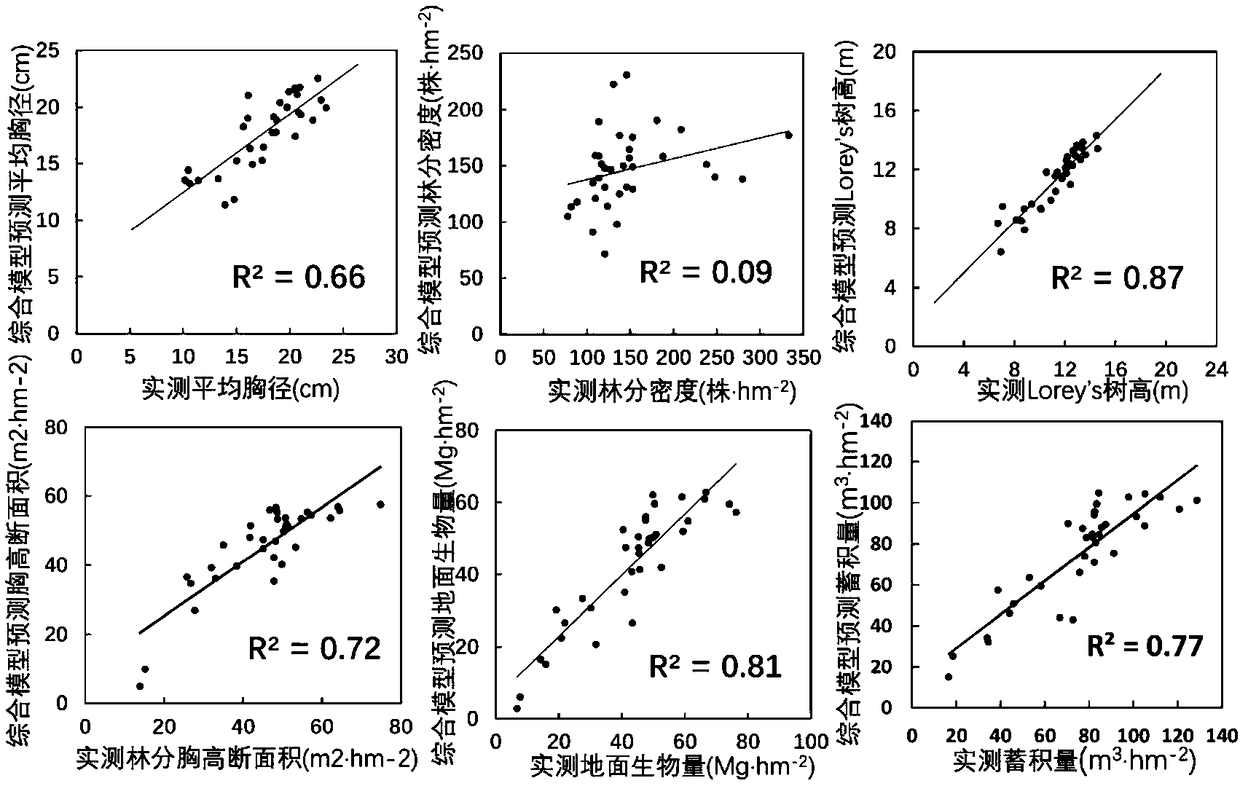

Forest stand feature inversion method based on UAV multi-spectral high overlap image

ActiveCN109212505AReduce flight costsData acquisition is convenient and efficientColor/spectral properties measurementsElectromagnetic wave reradiationEcological environmentPoint cloud

The invention discloses a forest stand feature inversion method based on a UAV multi-spectral high overlap image. The method comprises the steps of acquiring a highly overlap image by using a UAV-mounted multi-spectral sensor, and acquiring spectral data by using band combination and vegetation index transform; generating digital point cloud data by using an aerial triangulation algorithm and a point cloud dense matching algorithm; extracting a characteristic variable of a canopy structure of a to-be-tested forest according to normalized point cloud data and spectral data; and finally creatinga multiple regression model by combining stand data of measured to-be-tested forest on the ground and the extracted characteristic variable of the canopy structure of the to-be-tested forest, and inversing the stand characteristic of the to-be-tested forest. The method can help improve inversion accuracy of the stand characteristic of the forest, can acquire a space structure and a dynamic changerule of the to-be-tested forest, and is significant for sustainable production and operating of the forest, ecological environment modeling and maintenance of regional ecological balance.

Owner:NANJING FORESTRY UNIV

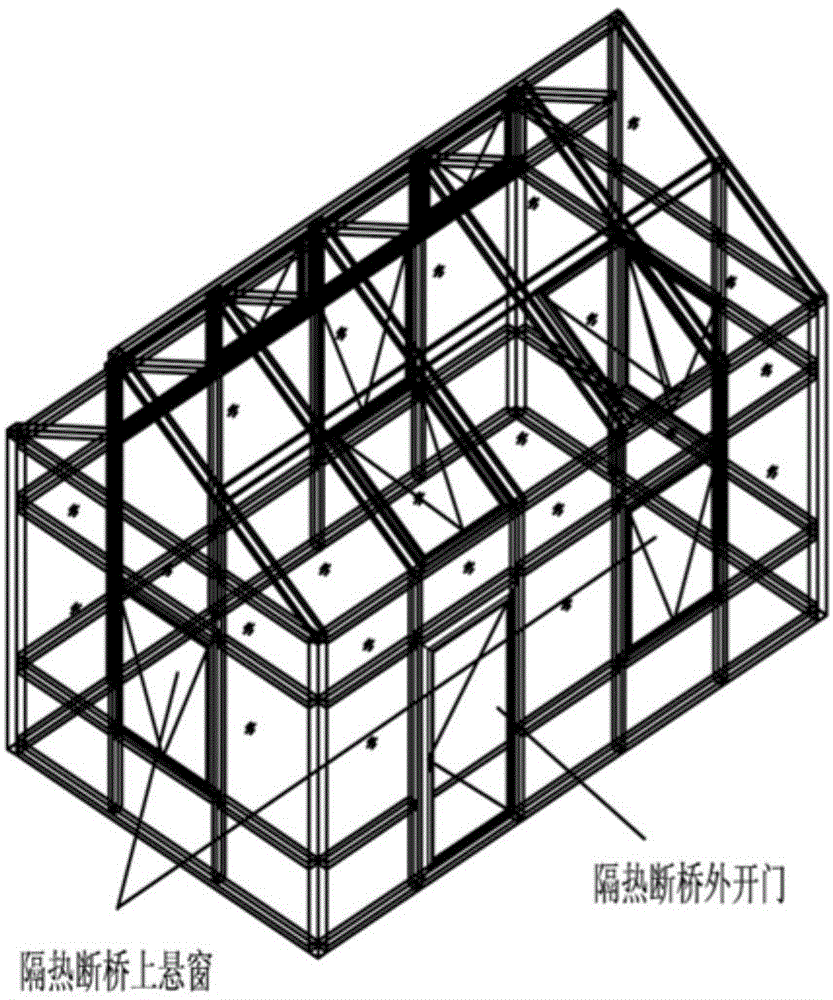

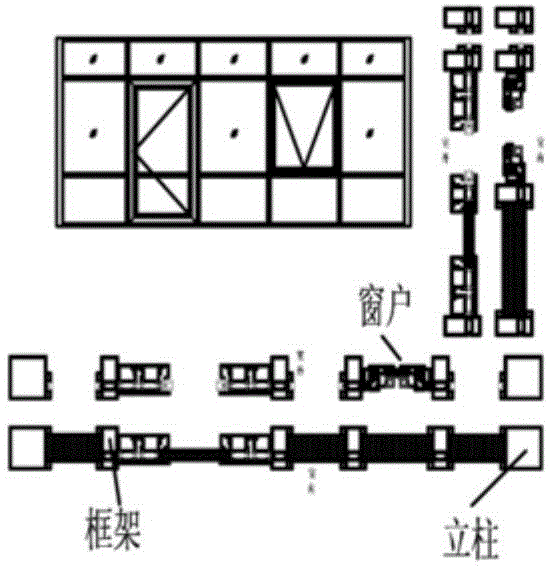

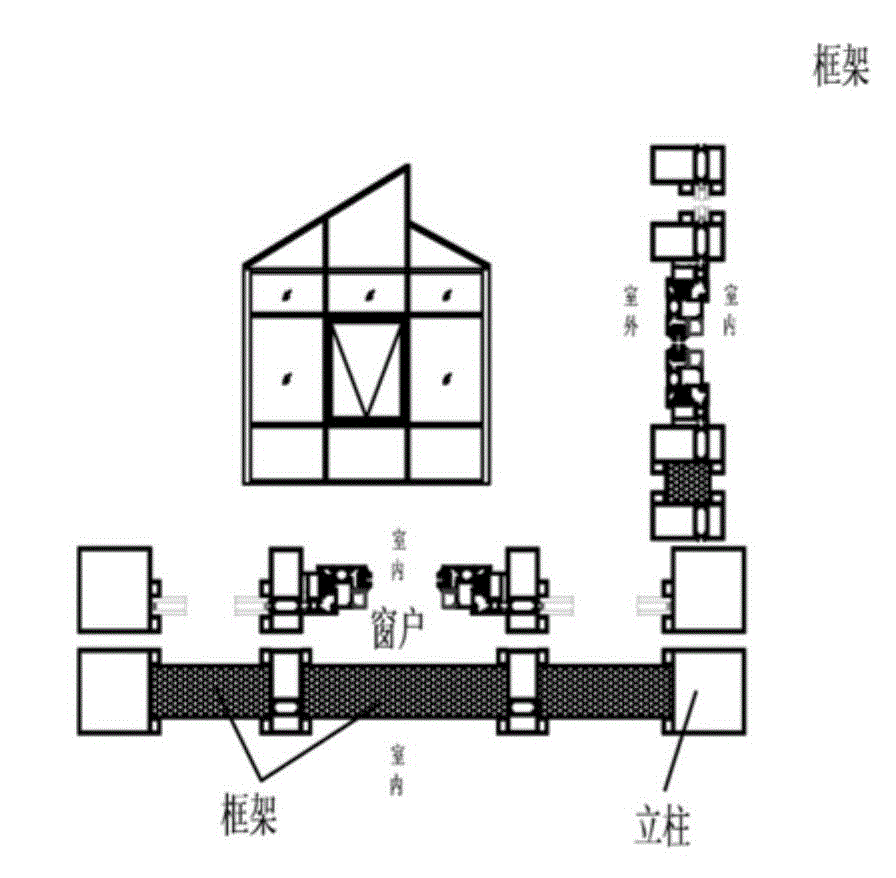

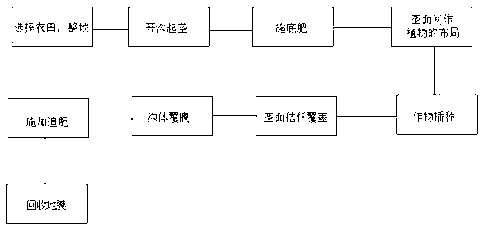

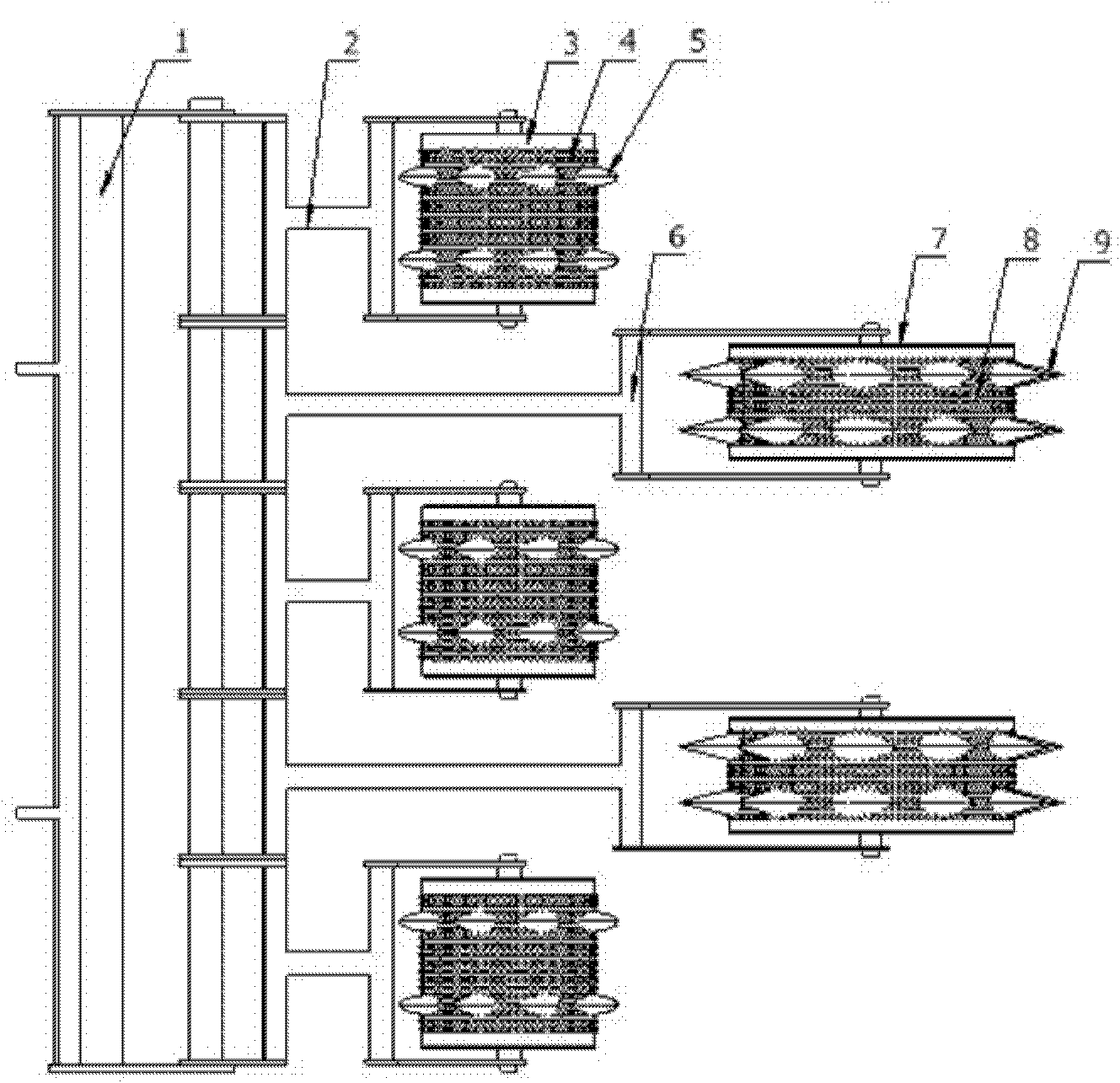

Household three-dimensional agricultural factory

ActiveCN104542231AImprove the immunityHigh riskAgricultural buildingsClimate change adaptationSustainable productionAgricultural engineering

The invention discloses a household three-dimensional agricultural factory. Three functional regions, namely, a plant growing region, a germination accelerating region and a water treatment region are arranged generally in the unit of a rural household; a plurality of multilayer plant growing frames are arranged in the plant growing region for planting forage grass and bean sprouts; a planting tray is arranged in each layer, artificial light supplement and water supplement are adopted, and the temperature and humidity of the whole plant growing region are adjusted in cooperation with a temperature adjusting system; in the germination accelerating region, a plurality of germination accelerating laminated disks are placed on each layer of the plant growing frames 1 to finish cultivation of seeds; the water treatment region comprises a filter, a pure water tank, a three-dimensional seed sowing tank and temperature adjusting equipment; a purified pure water source is provided, and the temperature and humidity in the plant growing region are adjusted in cooperation with a water spray cleaning device arranged on a roof in order to meet the growing demand of crops. By adopting the household three-dimensional agricultural factory, the time and space constraints on the conventional agricultural production are changed, and a large amount of sustainable production fresh forage grass can be provided; meanwhile agriculture and animal husbandry are organically combined together, so that the problems vegetables, meat, milk and eggs mostly concerned by people are finally solved.

Owner:孙以川 +1

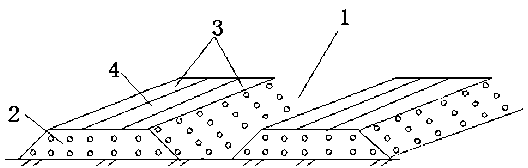

Furrow, film, ridge and straw combined type mulching cultivation method for crops

The invention belongs to field of agricultural cultivation techniques, and relates to a cultivation method for crops, in particular to a furrow, film, ridge and straw combined type mulching cultivation method for the crops. The method includes the steps of farmland selection, soil preparation, ditching, ridging, basal dressing, intercropping of plants among ridge surfaces according to specification layout, ridge surface straw mulching and furrow body film mulching after crop seeding, top dressing in the seedling stage and the fast-growing stage of the plants, and recovery of mulching film after harvest. The method overcomes shortcomings of straw mulching and film mulching, achieves sustainable production of the crops, reduces waste of agricultural resources and environmental pollution, improves rainfall infiltration, restrains soil evaporation, improves hydrothermal conditions of soil, improves the nutrient status of the plants due to nutrients provided by straw, protects cultivated land, prevents loss of water and fertilizer on the surface of the soil, improves yields of the crops, changes an existing mulching cultivation production method for the crops, and achieves the purpose of protective mulching cultivation.

Owner:INST OF AGRI ENVIRONMENT & RESOURCES YUNNAN ACAD OF AGRI SCI +1

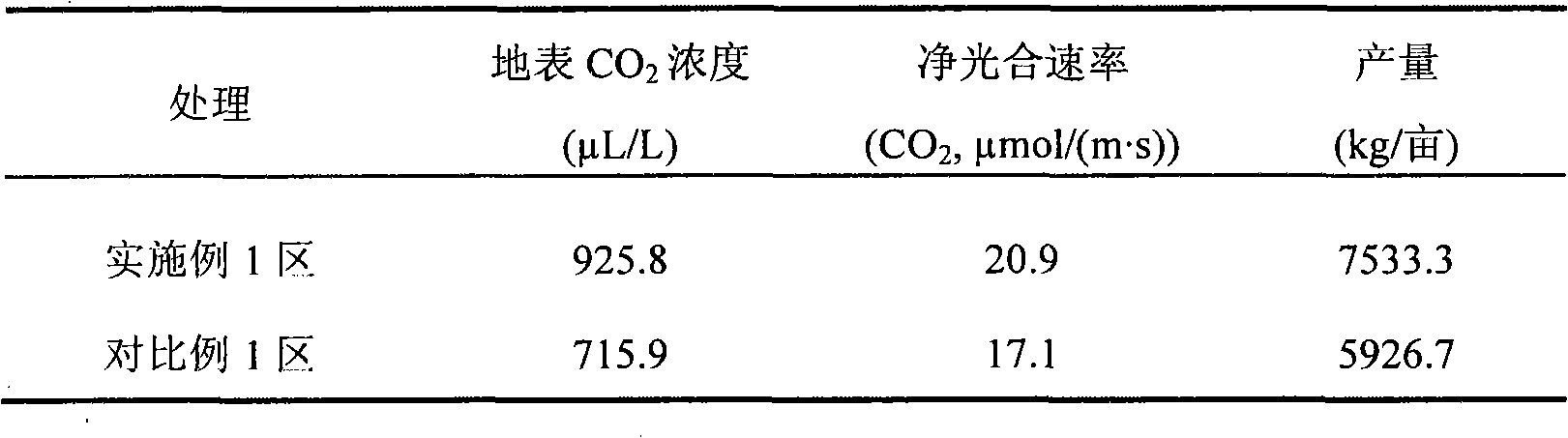

Greenhouse vegetable soil conditioner compatible with CO2 fertilizer application and preparation method thereof

InactiveCN101941854ARealize resource utilizationReduce pollutionBio-organic fraction processingOrganic fertiliser preparationContinuous croppingMicrobial agent

The invention relates to a greenhouse vegetable soil conditioner compatible with CO2 fertilizer application and a preparation method thereof. The greenhouse vegetable soil conditioner of the invention is prepared by grinding an agricultural waste, namely, crop straw serving as a main body, adding a conditioner and a microbial agent according to proportion for static composting and determining an optimal maturity extent by optimizing stack-turning time and stack-turning frequency. Aiming at the degenerative characteristic of the quality of greenhouse vegetable soil, the greenhouse vegetable soil conditioner can remarkably improve the physical and chemical properties of the soil, lower salt content, improve the workability of the soil, prevent and control continuous cropping obstacles of the soil, can remarkably enhance the CO2 concentration in a greenhouse so as to improve the photosynthesis of a crop, remarkably increases crop yield on the basis of improving the sustainable production capacity of the greenhouse vegetable soil and is a greenhouse vegetable soil conditioner compatible with the CO2 fertilizer application; and the soil conditioner has wide raw material source and simple and convenient preparation process and is suitable for large-area popularization and application in China.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

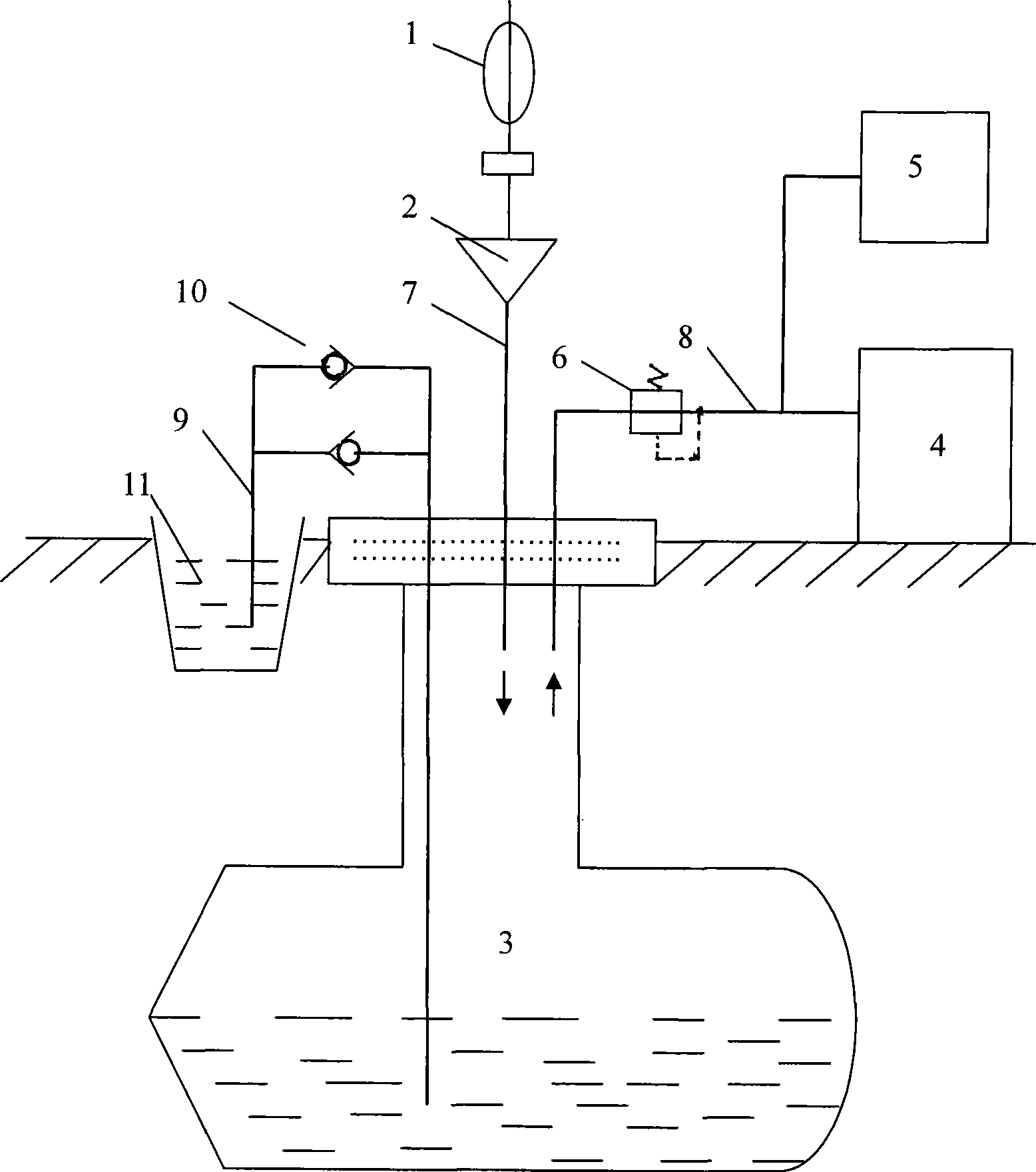

Wind energy storage and power generation apparatus

InactiveCN101487454AEfficient use ofImprove utilizationWind energy with electric storageEnergy storageWind drivenEngineering

The invention discloses a wind energy storage generating set. The generating set innovatively uses wind energy compressed air which is stored in a cellar and changed into pressure energy to generate electricity, optimizes wind power designs, solves the problem of becalming and overcomes the problem of variant wind speeds, and can generate stable and high-quality power supply in all weather. The pressure energy stored in the cellar is innovative and unique, has large storage capacity and high pressure, is safe and reliable, and can save large investment by replacing steel vessel. The price of a domestically assembled gas driven generating set is lower than that of an imported wind driven generating set, and the gas driven generating set has low running cost, can comprehensively improve economic benefit and is a new technique using wind energy with low cost and high efficiency. The main technical characteristic is arranging a voltage stabilizing control system in an enormous cellar to guarantee the wind energy to be optimally converted into pressure energy and electric energy. The pressure energy can be persistently produced and largely stored, transmitted over a long distance and centrally supplied, has excellent energy characteristics, is applicable to power supply devices such as generating sets as well as automobiles, agricultural machinery, trains, ships, aircrafts and the like, can replace petroleum oil, coal and electricity, has zero energy consumption, zero water consumption and zero blowdown, is environment-friendly and has ecological civilization.

Owner:韩统

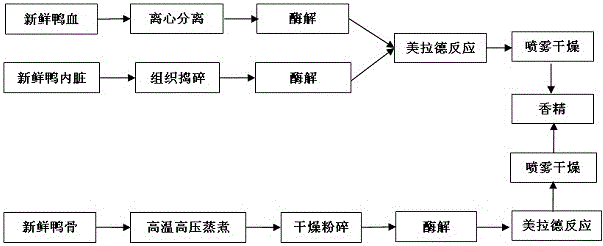

Method of preparing meat-flavor essence from duck meat processing wastes

InactiveCN103053993AIncrease added valueRealize low-carbon sustainable productionFood preparationMaillard reactionAmino acid

The invention provides a method of preparing meat-flavor essence from duck meat processing wastes. The method uses the duck meat processing wastes as raw materials, an enzymatic hydrolysis is performed, xylose and cysteine are added, and a maillard reaction is carried out under a certain condition to prepare the essence rich in meat flavor. The method comprises the following steps: (1) pre-treatment of raw materials, comprising pre-treatment of duck blood, duck bone and duck viscera; (2) enzymatic hydrolysis, comprising through hydrolysis of alkaline protease, hydrolyzing proteins in the raw materials into small-molecule peptides and amino acids under catalysis of a protease; (3) maillard reaction; (4) drying and crushing to obtain dry essence powder; and (5) detection, comprising detection of physical and chemical indicators of the product and microbial indicators. According to the invention, the essence is prepared from the duck meat processing wastes, thereby changing waste into valuables, protecting the environment, improving added values and realizing low-carbon sustainable production; and the prepared essence is advantageous by real and mellow meat flavor.

Owner:NANCHANG UNIV

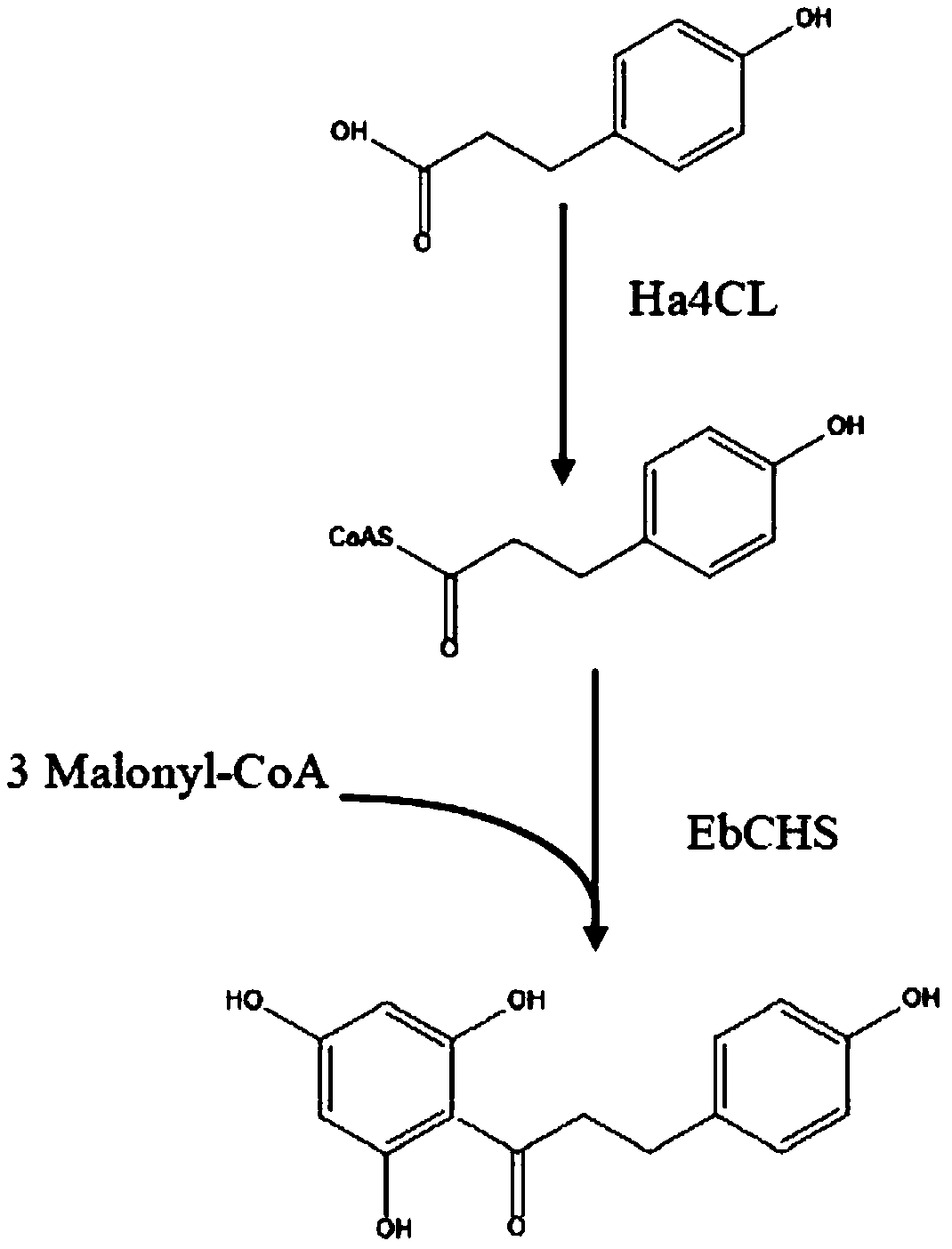

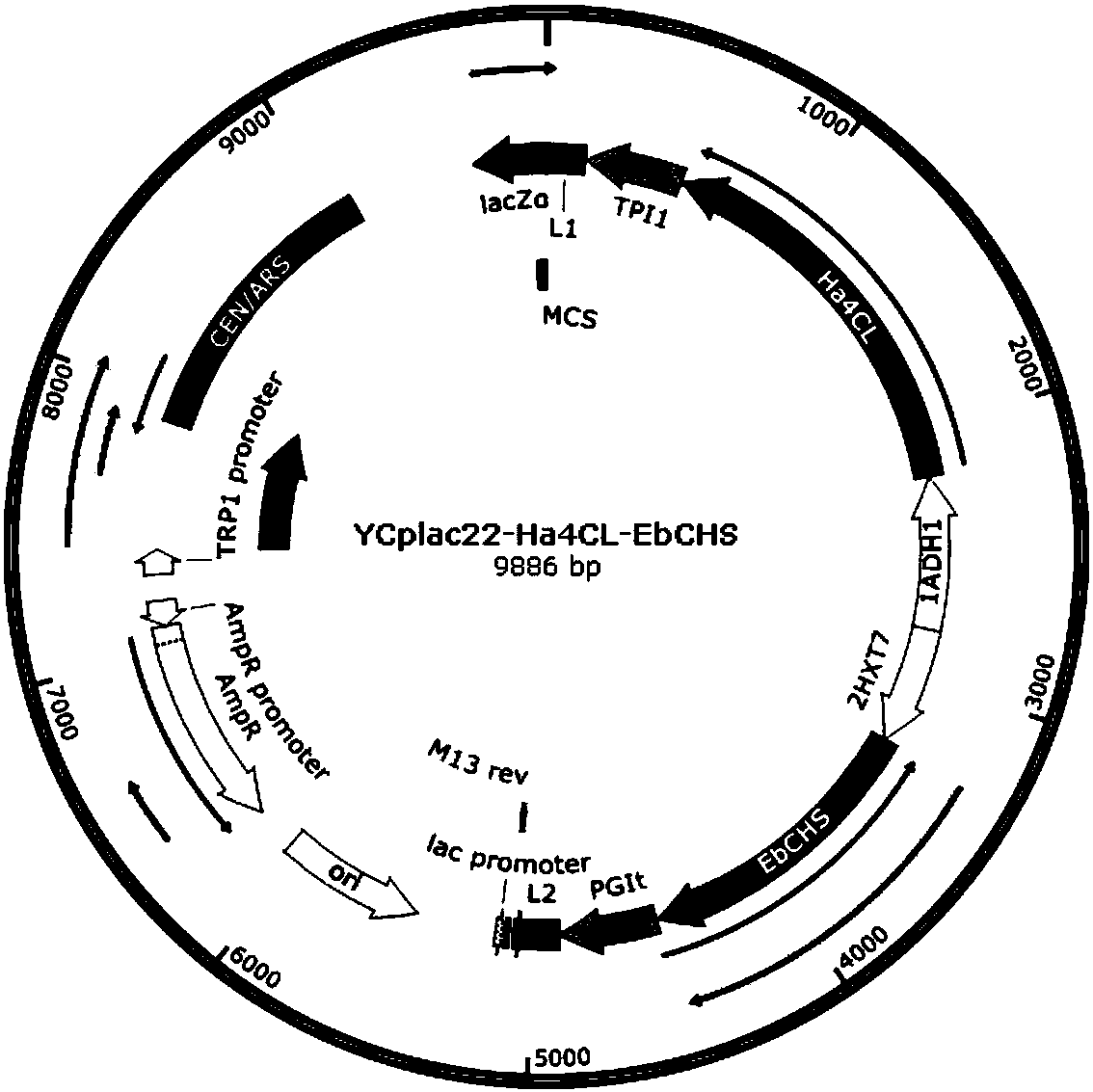

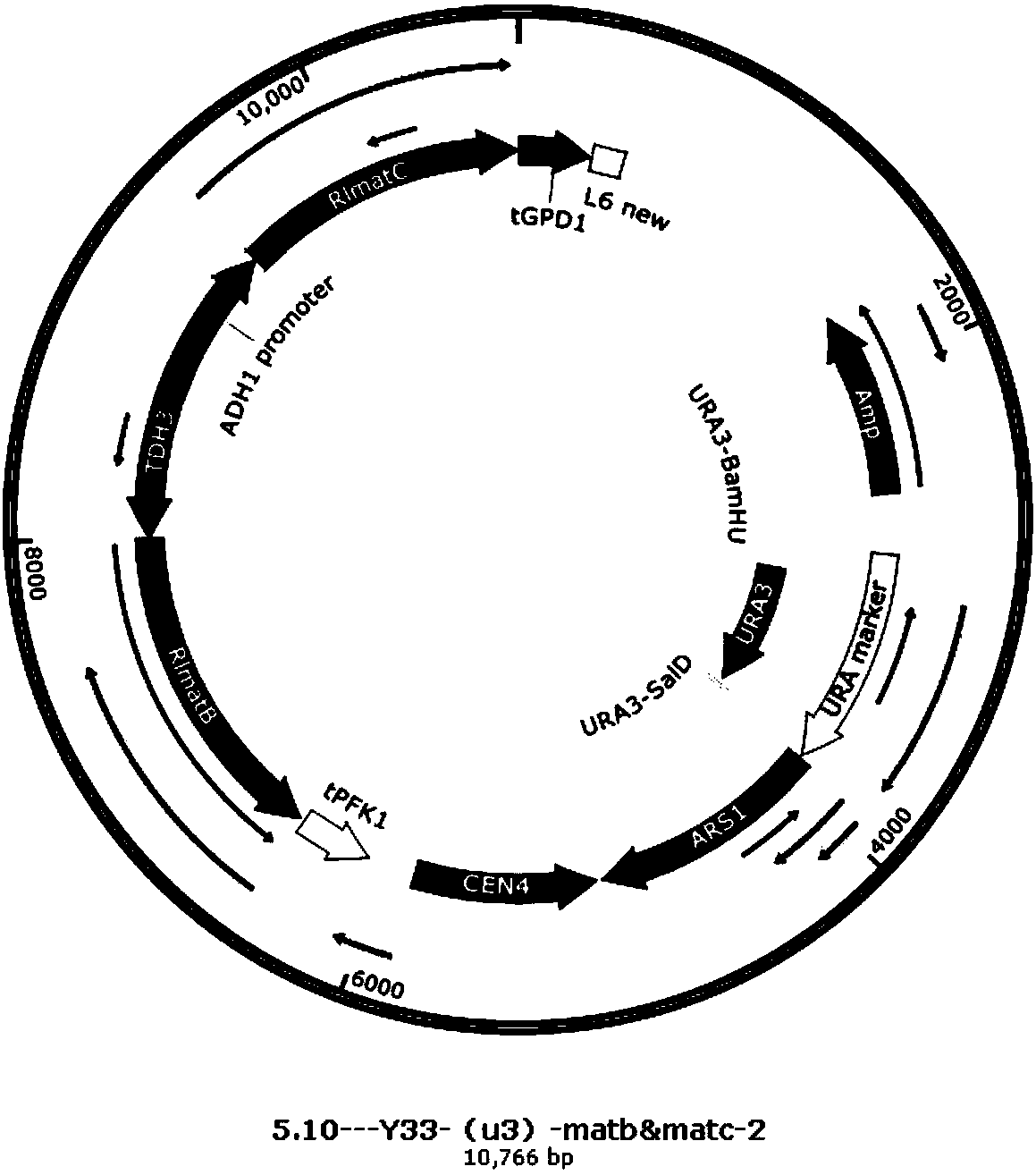

Method for producing phloretin by fermentation of saccharomyces cerevisiae

ActiveCN107586795ALow costFriendly and easy to controlMicroorganism based processesFermentationFermentationPollution

The invention relates to a method for producing phloretin by fermentation of saccharomyces cerevisiae. The method is completed by performing catalysis on p-hydroxyphenylpropionic acid serving as a rawmaterial and the saccharomyces cerevisiae serving as host bacteria through a plurality of enzymes in the host bacteria. Compared with the prior art, the method disclosed by the invention is characterized in that (1) by taking a low-cost compound as the raw material, the technological raw material is low in cost; (2) on the technical basis of modification of microorganisms, catalytic synthesis ofbiological enzymes is carried out in the microorganisms, so that large-scale extraction, separation and purification processes are avoided, and the production cost and the environmental protection areeasy to control; (3) the scale and the quantity of production equipment in the process are less than the scale and the quantity in other methods, and industrial transformation is facilitated; (4) separation and purification procedures are only carried out in the last step of the production in the process, so that a product purification process is simple, the product quality is higher than that ina general method, and the content is higher; (5) no waste liquid is discharged in a synthesis process, so that the method is environmentally friendly and pollution-free and can realize sustainable production.

Owner:嘉兴欣贝莱生物科技有限公司

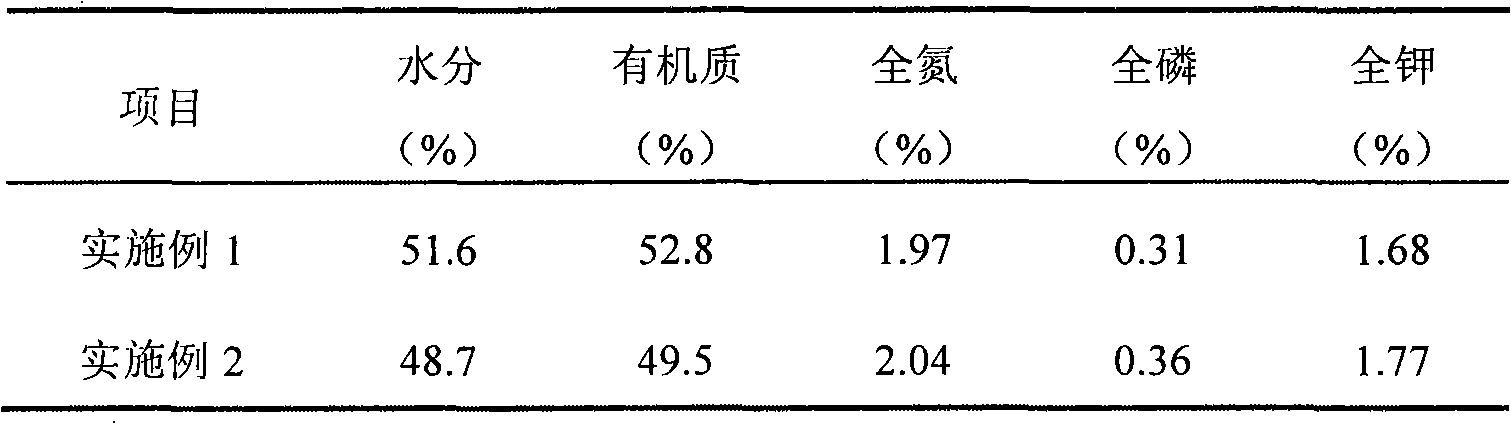

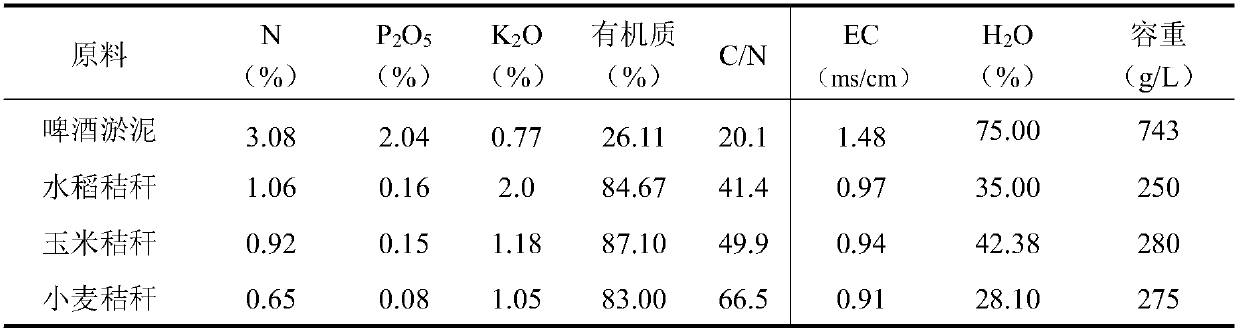

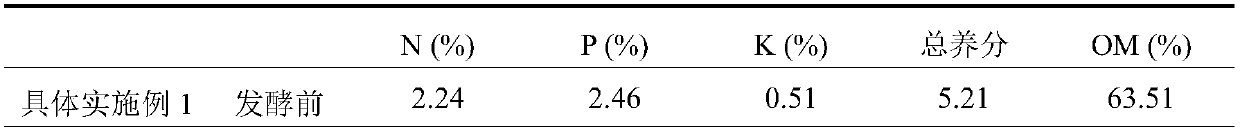

Rice seedling raising substrate produced from plant straws and beer active sludge and preparation method thereof

InactiveCN107641023APromote maturityStable pHBio-organic fraction processingGrowth substratesLand resourcesSludge

The invention relates to the technical field of agricultural substrate production, and provides a rice seedling raising substrate produced from plant straws and beer active sludge and a preparation method thereof. The rice seedling raising substrate is prepared from 50%-70% of plant straws and 30%-50% of beer sludge through mixing and high-temperature aerobic fermentation, secondary fermentation and thorough decomposition, addition of an inorganic material into thoroughly decomposed organic materials, and acid regulating agent preparation in sequence. The substrate preparation method is shortin fermentation time, and maturity of the straws is high. An acid regulating technology ensures that the pH value of the rice seedling raising substrate is stable, so that the rice seedling raising substrate is suitable for rice seedling growth, is good in water retention and fertilizer retention, is comprehensive in nutrition, can meet nutrition needs of growing rice seedlings for 40 days, and greatly reduces load of a rice transplanter. The rice seedling raising substrate solves the problems that soil take of mechanical rice transplanting is difficult, land resources are wasted, environmental pollution is caused by direct discarding or combustion of waste biomass, and the like; and meanwhile, development and use of the rice seedling raising substrate are beneficial for promoting sustainable production of high-efficiency agriculture, so that rural income is increased.

Owner:武汉乐活农业旅游发展有限公司

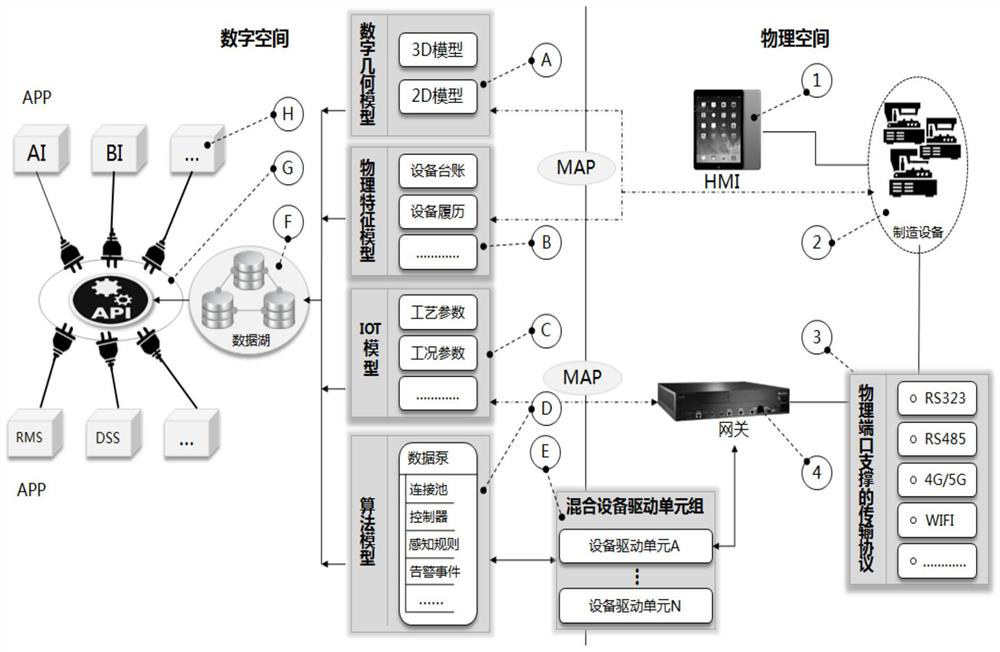

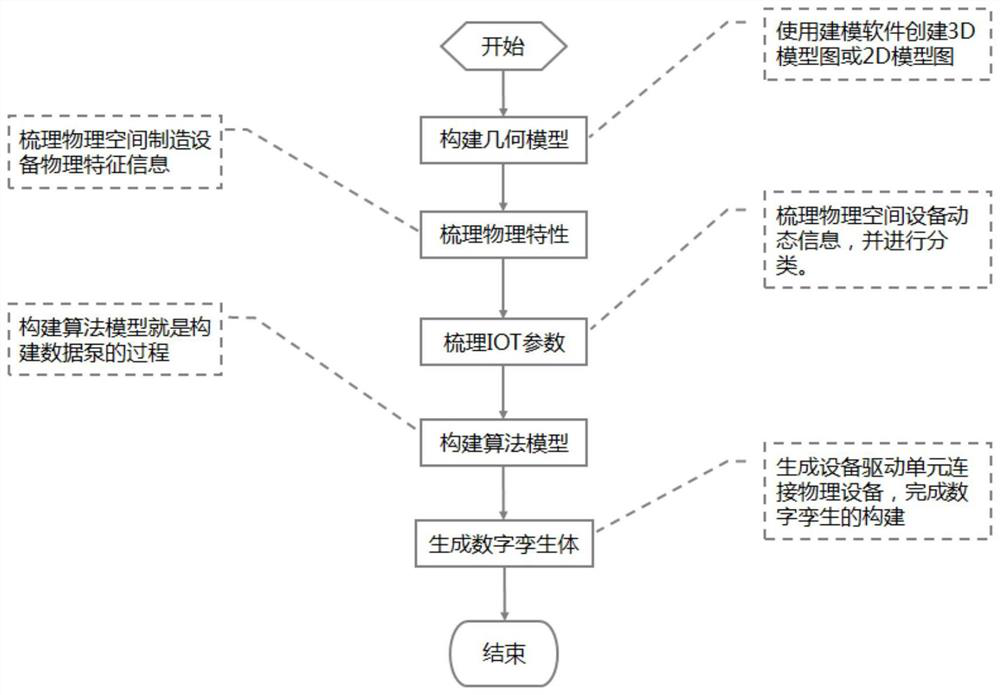

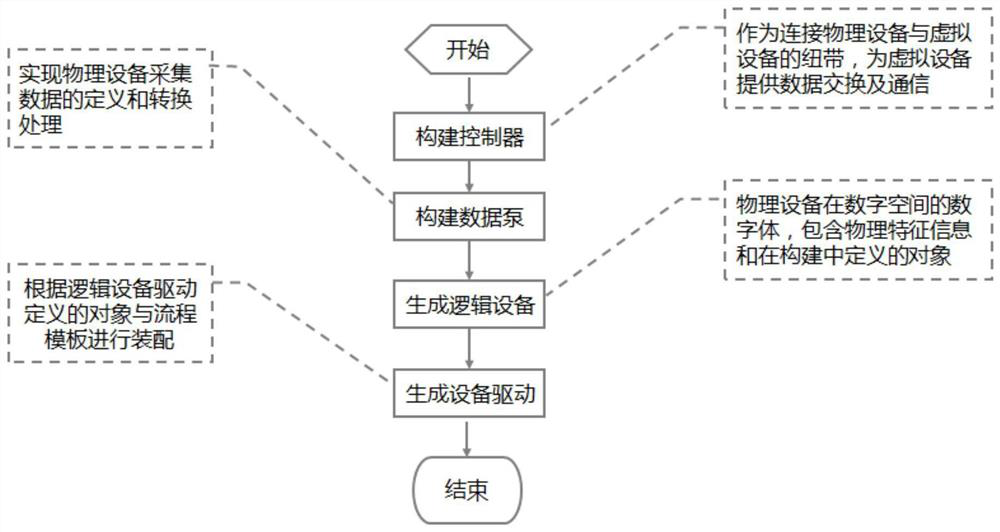

Manufacturing equipment-oriented digital twinborn model construction method

The invention belongs to the technical field of digital twinning, and provides a manufacturing equipment-oriented digital twinborn model construction method. The digital twinborn model is composed of a digital geometric model, an IoT model, an algorithm model, a physical feature abstraction unit and an equipment driving unit. The modeling process of the physical model is realized by parameterized data information and a digital virtual technology; by simulating behaviors of physical equipment during operation through model parameters, and applying the simulated virtual equipment, namely the digital twinborn body, to production, two-way communication with the physical equipment is established through the equipment driver. In the running process of the equipment driver instance, data are collected in real time through the equipment driver and transmitted to the digital twinborn model for analysis, and the health state and fault symptoms of the equipment are judged and predicted. The functions of task simulation, state monitoring, task optimization, fault analysis and prediction are realized. The sustainable production capacity of a manufacturing enterprise is improved, and production planning and decision analysis of the enterprise are supported.

Owner:CHONGQING SIOU INFORMATION TECH CO LTD

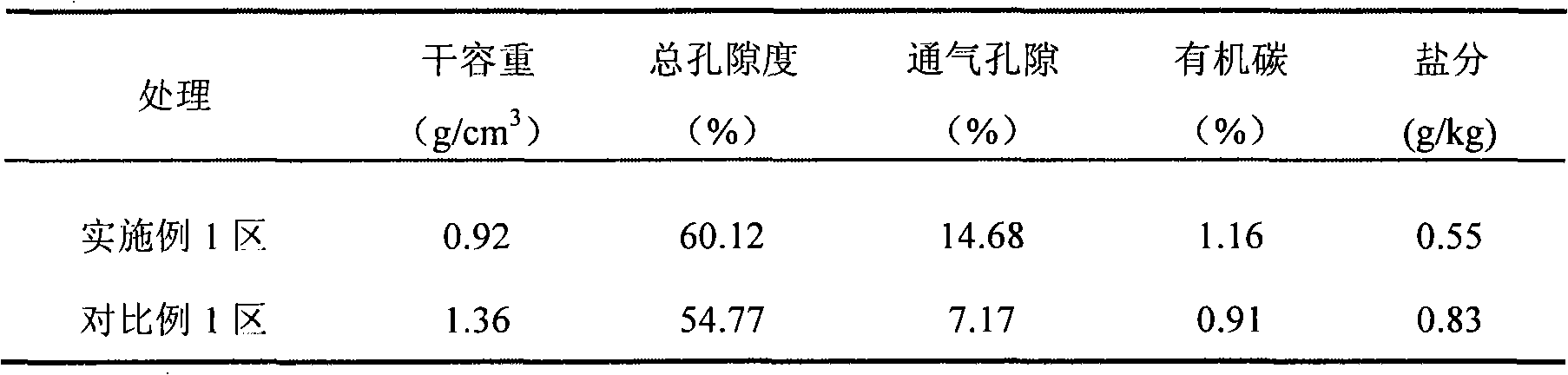

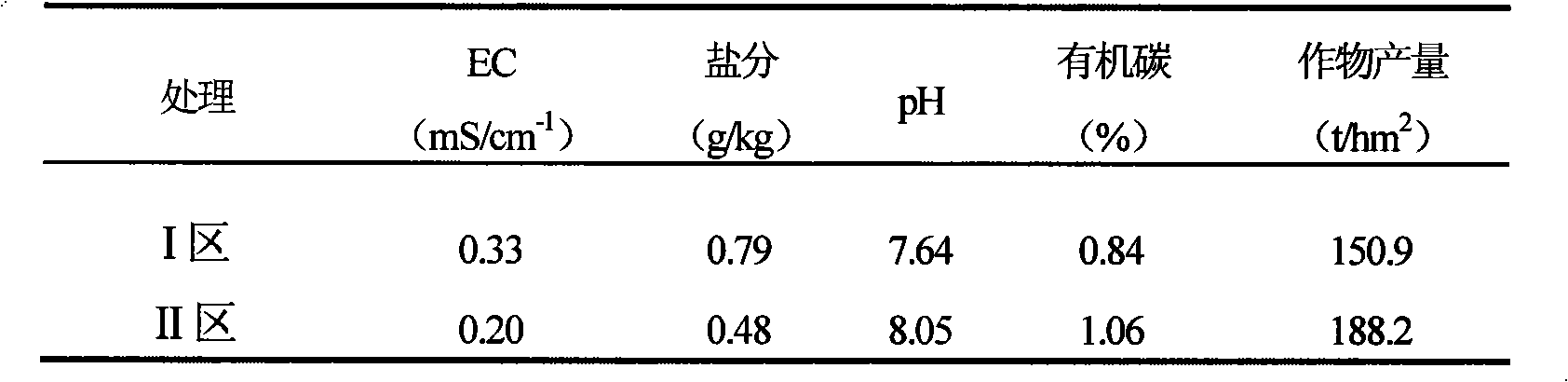

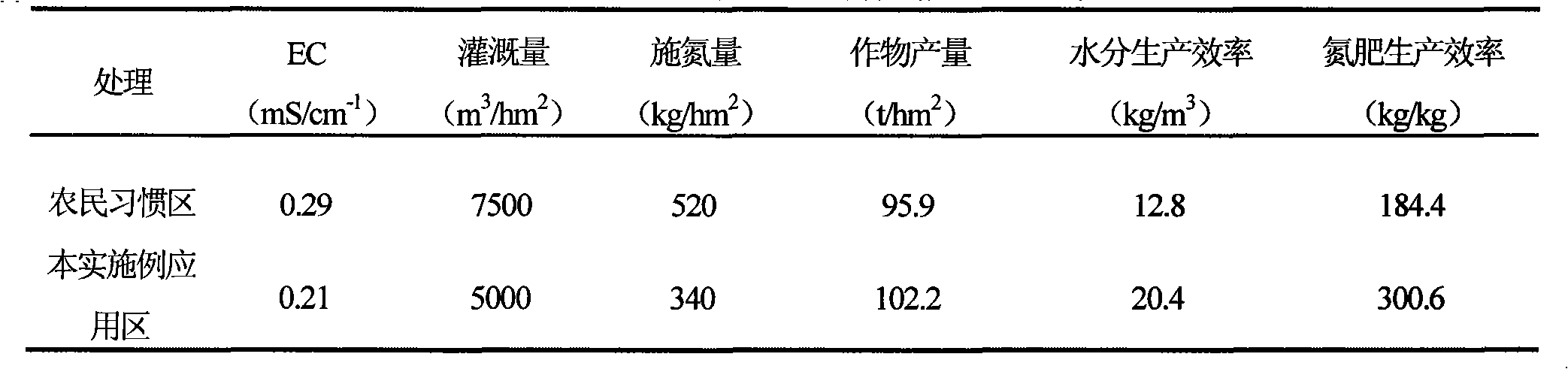

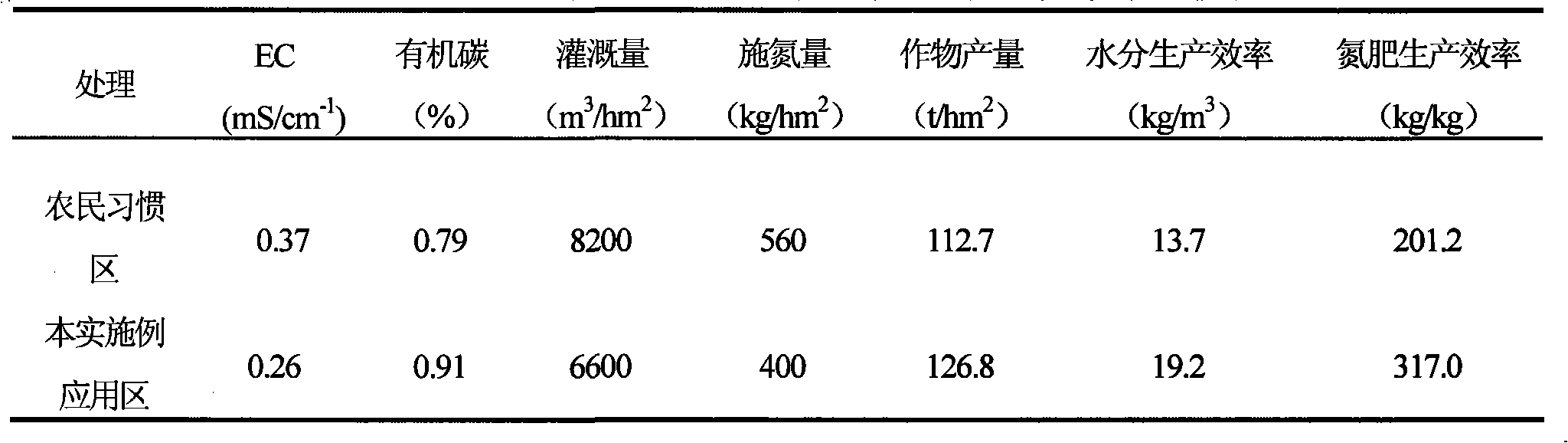

Method for maintaining sustainable production capacity of greenhouse vegetable soils

InactiveCN102057827AImprove utilization efficiencyImprove sustainable production capacityClimate change adaptationExcrement fertilisersSustainable productionGreenhouse

The invention relates to a method for maintaining the sustainable production capacity of greenhouse vegetable soils, aiming at the main reasons of the problem of soil quality degradation for greenhouse vegetable soils in China. The method mainly takes a soil C / N ratio adjusting and controlling technology as a core which is combined with the accuracy adjusting and controlling technology of a nitrogenous fertilizer, a water-saving irrigation technology and a catch crop cultivation technology, and other technical measurements. The method in the invention is scientific and simple, and is to implement. By using the method, the production efficiency of agricultural input products such as chemical fertilizers, irrigation water and the like is greatly improved, and the crop yield is increased, thus really saving the cost and raising economic benefits, remarkably improving soil physical and chemical properties, and strengthening the sustainable production capacity of the greenhouse vegetable soils.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Handling arrangement for recovering and utilizing organic solid rubbish

InactiveCN101381646AAvoid pollutionAchieve recyclingSolid waste disposalBiofuelsSustainable productionCarbonization

The invention discloses a treatment device for recycling of organic solid garbage, which belongs to the technical field of garbage recovery and treatment devices. The treatment device for recycling of the organic solid garbage comprises a drying section (1), a pressurization section (2), and a high-temperature carbonization section (3) which are orderly connected. With the structure, the device, by changing organic domestic garbage into carbon coal for recycling, realizes the complete recycling of domestic garbage, particularly solid matters of the domestic garbage, avoids the pollution to the environment, and transforms waste into fuel with economic value at the same time. The device is suitable for sustainable production, and has the advantages of high production efficiency, low treatment cost, and low energy consumption.

Owner:练其辉

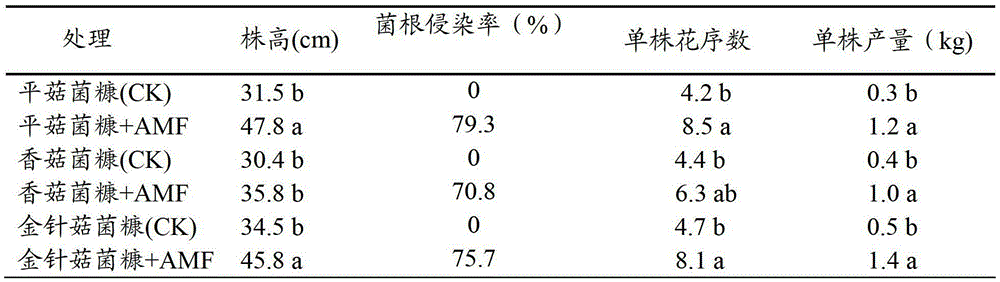

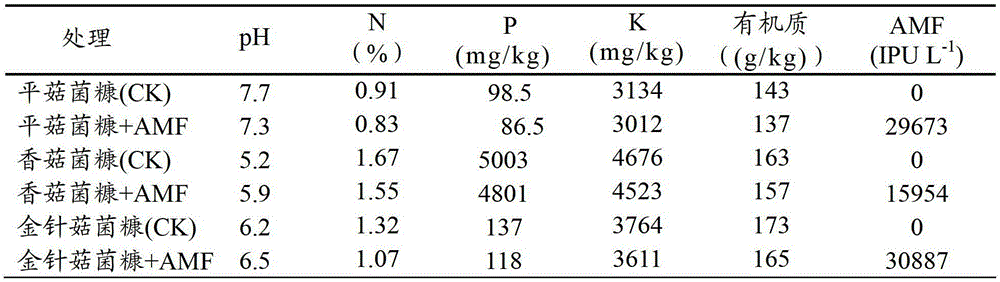

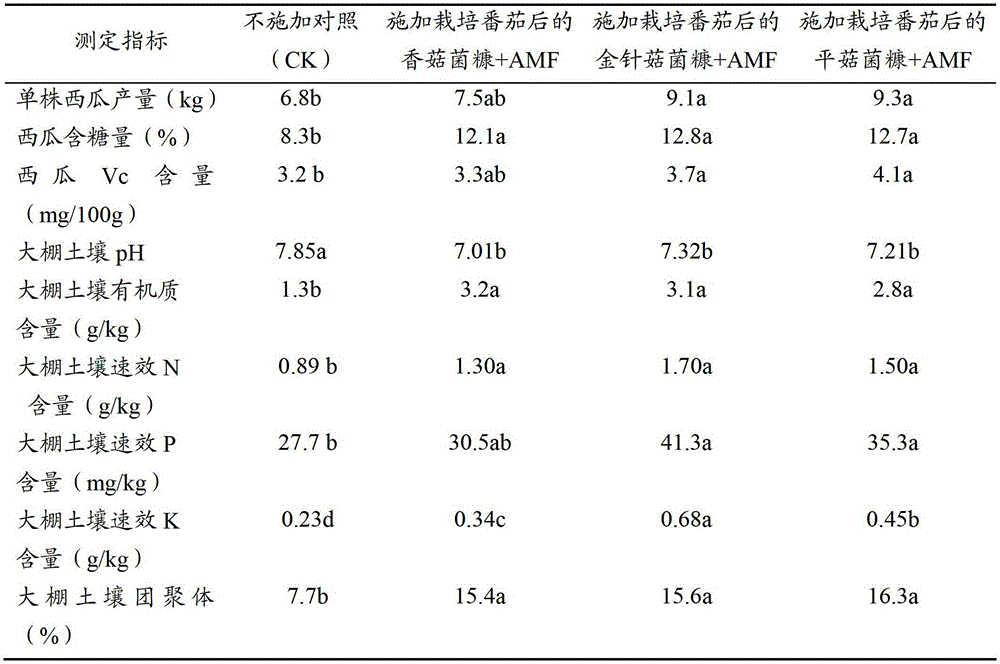

Novel mushroom residue and arbuscular mycorrhizal fungi (AMF) culture medium, and preparation method and application thereof

InactiveCN103145497AImprove reuse efficiencySolve environmental problemsHorticultureFertilizer mixturesArbuscular mycorrhizal fungiGrowing season

Owner:QINGDAO AGRI UNIV

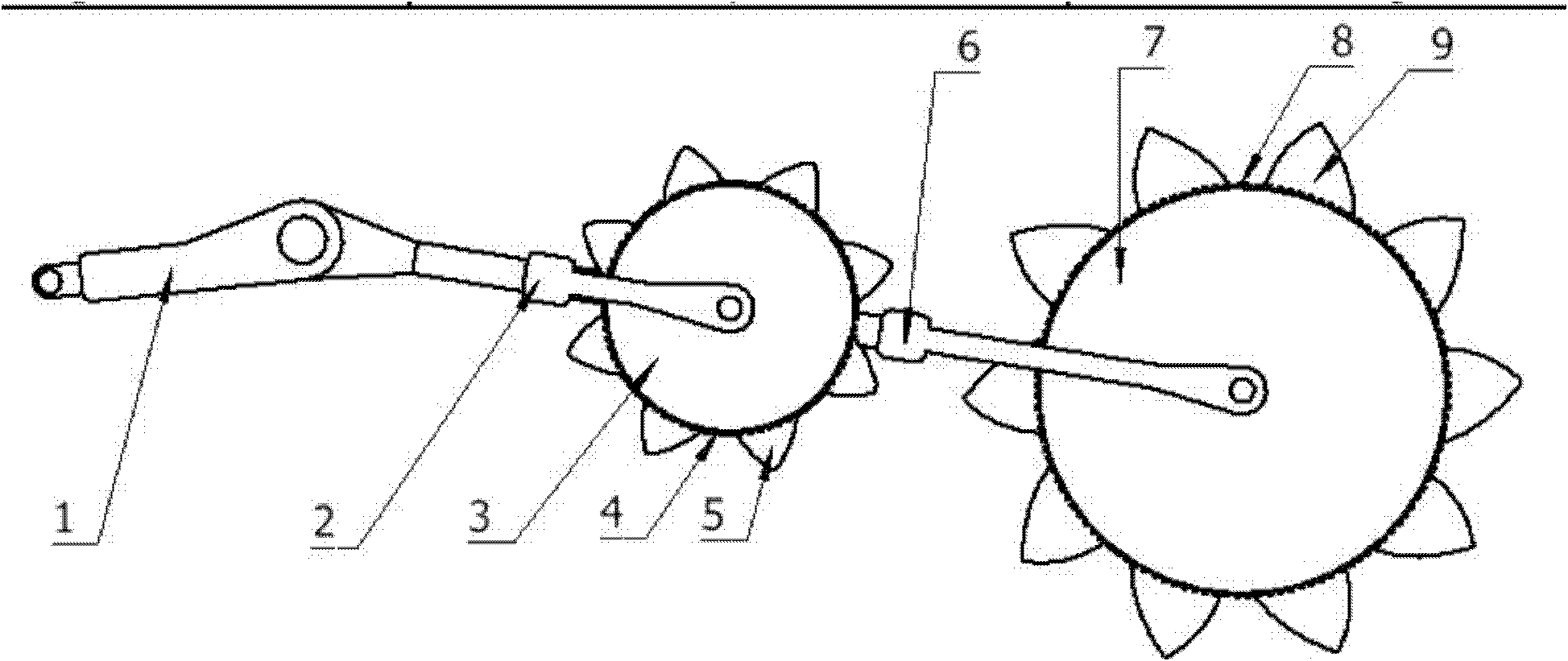

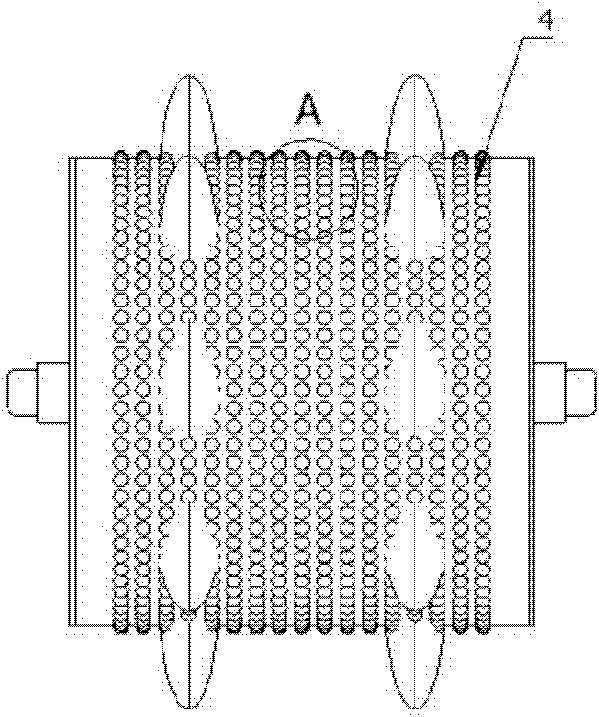

Ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part

The invention belongs to agricultural machinery, in particular relates to a rolling soil-engaging part for compacting soil and changing soil surface microtopography after seeding in a ridge culture mode, and in particular relates to a ridge culture field soil surface microtopography processing bionic structure rolling soil-engaging part. The part mainly comprises ridge table rollers, ridge trenchrollers and a total frame, wherein a plurality of ridge table rollers and ridge trench rollers are arranged, are connected in series on the total frame through a ridge table roller frame and a ridge trench roller frame respectively and can rotate around the total frame; a ridge table roller bushing and a ridge trench roller bushing are arranged on the surfaces of the ridge table roller frame and the ridge trench roller frame; and ridge table roller teeth and ridge trench roller teeth having geometric structures are uniformly distributed on the circumferences of the surfaces of the ridge tablerollers and the ridge trench rollers. On the premise of guaranteeing a soil compaction function, the rolling resistance is reduced, the adhesion between the part and soil is reduced, soil microtopography is changed, and soil water storage and soil moisture conservation capacity and agro-ecology are improved; therefore, farmland resists severe weather conditions, and sustainable production increase capacity is improved.

Owner:JILIN UNIV

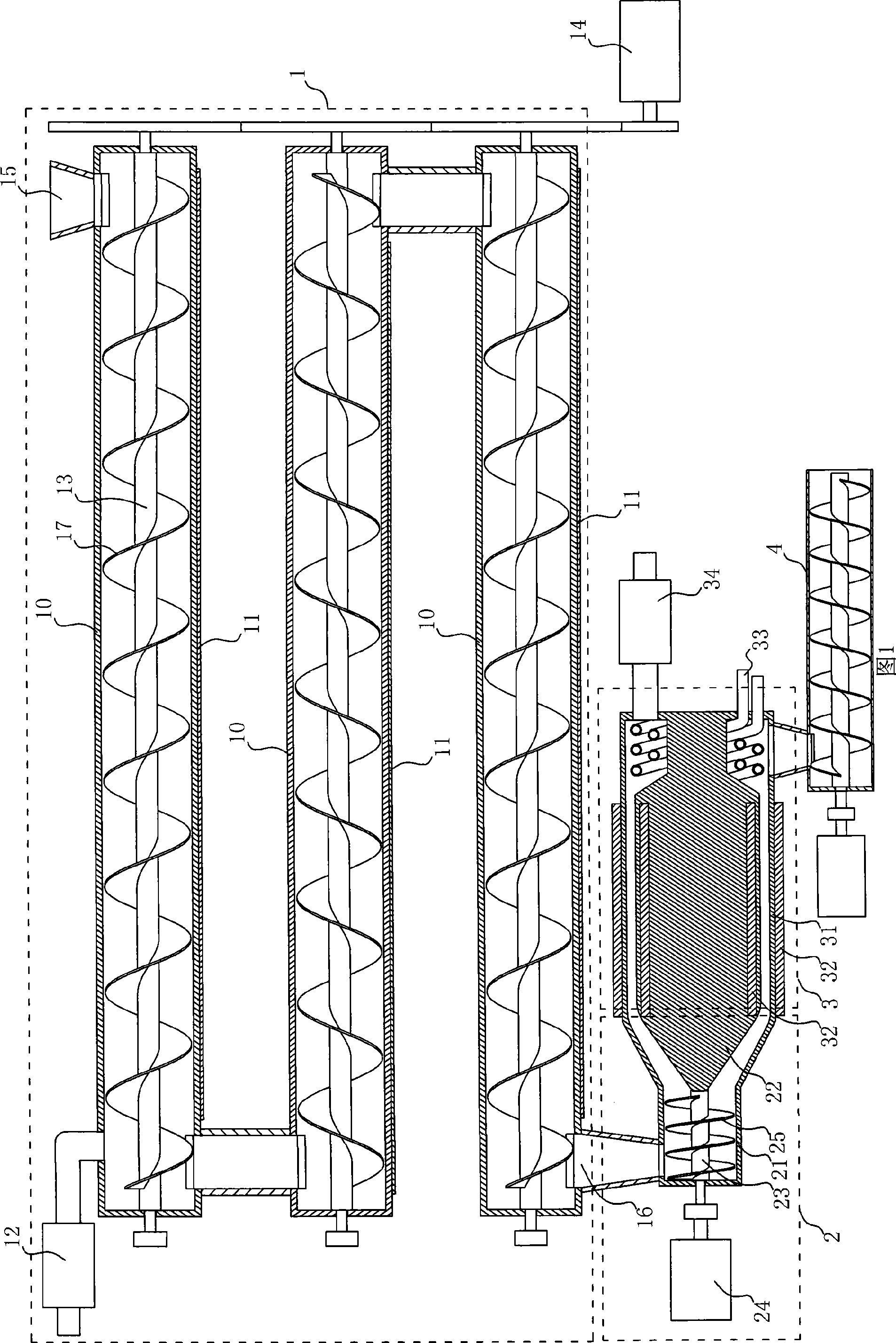

Firework assembling machine

The invention discloses a firework assembling machine. The firework assembling machine comprises a blanking discharge barrel system, a conveying roller group and a moving inserting fuse system which are sequentially arranged along a worktable surface of a main machine frame, wherein a pushing device working corresponding to the blanking discharge barrel system is arranged at the back of the worktable surface, and a forming system working corresponding to the moving inserting fuse system is arranged in front of the worktable surface. The scheme changes horizontal feeding processing through firework barrels one by one in the prior art into longitudinal feeding processing through a plurality of firework barrels in rows, so that processing flow path is shortened, production efficiency is greatly improved, operation is stable, adverse factors like tube body rolling and error accumulation are avoided, work load for maintenance and adjustment in operation is greatly reduced, and the firework assembling machine can perform production continuously without being limited any more. The firework assembling machine solves technical problems and lays good foundation for full automation and mechanized process of fireworks production.

Owner:浏阳市百合机械制造有限公司

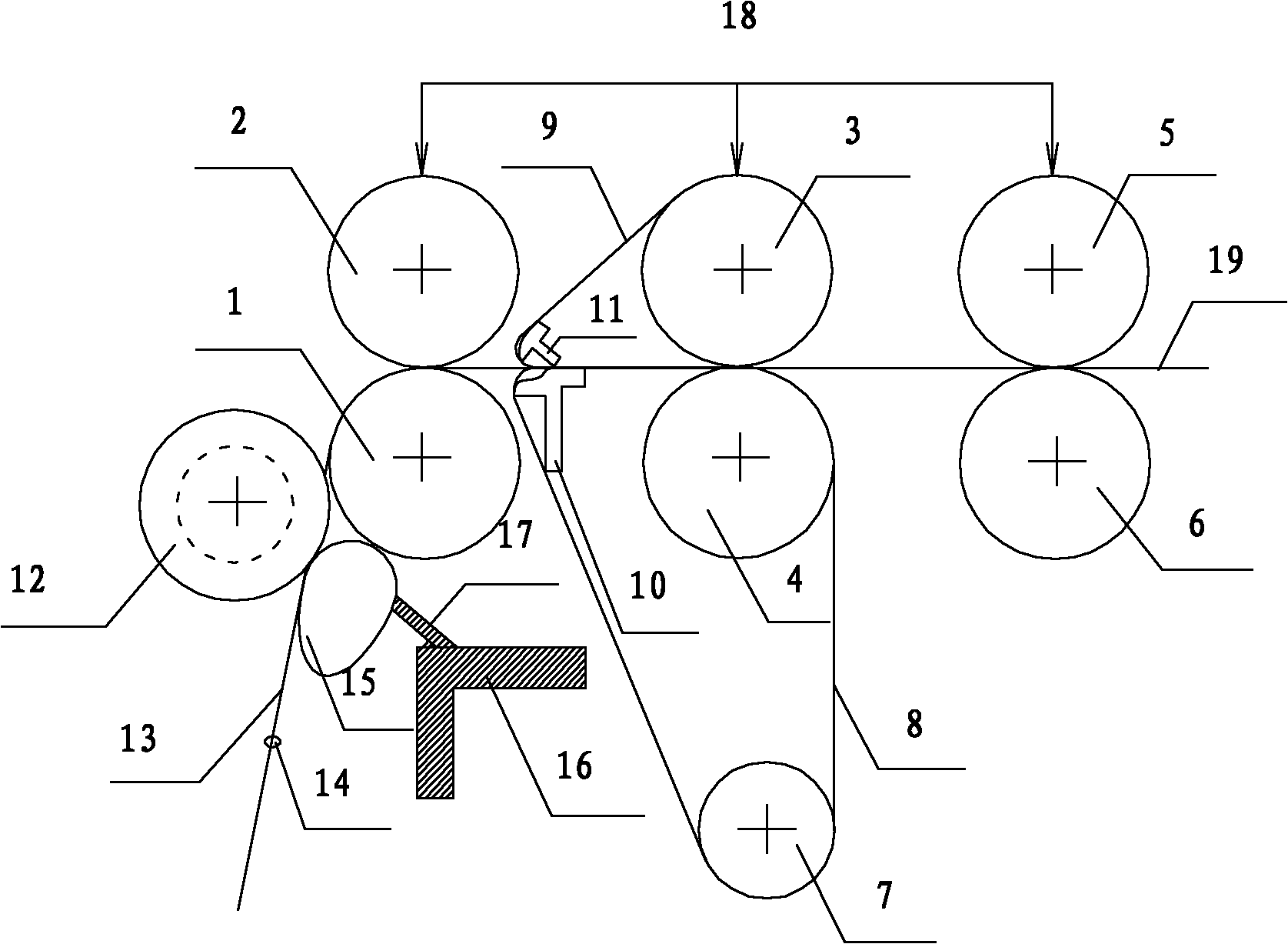

Synchronous humidifying wet spinning device

The invention discloses a synchronous humidifying wet spinning device, which comprises a front lower roller, a front upper leather roller, a guide wire and a pressurization device which are all arranged on a frame. A synchronous humidifying mechanism is arranged between the front lower roller and the guide wire. The synchronous humidifying mechanism comprises a groove roller with a groove, a hollow shaped tube with a humidifying hole, a grid ring capable of rotating around the shaped tube and a humidifying device, wherein the groove on the groove roller corresponds to the humidifying hole; the front upper leather roller drives the groove roller to synchronously rotate; the groove roller drives the grid ring and the front lower roller to synchronously rotate; and the humidifying device is used for outputting humidifying liquid to the humidifying hole. The synchronous humidifying wet spinning device has the advantages that the raw materials have good adaptability; spun yarns with less fuzz and more uniform evenness can be produced from any short fiber ring spinning yarn raw materials which are being spun; the synchronous humidifying wet spinning device has the characteristics of simple structure, stability and reliability in operation, convenience for reconstruction on the original spinning frame, low cost and easiness in popularization; and the requirement for sustainable production is met.

Owner:XINJIANG YIDA TEXTILE +1

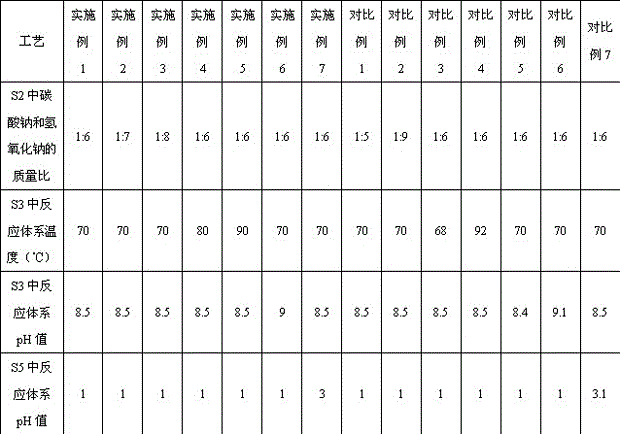

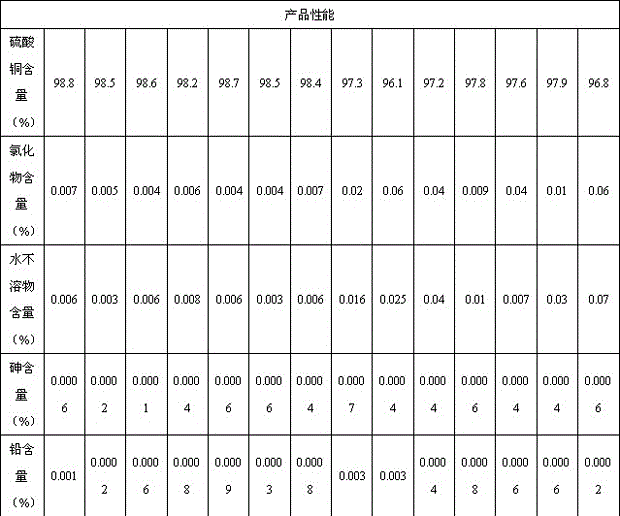

A kind of production method of utilizing acidic copper-containing etching waste liquid to produce electroplating grade copper sulfate

ActiveCN103693673BEmission reductionReduce processing costsCopper sulfatesHydrogenSustainable production

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

Method for manufacturing bamboo beam

InactiveCN101870132AStrong toughnessImprove stress resistanceWood working apparatusSustainable productionEngineering

The invention relates to a method for manufacturing a building material and discloses a method for manufacturing a bamboo beam used as a substitute for wood. In the method, bamboo with a short growth cycle, which is low in carbon content and environmentally-friendly, is used as a raw material, so the mass continuous production of the bamboo beam become possible; and due to the adoption of a longitudinally staggered and transversely overlapped lamination method, the joints at the ends of adjacent bamboo sheets are staggered and the glued bamboo beam has high toughness and compared with the traditional wood beam, has higher pressure resistance, tensile strength and anti-bending performance. The method is particularly suitable to be used as a substitute scheme for the conventional wood beam and meets the low-carbon and environmentally-friendly requirements advocated worldwide.

Owner:ANJI CHENGFENG BAMBOO PRODS

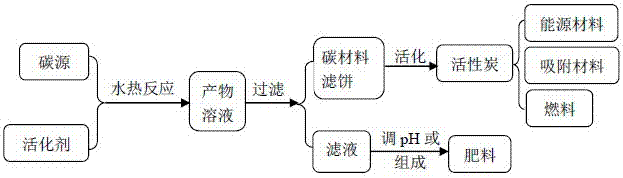

Method for preparing carbon material at low temperature and co-producing fertilizer

InactiveCN107459037ANo emissionsNo pollution in the processCarbon compoundsAlkali orthophosphate fertiliserHigh energyBiological activation

The invention relates to a method for preparing a carbon material at low temperature and co-producing a fertilizer. Processes of carbon source pyrolysis and carbon material activation are integrated; through a green process route in a closed system, low-temperature preparation of carbon is achieved; the produced carbon material can be further activated, modified and the like. By the method, the defects of high energy consumption, low yield, high dust pollution, a complicated posttreatment process, and serious environment pollution and difficult treatment of a waste solution and the like in the current carbon producing process are overcome; through the control of the types and the addition amounts of a carbon source and an activator as well as the temperature and the residence time in a reaction kettle, continuous clean production of the carbon material is achieved; through adjustment of the pH or the components, the produced waste solution is used as the fertilizer, so that harmless treatment and high-value conversion of the waste are achieved. In the method, the carbon source is wide (including biomass carbon, tar carbon, bitumen carbon and the like); by the method, the reaction condition is mild, the yield is high, the waste emission is avoided, the energy is saved and the consumption is lowered; therefore, the method is an environmentally friendly, efficient and economical method for sustainably producing the carbon material and co-producing the fertilizer.

Owner:SICHUAN UNIV

Nutritional combined fertilizer applicable to acidified soil and special for solanaceous vegetables and application method thereof

ActiveCN105348008AImprove sustainable production capacityMeet nutrient needsFertilising methodsFertilizer mixturesSustainable productionBiology

The invention relates to nutritional combined fertilizer applicable to acidified soil and special for solanaceous vegetables and an application method thereof. The nutritional combined fertilizer is prepared from, by weight, 150-270 parts of a soil acidification modifier, 700-1350 parts of base fertilizer, 164-492 parts of seedling strengthening fertilizer and 279-1066 parts of fruit swelling fertilizer. By applying the soil acidification modifier, physiological alkaline or neutral inorganic fertilizer and organic fertilizer, the requirements of the solanaceous vegetables in different growth stages for nutriment are met, the soil acidification effect of the solanaceous vegetable protected land is reduced from the source, and the soil sustainable production capacity is enhanced.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com