Method for preparing carbon material at low temperature and co-producing fertilizer

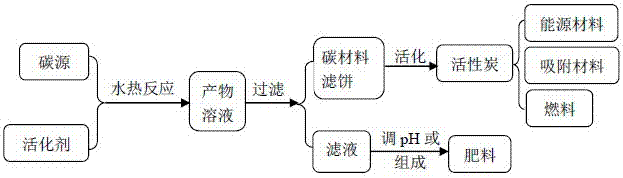

A carbon material and fertilizer technology, applied in the field of low-temperature preparation of carbon material co-production fertilizer, can solve the problems of low activation rate, equipment corrosion, complex treatment process, etc., and achieve the effects of low reaction conditions, reduced environmental pressure, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Using microbial action and hydrothermal method to prepare coal-like carbon materials from tobacco stalks, put 2 g of tobacco stalk powder, 20 mL of deionized water and 5 mL of microbial culture solution into a 50 mL reactor and seal it. After 5 hours of biochemical reaction Then react at 150 °C for 3 h, filter and wash the reaction product, and dry the filter cake at 100 °C for 10 h to obtain a coal-like carbon material. Corresponding pH value or composition), used as fertilizer for greening grass. Combustion performance analysis of the obtained carbon material shows that its combustion activation energy is about 50% higher than that of the raw material. The microorganisms produced in the early stage of the reaction enter the carbon material or waste liquid during the later hydrothermal reaction process, reducing the harm of microorganisms to the environment after the reaction, and realizing the integration of growth, reproduction, efficient utilization and transformati...

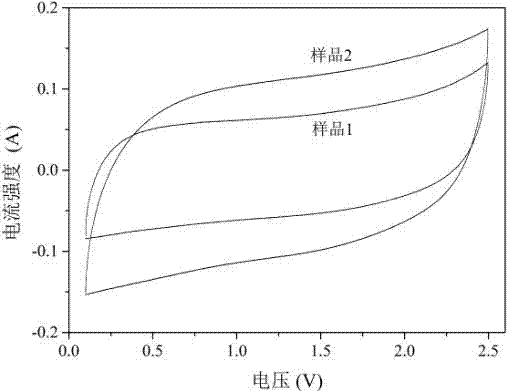

Embodiment 2

[0024] Preparation of activated carbon and ammonium phosphate fertilizer from magnolia bark waste by hydrothermal method. Magnolia officinalis powder and activator (mass content of 20% H 3 PO 4 ) into the enamel reaction kettle at a mass ratio of 1:1, and reacted hydrothermally at 200 °C for 24 h. After the reaction, the reaction product solution was filtered to obtain a carbon filter cake and the first filtrate. Activated in an argon atmosphere for 2 h (without adding other activators), the product was washed with water until neutral, and the filtered filter cake was dried to obtain activated carbon. After mixing the washing water and the two filtrates, adjust the pH value to 4.0 ~ 4.5 with ammonia water. Concentrated granulation can be nitrogen-phosphorus binary compound fertilizer based on ammonium dihydrogen phosphate; adjust the pH value to 7.8 ~ 8.2, concentrated granulation can be based on diammonium hydrogen phosphate binary nitrogen-phosphorus compound fertilizer. T...

Embodiment 3

[0026] Activated carbon was prepared from waste walnut shells by alcohol thermal method. Put 3g of walnut shell powder, 10mL of ethanol and 15mL of water into a reaction kettle made of Hastelloy C, and react at 300 ℃ for 4~7 h. After the reaction, the product solution Filter to obtain carbon material filter cake and the first filtrate, filter cake and NH 4 h 2 PO 4After mixing, it is activated at 700°C for 3 hours to obtain activated carbon, which is washed to nearly neutral and filtered again to obtain activated carbon filter cake and the second filtrate. The activated carbon filter cake is used for wastewater treatment, and the adsorption capacity of methylene blue is higher than that of walnut shell activated carbon obtained by ordinary methods. About 60% higher, the two filtrates and washes are treated by anaerobic digestion, mixed with grass ash and wood ash, and used as organic fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com