Synchronous humidifying wet spinning device

A technology of humidifying device and pressurizing device, which is applied in the direction of textile and papermaking, continuous winding spinning machine, spinning machine, etc. It can solve the problems that ring spinning hairiness level cannot meet the requirements and spinning hairiness is too much, etc. Achieve the effect of easy promotion, less hairiness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

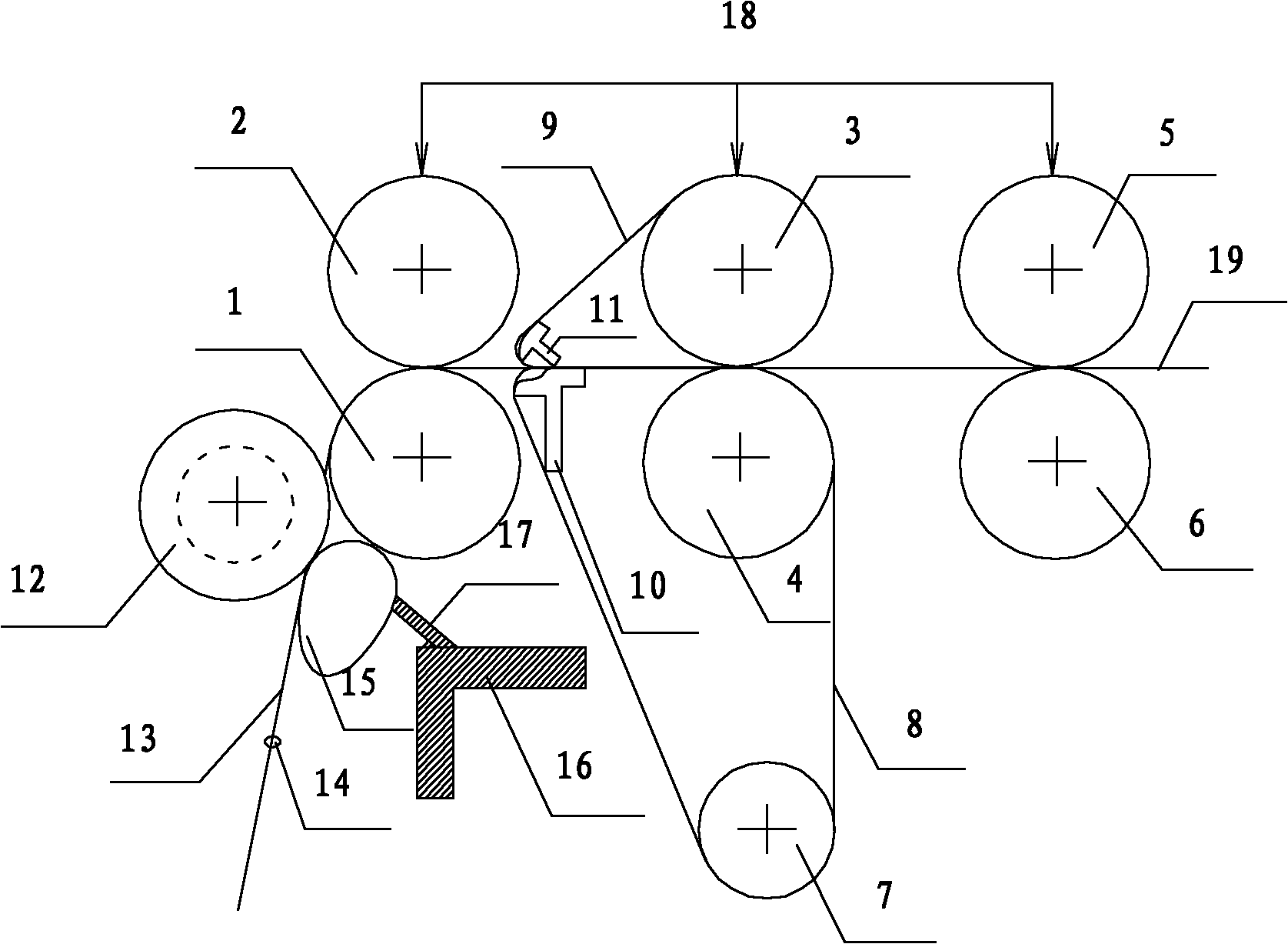

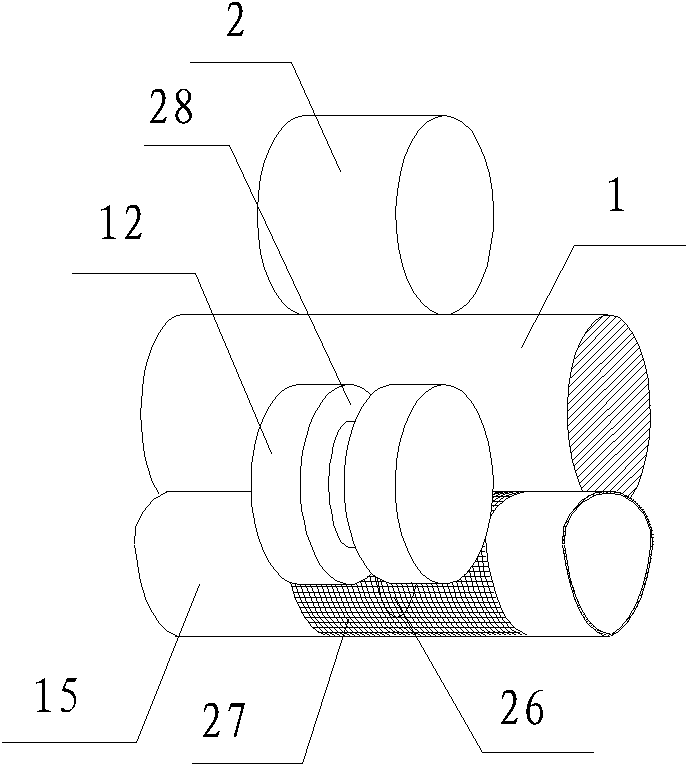

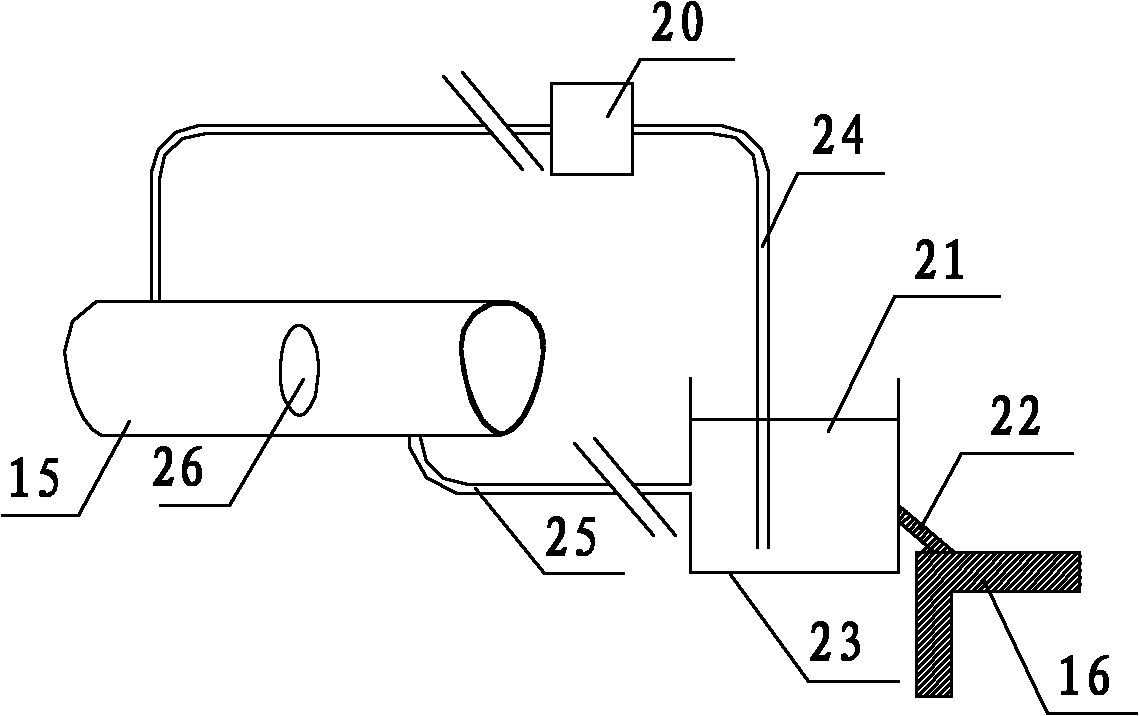

[0019] refer to Figure 1-4 , a synchronously humidified wet spinning device, comprising a front top roller 2, a front bottom roller 1, a middle top roller 3, a middle bottom roller 4, an upper short apron 9, a lower pin 10, Three-roller double-apron drafting mechanism consisting of upper pin 11, lower long apron 8, tension roller 7, rear upper top roller 5, rear lower roller 6, and pressurizing device 18, and roving 19 from rear upper top roller 5 and rear lower roller 6, and is pulled out by the yarn guide hook 14 between the front top roller 2 and the front bottom roller 1. A synchronous humidifying mechanism is provided between the front bottom roller 1 and the guide hook 14. The synchronous humidifying mechanism consists of a grooved roller 12 with a groove 26, a hollow special-shaped tube 15 with a humidification hole 26, and can rotate around the special-shaped tube 15. The grid ring 27, humidification tank 23, water pump 20, liquid inlet pipe 24 and liquid return pipe...

Embodiment 1

[0028] Embodiment 1 of the present invention: adopt the wet spinning device of the present invention to spin 80 British count pure cotton yarns;

Embodiment 2

[0029] Embodiment 2 of the present invention: Spinning 40 lbs. 65 / 35 cotton / viscose blended yarn with the wet spinning device of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com